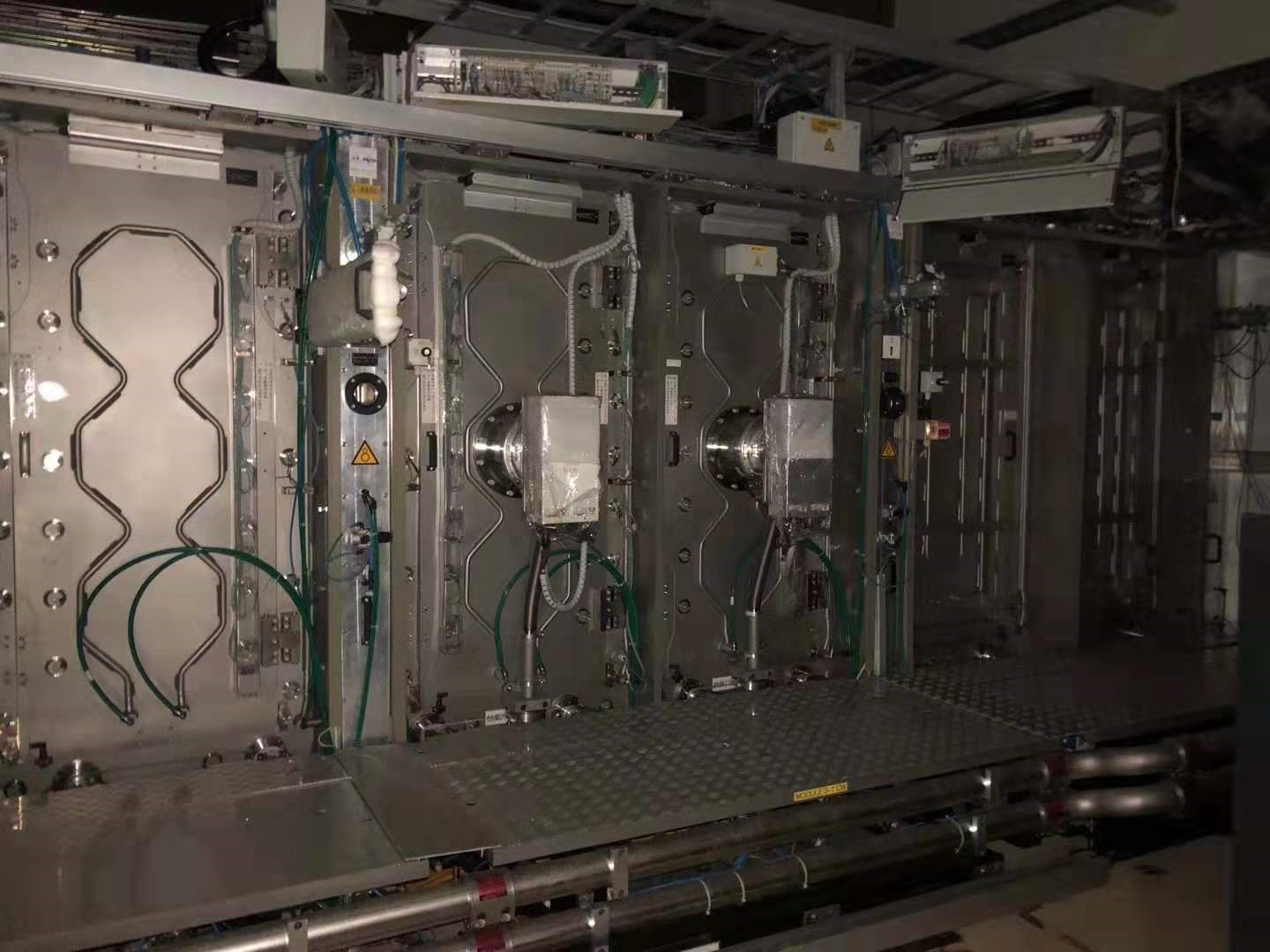

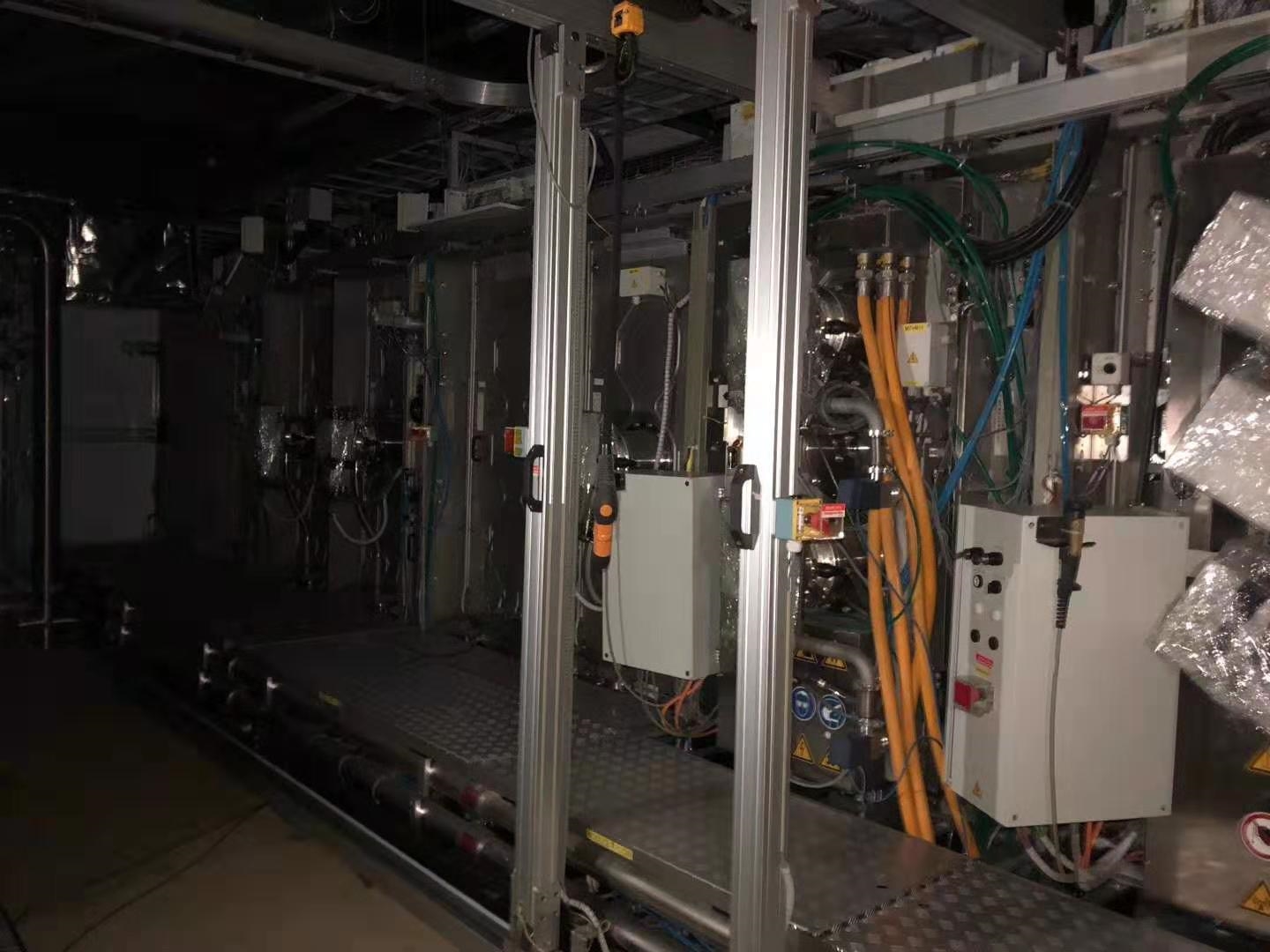

