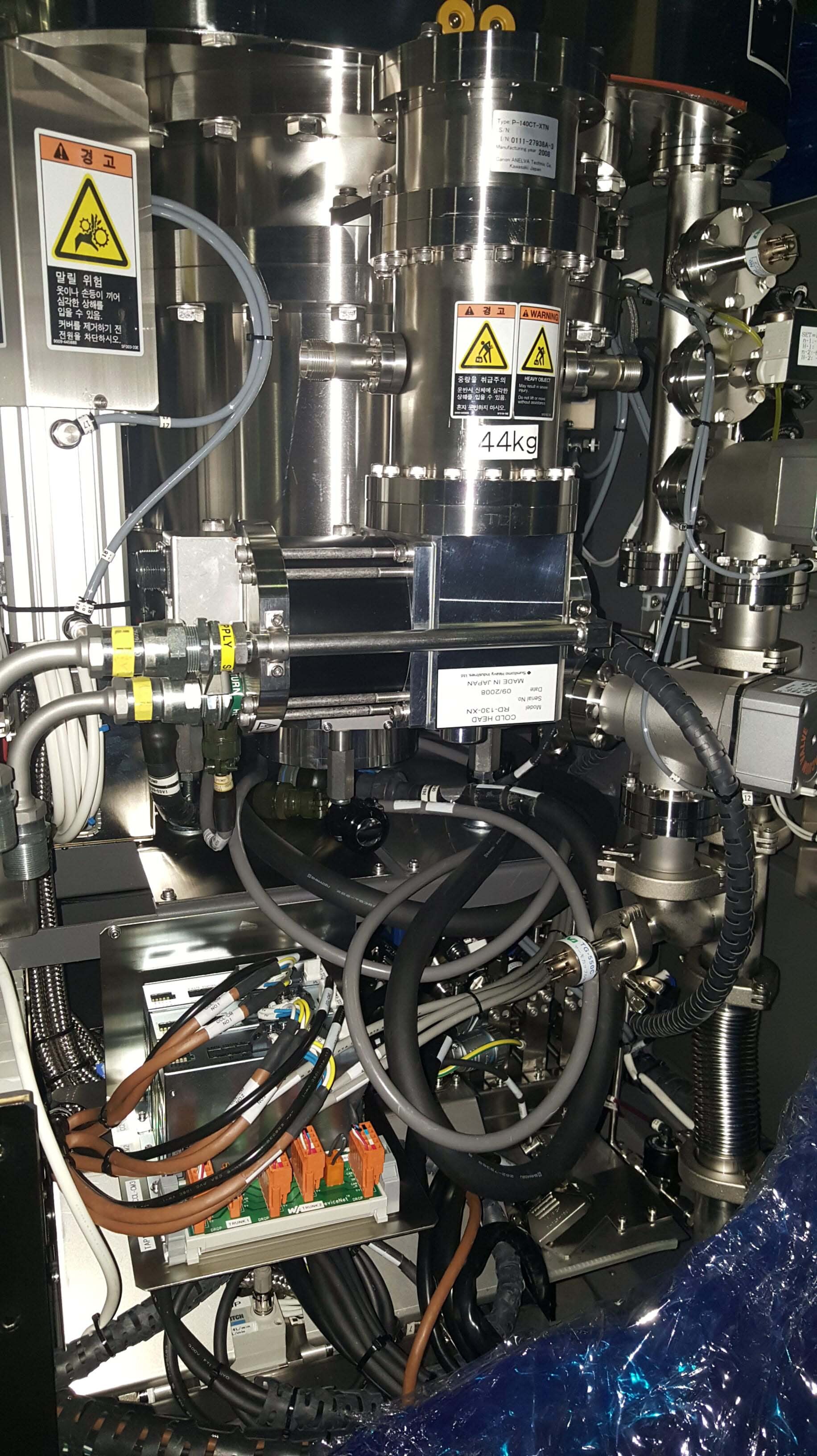

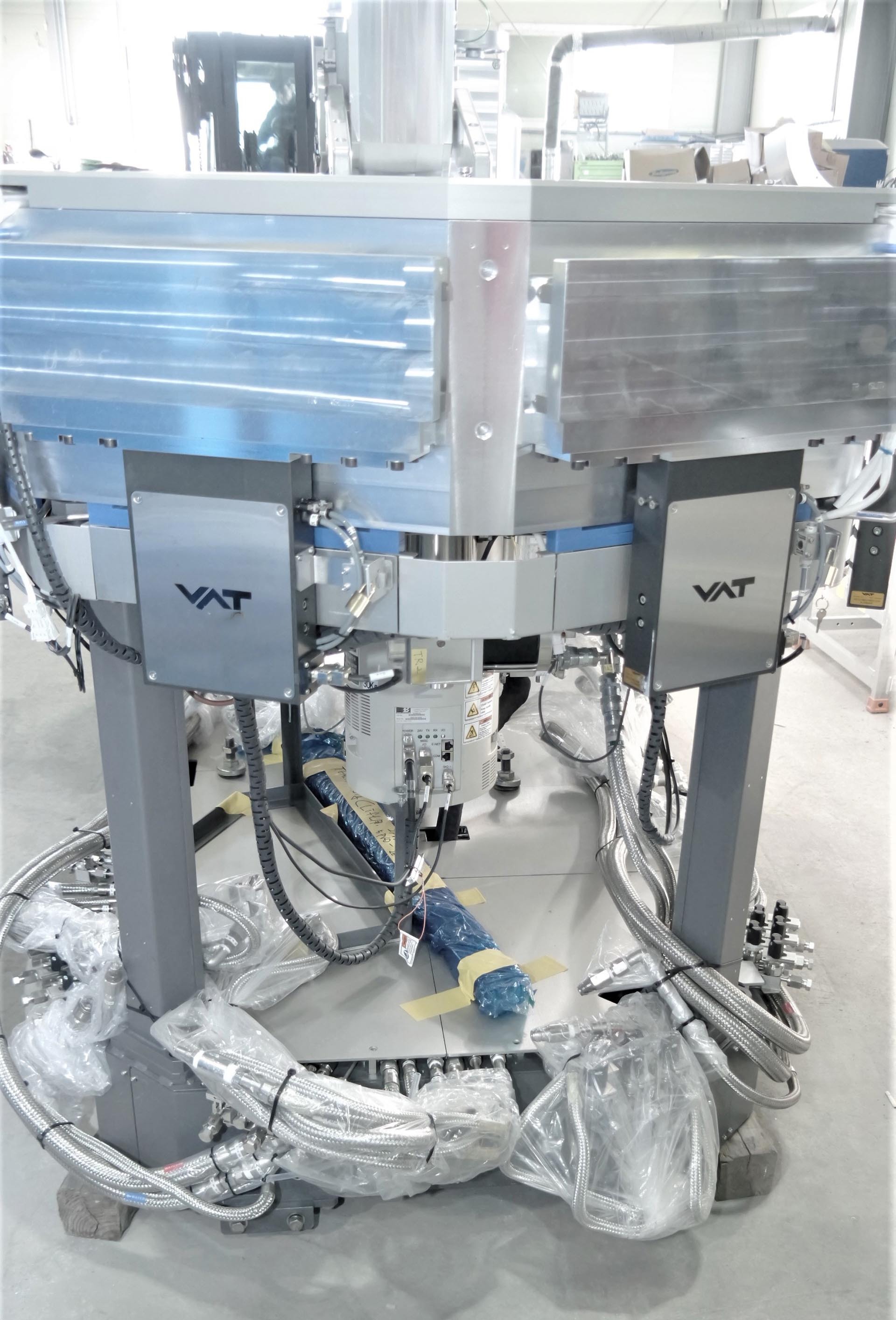

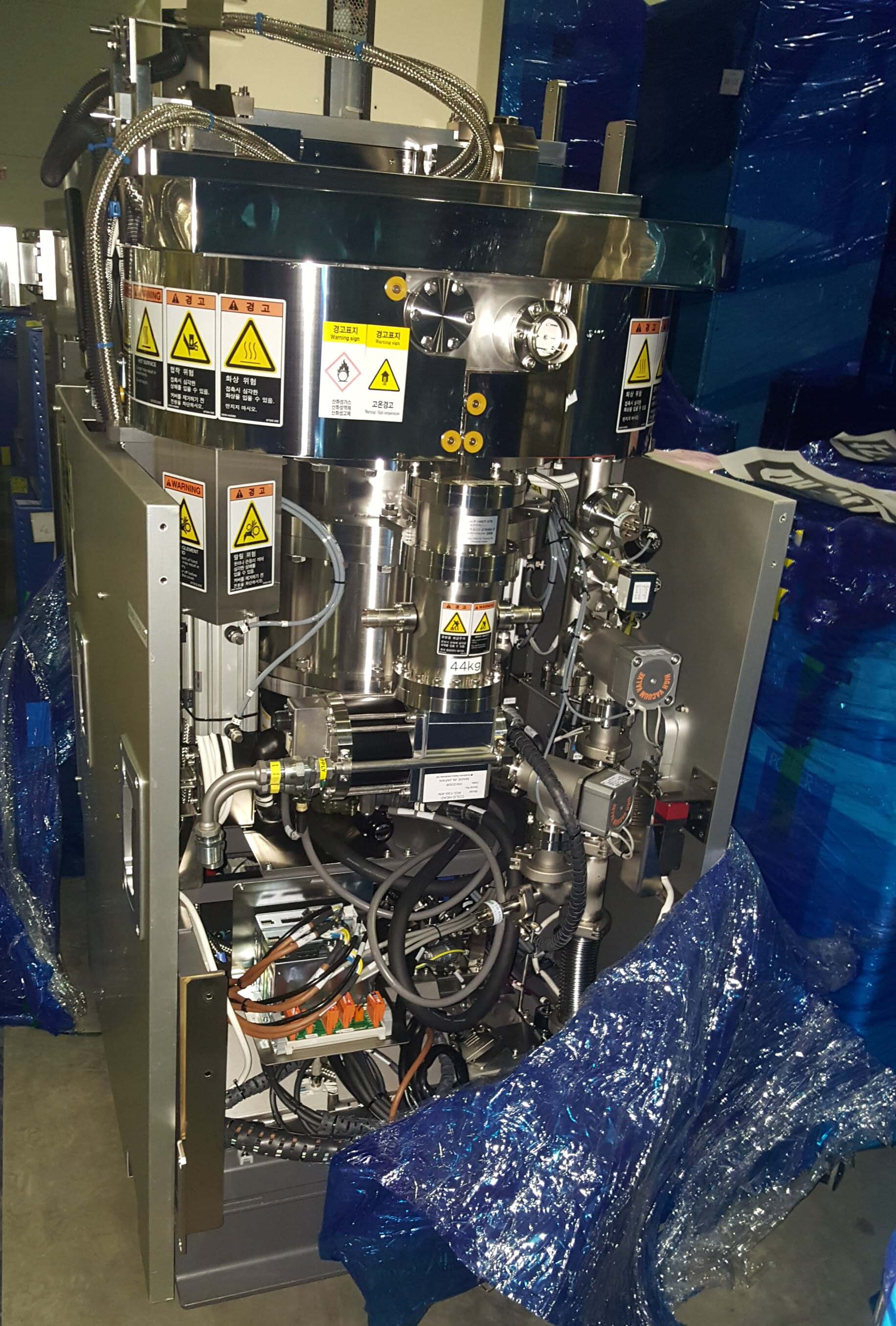

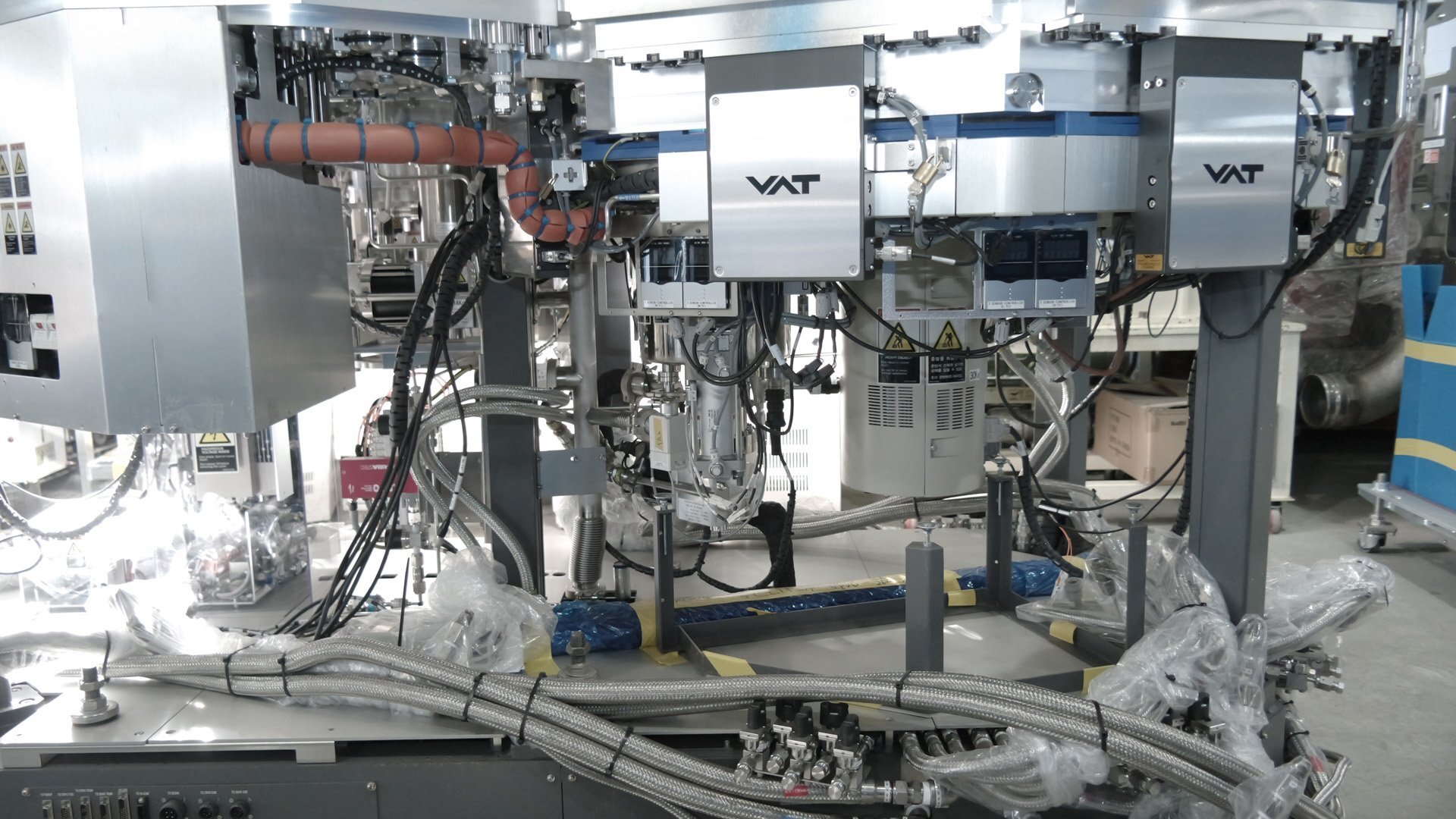

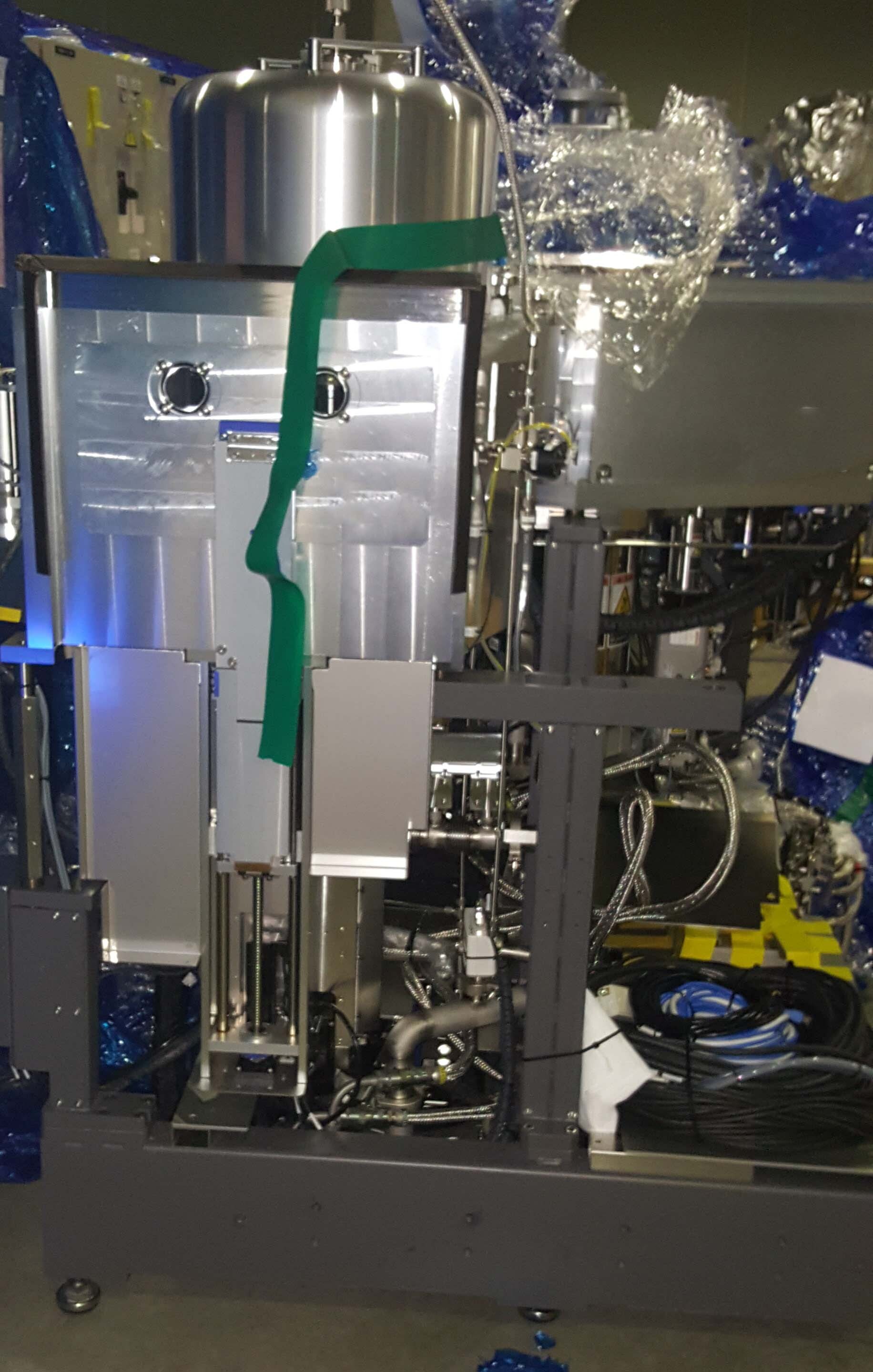

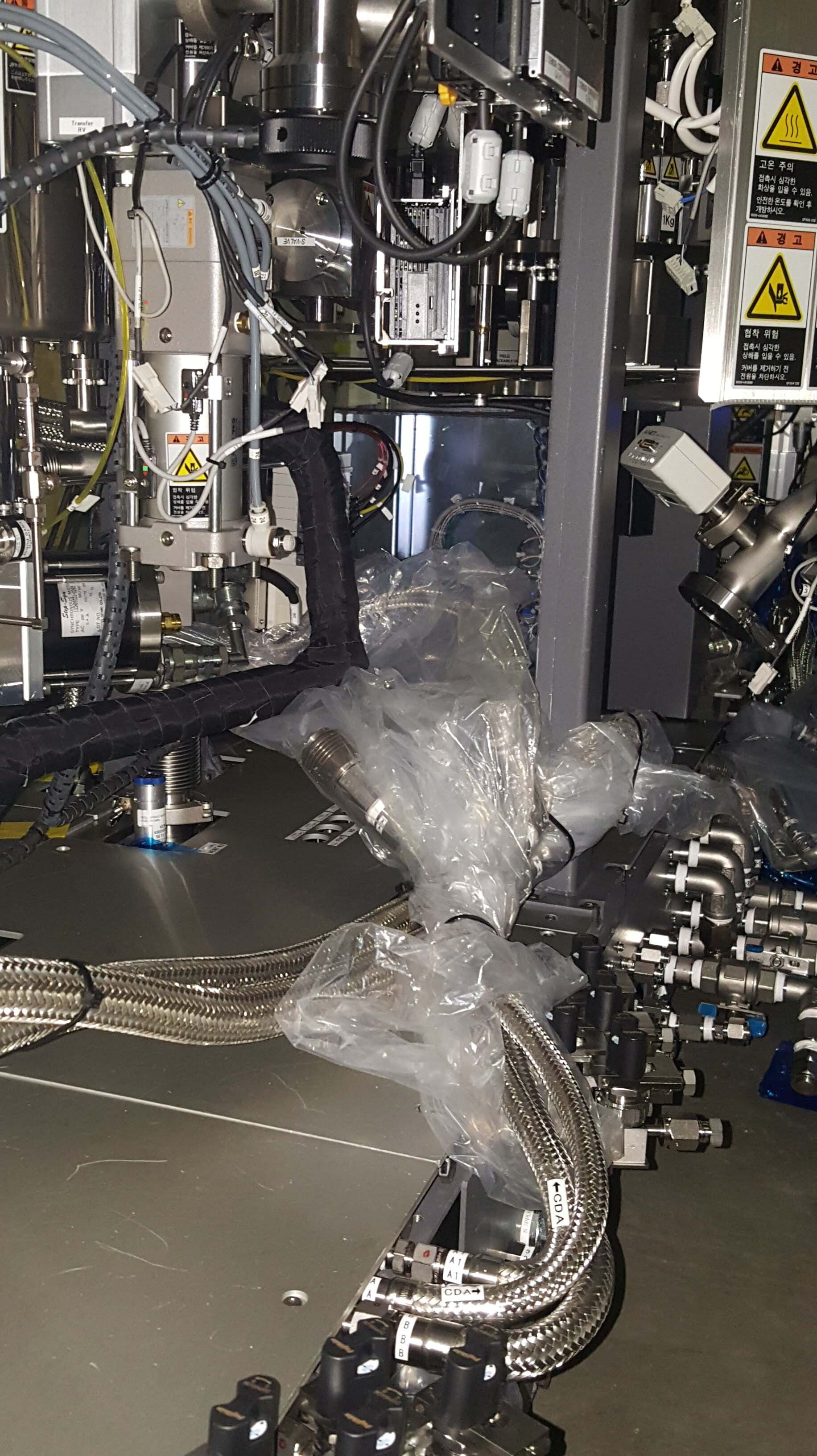

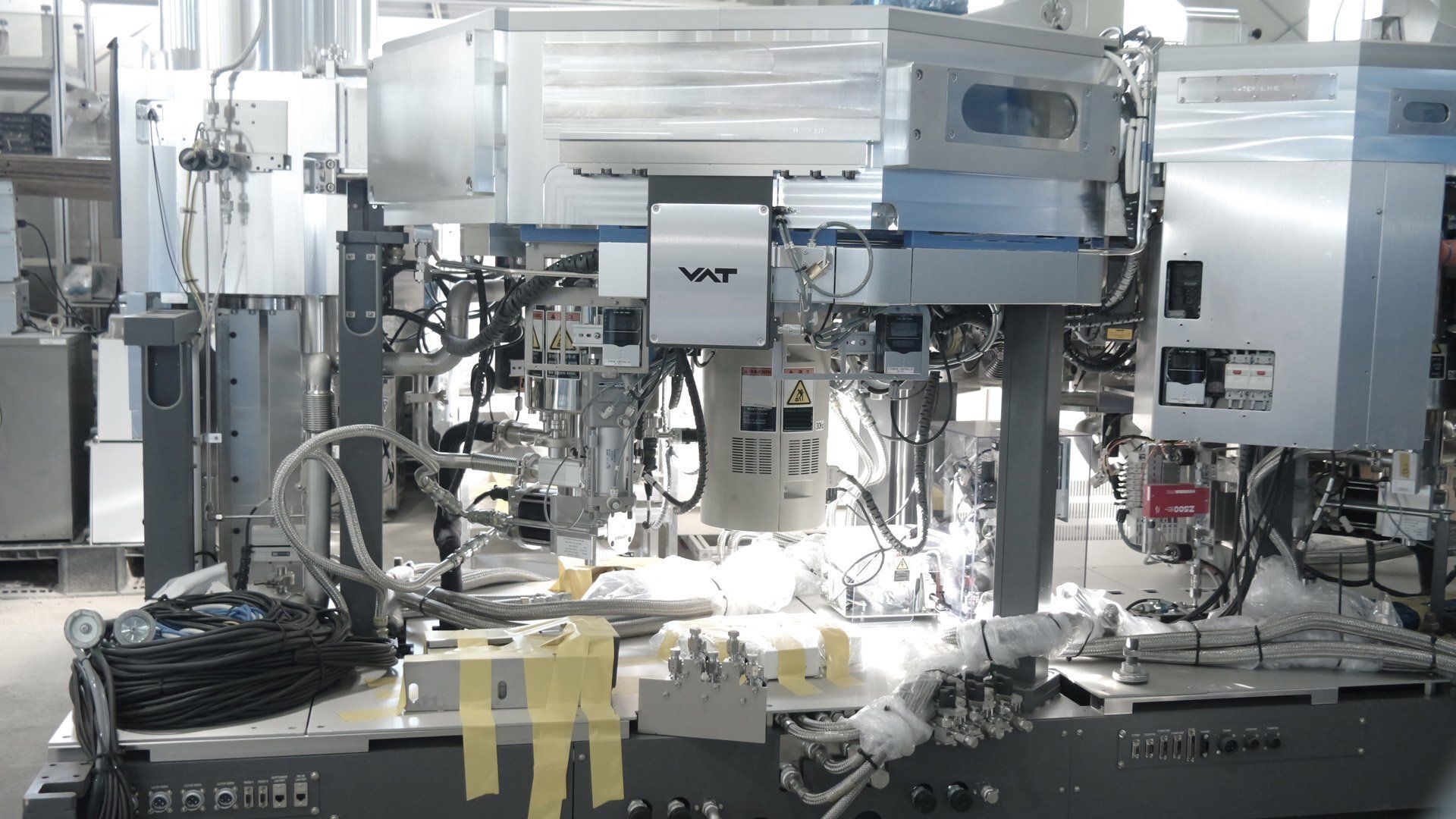

