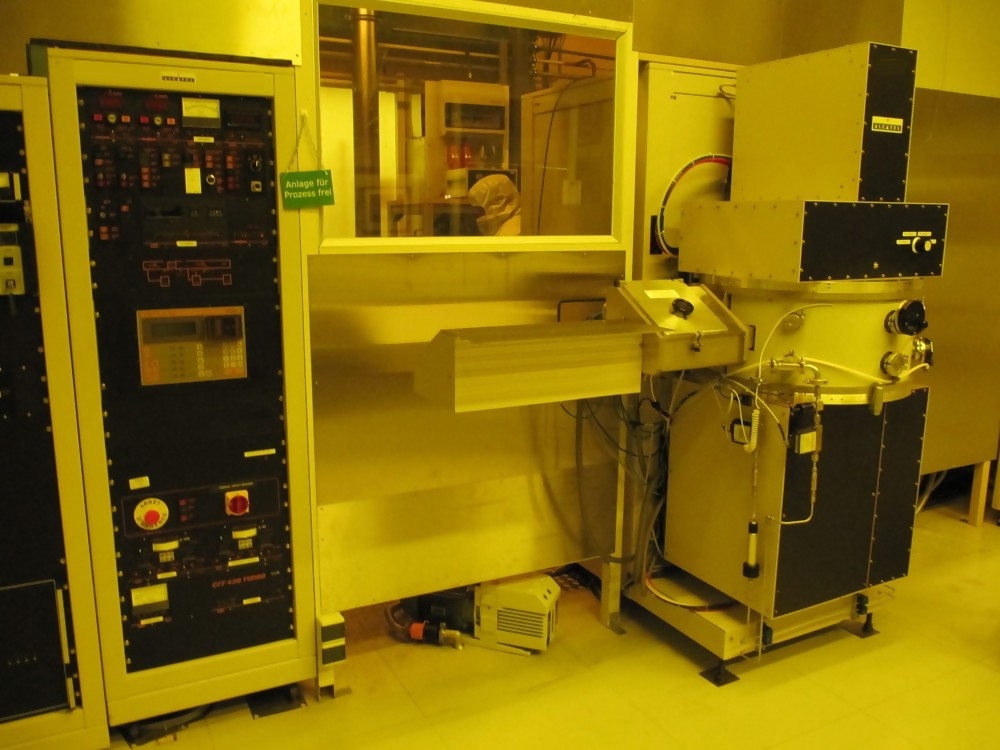

Used ALCATEL / ADIXEN / PFEIFFER SCM 650 #9253767 for sale

URL successfully copied!

Tap to zoom

ID: 9253767

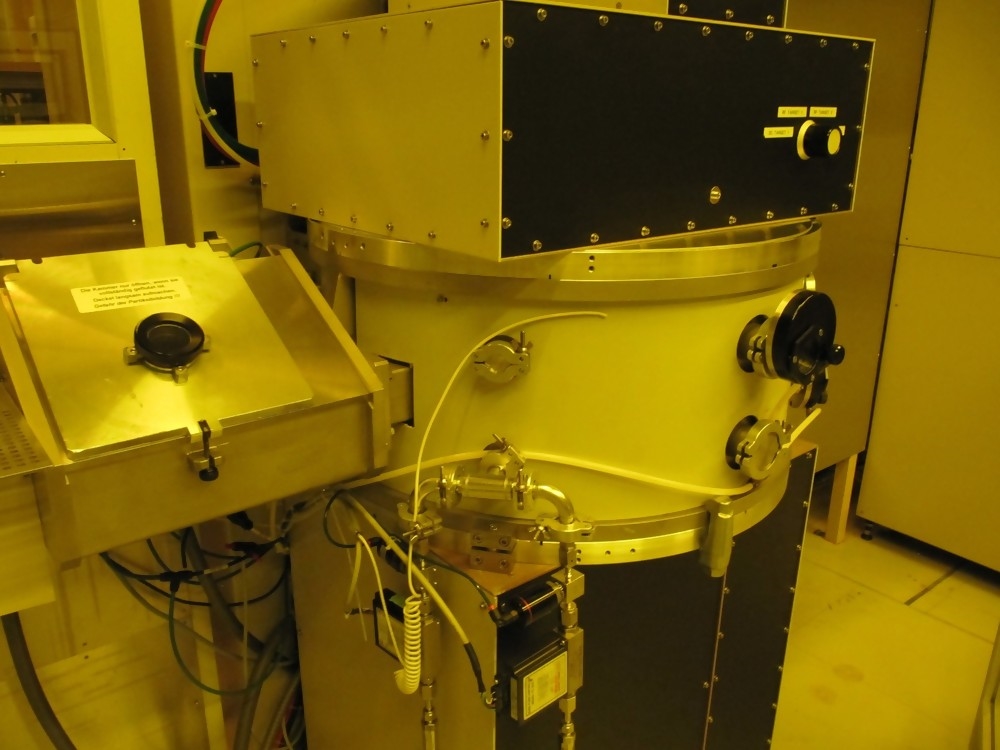

Sputtering system

With loadlock

RF/DC Sputtering (with or without bias)

