Used BALZERS LLS 801 #9171464 for sale

URL successfully copied!

Tap to zoom

ID: 9171464

Wafer Size: 6"

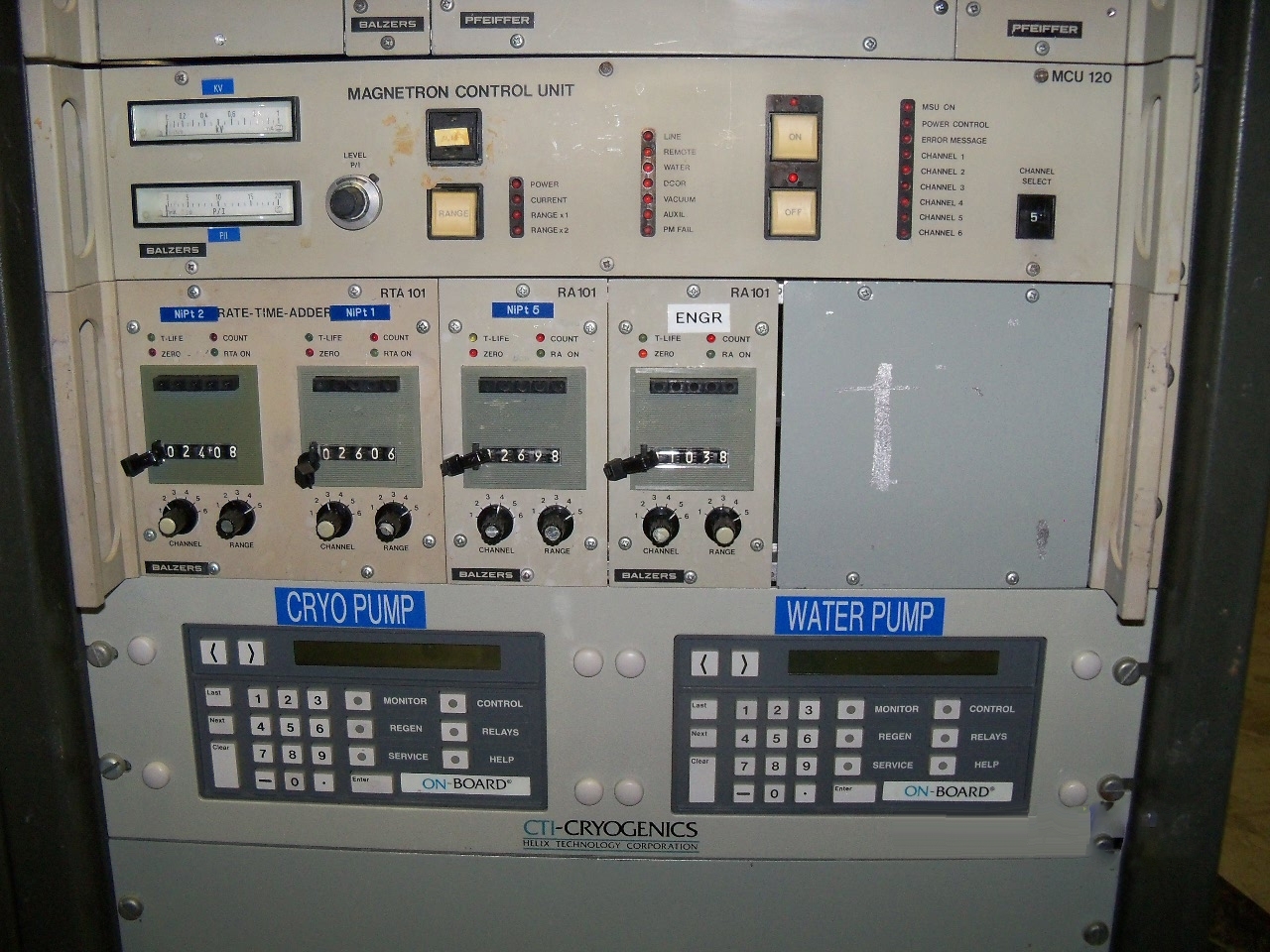

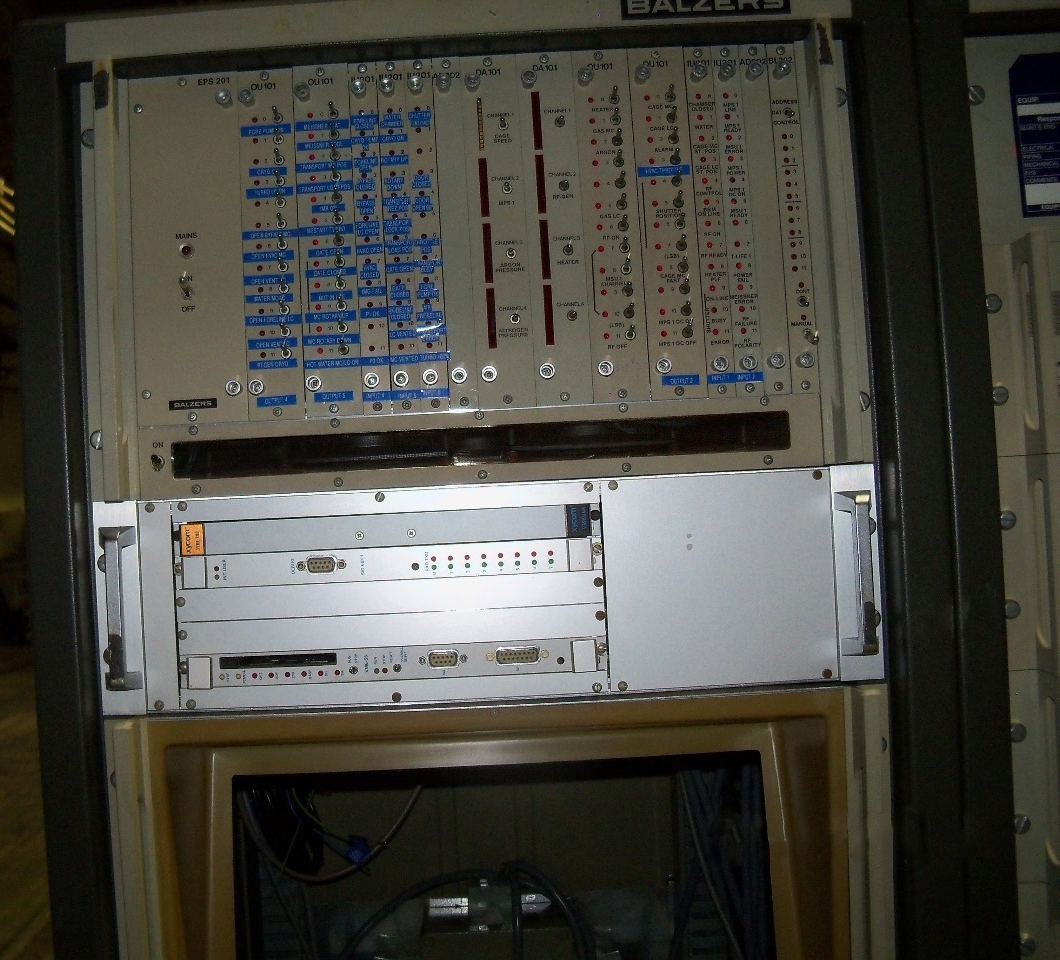

Barrier metal sputtering system, 6"