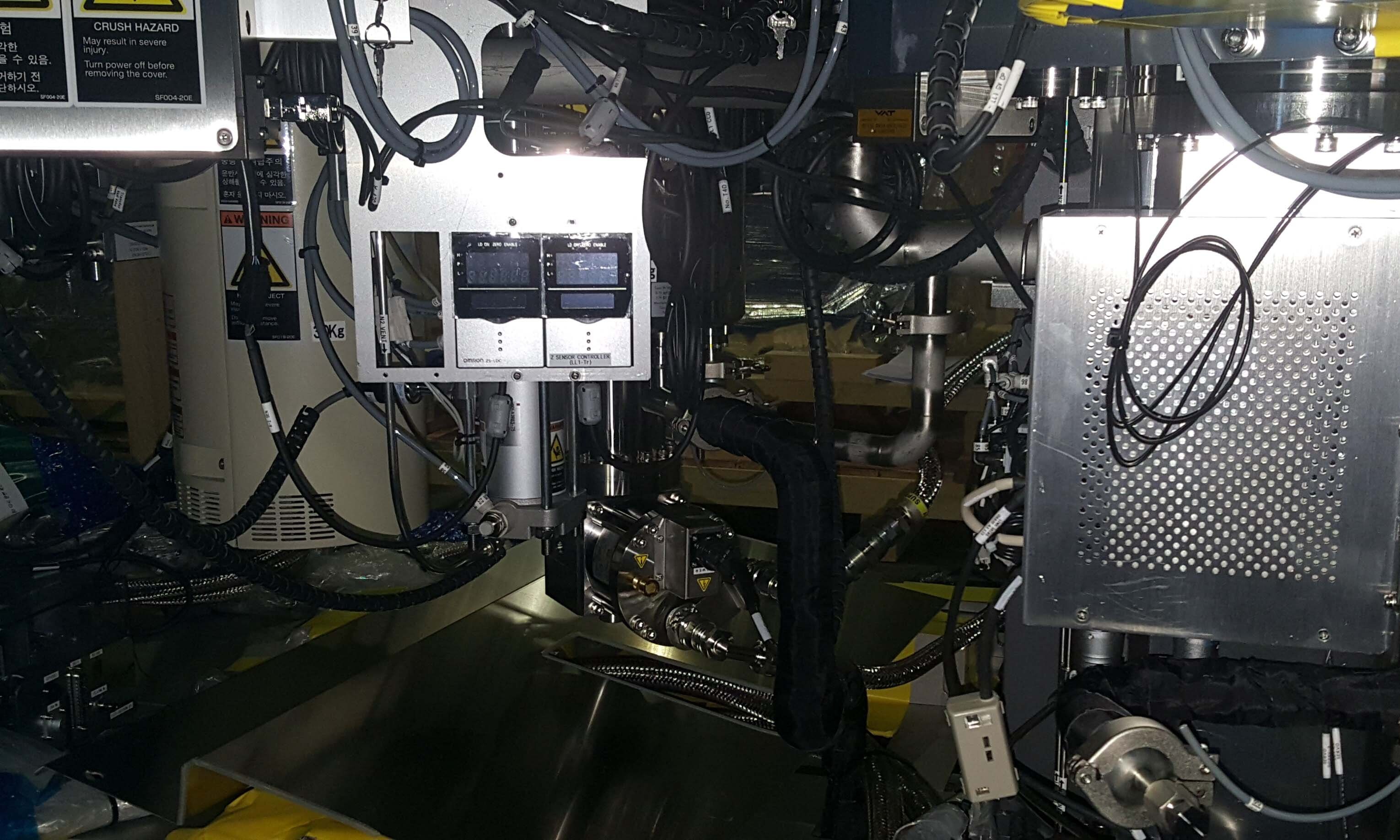

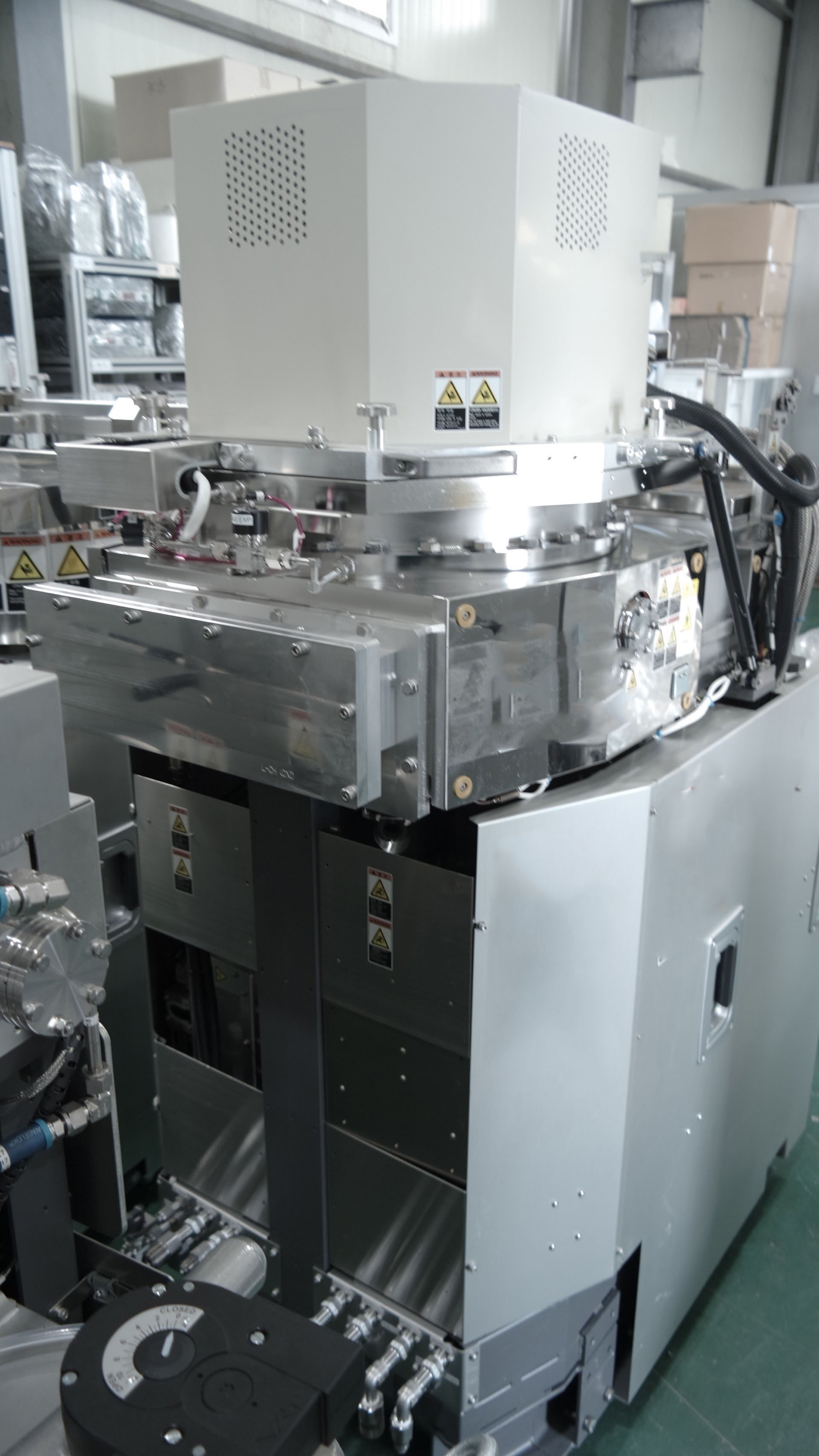

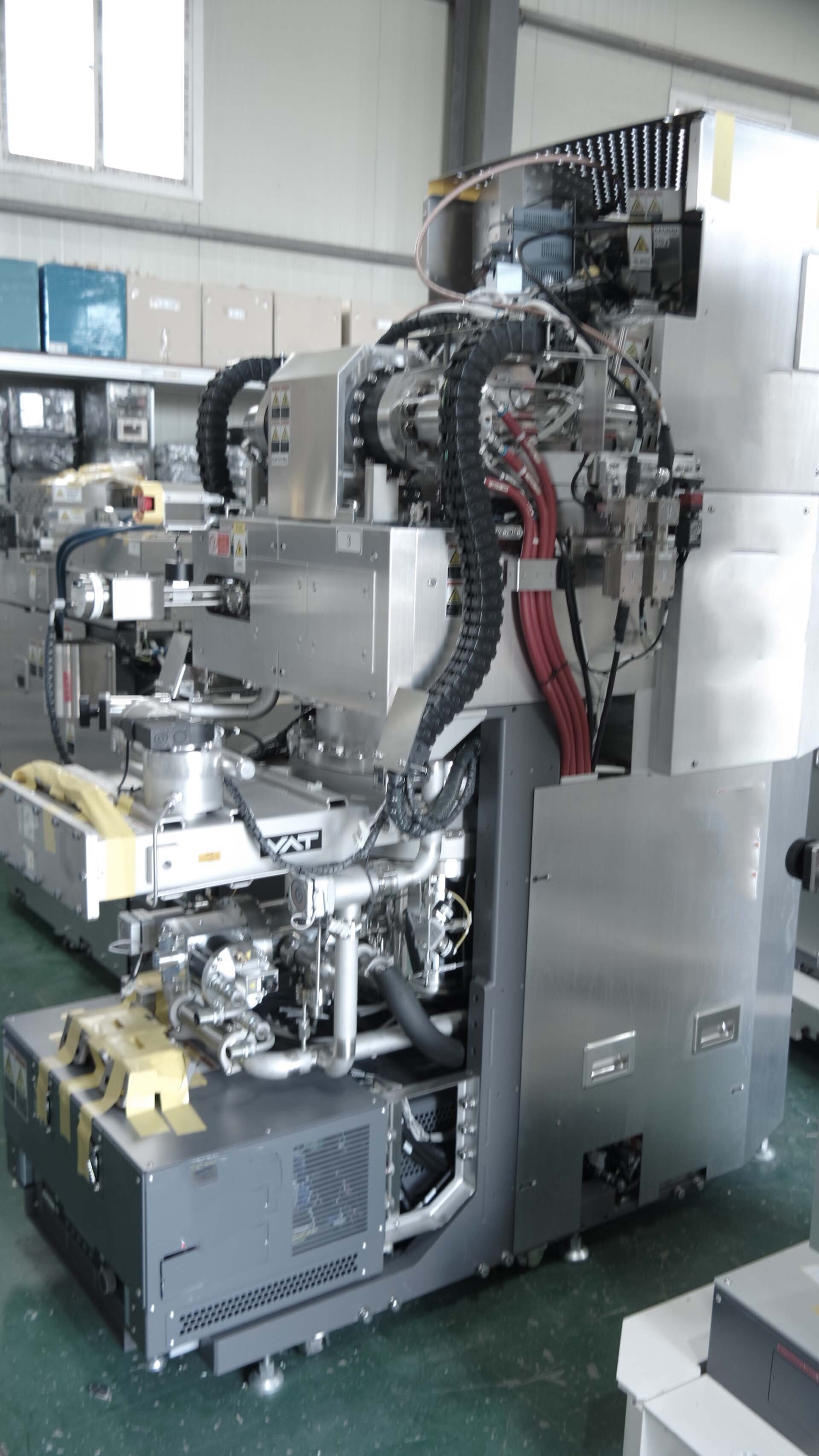

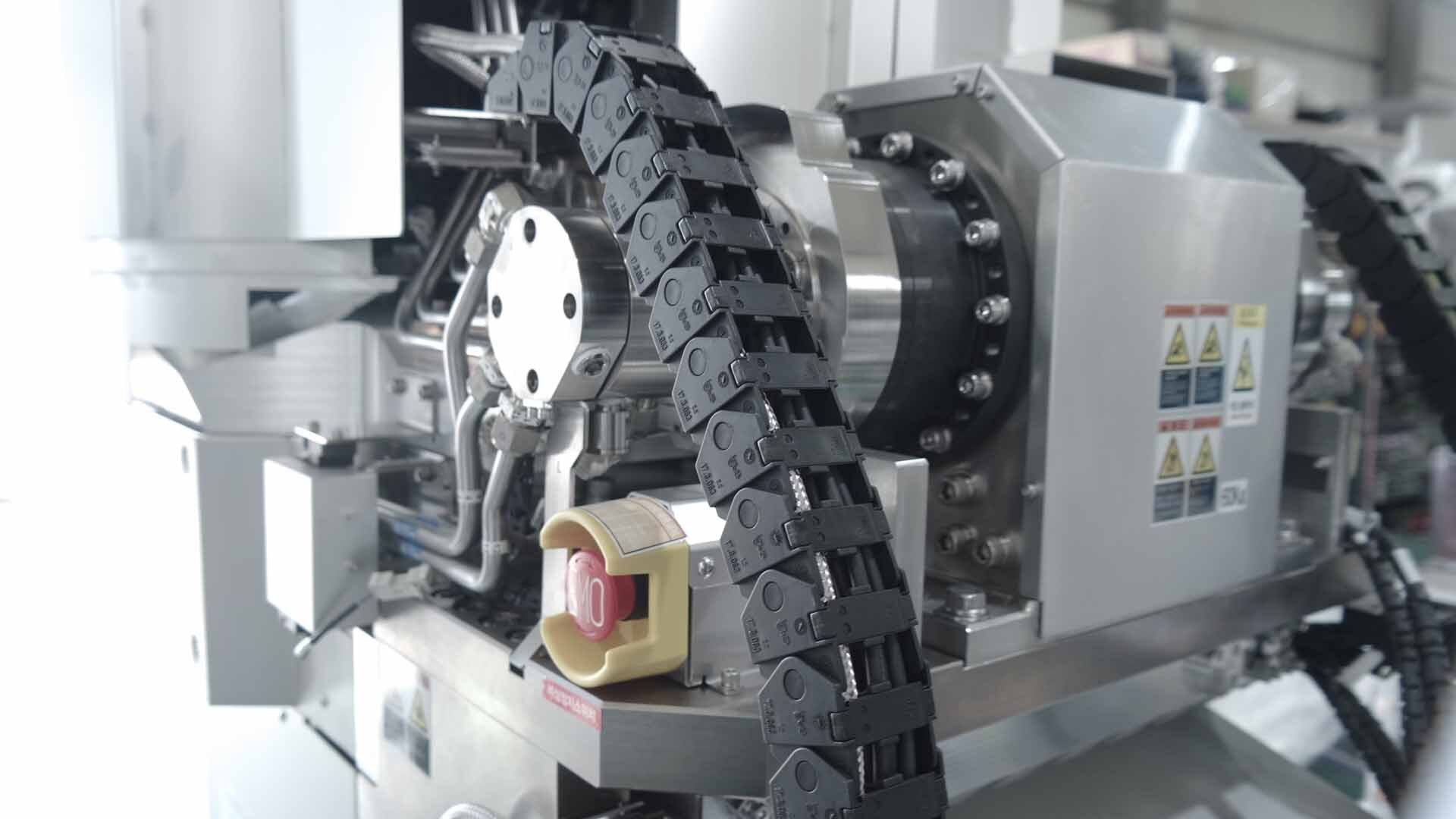

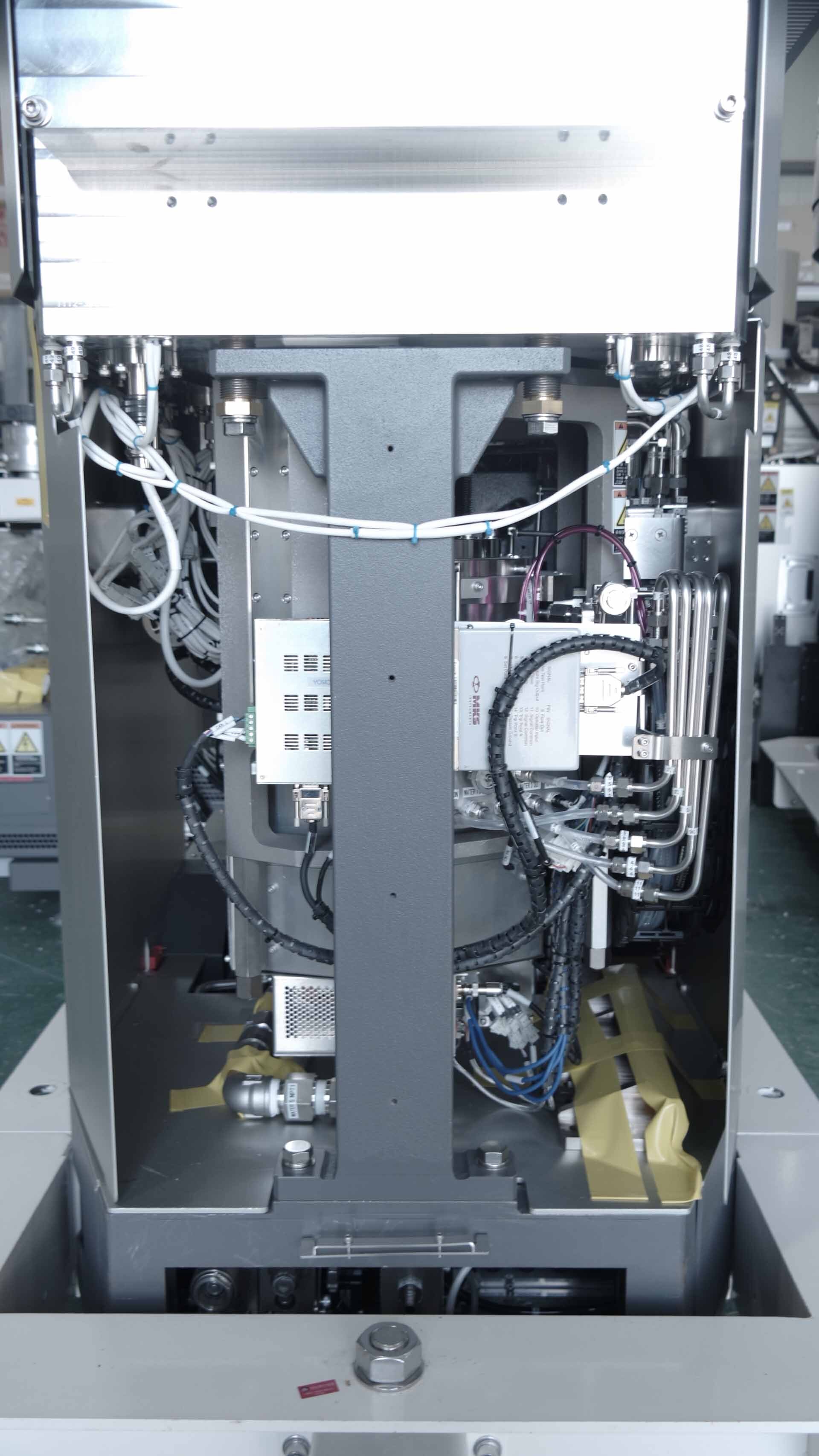

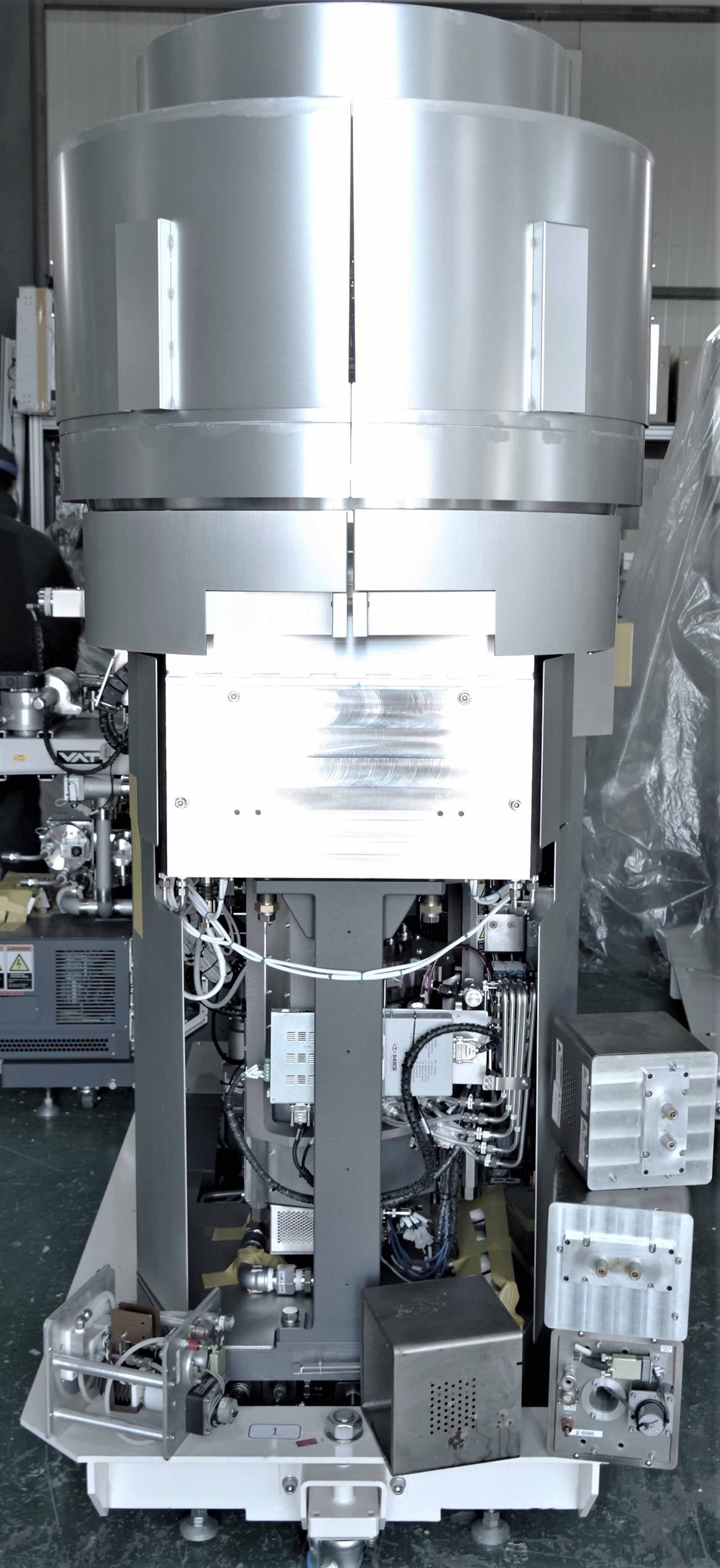

