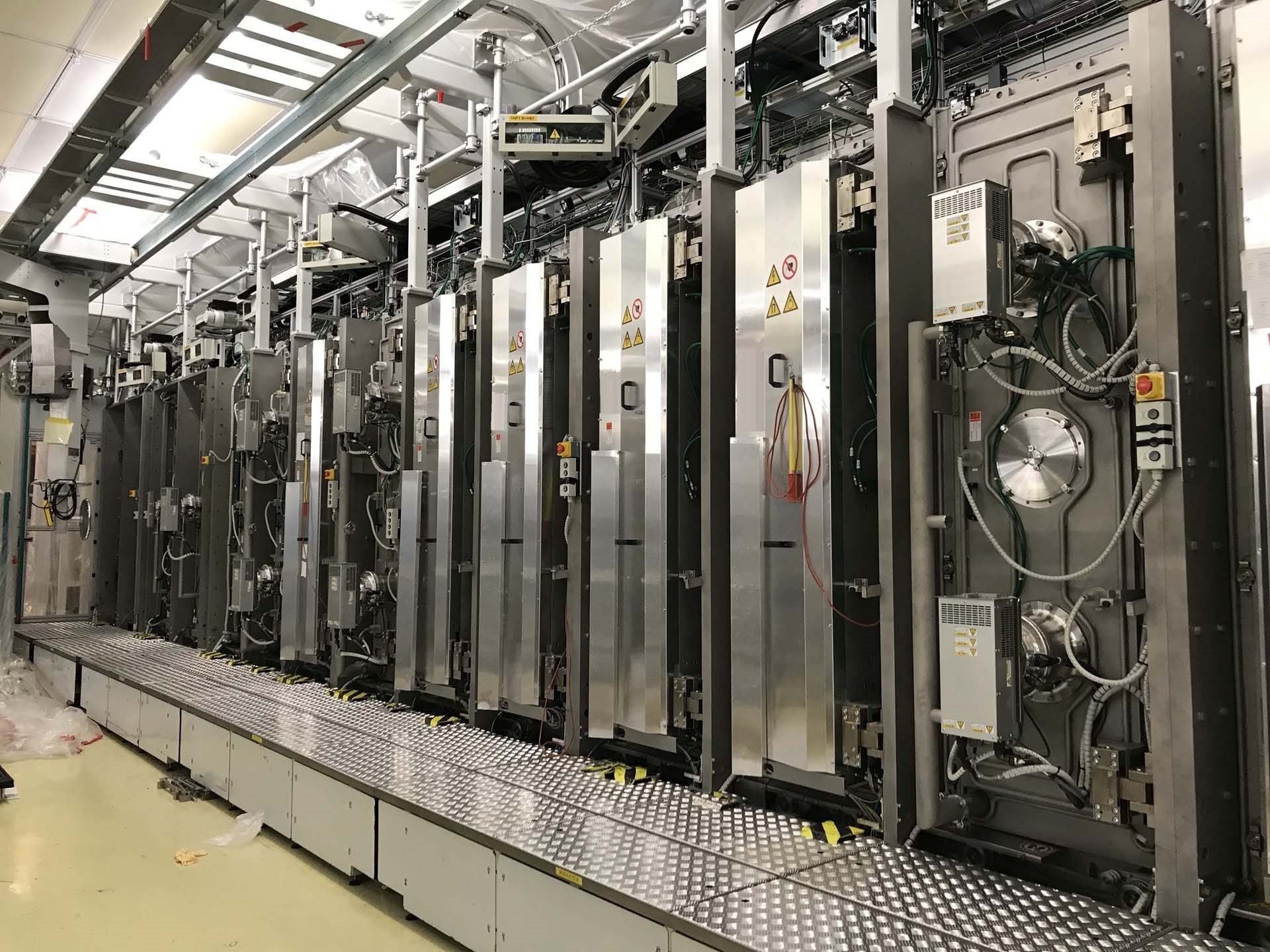

Used AMAT / APPLIED MATERIALS NAR 1800 Twin #9243193 for sale

URL successfully copied!

