Used BALZERS 810 #293650477 for sale

URL successfully copied!

Tap to zoom

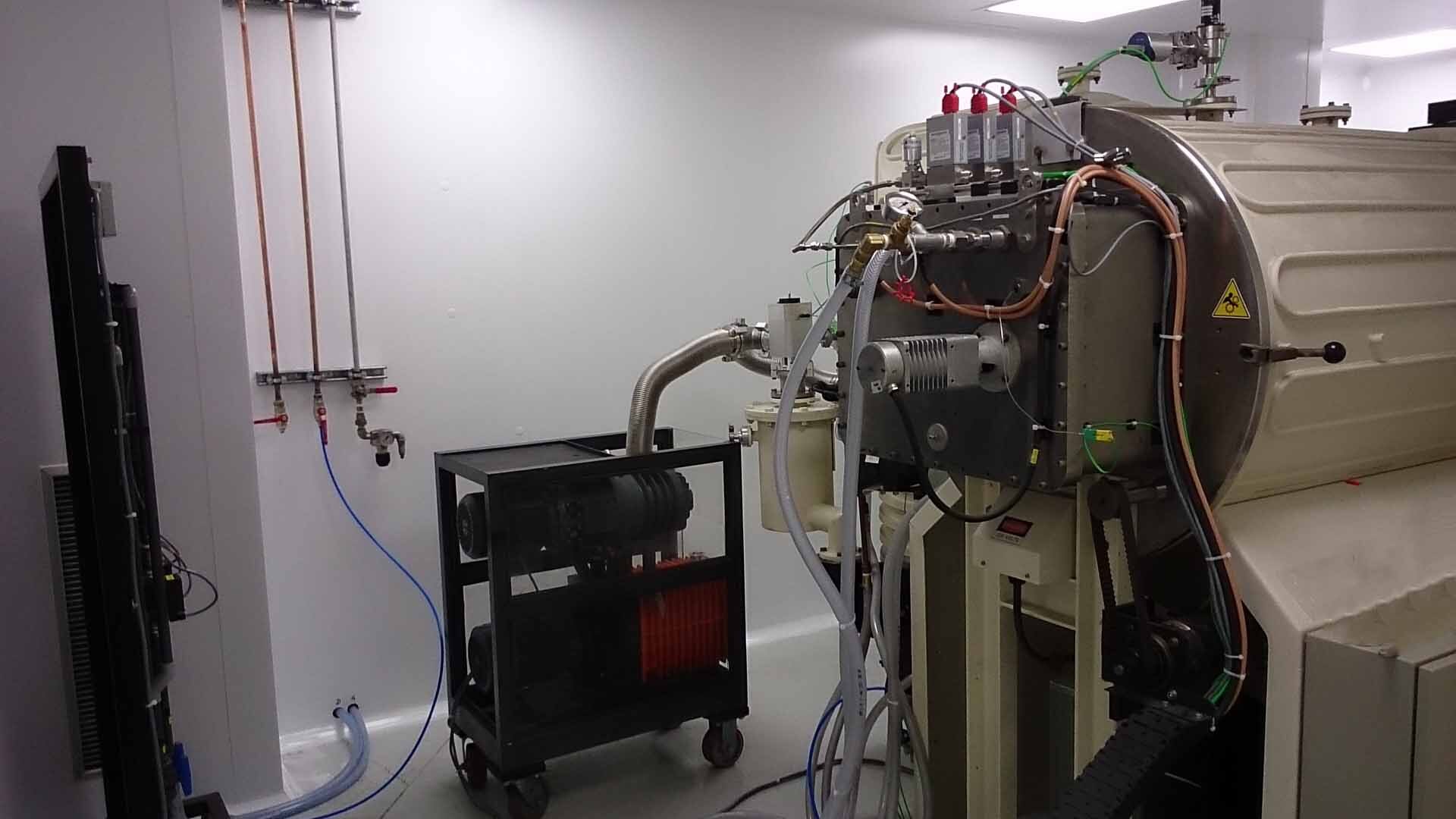

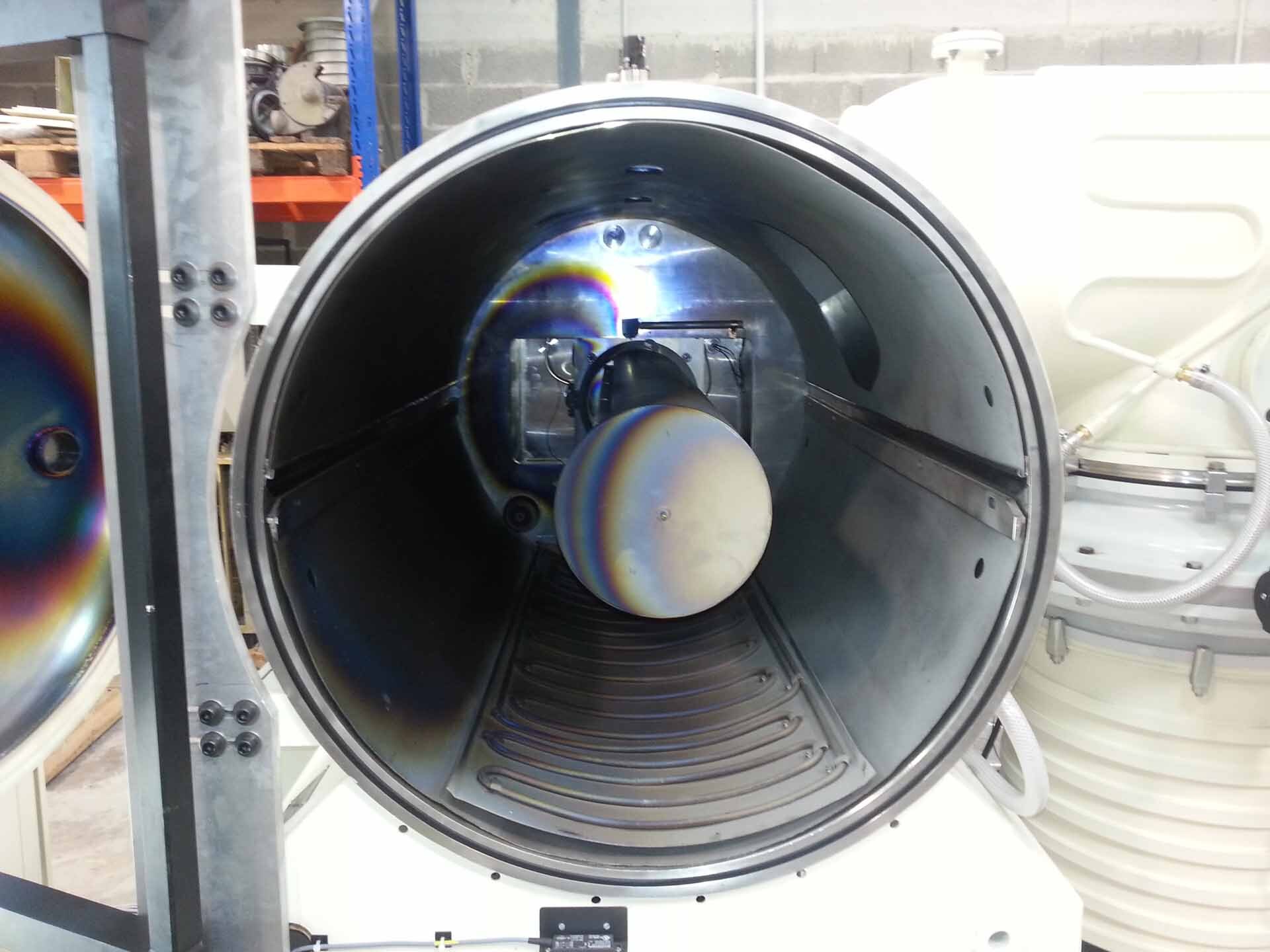

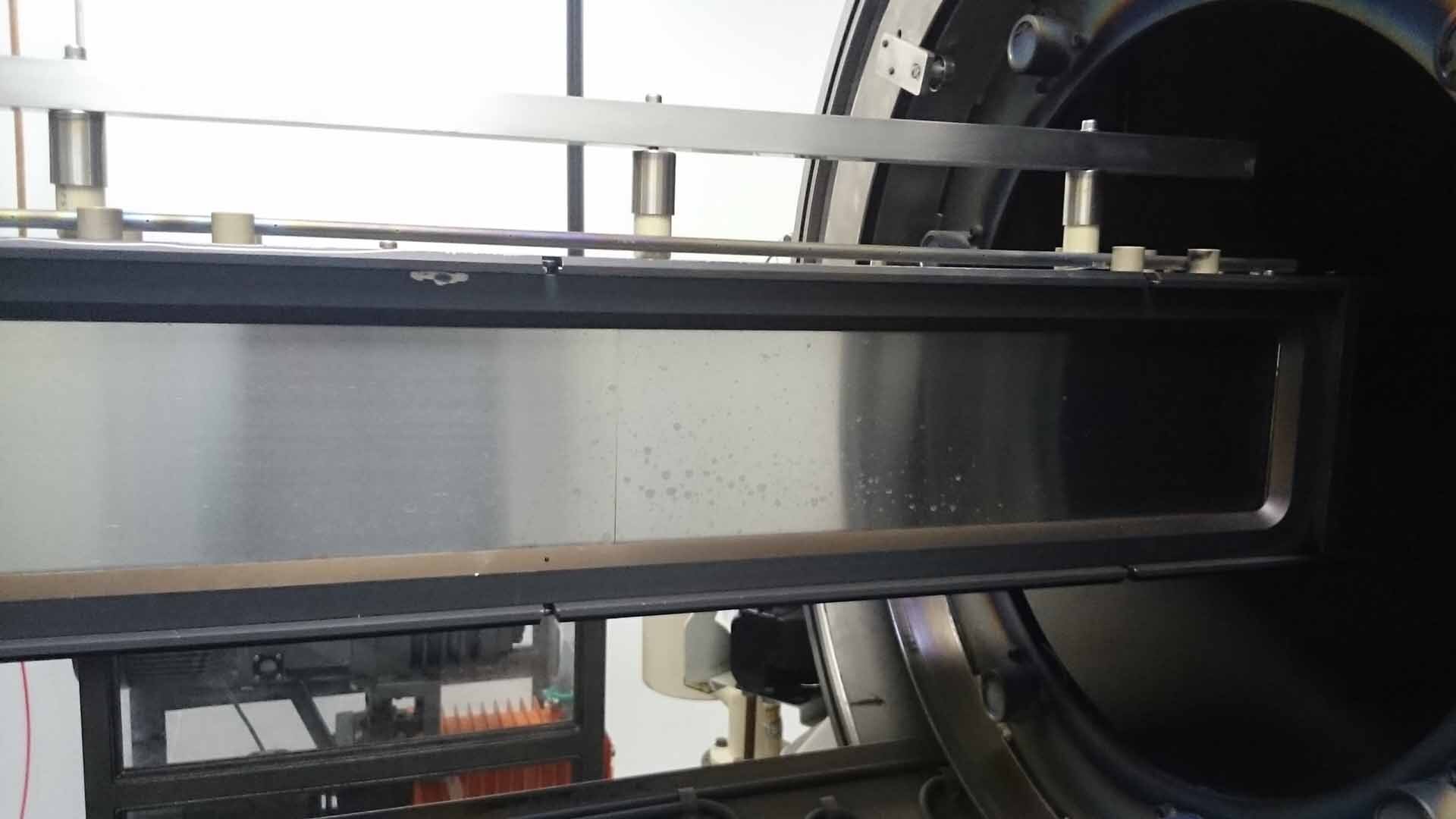

BALZERS 810 is a sputtering equipment that uses radio frequency plasma sputtering to produce thin films of metals, alloys, and compounds via thermal evaporation or sputtering. The system consists of a wide range of components, including an ion source, a wafer stage, a deposition chamber, RF power supplies, a substrate holder, an evacuation pump, and a process controller. The ion source is used to generate the plasma required to sputter the target material. The ion source is typically an electrostatic, hot electron, or high-density plasma source, depending on the application. The wafer stage of the unit is used to hold the substrate during the deposition process. This stage is typically composed of