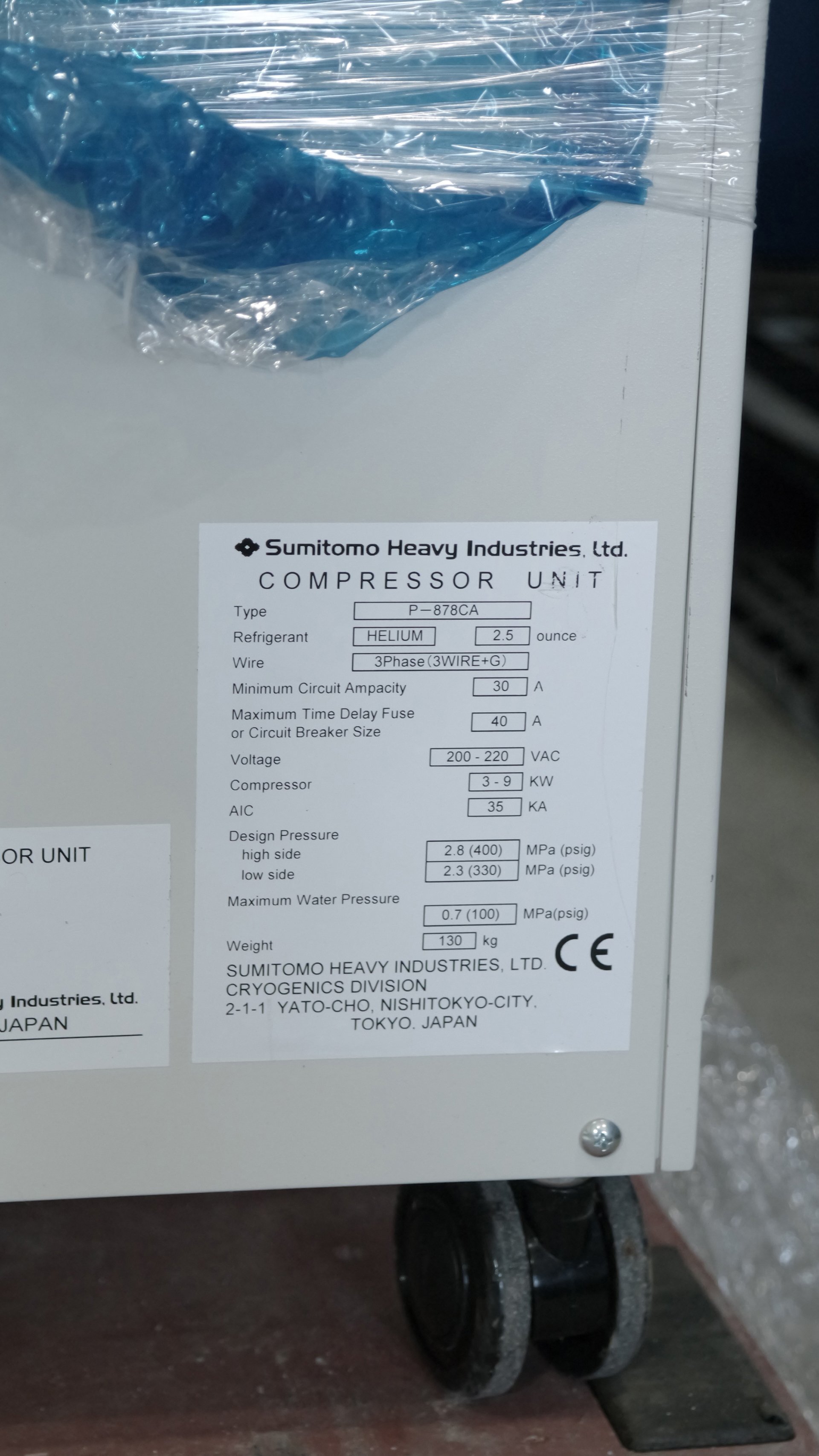

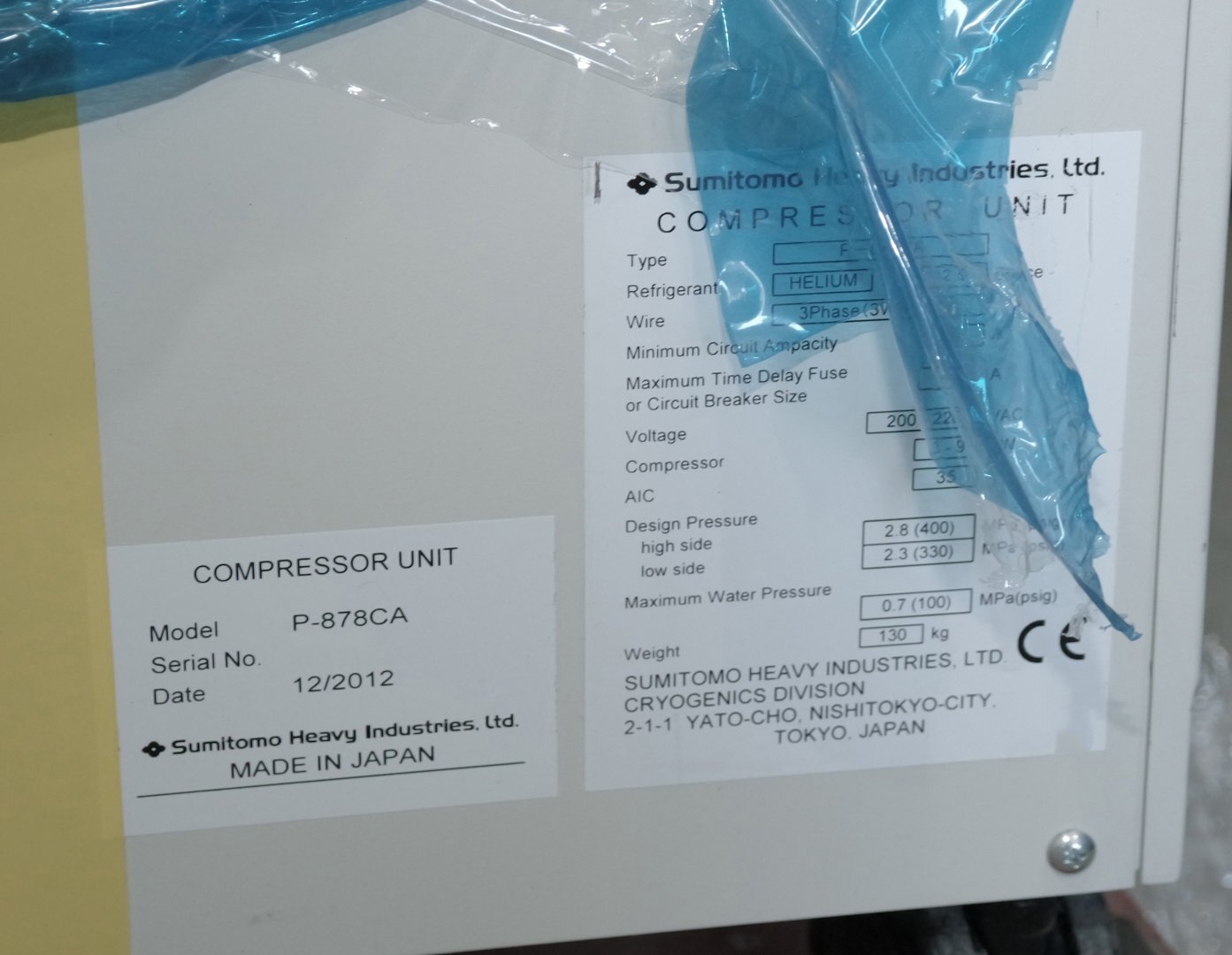

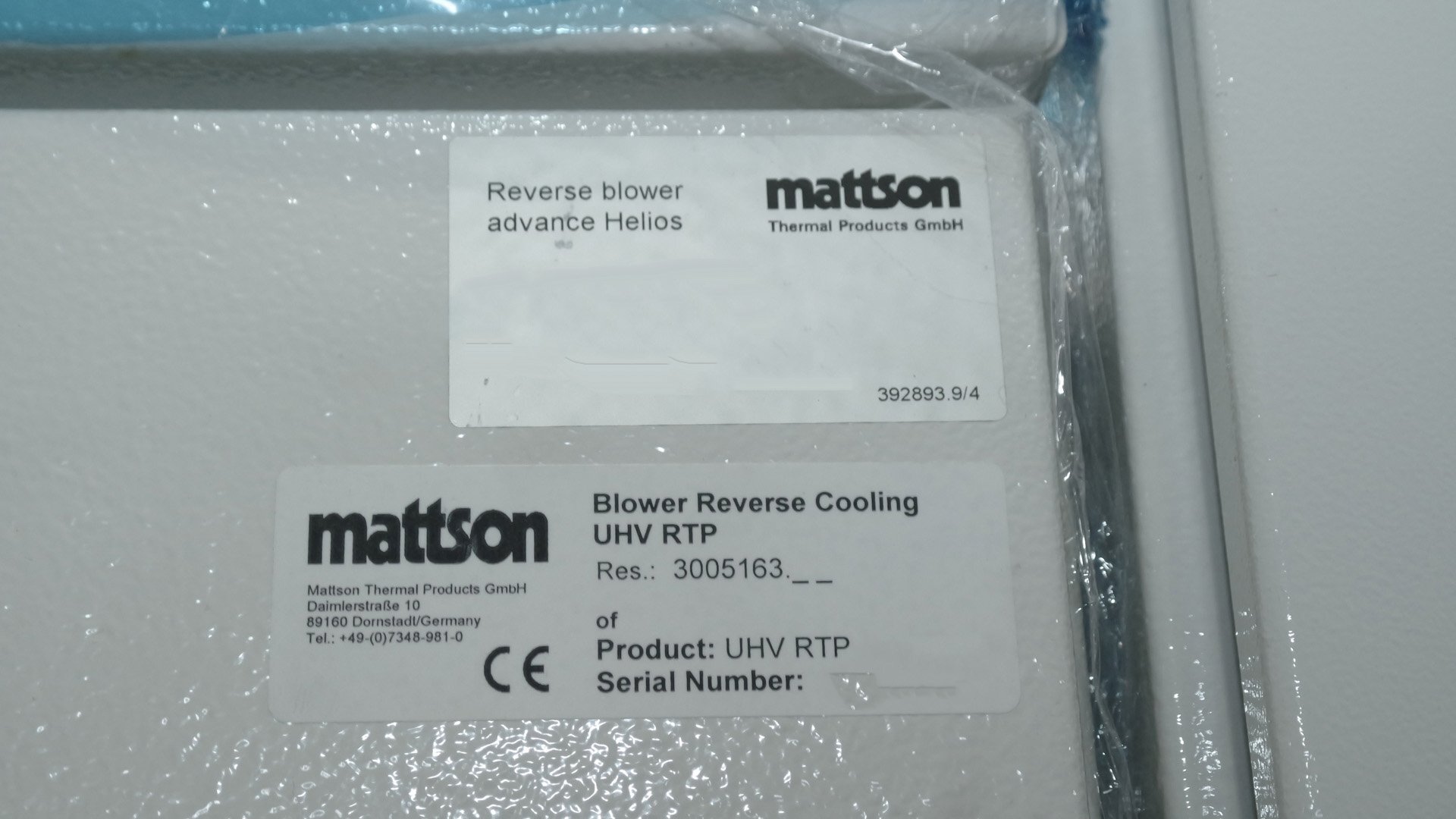

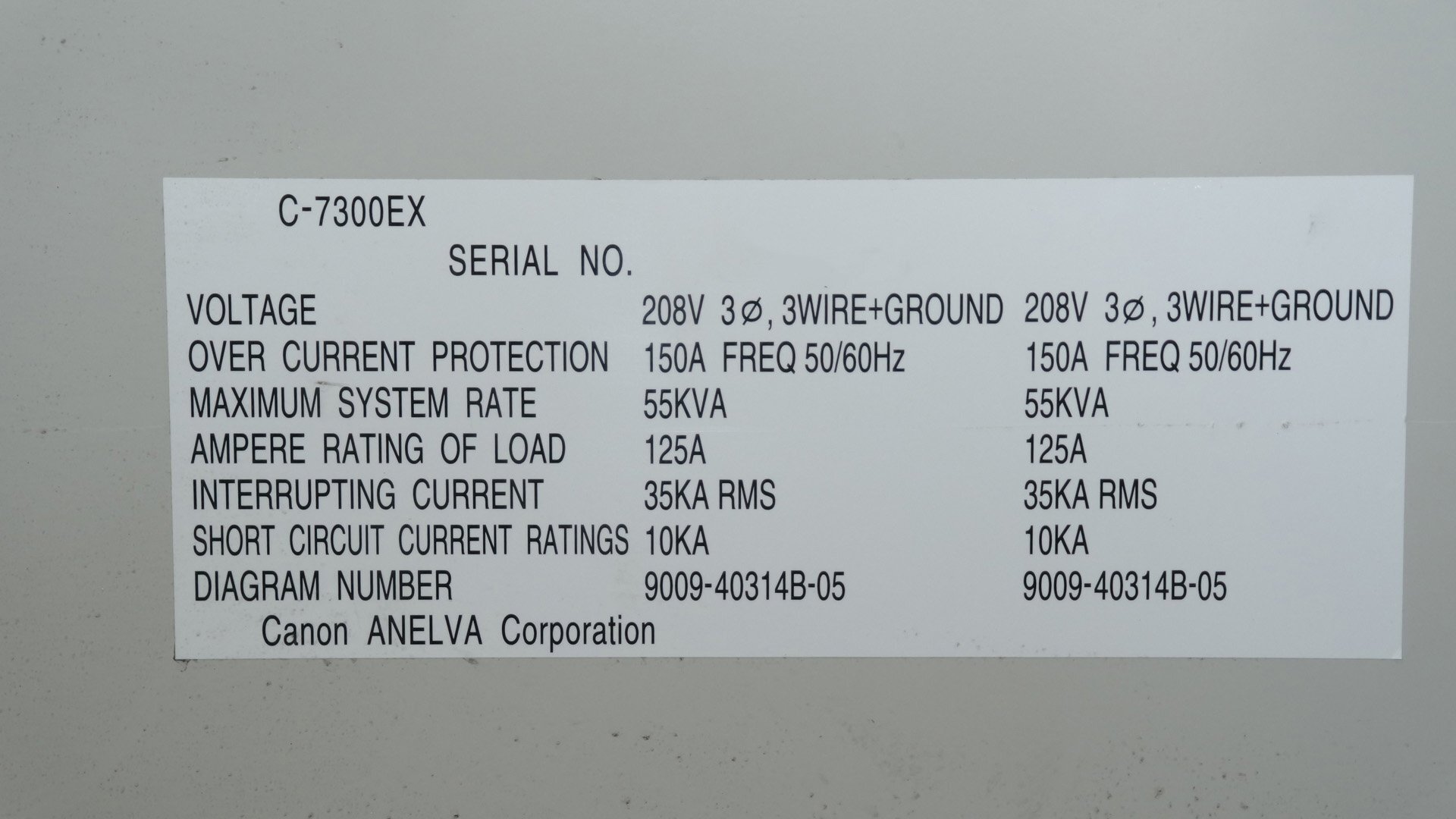

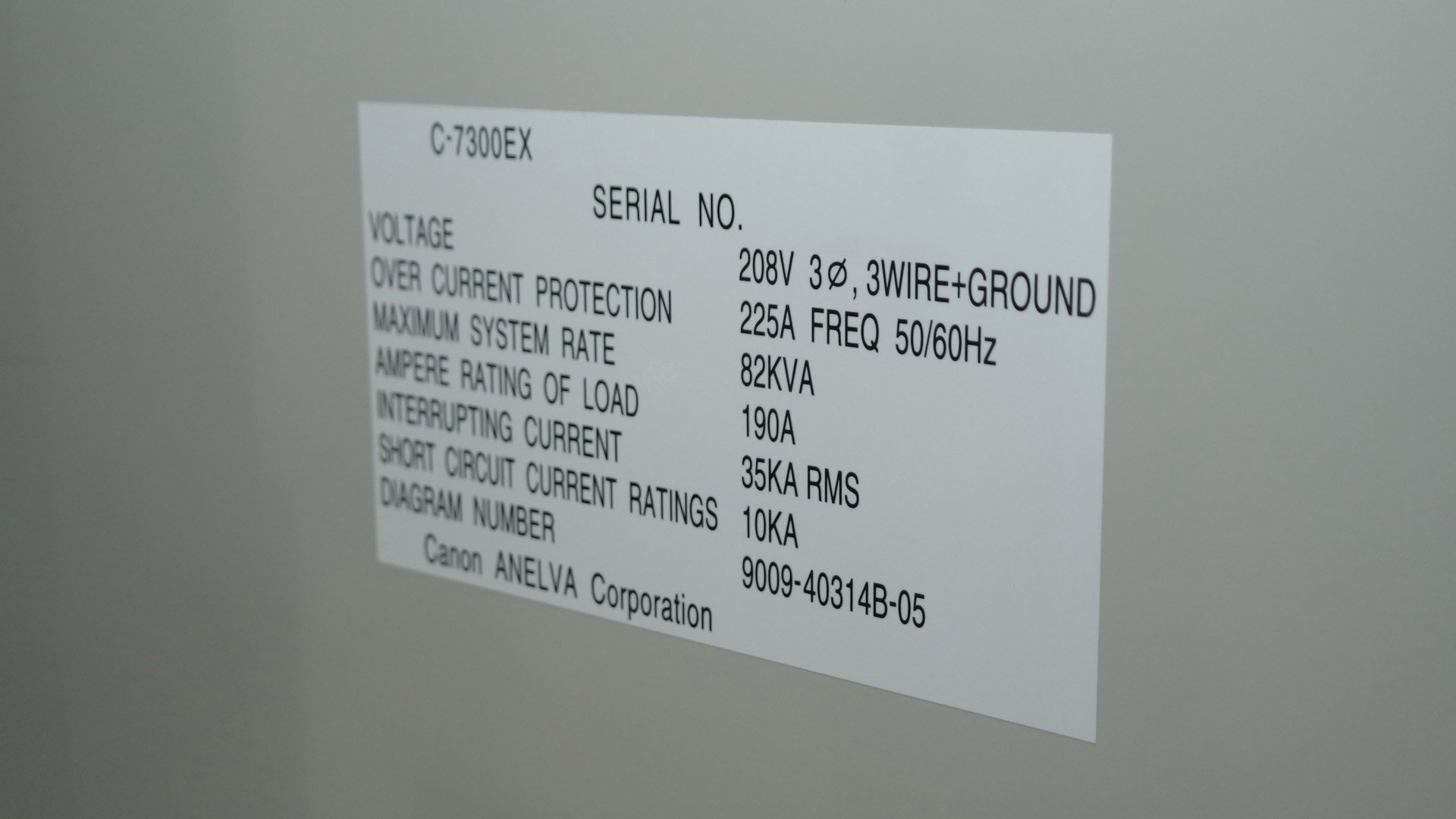

Used CANON / ANELVA C-7300 #9366161 for sale

URL successfully copied!