Tap to zoom

ID: 9243193

Vertical inline sputtering system

Substrate carrier:

Substrate dimensions: 730 x 920 mm

Carrier dimensions:

Approximate 1840 mm length

Approximate 2527 mm height

Carrier loading capacity: (4) Substrates

Carrier material: Ti / Al

Glass breakage rate within vacuum area:

Glass thickness:

< 0.5 mm: 0.3%

≥ 0.5 mm: 0.1%

Vacuum measuring equipment:

Pirani vacuum meter:

Range: 10³ hPa to 1x10^-3 hPa

Ionization gauge:

Range: 10^-2 hPa to 1x10^-9 hPa

Capacitance vacuum meter sensor head:

Range: 10^-2 hPa to 10^-4 hPa

Pumps:

SHIMADZU TPH1503 Turbo-molecular pump

Rough vacuum pump SP630 plus WSU-2001

Sputter cathodes:

Type: Rotary cathode & water cooled

Material of backing tube: Stainless steel

Magnetic field: Static magnet array

Target: sprayed onto backing tube

Target length: 2150 mm

Planar cathode:

Type: DC Magnetron

Material of backing plate: Titanium with water cooling channels

ITO / MO BP

Al (2) BP

Magnetic field: Move mag

Target fixing: Bonding

Target length: 2100 mm

(2) 300 x 265 x 9 mm³ (Two end pcs)

1500 x 265 x 7 mm³ (Middle part segmented in pcs)

Heater system:

Heating chamber equipped with resistance heater which emits IR radiation

Mode of operation: PID Regulation

Heater set point capability: 650°C

Shielding:

Shielding material: Stainless steel

High sticking coefficient to prevent particle generation

Machine control system:

Programmable logic controller with decentralized IO’s

Digital & analog controls:

Pumps

Valves

Power supplies

Interlocks for water and compressed air

Error messages

Operating system: Windows

Cooling water:

Pressure: 5/7 Bar absolute

Maximum back pressure: Open drain

Water inlet temperature range: 18-25°C

Temperature level within: ± 2°C (for TMP’s only)

Hardness of water: 6-8°dH (Equivalent 107-143 ppm CaCO3)

Electric conductivity: 100 - 200 μS/cm

pH-Value: 8 - 10

Foreign particles size: Maximum 100 μm

Foreign particles concentration: Maximum 10/cm³

Dissolved Cl: Maximum 20 mg/l

Dissolved CO2: Maximum 15 mg/l

Compressed air:

Pressure: 6/8 Bar absolute

Sputter gases:

Argon

Oxygen

Nitrogen

Argon / Oxygen

Purity of sputter gas: 99.999 %

Venting gas: Nitrogen or dry compressed air

Dew point: ≤ -30°C

Pressure maximum: 1.5 Bar absolute

Ambient requirements:

Temperature at machine & machine control room: 20-30°C

Relative humidity: ≤ 60 %

Machine SiO2 / ITO Track consumption values:

Power: 760 kVA / 1000 A

Machine metal track consumption values:

Power: 1000 kVA / 1500 A

Electric power: 400 V ±10 %, 50/60 Hz, 3 Phase, 5 wires (3 AC, N, PE).

AMAT / APPLIED MATERIALS NAR 1800 Twin is a sputtering equipment designed to coat or deposit thin films of material onto a substrate. It is a two-chamber system, meaning it has two independent vacuum chambers which can be used to sputter different materials in a single operating cycle. The unit is setup for unattended operation, allowing users to set parameters and leave the machine unattended until the required film has been deposited. It is based on high-vacuum, direct-current, planar magnetron sputtering technology and can operate with twin cathodes. This allows for high deposition rates and excellent uniformity across the entire substrate. The tool can also be docked with the load-lock to automate substrate handling. The asset is capable of depositing materials such as aluminum, stainless steel, titanium, copper, tungsten, and chromium. It is also capable of depositing multiple layers in one operating cycle to create multilayer thin films, and it can also produce concave and convex structures on curved surfaces. In terms of its operating specifications, the model has a vacuum chamber volume of 4 liters, a base pressure of 2x10-7 torr, a cathode configuration of two single-sided planar magnetrons, and a power of up to 2000 Watts per magnetron. The equipment can also accommodate substrates up to 200mm in diameter and has a substrate heating range from room temperature up to 600C. AMAT NAR 1800 Twin is a safe and reliable sputtering system that offers excellent performance and uniformity.

There are no reviews yet