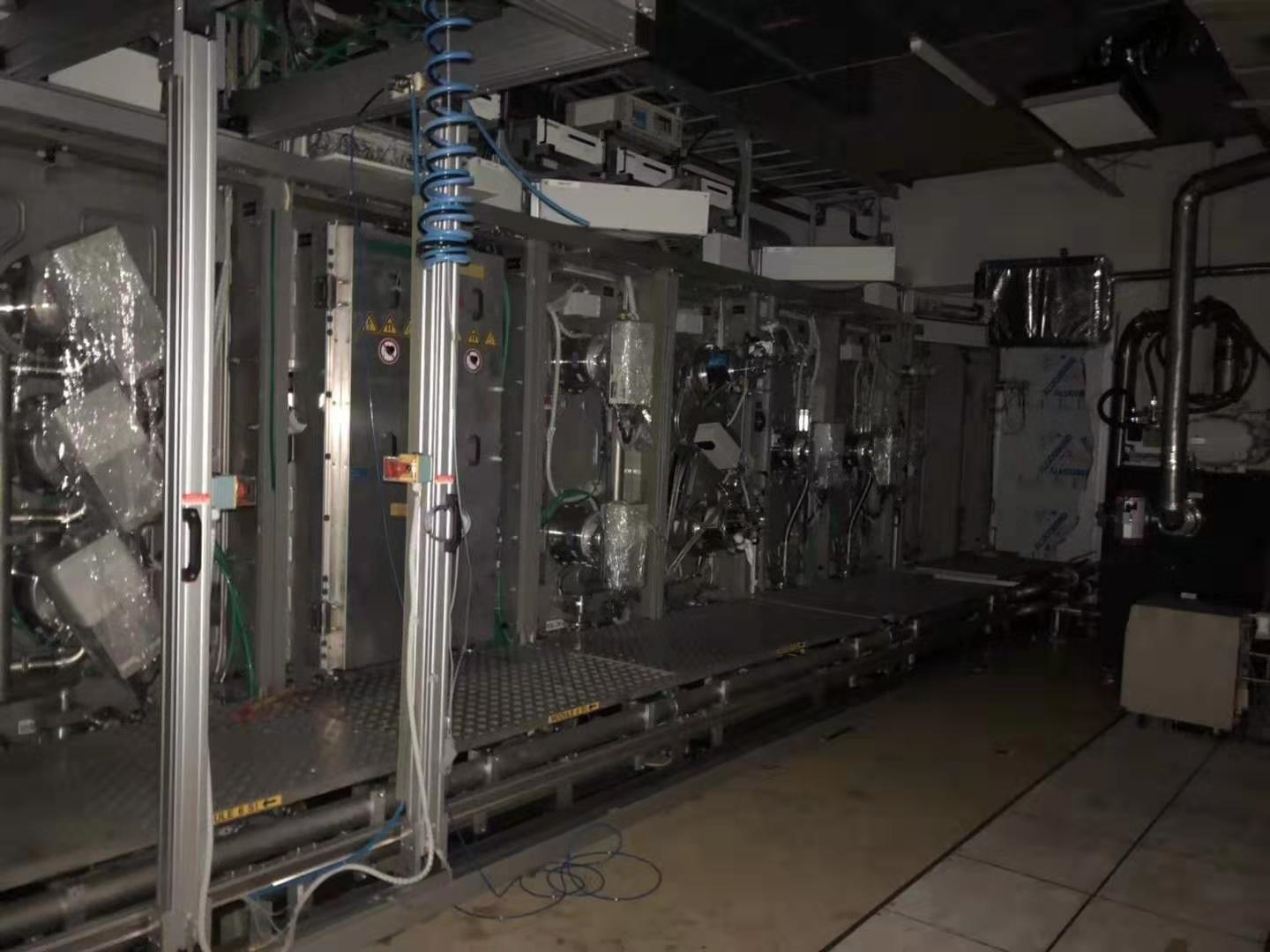