Tap to zoom

ID: 9366161

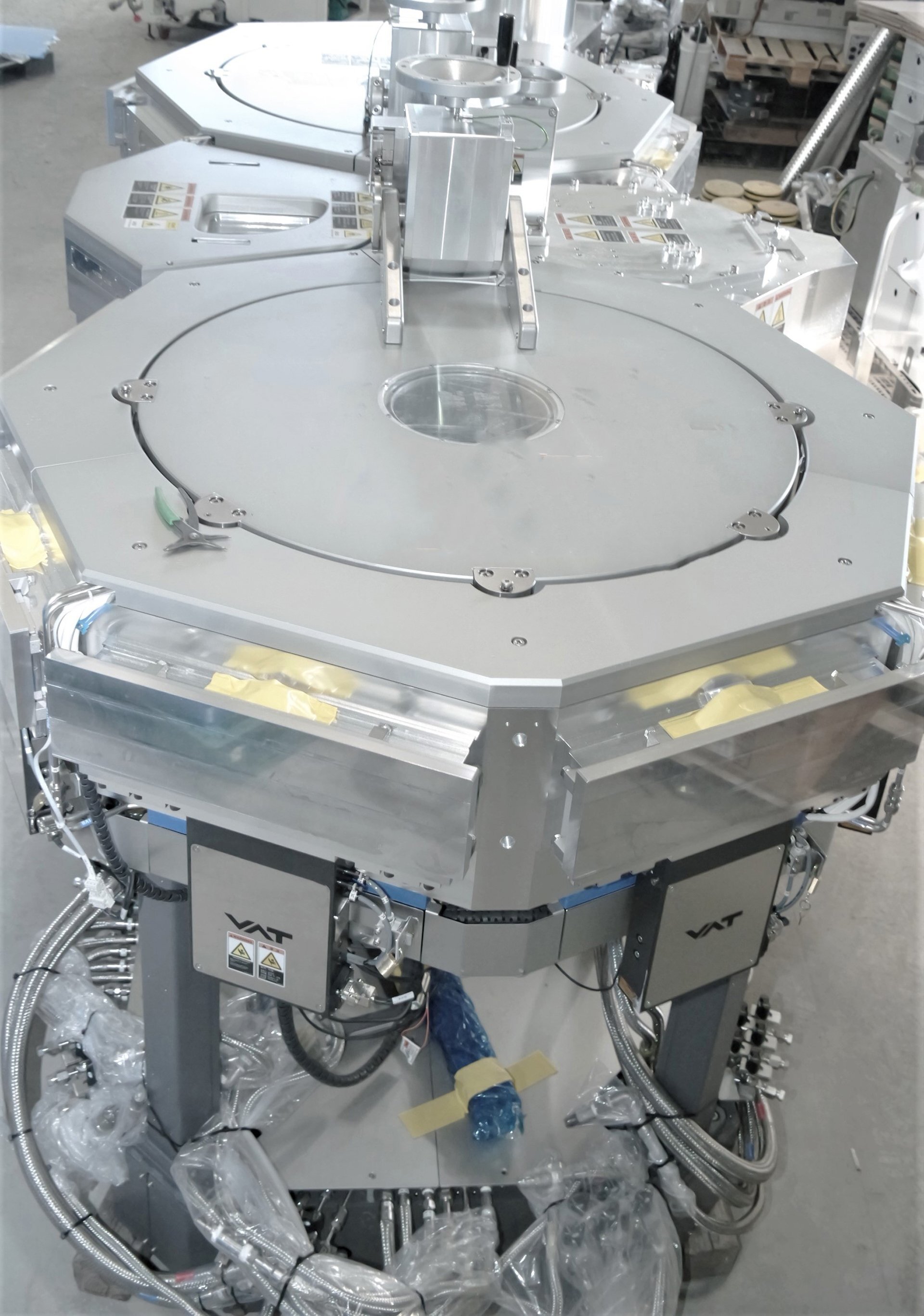

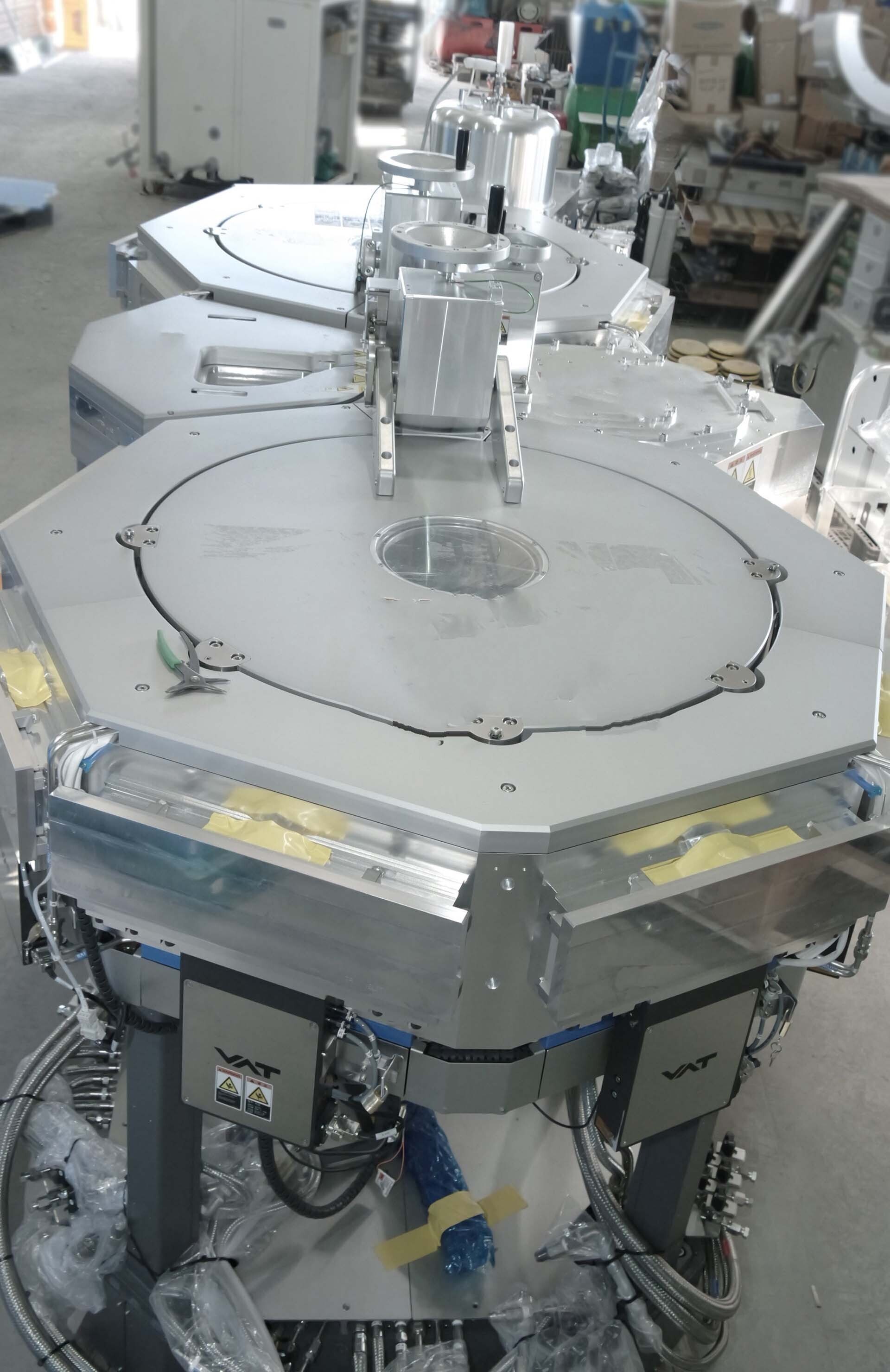

Wafer Size: 12"

