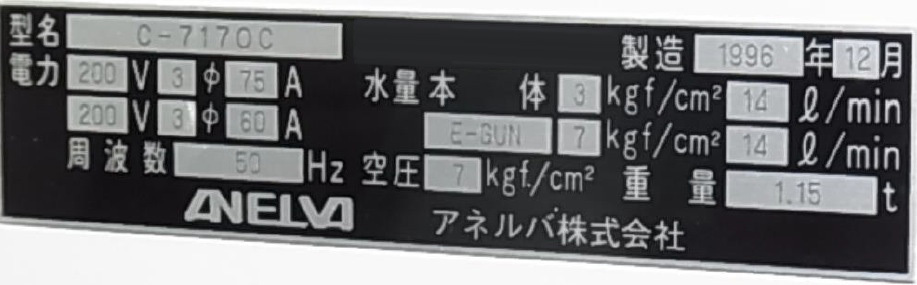

Used CANON / ANELVA C-7170C #9031249 for sale

URL successfully copied!

Tap to zoom

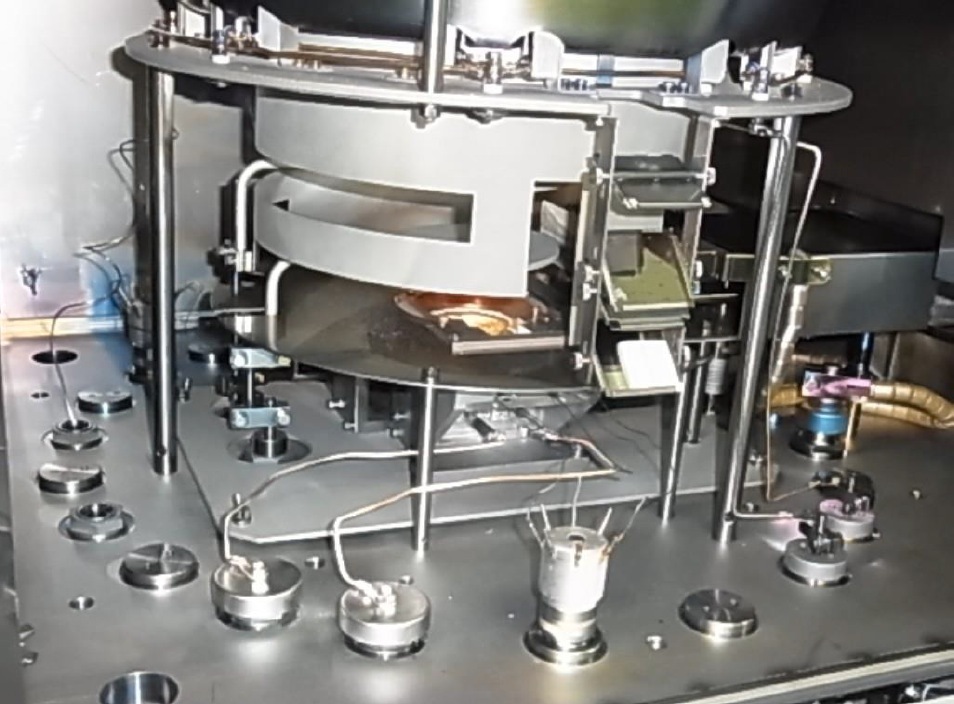

CANON / ANELVA C-7170C Sputtering Equipment is a cost-efficient, performance-driven sputter deposition system for the production of thin films with excellent reproducibility. CANON C-7170C unit is designed for use in industrial production, research and development, and laboratory applications. The machine features a sophisticated scanner, automated substrate loading and unloading, and a wide variety of process options including Ar-ion cleaning, sputter deposition, electrical measurement, and in-situ observation. ANELVA C-7170C tool consists of several components: a two-chamber sputtering asset, two RF power sources, an automatically moving scanner, a substrate holder, vacuums pumps, an ionization gauge and a controller. The two-chamber model can be used for both argon sputtering and electrostatic sputtering. The two RF power sources provide the necessary power to the targets to enable high deposition rates, while the automated scanner allows for selective area deposition of desired thin films. The substrate holder is designed to allow for the uniform uniform application of thin films in either 8 inch or 6 inch diameter windows. The high vacuum pumps provide the necessary vacuum level for the sputtering process, and the ionization gauge assists in monitoring the equipment's absolute pressure. Finally, the controller system enables automated operation of the unit, and provides real-time feedback on the machine's performance. C-7170C tool provides a wide range of process possibilities, such as high ARS (Argon Sputter), low ARS (Sputter), electrostatic sputter and deposition, etching, in-situ observation, and electrical measurement. The asset can process materials with varying degree of difficulty such as polymers, metals, ceramics, and oxides. Furthermore, the model can be used to produce a wide range of thin films, from metals to metallic alloys, and amorphous, crystalline and composite semiconductors. The equipment can also be used to produce thick films, with a consistently even surface. The system provides excellent control over the process parameters, and has a quick substrate changing time of 6 seconds per substrate, enabling high throughput for production applications. Additionally, the unit is capable of ultra-precise ion-beam etching with a base pressure of 5 x 10-7 Torr to achieve extremely low material surface contamination. The automated features of the machine help reduce labour costs and improve overall tool throughput, making it ideal for production runs. Overall, CANON / ANELVA C-7170C is an excellent cost-effective and performance-driven sputter deposition asset for production, research and development, and laboratory applications. The features of the model provide users the ability to achieve a wide range of deposition processes with excellent reproducibility and yields.

There are no reviews yet