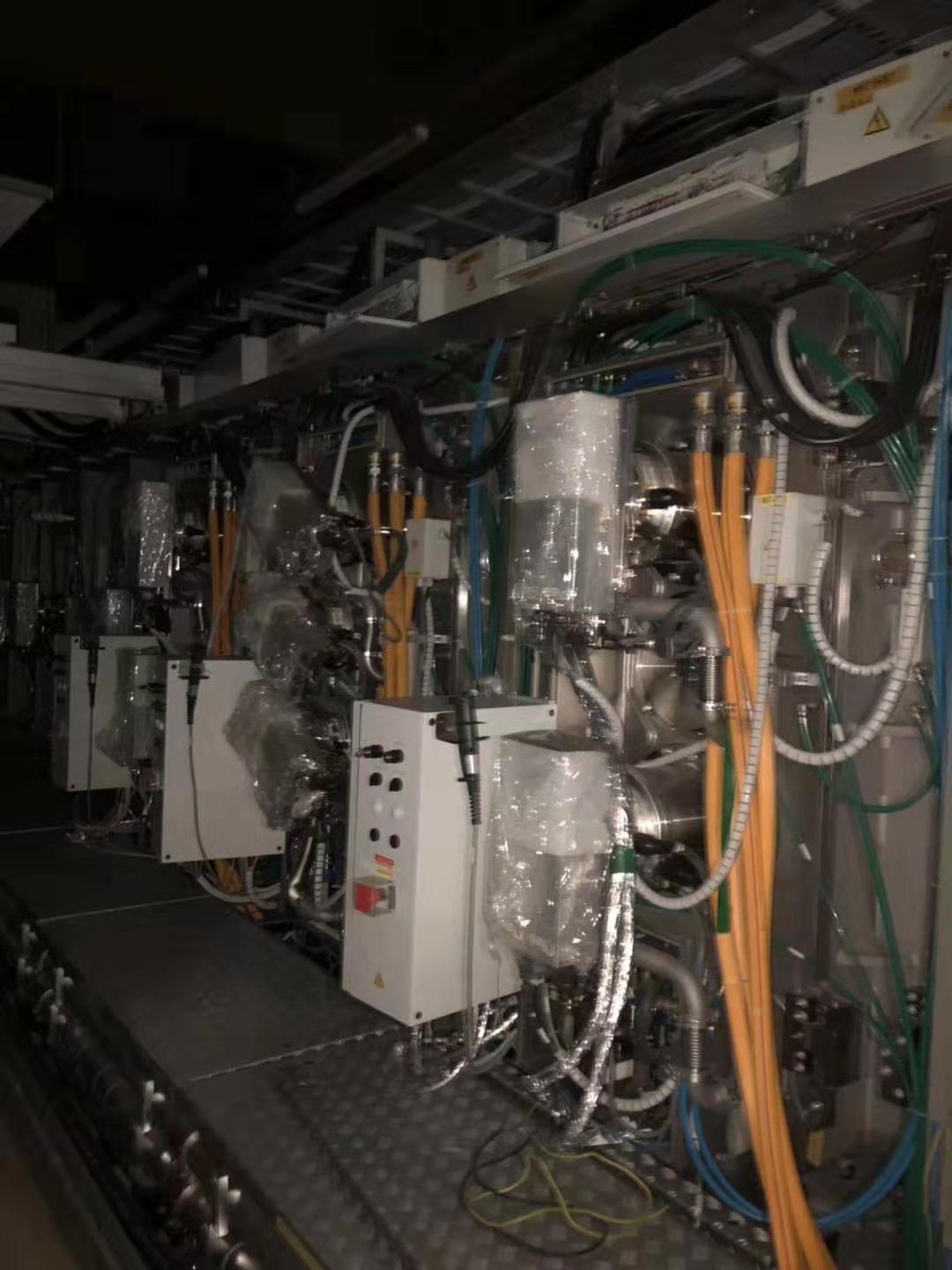

Used AMAT / APPLIED MATERIALS NAR 1200L #9250995 for sale

URL successfully copied!