Vintage: 2010

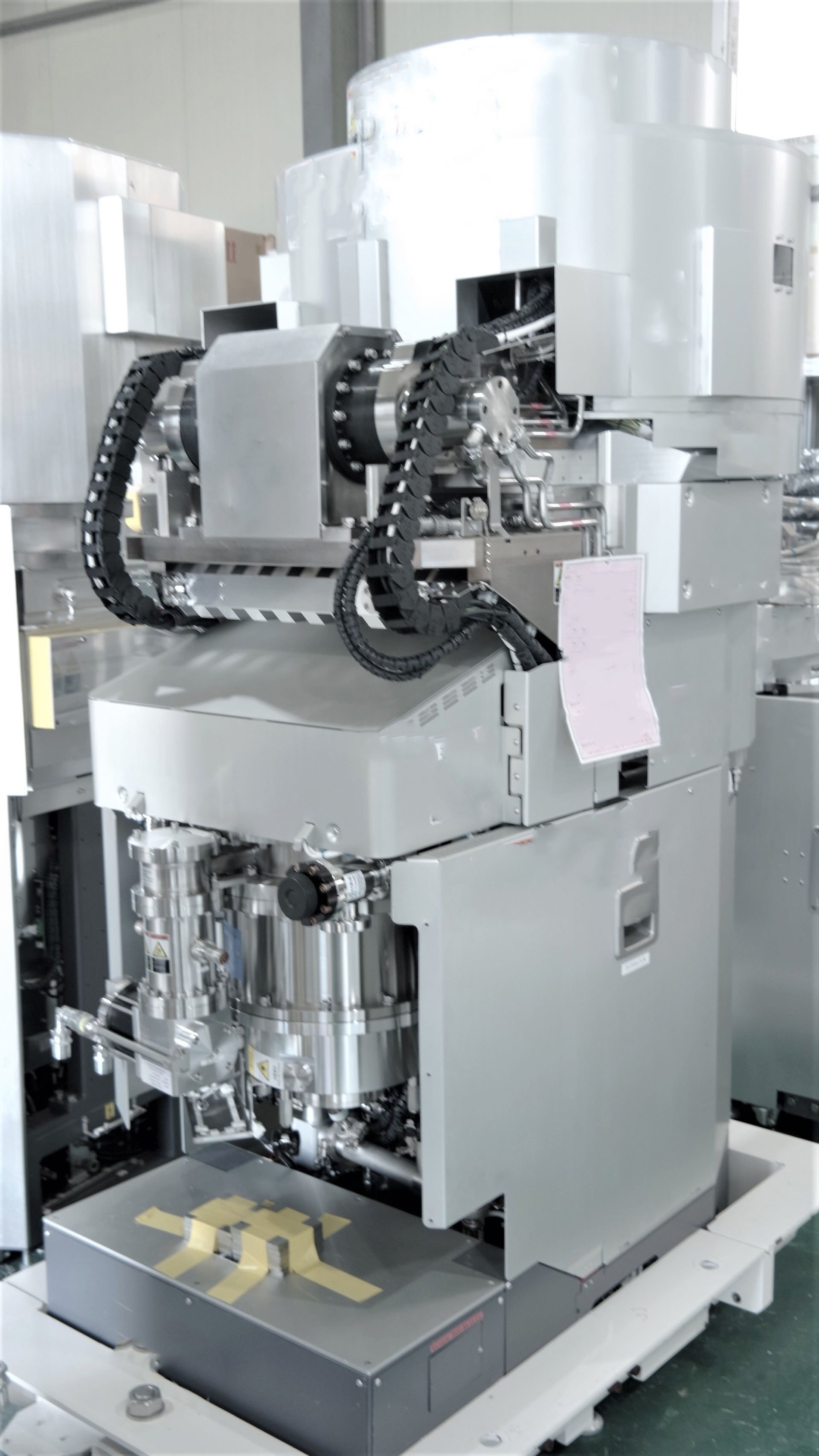

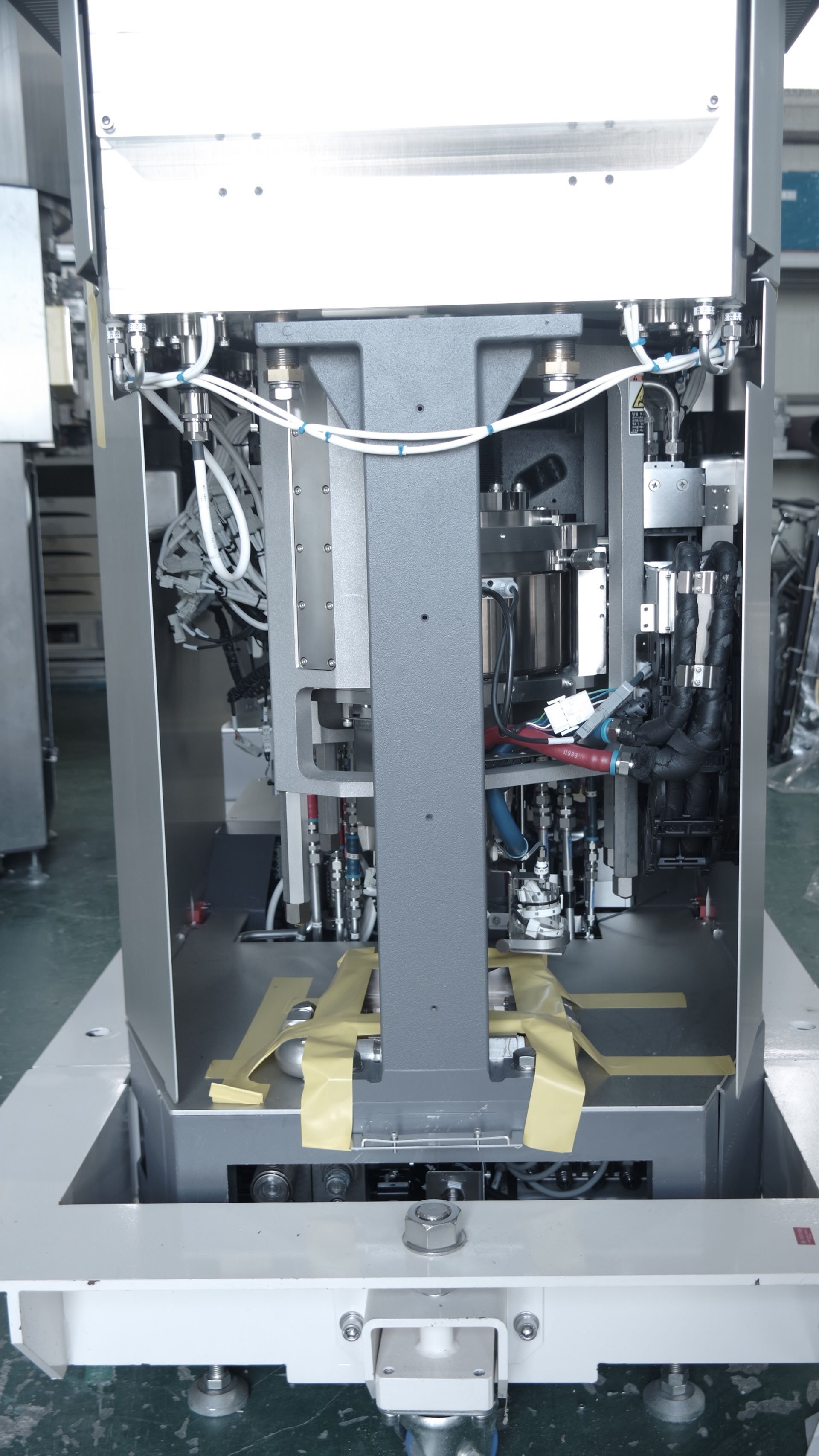

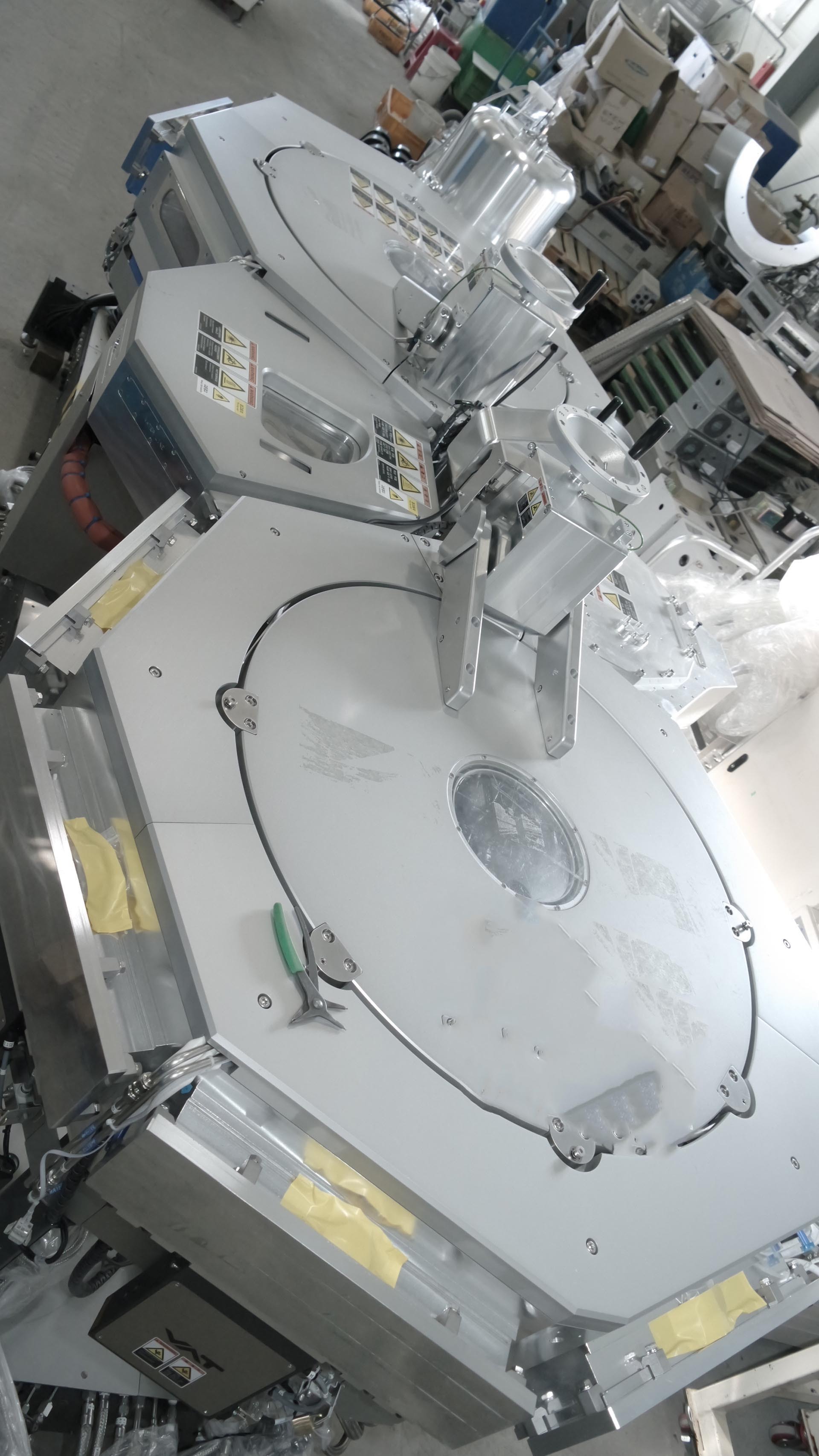

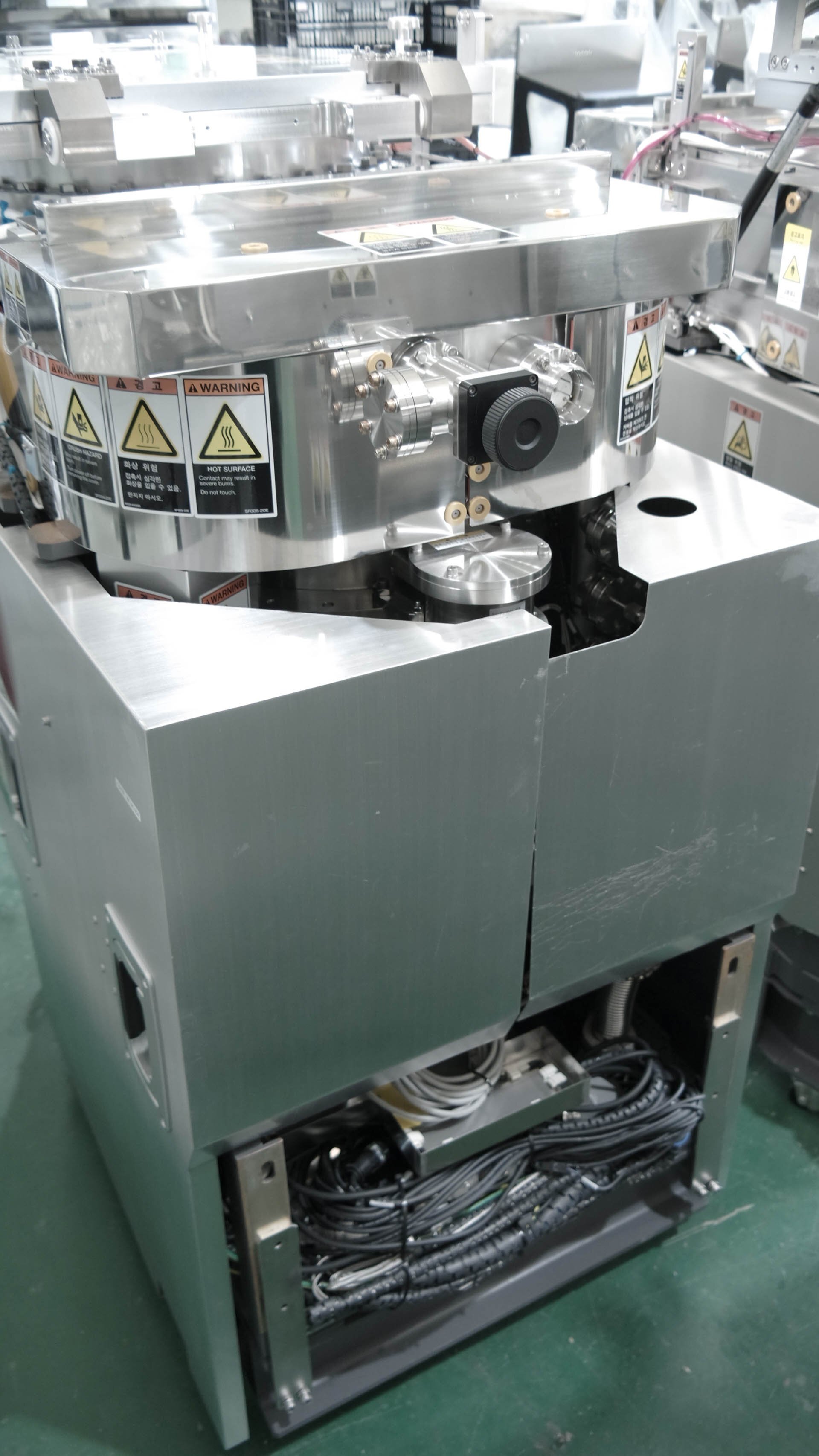

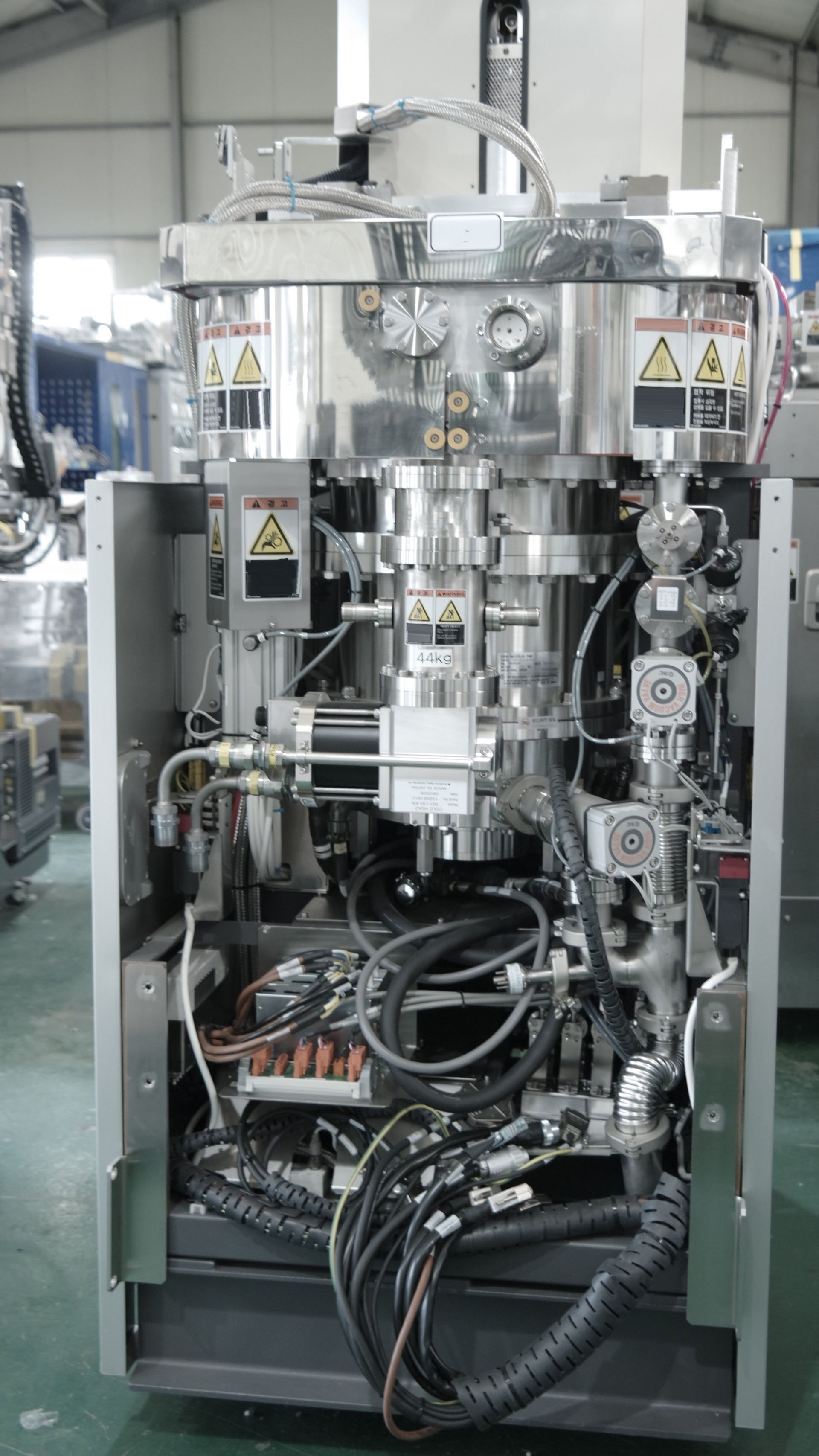

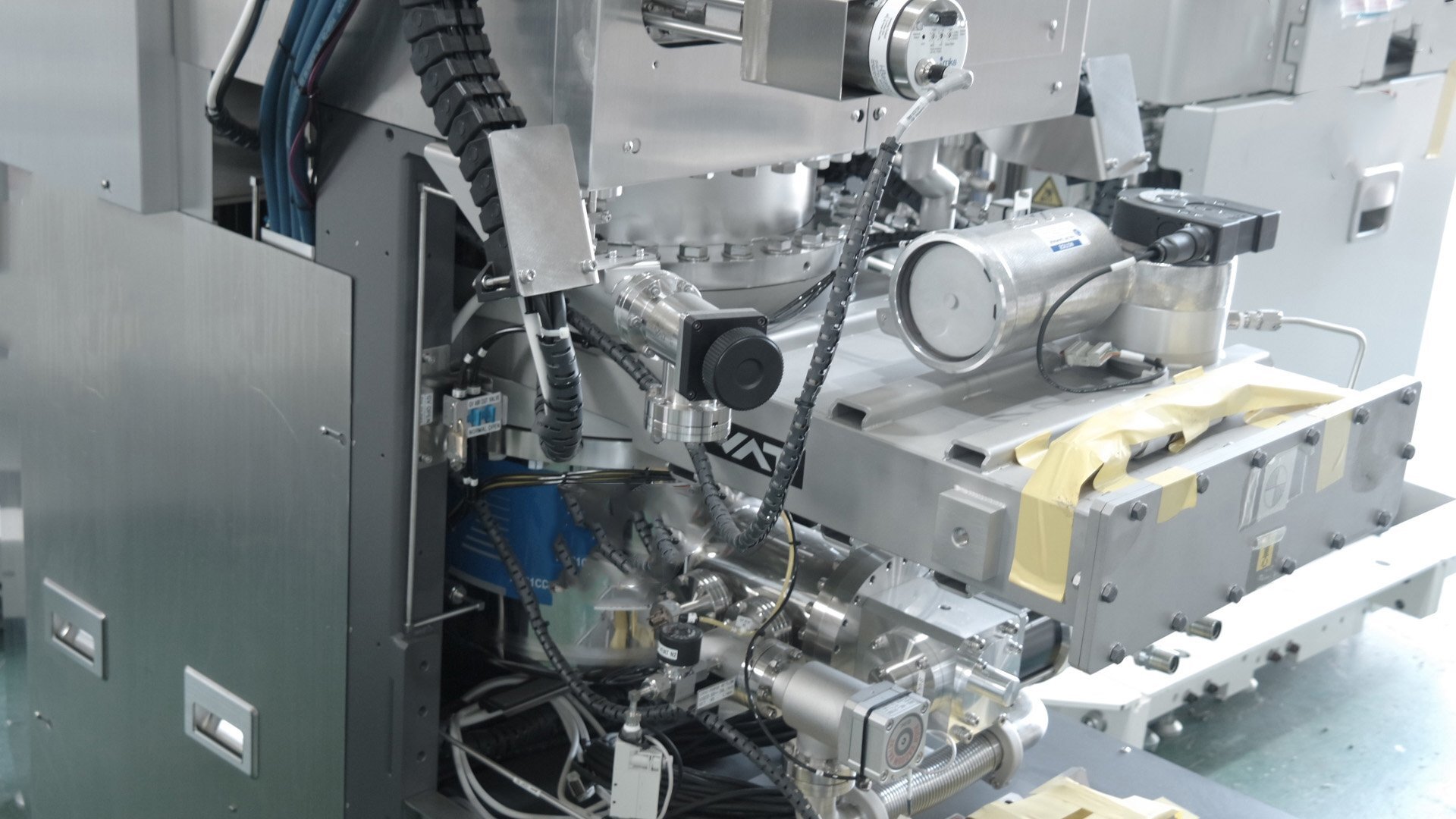

Sputtering system, 12"

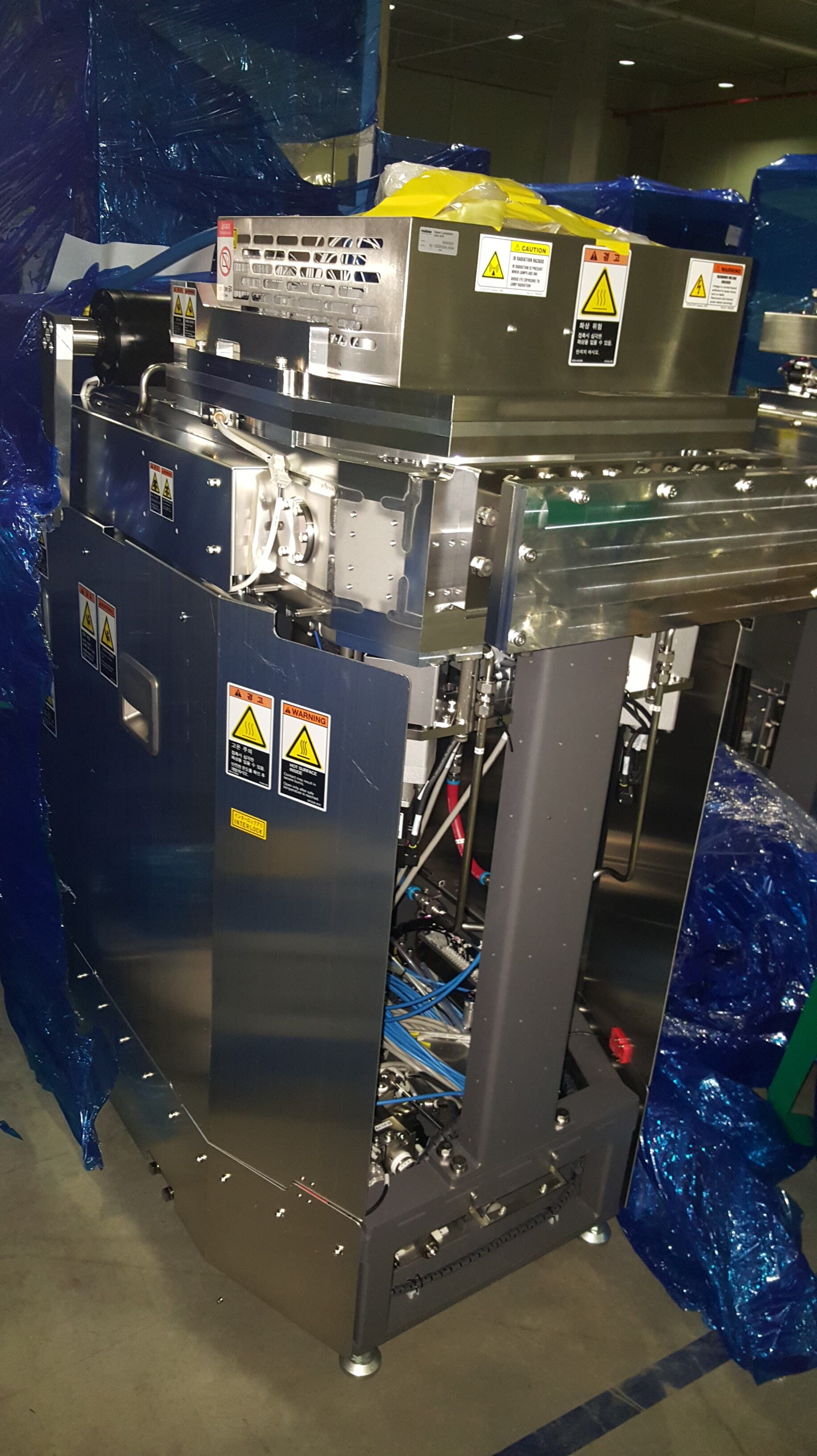

Non-SMIF type

Wafer type: Notch

Pin chuck

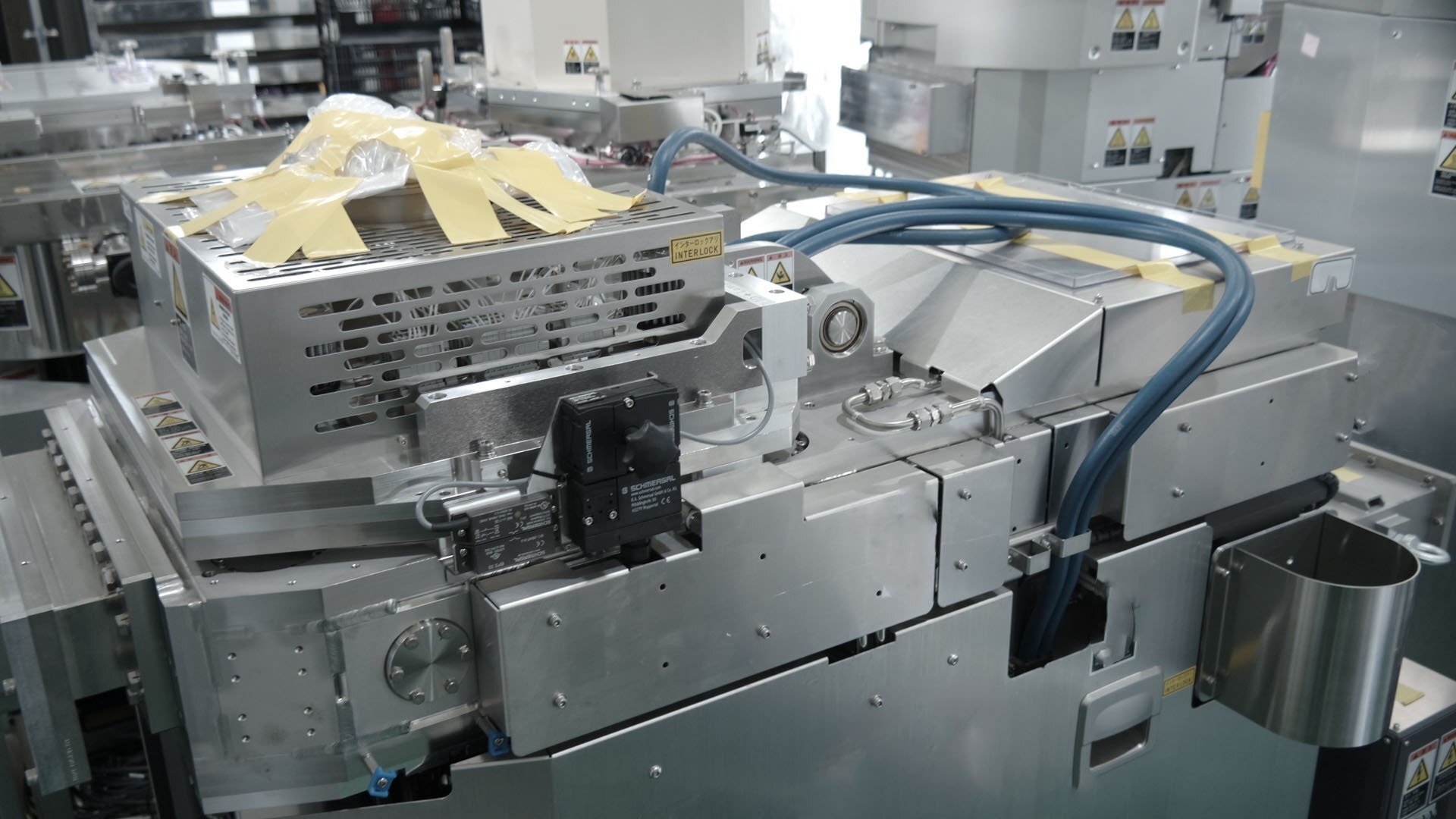

Operation system: Windows

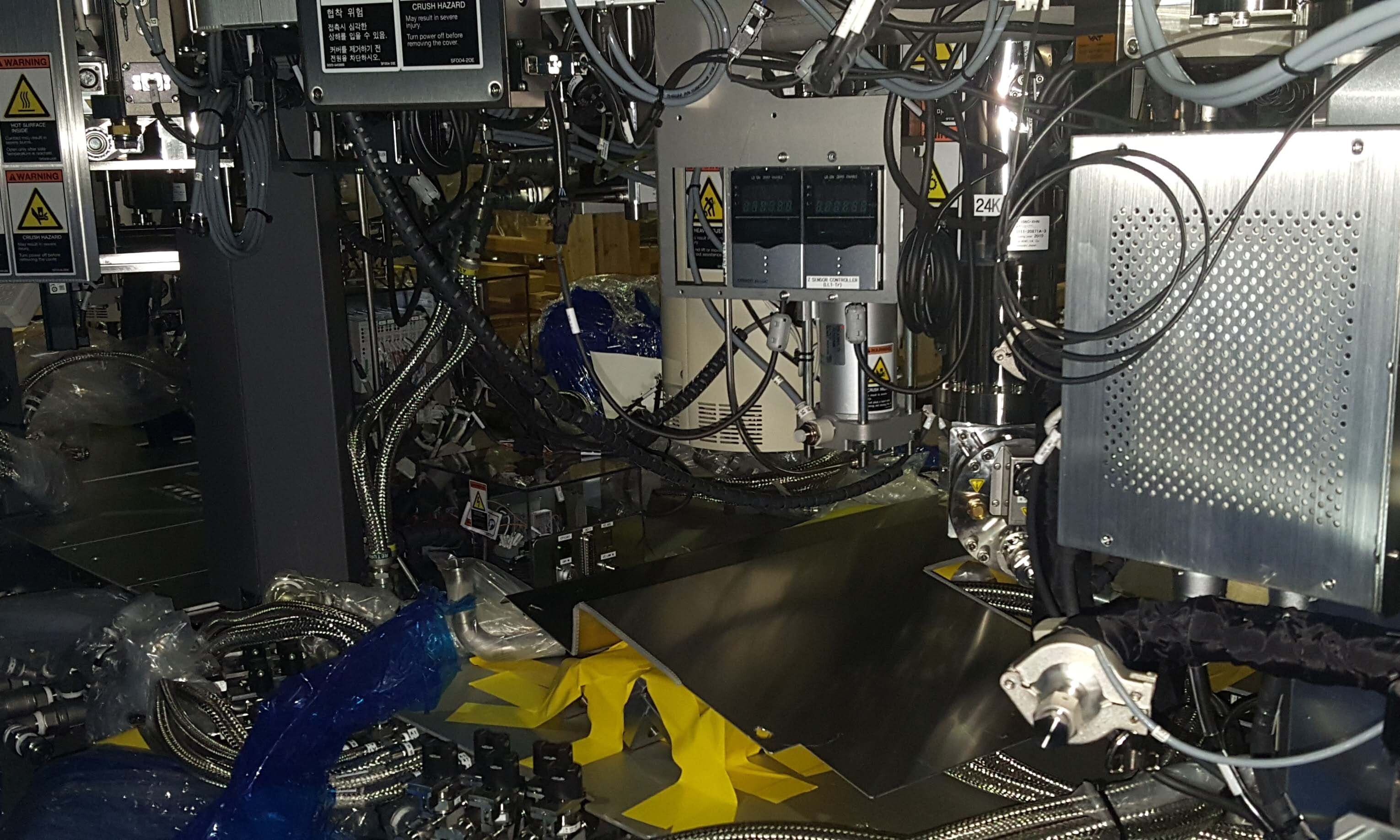

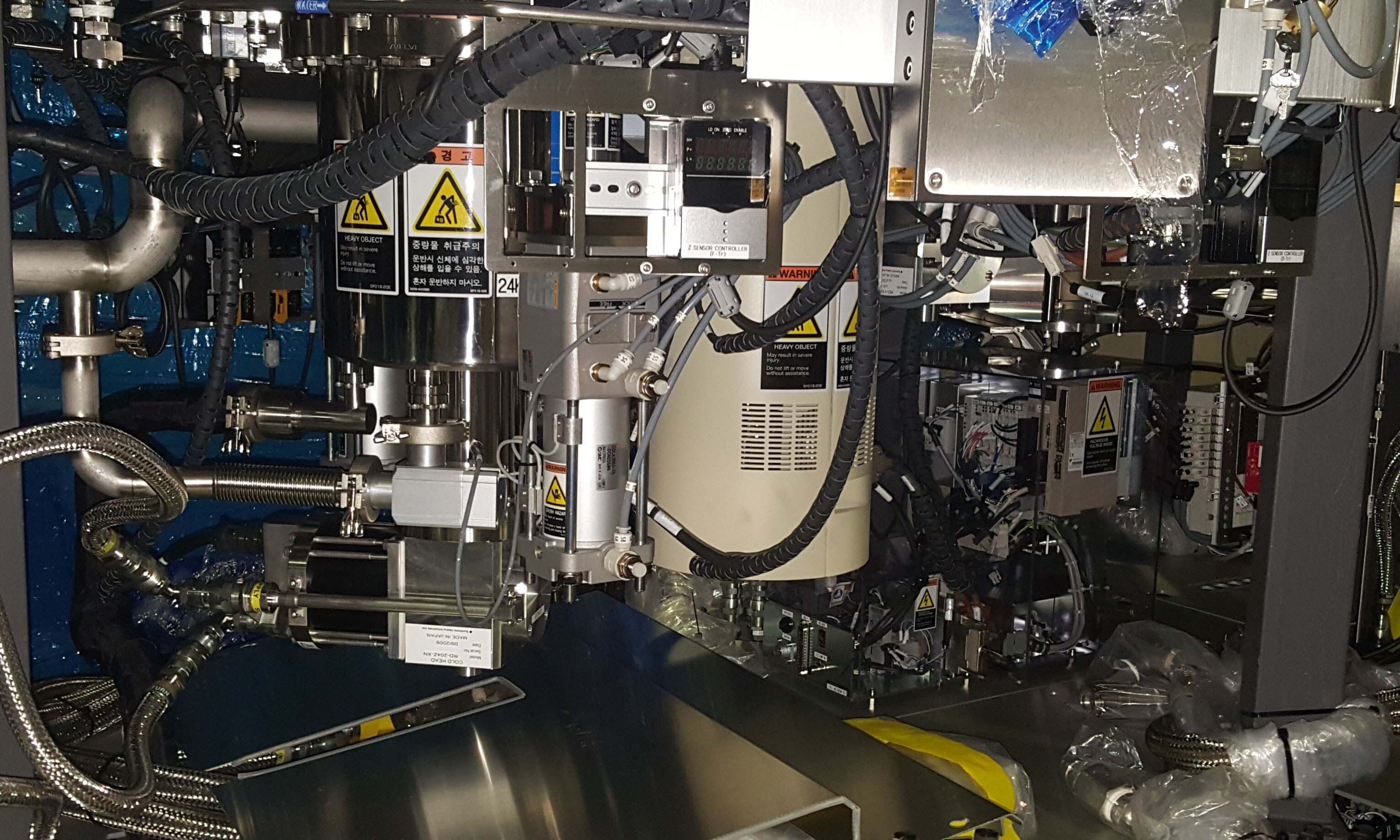

Missing parts:

CHM Stage heater

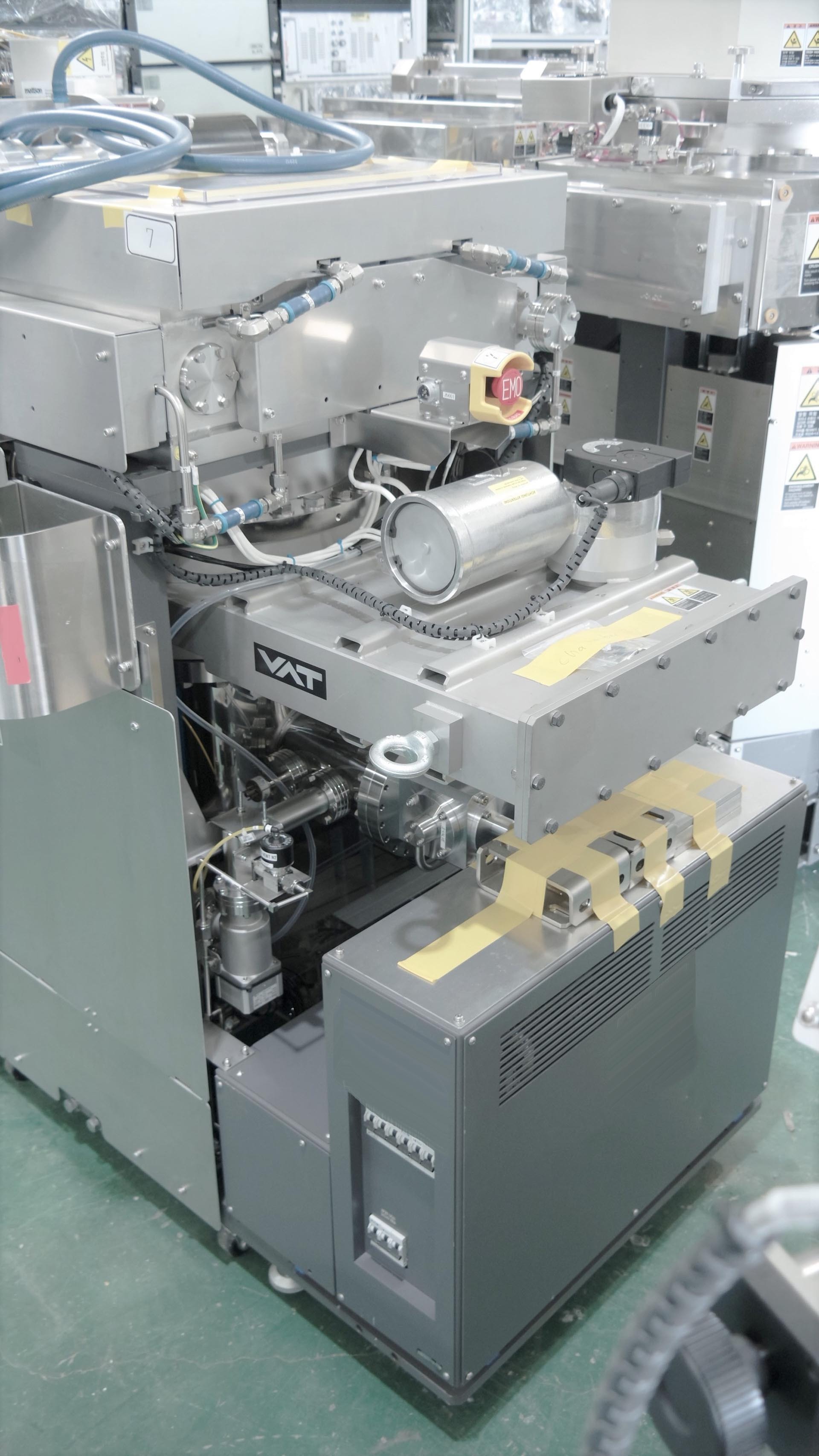

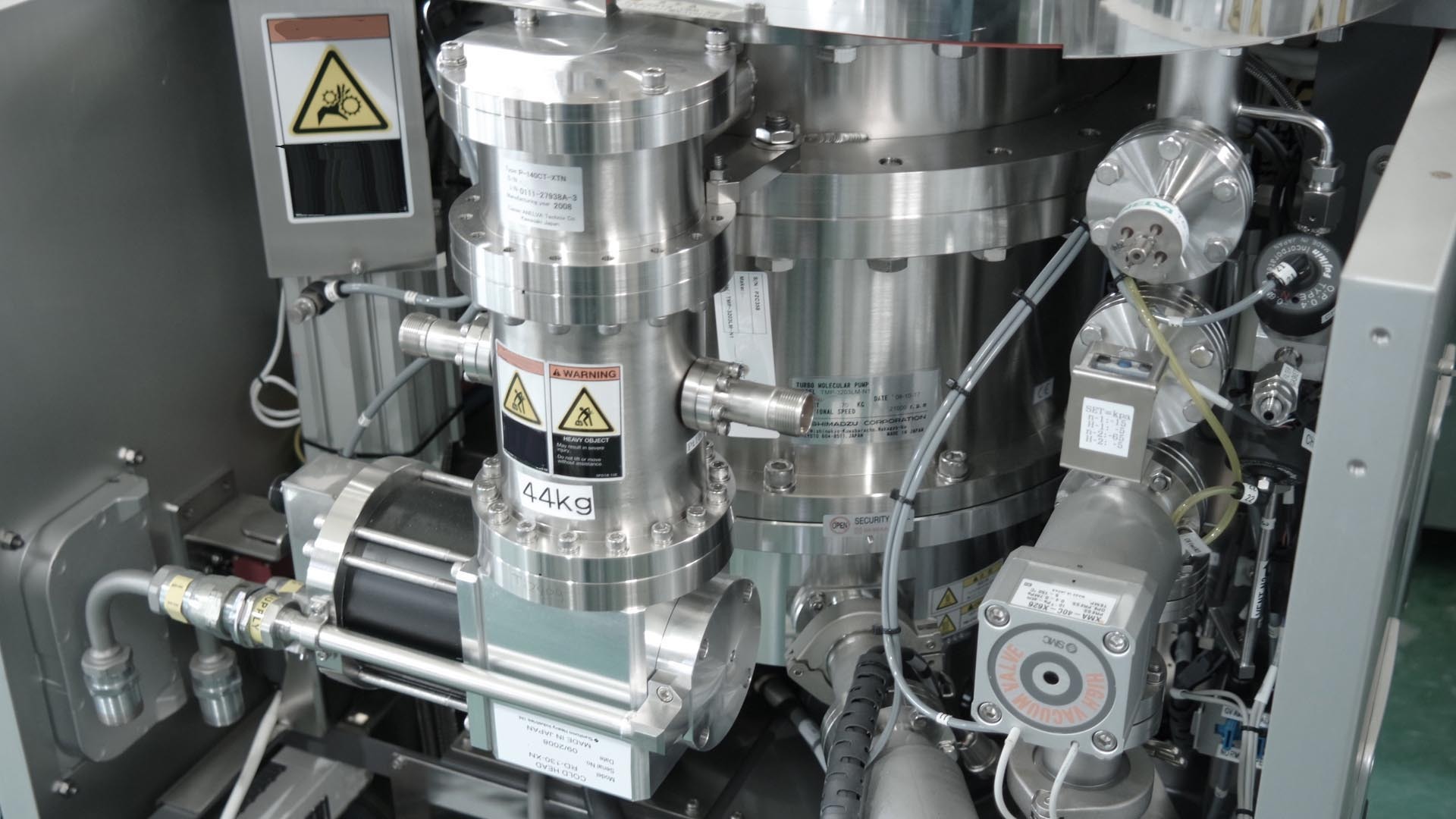

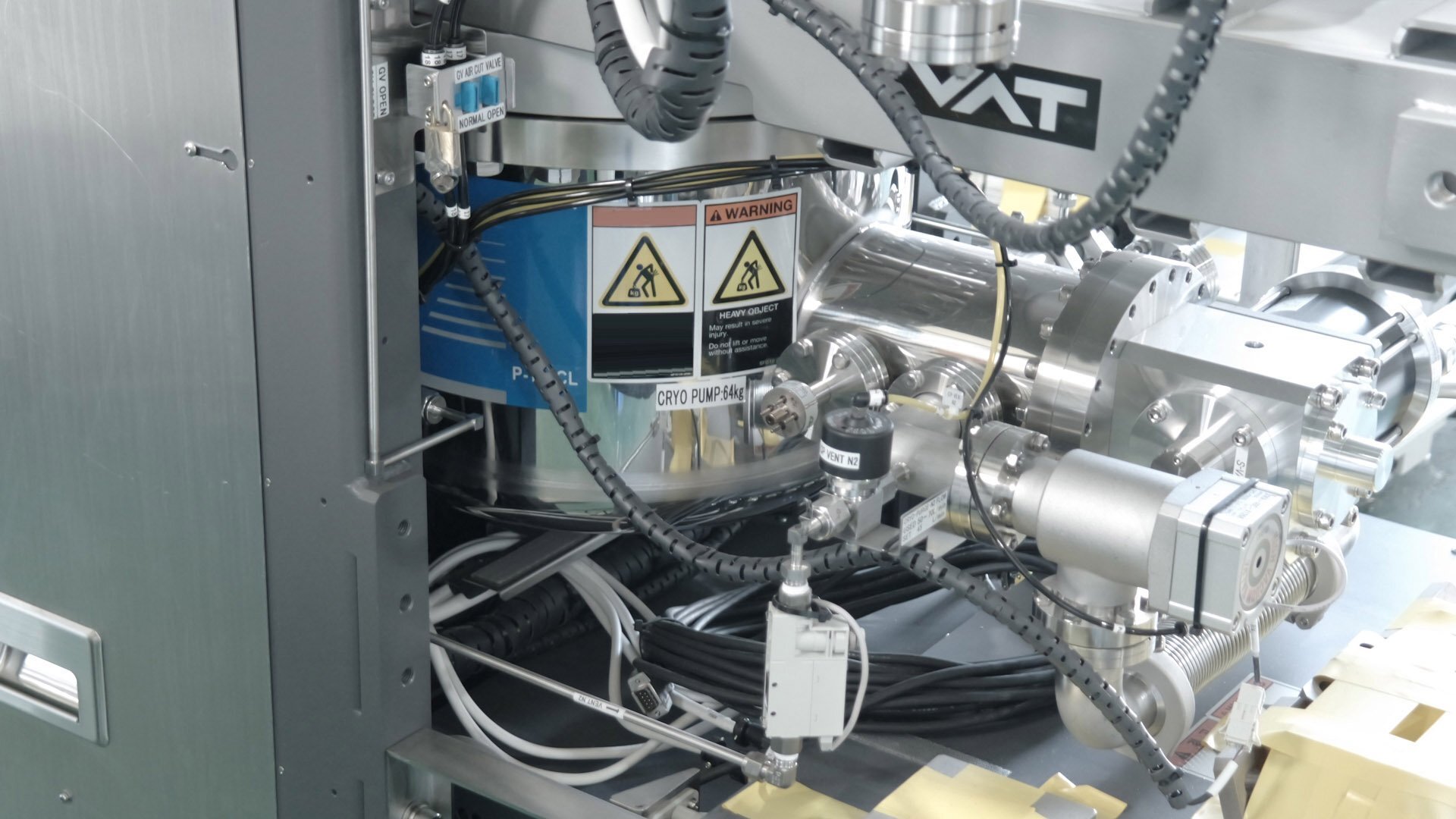

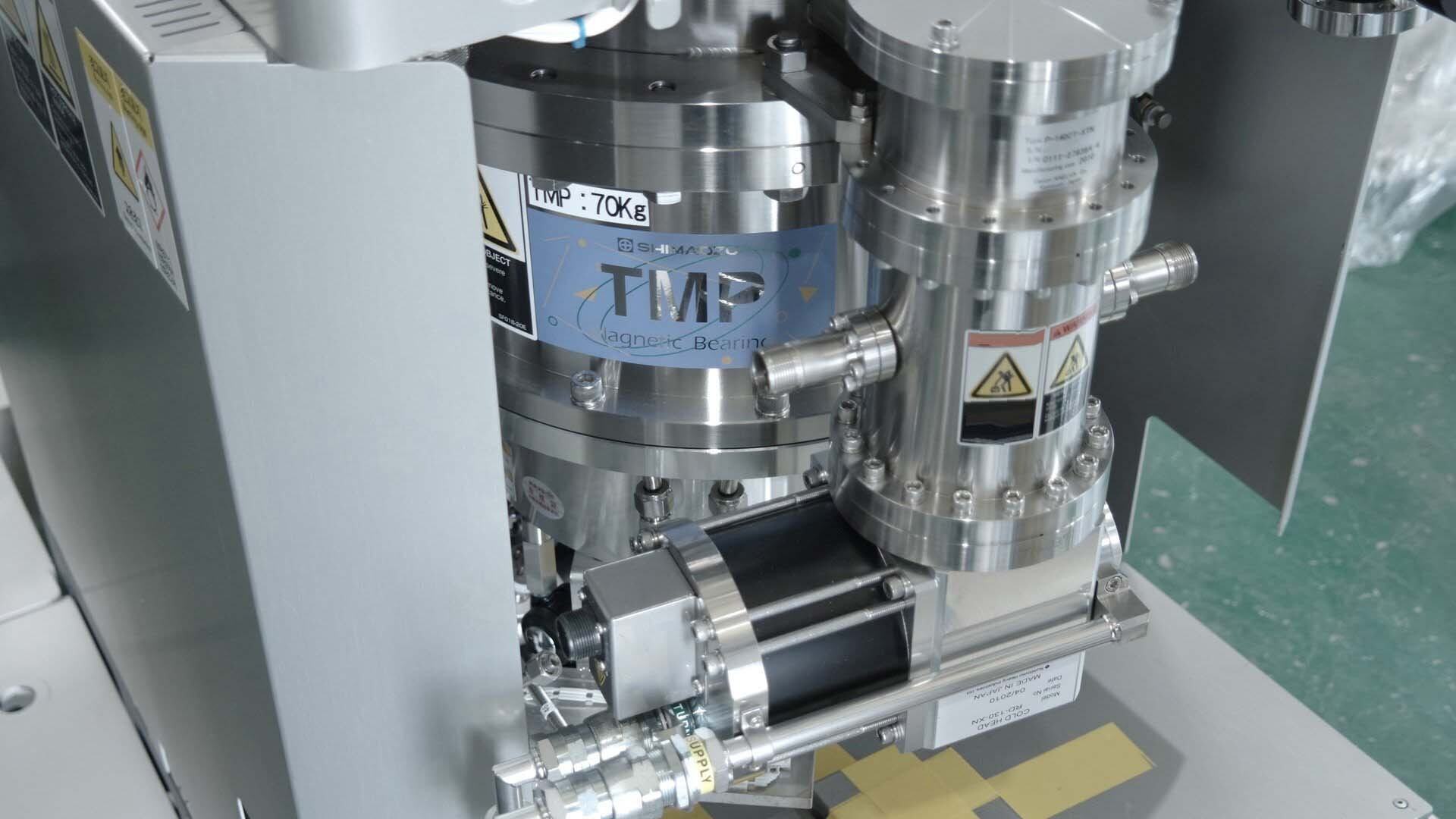

Load lock cryo pump

2010 vintage.