Ionic cleaning

Process gas: Argon, Nitrogen

Stainless steel chamber, 26"

Diameter: 650 mm

Fitted with port-holes and flanges

Port pumping, 6"

(2) Magnetron targets, 8"

Water flow: 15 l/min

Pressure: 6 bar

Compressed air pressure: 6 bar ±0.5

Dry nitrogen pressure: 1.5 bar

Manuals included

Load lock: 6" Substrates

Substrate holder: (4) Stations

(6) Indexed positions

(4) Transfer positions

(2) Sputtering positions

Rotation: 1 to 30 rpm

Vertical translation: 50 mm - 100 mm

One 3/4 automatic shutter

RF Generator: 2000 W

DC Generator: 3000 W

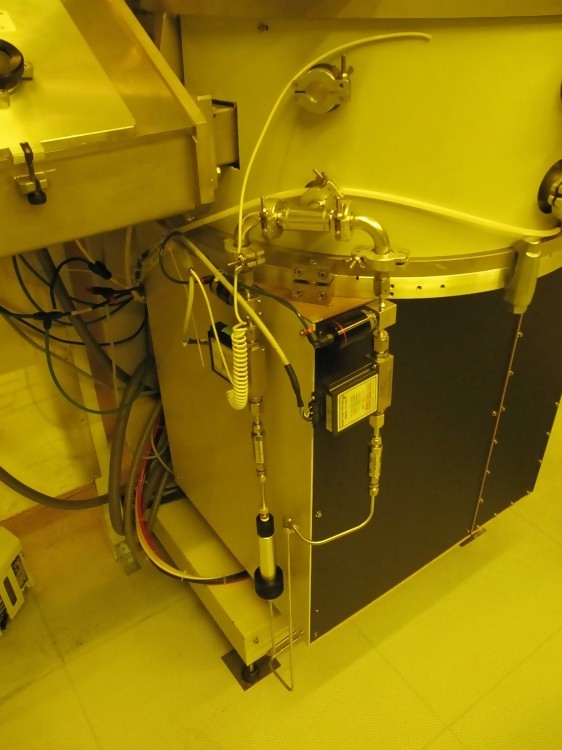

Pump:

Load lock:2012 A Rough rotary vane pump: 15 m³/h

CHAMBER: 2033 A Rough rotary vane pump: 35 m³/h

Secondary: 5402 CP Turbomolecular pump: 380 l/s

INTER-SEAL: 1004 A Rough rotary vane pump: 4.5 m³/h

Measurement:

Load lock: PIRANI PB 122 Rough vacuum

Chamber: PIRANI PB 111 Rough vacuum

BAYARD ALPERT BN 111 Secondary vacuum

BARATRON MN 121 Process vacuum

(2) Gas lines

Machine control : Programmable logic controller

SIEMENS Simatic with an OP 395

CE Marked

Power supply: 380 V, 3 Phase, 18 kVA.

ALCATEL / ADIXEN / PFEIFFER SCM 650 is a full-featured, high-performance sputtering equipment designed specifically for industrial and academic production applications. ADIXEN SCM 650 provides precise and cost-effective sputtering of a wide variety of metal and non-metal thin-film deposition materials under the exacting control of its reliable PLC-based automation system. This robust sputtering unit is the ideal choice for cost-sensitive processes, especially in laboratory or research and development setting. Using a modular magnetron sputtering process, ALCATEL SCM 650 deposits metal, alloy, and non-metallic coatings with excellent adhesion, uniformity, and step coverage. Its advanced process control allows for qPCR, optical emission spectroscopy, and Auger curves, as well as temperature and time enhancements for improved thin-film deposition. SCM 650 also makes it simple to implement fine-tuning for different substrate use. PFEIFFER SCM 650's large pumping chamber is built with high-quality construction materials and has a motorized gate to access the processing chamber, making it easier to add or remove substrates. It also comes with a welded O-ring for the door to ensure a leak-free environment. The machine can be remotely monitored and operated via a web browser, allowing users to access critical tool information as well as real-time process control and process data monitoring. ALCATEL / ADIXEN / PFEIFFER SCM 650 is equipped with active gas control, including a high-compression argon asset mounted to the rear of the model. It also has a purge orifice to minimize helium consumption. The versatile design of ADIXEN SCM 650 allows users to easily customize their thin-film coating process for different applications. For example, a dual-colour configuration is easily achievable by connecting two sputtering targets to the same magnetron source, and various other configurations are achievable through its range of installation options. The rugged construction of ALCATEL SCM 650 is tested to ensure that it runs with maximum efficiency and durability even in the most challenging environments. It also includes a series of safety features such as interlocks and alarms that offer maximum protection for users and the equipment as a whole. In conclusion, SCM 650 is a reliable, user-friendly sputtering system that offers unmatched performance and reliability. It is the perfect solution for industrial and academic production applications requiring precise and cost-effective thin-film deposition processes.

There are no reviews yet