Tap to zoom

ID: 9250995

Vintage: 2010

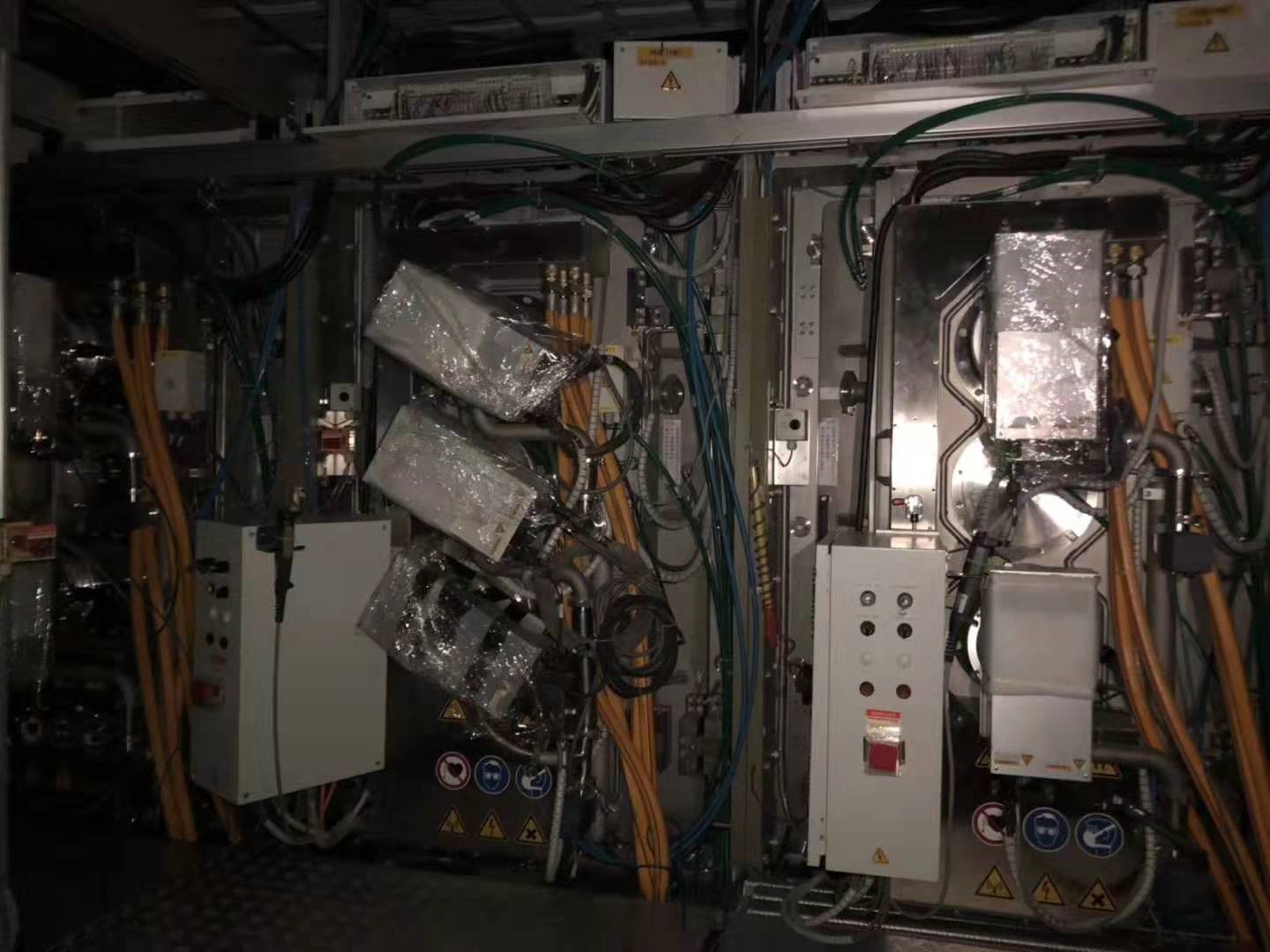

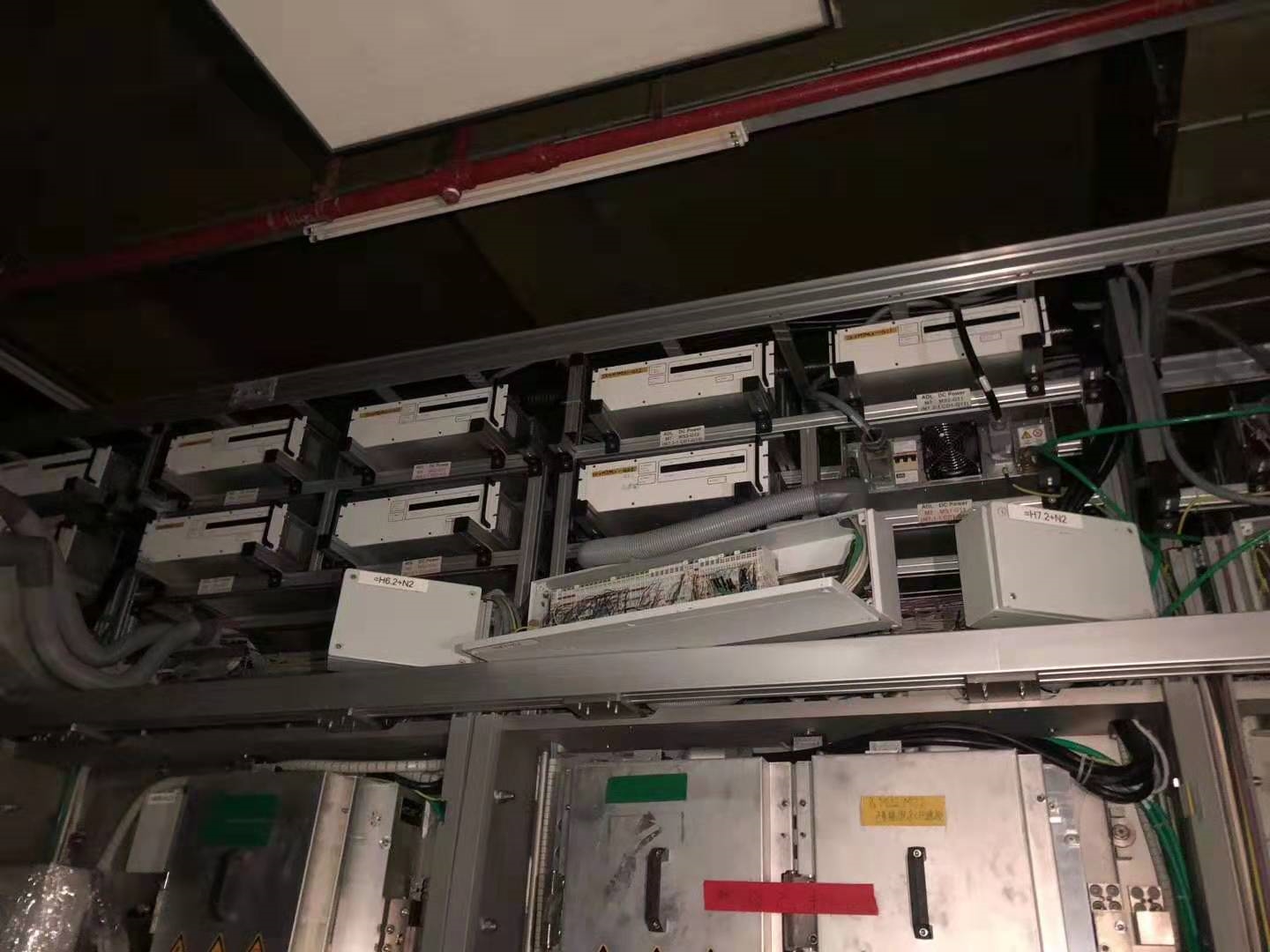

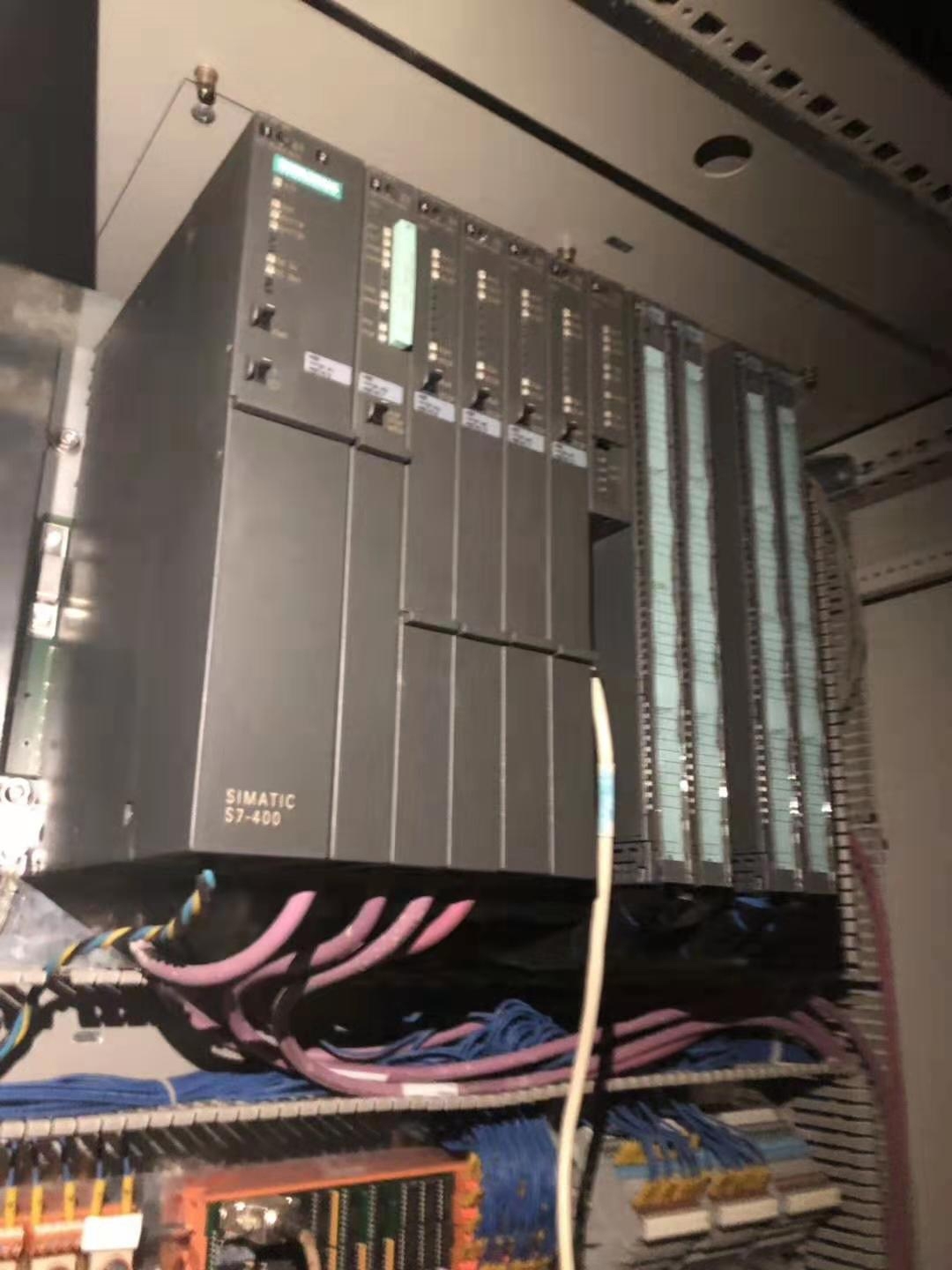

Vertical inline sputtering system

Cycle time: 35 seconds each side

ITO Application

2010 vintage.

AMAT / APPLIED MATERIALS / AKT NAR 1200L is a high-precision sputtering equipment used to deposit thin films of material onto a substrate such as a semiconductor wafer. This system facilitates the production of integrated circuits such as computer chips, which require layers of different materials on top of each other as part of their fabrication process. The 1200L specifically is an automated, digital sputter deposition unit that can work on dual pallets, allowing for the deposition of different materials onto separate substrates in parallel. This sputter deposition machine employs an advanced Direct Drive Design in which the sputter heads are motor driven directly without