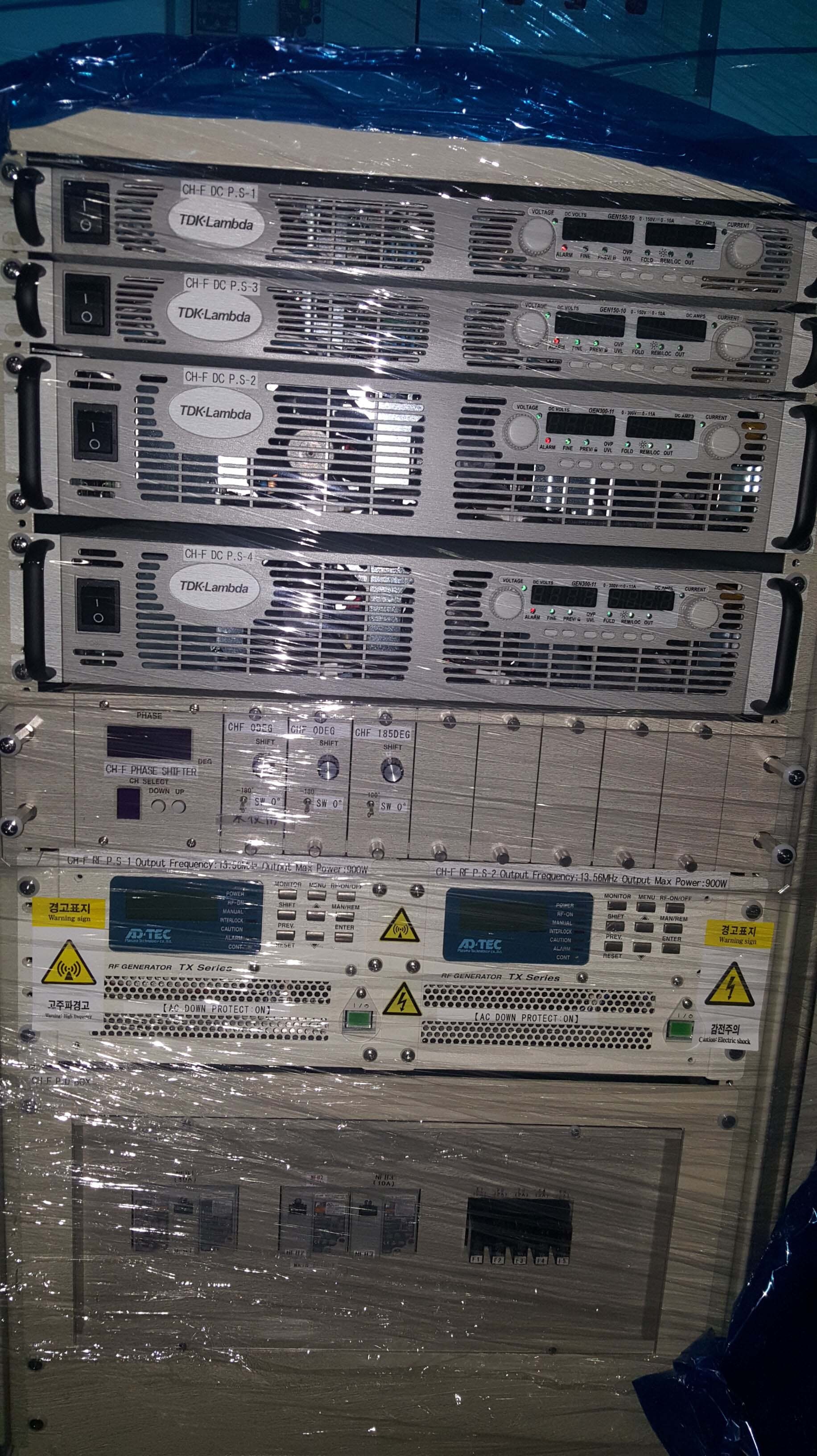

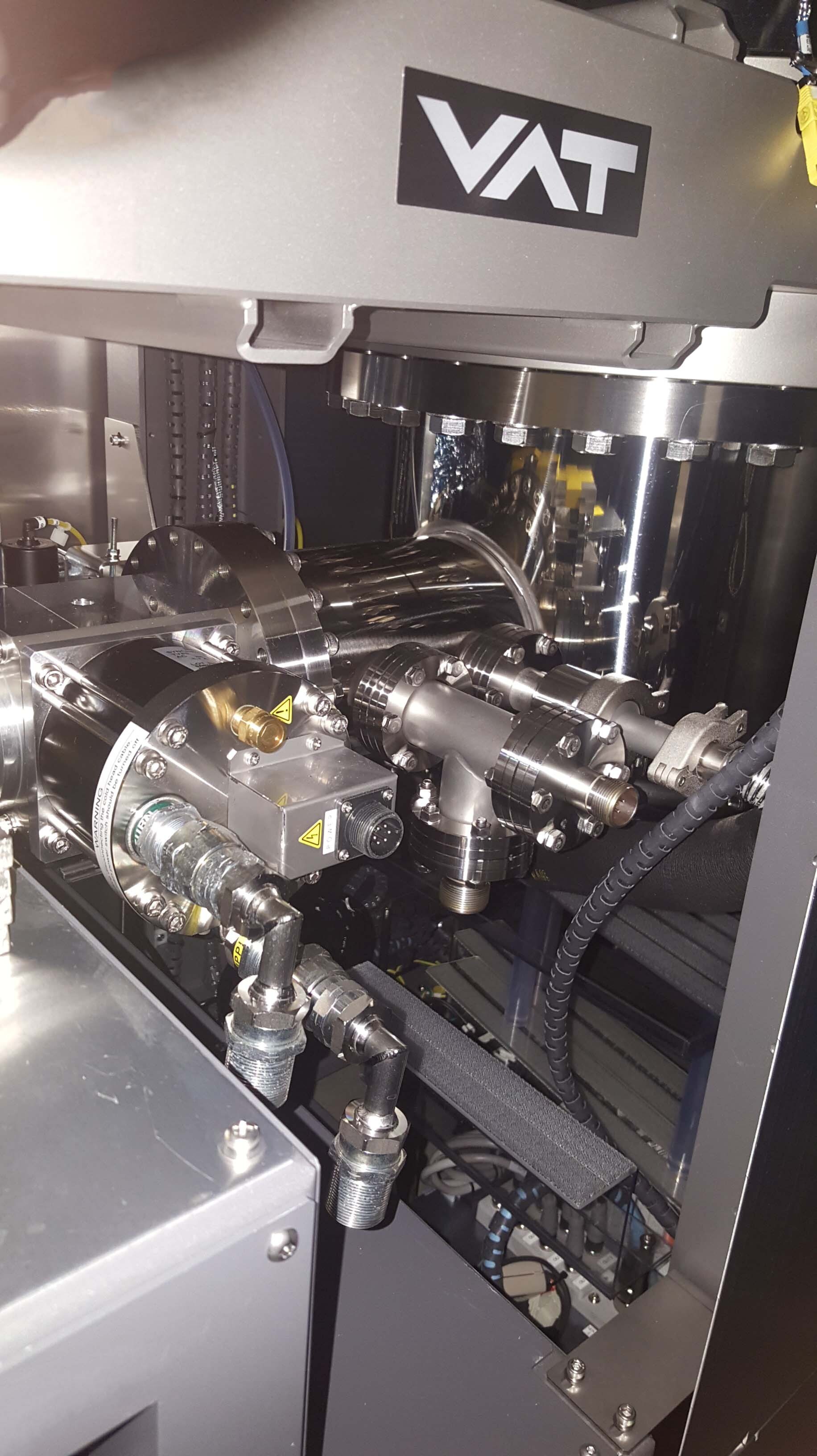

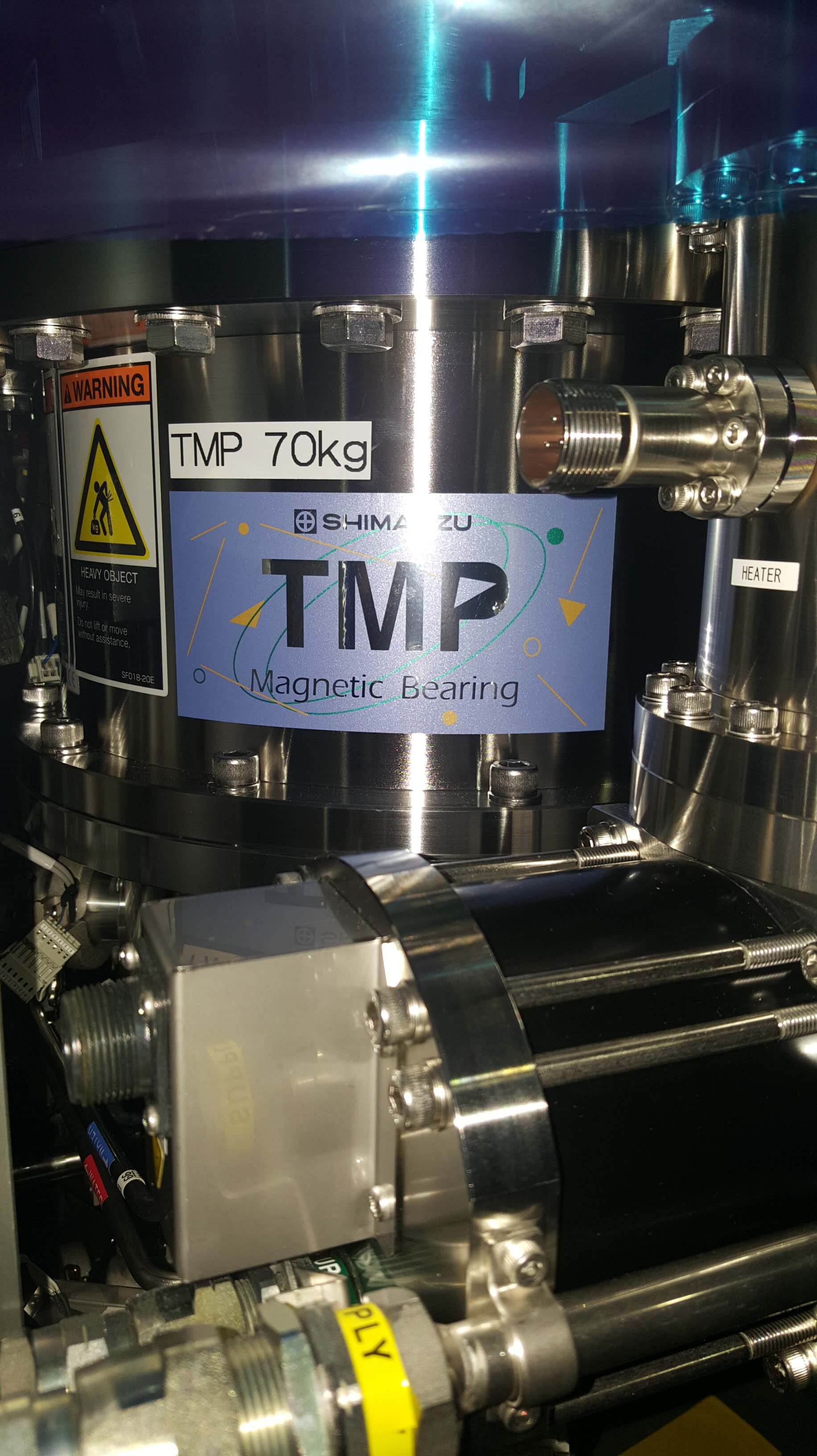

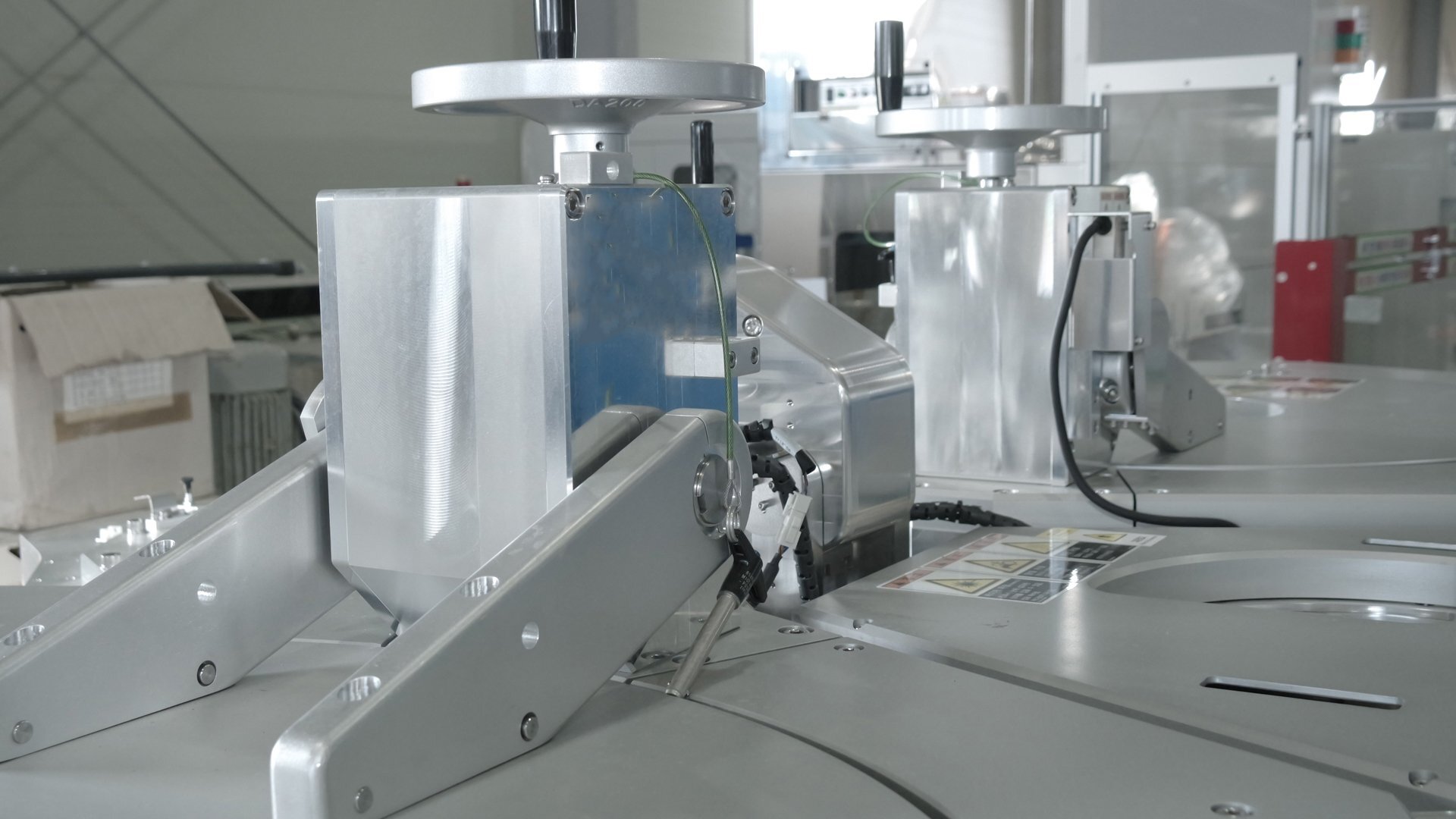

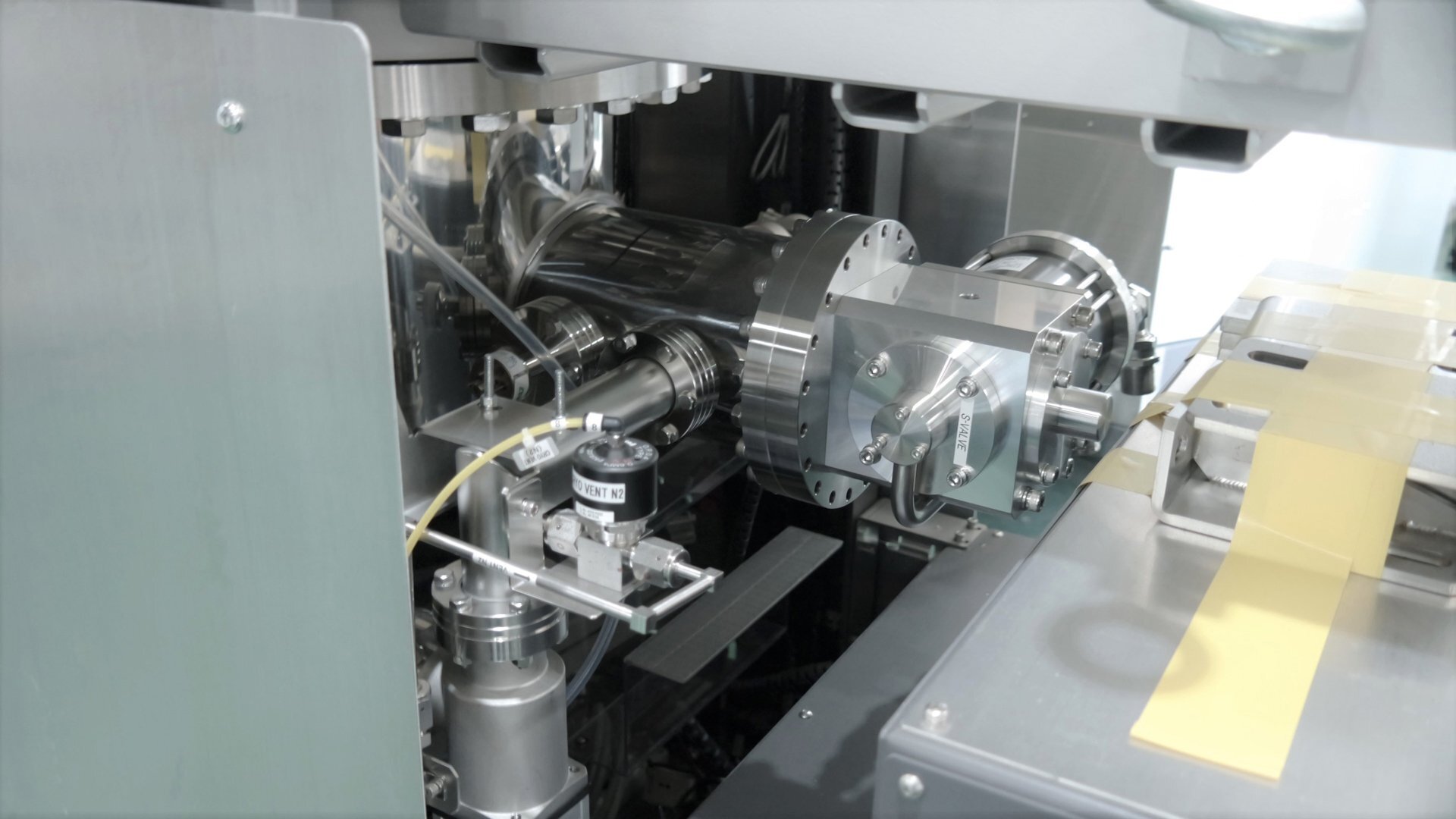

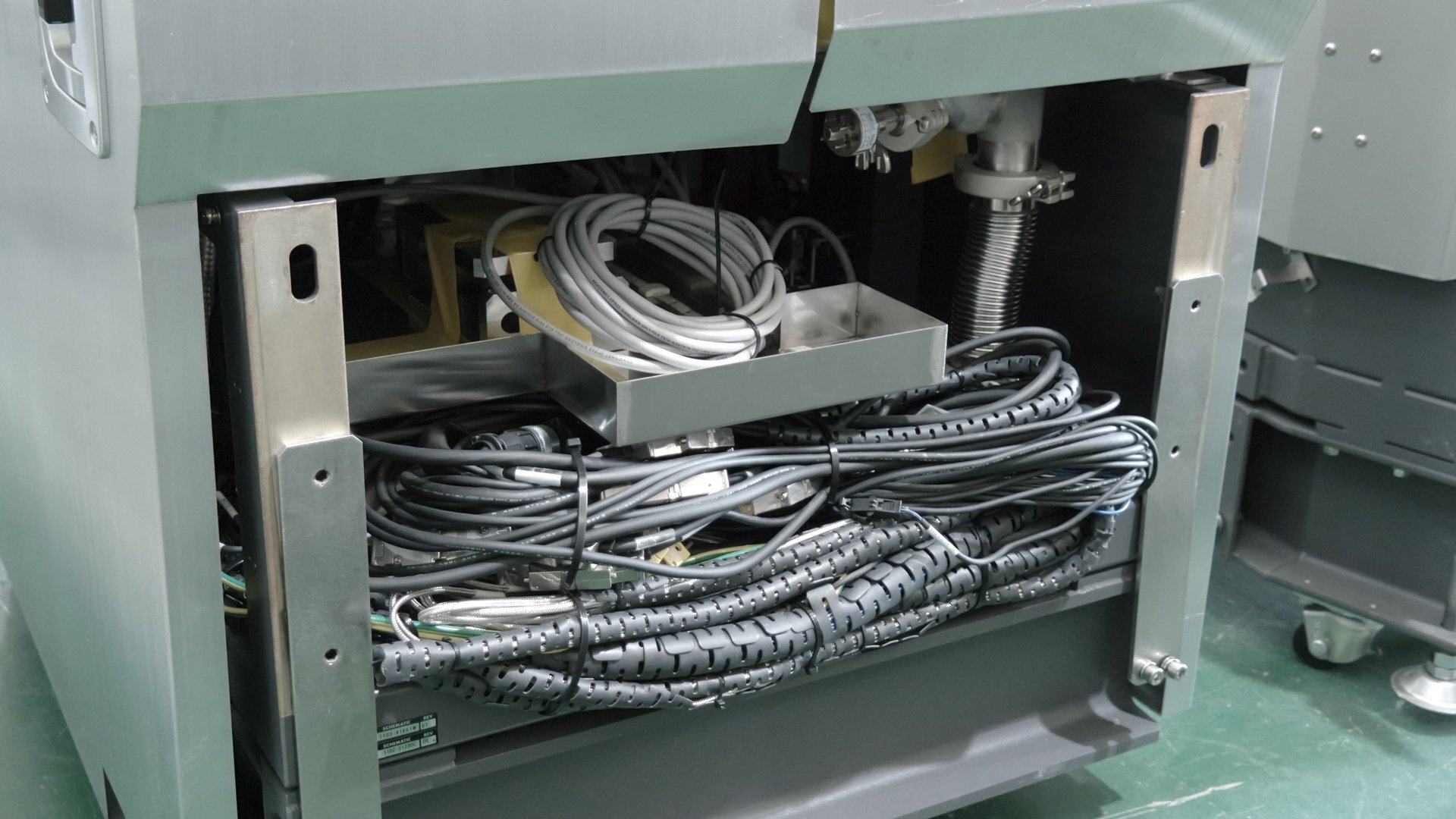

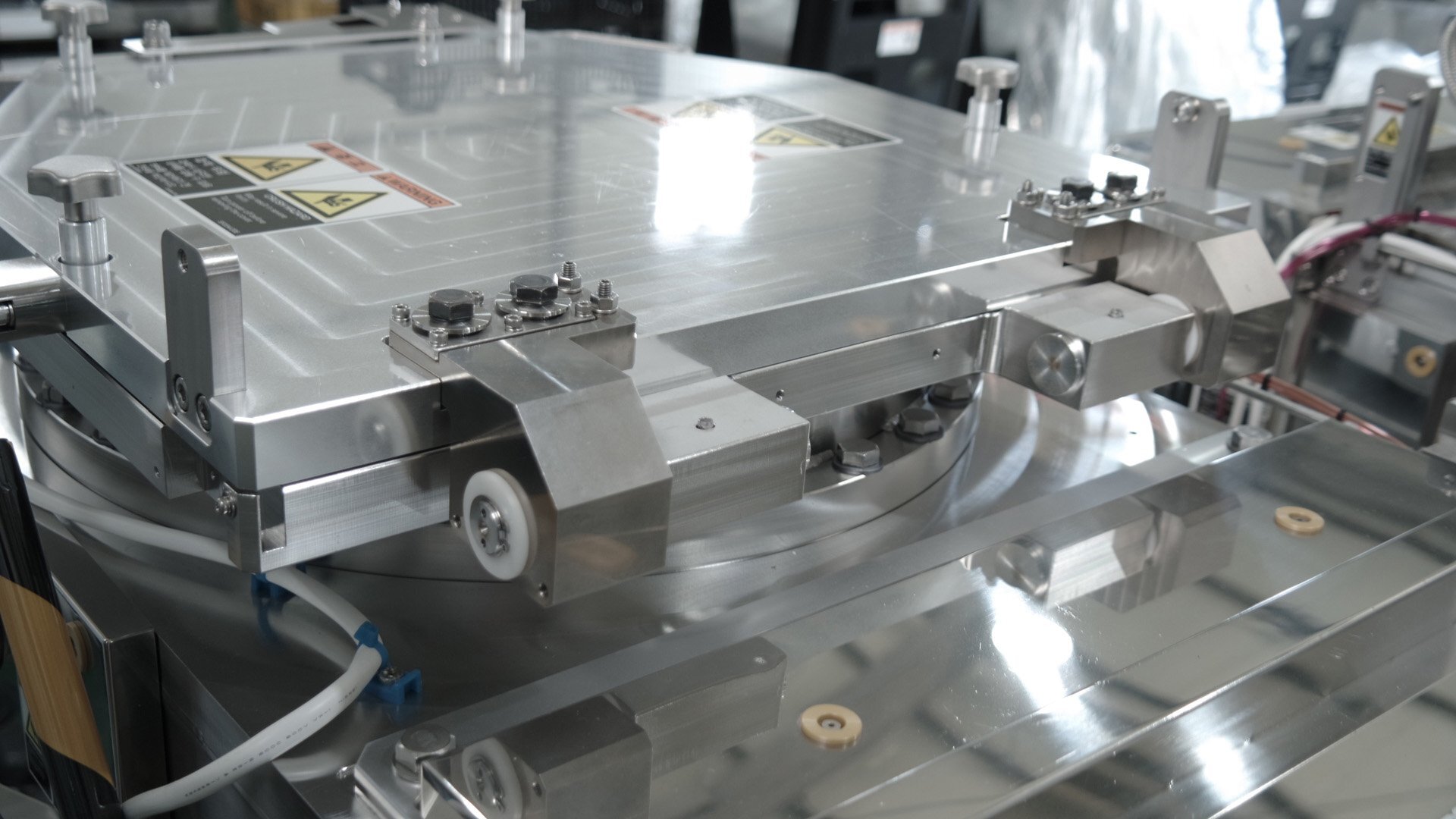

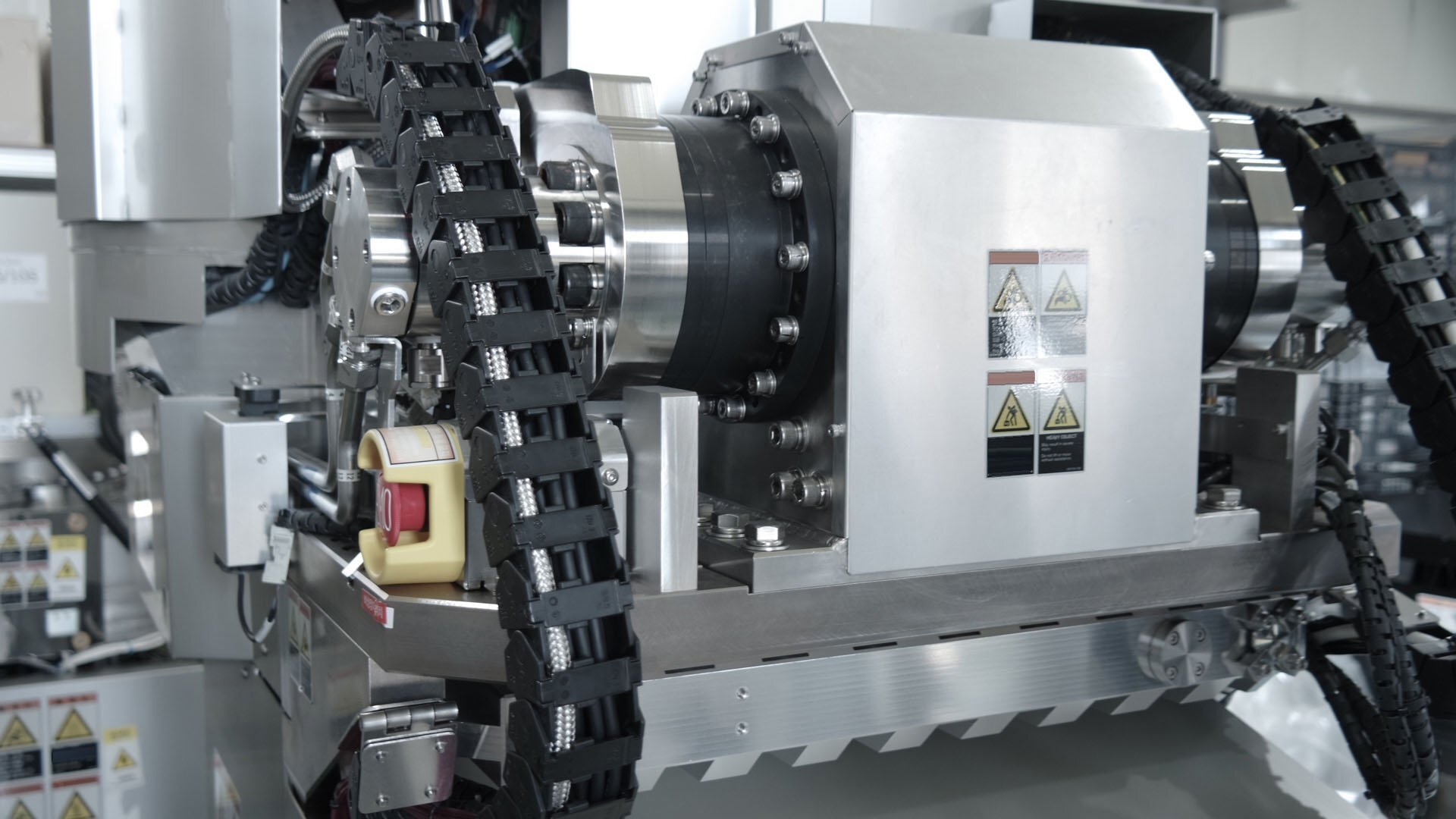

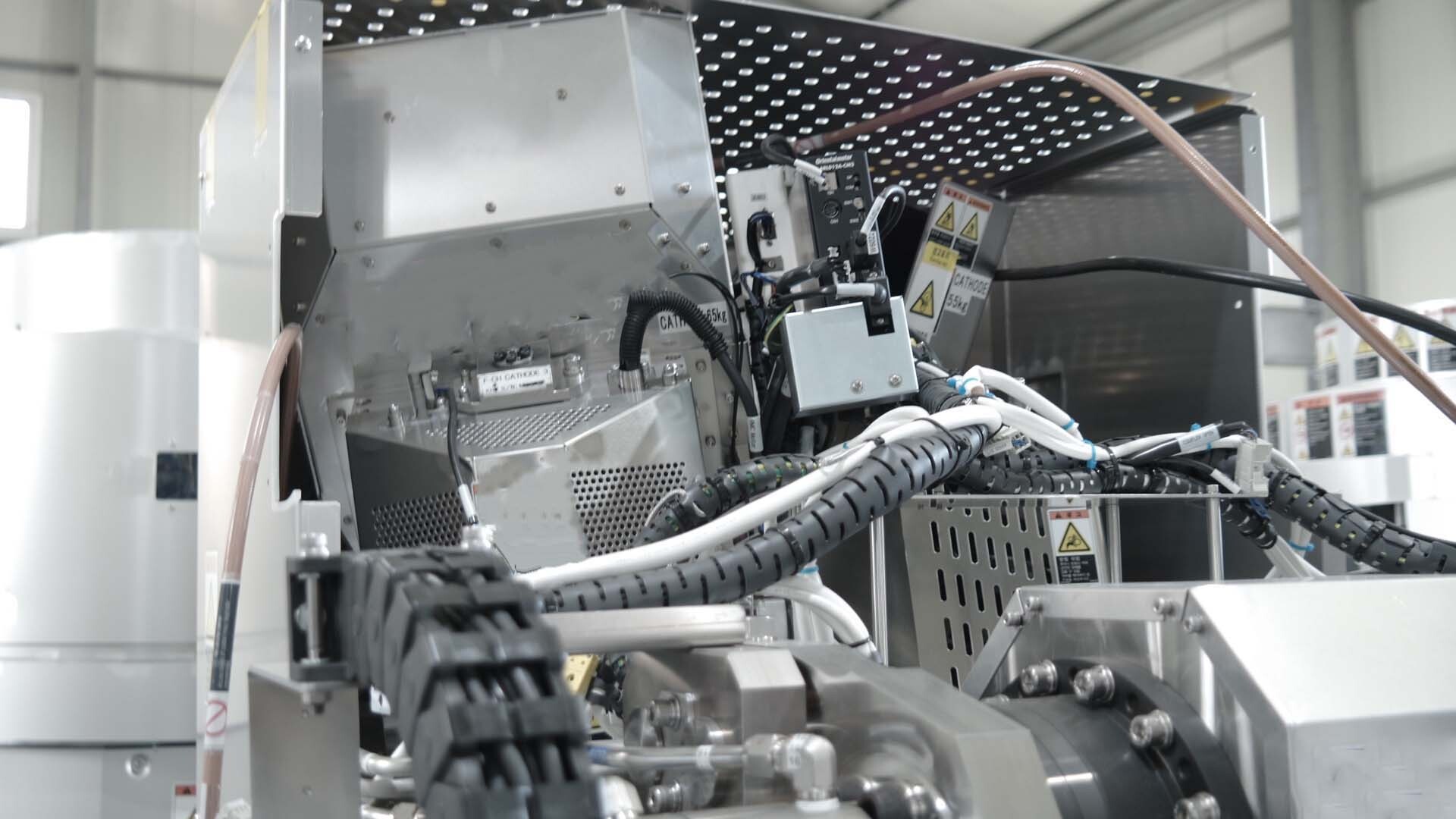

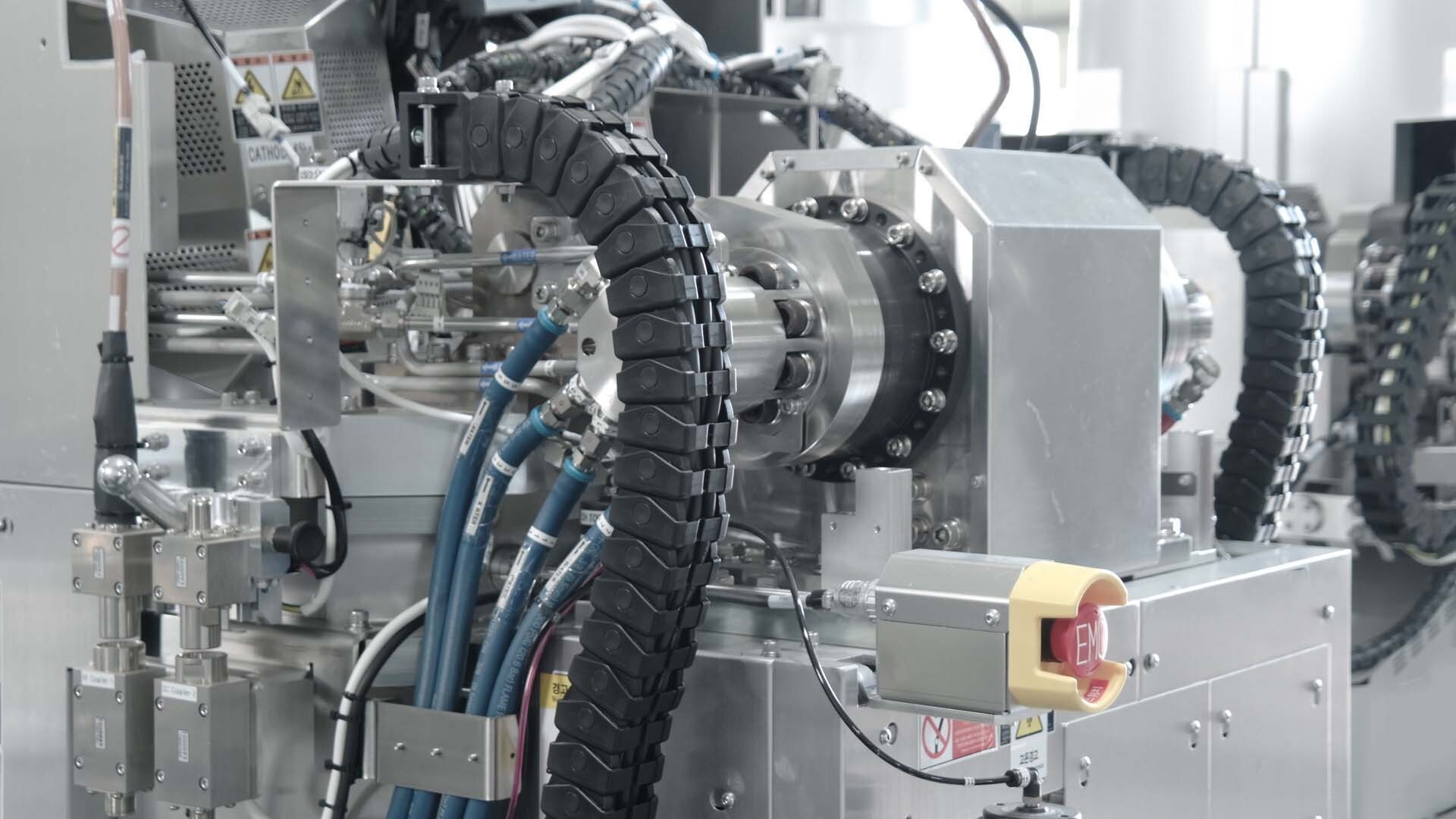

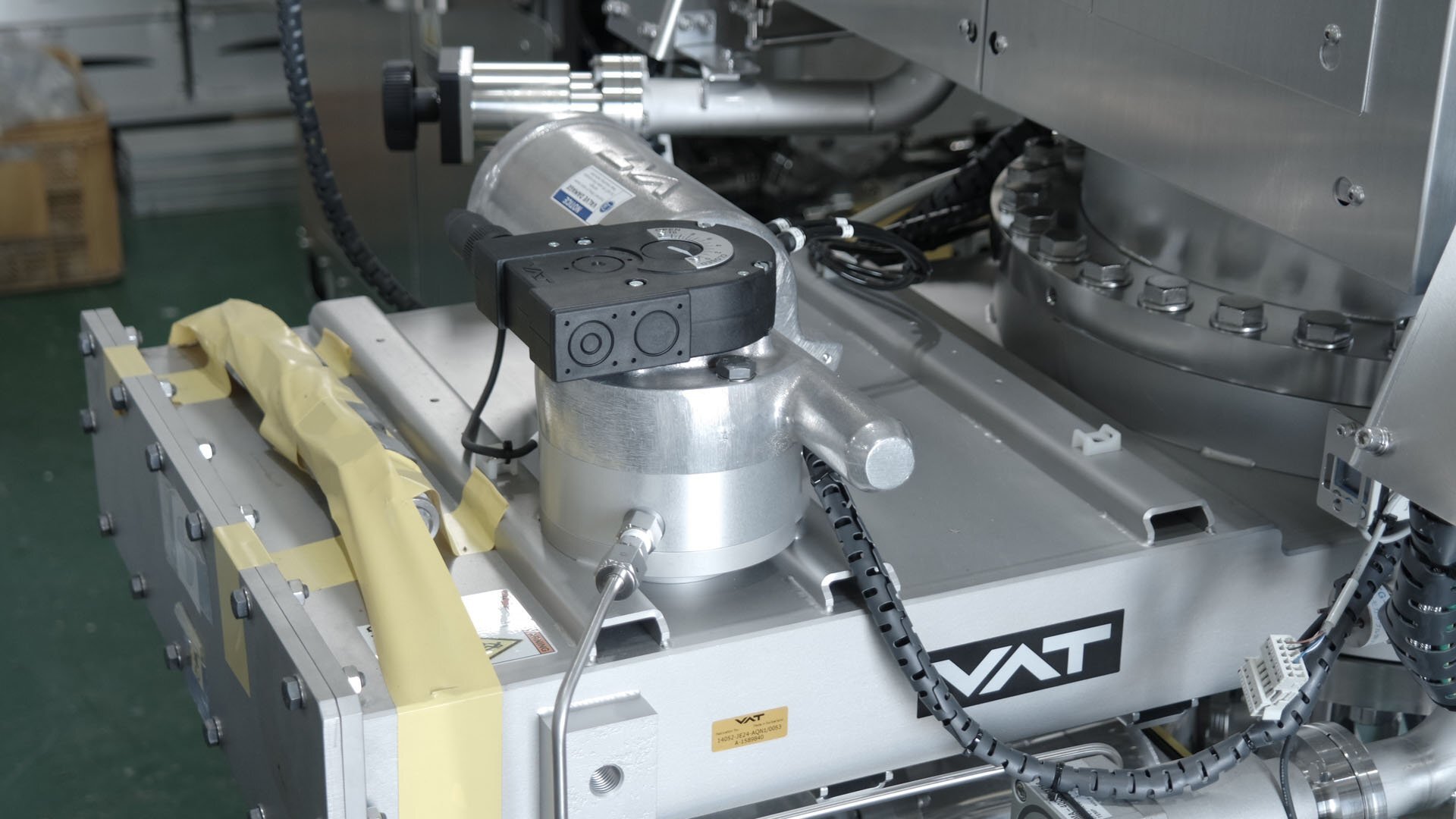