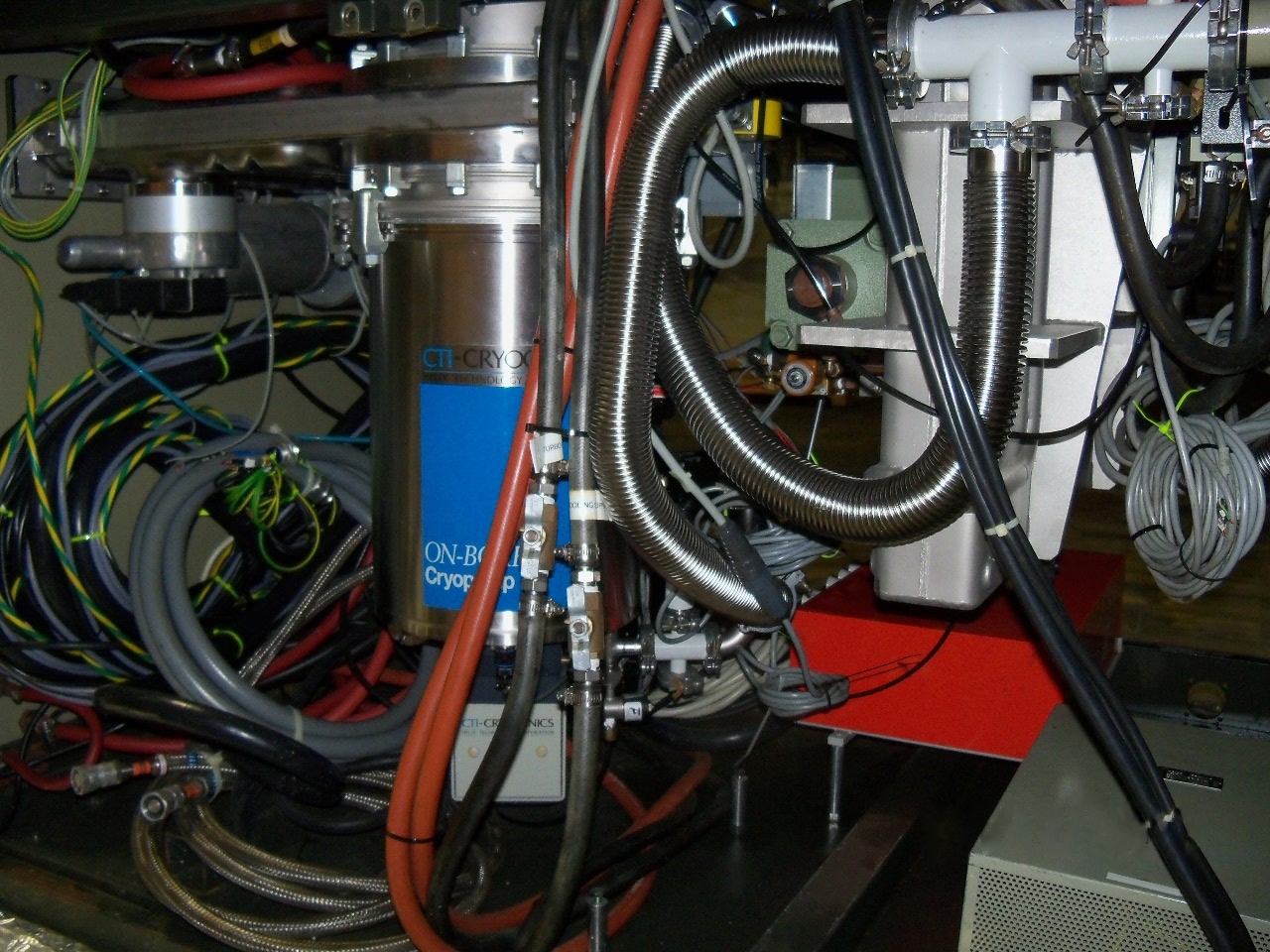

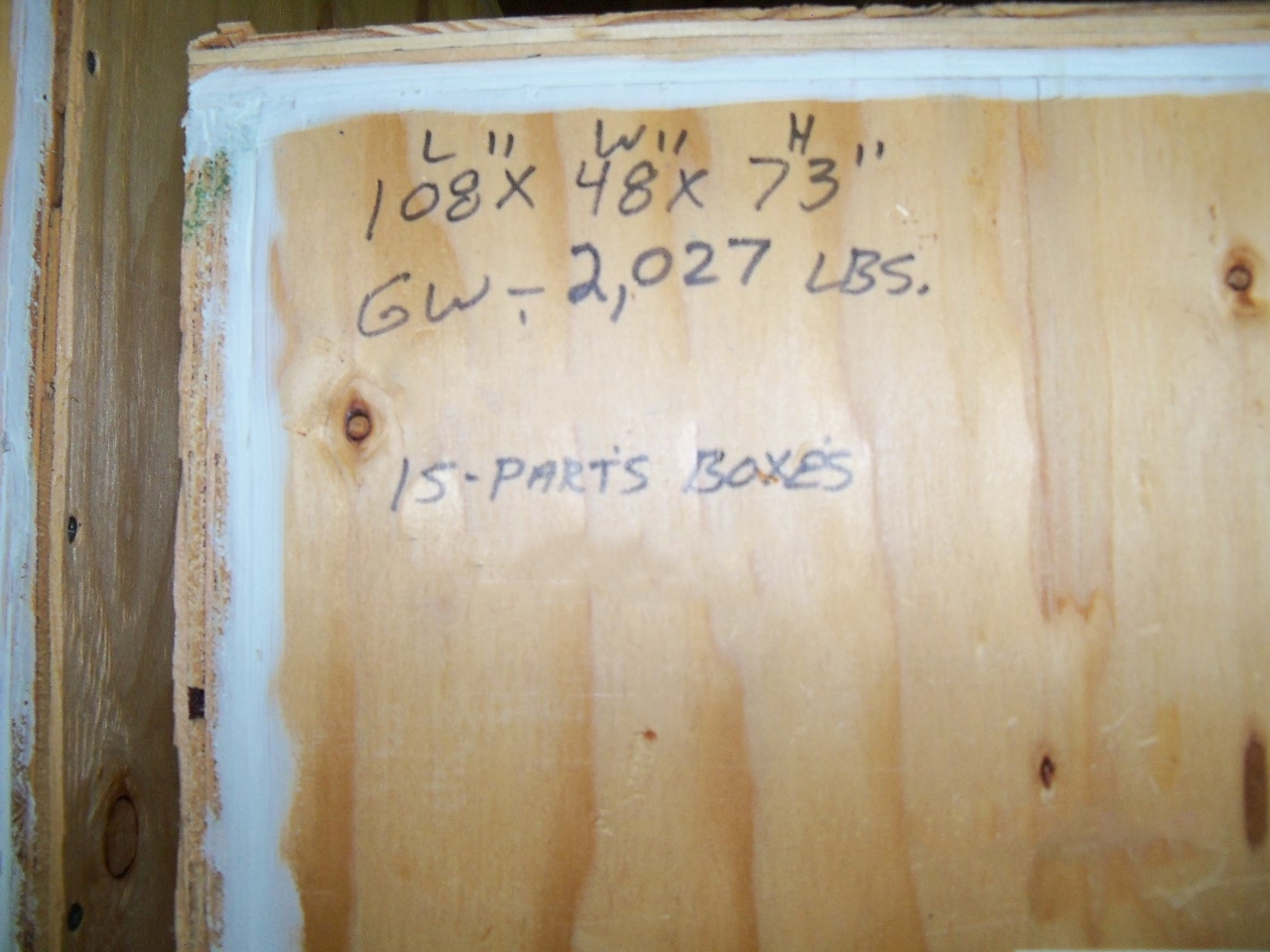

Water heater

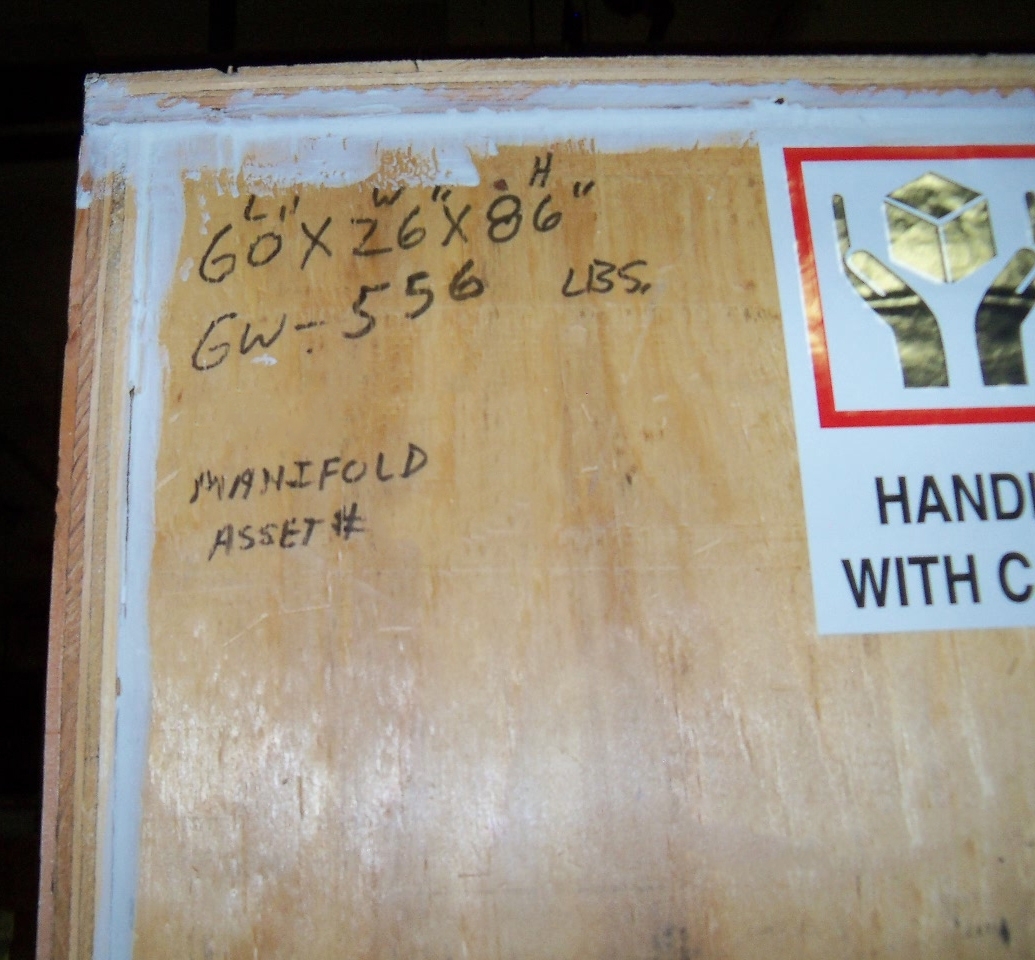

Water manifold

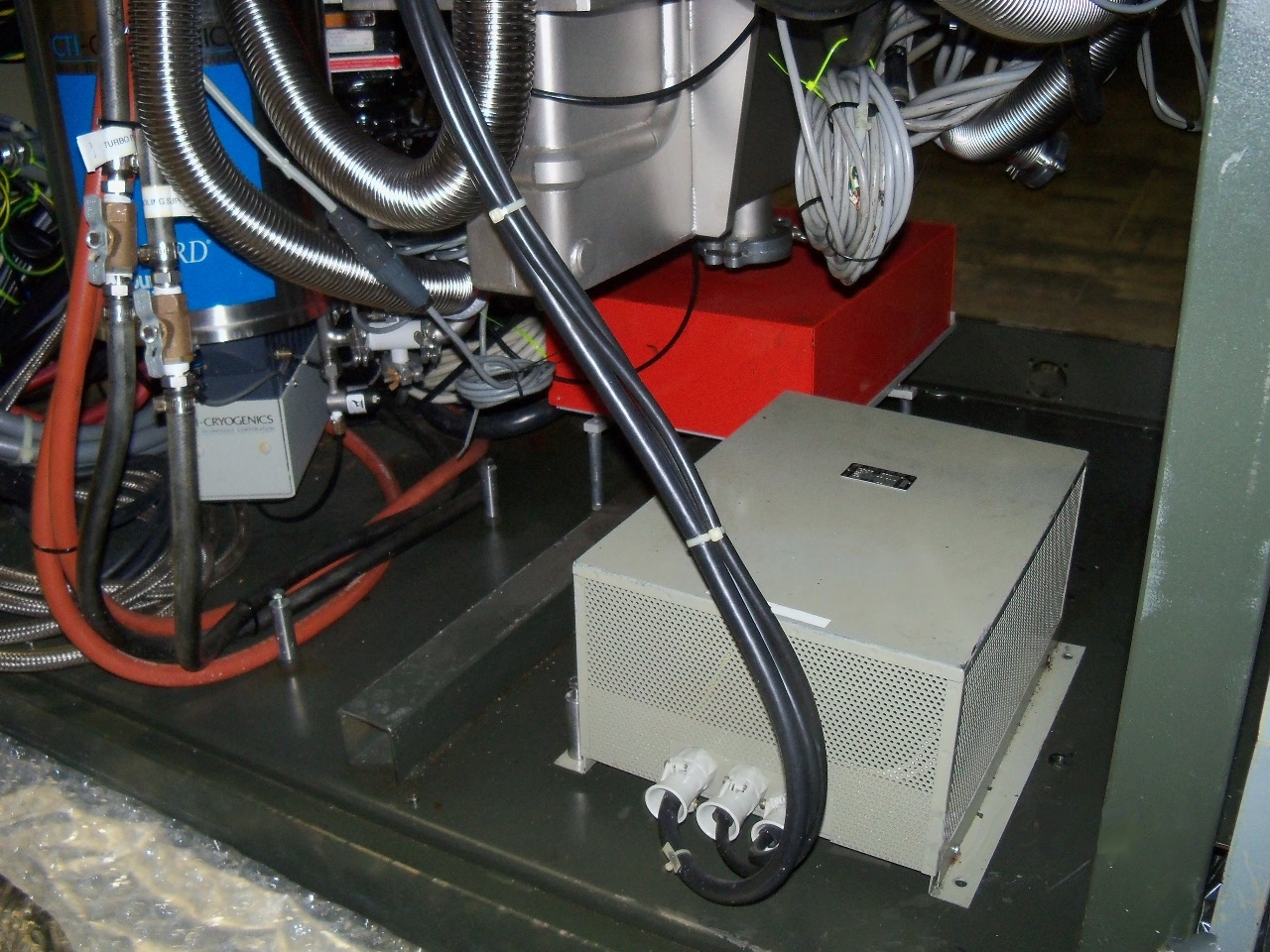

Strong earth magnet

Power supply

(2) Cryo compressors.

BALZERS LLS 801 Sputtering Equipment is an advanced vacuum processing tool used for creating protective coatings on a variety of substrates. It is designed to deposit thin layers of target materials onto the surface of a substrate in order to produce an optically attractive, chemically inert, and mechanically durable protective coating. LLS 801 Sputtering System builds upon the already renowned LLS family of Systems from BALZERS, as it provides improved uniformity and deposition rates while maintaining superior process repeatability. BALZERS