Used ACCUSPUTTER AW 4450 #9201786 for sale

URL successfully copied!

Tap to zoom

ID: 9201786

Wafer Size: 8"

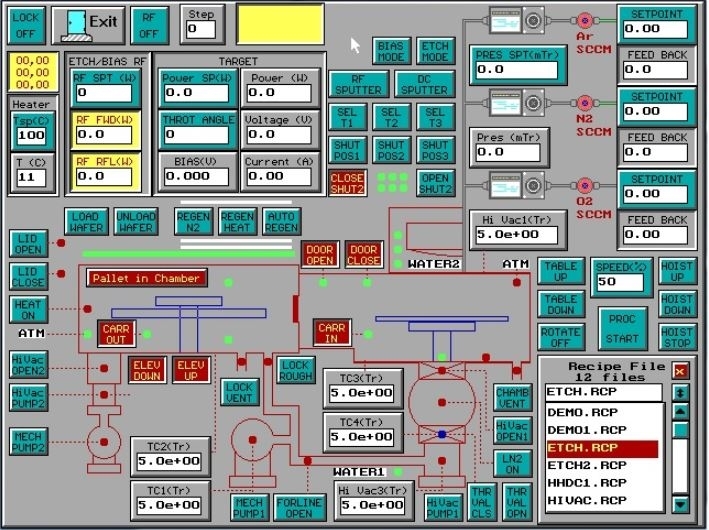

Sputtering system, 8"

Wafer loading: Manual

With load lock

Cathodes: (3) Delta shapes / (4) Circle shapes

Sputter methods: RF / DC

Diode / MAGNETRON

Gas lines: 1~3 MFC

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration I II

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

Configuration I II III

DC Power 5 kW 10 kW -

RF Power 1kW 2 kW 3 kW

Pulse DC power 5 kW 10 kW -

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Gas line with MFC

Ar, 200 SCCM, customized

Power box: AC 380 V / 208 V / 3 Phase.

ACCUSPUTTER AW 4450 is an advanced thin-film deposition equipment. This piece of industrial equipment is designed to create thin metal and dielectric layers on the surface of a wide range of substrates such as silicon wafers, wires, fibers, electronic components, and more. Using physical vapor deposition, AW 4450 produces thin films of uniform and consistent thickness in a highly efficient manner. ACCUSPUTTER AW 4450 is powered by an advanced radio frequency (RF) generator with a frequency range of 13.56 MHz or 40 kHz. This allows precise and powerful sputtering, enabling the deposition of thin films with very consistent characteristics in a highly repeatable fashion. Furthermore, the RF power is adjustable, giving the user precise control over the deposition rate and the layer thickness. AW 4450 is equipped with a high-vacuum chamber capable of reaching 1.3×10-4 Pa, an automatic vacuum setup, and turbo-pump integrated with the differentially-pumped process chamber. This allows accurate and precise control over the sputter coating process. In addition, the system can accommodate sample sizes up to 50 mm. With its HVQ polarity control, ACCUSPUTTER AW 4450 can also deposit multi-layered films with greater accuracy and control. To ensure a high-quality product, AW 4450 is equipped with advanced control and monitoring systems. This includes a process potential monitor, a substrate bias voltage monitor, and a plasma potential monitor, all of which can be monitored in real-time. In addition, the unit is equipped with a mass flow controller to make sure that the purity of the process gas is kept at a consistent level throughout the entire process. ACCUSPUTTER AW 4450 is a powerful and highly accurate sputtering machine that was designed to handle a wide range of sputtering applications. Through its precise RF power adjustment, its high-vacuum chamber, its differential pumping of the sputtering chamber, its precise control and monitoring systems, and its ability to handle sample sizes of up to 50 mm, this tool is the perfect choice for a range of industrial applications where precision and repeatability are essential.

There are no reviews yet