a vacuum-sealed wafer holder, which can be programmed to move the substrate in three dimensions for improved deposition uniformity. The deposition chamber is where the sputtering process takes place. This chamber is typically constructed from aluminum and stainless steel, with a vacuum-tight seal and is equipped with a viewport to allow visual inspection of the deposition process. The chamber houses the ion source and the substrate stage, and is also equipped with an exhaust machine to evacuate the process gases. The RF power supplies are used to supply the electrical energy required for sputtering. These power supplies typically provide power levels of up to 1000 watts and feature variable pulsing frequency, enabling the process window to be optimized for each application. The substrate holder of the tool is used to hold the substrate during the sputtering process and is typically constructed from stainless steel. This holder can be programmably positioned to allow for improved depositions uniformity. The evacuation pump of the asset is used to maintain a low pressure during the sputtering process and typically is composed of a turbo or scroll pump. The process controller is used to control the process parameters, including temperature, pressure, power, and deposition rate. This controller can be programmed to provide precise control of the deposition process, allowing for improved deposition uniformity. Overall, 810 is a highly advanced sputtering model that can be used to deposit a wide range of materials for various applications. This equipment is ideal for research applications and is particularly useful for producing ultra-thin films of metals and alloys. The sputtering process can be precisely controlled for uniform deposition of high-quality thin films.

There are no reviews yet