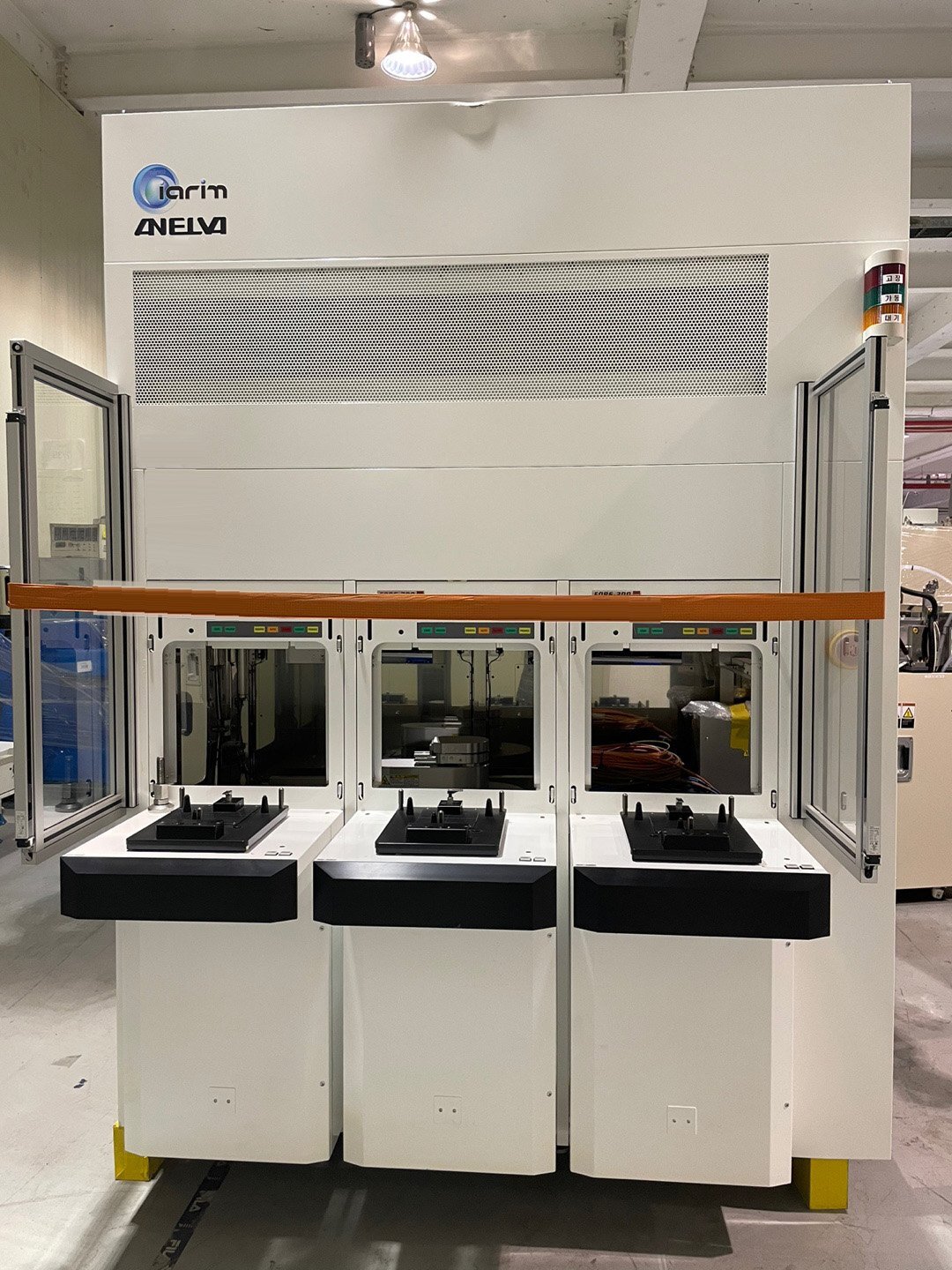

Used CANON / ANELVA C-7100GT #9281807 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9281807

Wafer Size: 12"

Vintage: 2011

PVD System, 12"

(3) Chambers:

Chamber 1: TiN

Chamber 2: TiN

Chamber 3: SiO2 ETCH (A-CH)

Pre-clean chamber

Missing parts:

Qty / Part number / Description

(1) / - / D-Chamber

(4) / 99009-58901 / DC5KW Plasma generators Dual, QIP

(4) / 1055-08698 / Stages, RF 2PVD

(8) / 1055-17508 / Sheet, carbon stages

(4) / 1038-05492 / Quartz rings, PY362

(1) / - / D-Chamber rack

(1) / - / Cable

(4) / 1042-17090 / 25V 250W Heaters

(1) / 9007-58377 / Termo couple, RD310

(3) / 0111-90397 / Multi navi

(3) / N50023210 / Ion gauge controllers

(9) / N12004545 / Lamp heater powers

(3) / 9006-86546 / RF Power supplies 2KW (AX-20003A)

(1) / 9001-14094 / LL / Slit valve

(3) / 9001-13959 / PVD Slit valves

(4) / N20208864 / Z, Sensor controllers

(12) / 1042-17090 / 25V 250W heaters

(3) / 9007-58377 / Thermo couples, RD310

(3) / N50023131 / Stabil-ion gauges

(3) / N50025919 / Baratron gauges

(5) / - / Brakets

(20) / 1063-41277 / PLCs

(20) / 1071-76104 / PLCs

(20) / 1072-27727 / PLCs

(4) / 9007-60358 / Thermo couple controllers

(1) / 9007-61508 / CCD

(4) / 9007-58822 / CCD Cameras

(4) / N20208711 / Z, Sensor

(1) / 9014-41321 / TR Robot EE

(1) / 9009-87803 / EFEM Robot EE

(9) / - / Destrubting sheets

(1) / 1042-08203 / Lamp heater assy, connect

(1) / 1037-34502 / Heater base

(3) / 1042-17090 / 250W 25V Heaters, (2) assys

(1) / 1042-17171 / Cable, heater assy

(1) / 1023-20960 / Shutter shaft cover

(1) / 1037-27377 / Stage, RF (2) PVD

(8) / 1055-08698 / Springs, hold stage

(1) / 1055-17427 / Quartz ring, PY362

(3) / 1038-05492 / Quartz RPIN, L15xD5

(2) / 1046-92614 / Bolt, location al203

(3) / 1057-53934 / Stopper pins

(16) / 1035-18922 / H3 x 8, AG

(20) / N31000015 / S SUS304 WA x 3 Flat washers

(2) / TMF-403M / RF 2PVD

(10) / - / Shield adaptors

(10) / - / HE Elbows

(2) / - / Power cables

(4) / - / LID Lamp heaters

(1) / - / Maintenance USB port

(3) / - / PLC Racks

(1) / - / Heater connection box

(1) / - / SMKE Sensor

(1) / - / EMO

2011 vintage.

CANON / ANELVA C-7100GT Sputtering Equipment is a versatile and highly efficient sputtering system that can be used to deposit conformal thin films onto substrates of various sizes. It is capable of sputtering both resistive and electron beam processes, as well as multiple film types, thicknesses, and compositions. CANON C-7100GT consists of a compact two stage unit that is equipped with two reactive (magnetron) and one direct current (DC) sputtering chamber. ANELVA C-7100GT is designed for higher power processes and can deposit up to two films at once, allowing for in situ deposition of films, such as alternating layers of metals and dielectrics, as well as complex overlayers and high aspect ratio structures. C-7100GT is equipped with fully programmable DC power supplies and solid state relays to ensure precise control of all process parameters. The machine can also be equipped with an optional RF power supply for magnetron sputtering applications. In addition to the sputtering station, CANON / ANELVA C-7100GT also contains a Multi Chamber Substrate Transfer Tool (MCT) for loading/unloading substrates from the sputtering chamber(s). The MCT makes it easier to change substrates in a timely manner while also allowing for convenient substrate transfer and heating of the chamber(s). CANON C-7100GT also has a high capacity turbo source for more precise targets, high deposition rates, and greater uniformity of the coating. In terms of safety, ANELVA C-7100GT has a vacuum interlock asset which prevents the processing chamber from opening while the chamber has not been properly evacuated. This, along with a hermetically sealed chamber, ensures there are no hazardous gas exposure risks during operation. C-7100GT also has an integrated emergency stop button and a thermal monitoring model to protect both the equipment and the operator. In conclusion, CANON / ANELVA C-7100GT Sputtering Equipment is an efficient and highly versatile sputtering system ideal for depositing conformal thin films and complex overlayers onto substrates. It is equipped with two reactive and one DC sputtering chambers, as well as a Multi Chamber Substrate Transfer Unit and high capacity turbo source for precise target control and high deposition rate. The machine also incorporates a variety of safety features, such as a vacuum interlock tool, hermetically sealed chamber, and emergency stop button.

There are no reviews yet