LLS 801 Sputtering Unit is comprised of several important subsystems, which include the following: * RF Power Supply: This subsystem provides a means to generate RF power necessary for sputtering. * Target Magnet Assembly: This subsystem includes two electromagnets and control electronics used to maintain a stable attractive force in the gap region between the target and the substrate. * Target Assembly: The target assembly houses the target material, and has a connected RF electrode. * Substrate Assembly: The substrate assembly contains the substrate holder and a grounded shield. * Vacuum Machine: This subsystem consists of a diffusion pump, roughing valve and a turbo pump. The Operating Principle of LLS 801 Sputtering Tool is based on the physical sputtering process. The RF power supply generates RF power from an external source, which is then directly coupled to the target assembly. This creates an attractive force in between the target and the substrate, such that the target material is ablated and then deposited onto the substrate. Since the RF power supply is typically operated near 13.56 MHz, the targets are almost constantly in the vapor-plasma state, which helps to further enhance the uniformity and deposition rate, provided by BALZERS LLS 801 Sputtering Asset. Furthermore, the two electromagnets within the target magnet assembly are used to help maintain a stable attractive force in between the target and substrate, which helps to ensure a uniform coating every time. The magnets also serve to reduce the amount of power being dissipated in the target, thus helping to make LLS 801 Sputtering Model exceptionally energy efficient. BALZERS LLS 801 Sputtering Equipment is highly versatile, as it is capable of sputtering a variety of materials. This system is widely used in industries such as medical device manufacturing, electronic component manufacturing, optics production, and aerospace coating. Overall, LLS 801 Sputtering Unit is an exceptional tool for creating thin protective coatings on a variety of substrates. It is a reliable and energy-efficient sputtering machine that is capable of depositing uniform thin films quickly and efficiently every time. It has the extra advantage of having two magnets that maintain a steady attractive force in order to ensure optimal deposition uniformity and rate.

There are no reviews yet