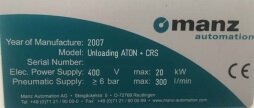

Used AMAT / APPLIED MATERIALS ATON 1600/2 PREHT #9281105 for sale

URL successfully copied!

Tap to zoom

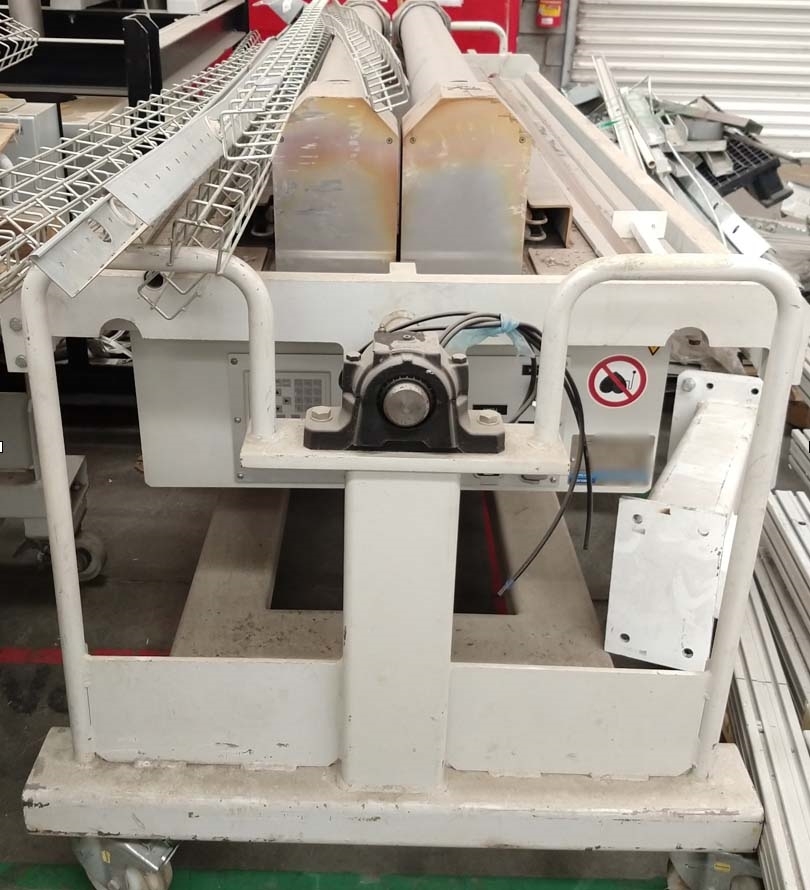

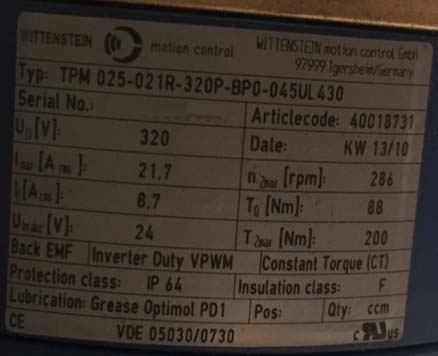

AMAT Aton 1600/2 PREHT is a sputtering equipment used for physical vapour deposition of materials onto a substrate. The system is designed for maximum efficiency and has many features that contribute to its ability to accurately deposit material. It is capable of depositing nearly any material, including metals and insulators, making it a versatile tool for many applications. The Aton 1600/2 PREHT utilizes a compact design, allowing for more efficient use of space on the production floor. The unit contains two targets, which can be used to deposit different materials onto the substrate for various film-stack configurations. The target's ceramic feed-thru pin allows for secure contacts and minimal maintenance and leakage. It also contains an advanced RF Auto-Tune machine. The tool is capable of adjusting the generated frequency to different substrates automatically, providing better temperature and rate control. The Aton 1600/2 PREHT contains a number of features to improve process efficiency, accuracy, and repeatability. The precision vacuum asset ensures uniform deposition and eliminates any risks of contamination. It uses a large variety of shutters, sensors, controllers and gauges to ensure a consistent pressure environment in each chamber of the model. It is also equipped with a closed loop pressure control equipment, which can monitor and control the pressure during sputtering automatically, as well as a pneumatic sample changing mechanism. The Aton 1600/2 PREHT also features a powerful automation and control system. It utilizes multiple layers of software and hardware to improve unit management and reduce cost. It features a Graphical User Interface (GUI) that allow users to customize the sputtering process. The machine also incorporates dynamic process monitoring and fault diagnosis that can detect any fault or deviation in the sputtering process. Overall, APPLIED MATERIALS Aton 1600/2 PREHT is a powerful sputtering tool that offers maximum efficiency and accuracy. Its robust automation and control asset ensures a reliable and repeatable production environment. Its compact design conserves space on the production floor, and its versatile target model allows for the deposition of nearly any material. The equipment has a number of features that make it a useful tool for many applications, including thin film deposition and semiconductor production.

There are no reviews yet