the use of any bearings or seals, which improves the reliability and the uptime of the tool. The 1200L asset is a 12" model, capable of deposition big substrates. The integration of robotics in sputter deposition systems allow for efficient wafer handling and higher throughput. The advanced low-profile sputtering chamber design of the equipment ensures high uniformity over the entire substrate. The system is built on a wide range of both custom and commercially available hardware and software solutions, allowing customers to choose the most efficient technology fitting their specific process needs. It has a separate control module to optimise the sputtering process by controlling the vacuum levels, target to substrate distance and other properties while maintaining process uniformity and repeatability. The 1200L unit is equipped with a powerful, computer-controlled sputtering source, capable of high-rate deposition of conductive, insulating, transparent and semiconducting thin films. It is also capable of customising individual recipes for different processes and sub-processes. Additionally, the machine has an internal hardware to monitor the process conditions and gas pressures in order to control and improve process repeatability. This tool also includes a high-resolution camera to monitor and visualise the process in real-time and an in-situ resistivity monitor that gives feedback on the film properties that are currently being deposited. With its flexible, robust and high-performance features, AKT NAR 1200L sputtering asset is the perfect solution for producing integrated circuits that require thin films of material. Its Dual Pallet design allows for parallel deposition processes, and its powerful deposition source makes it capable of producing high-quality films that meet the demanding specifications of integrated circuit production.

There are no reviews yet