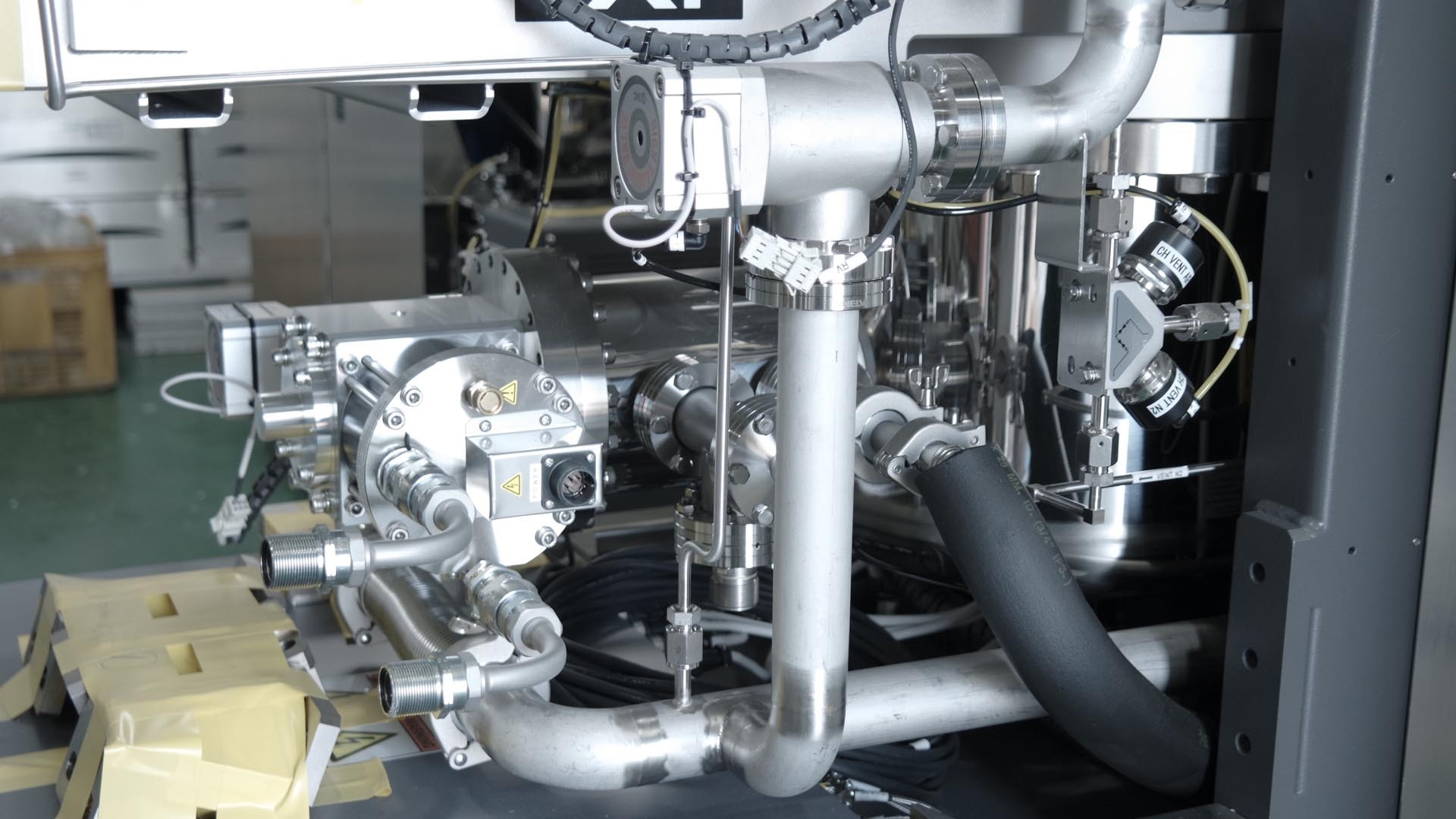

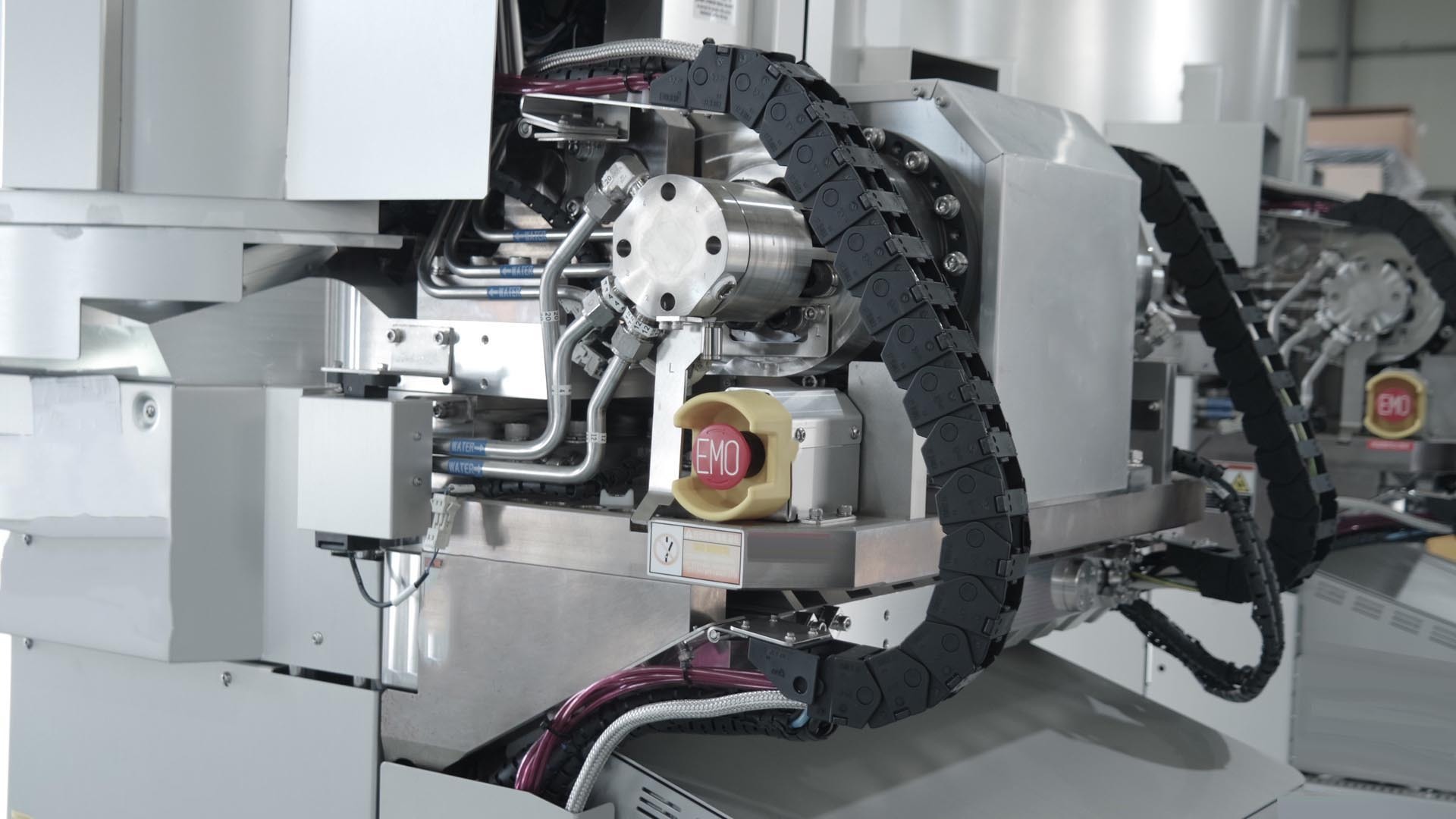

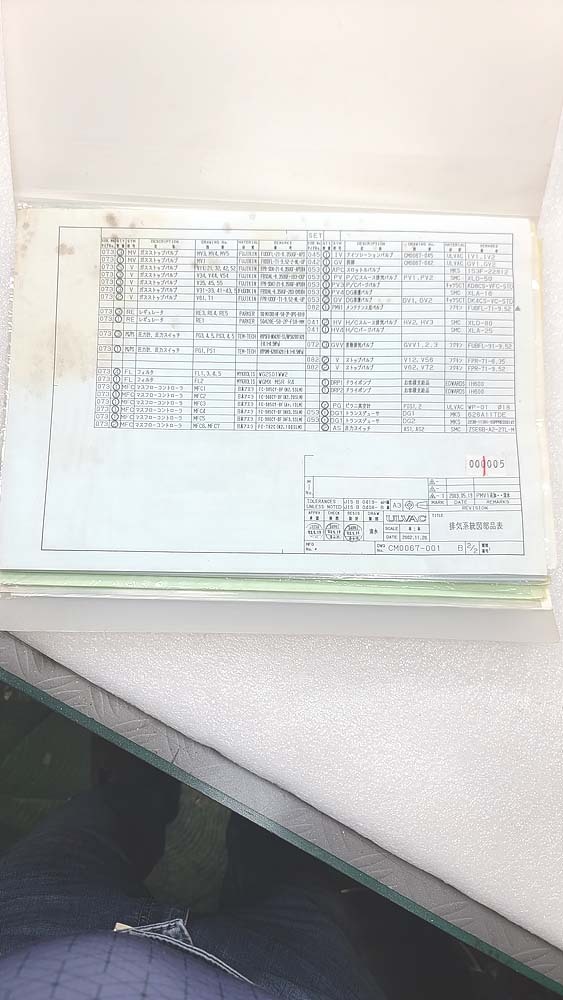

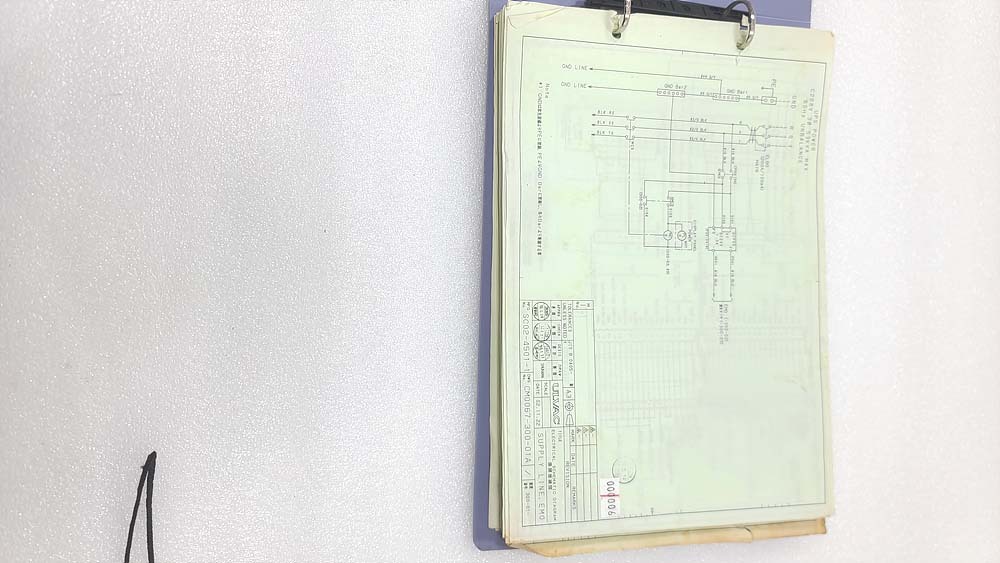

CANON / ANELVA C-7300 is a magnetron sputter coating equipment designed and manufactured by CANON Corporation. Developed to meet the increasingly stringent requirements of surface processing and deposition applications, CANON C-7300 uses a remotely operated Cathodic Magnetron Sputter (CMS) process, which is ideal for coating large areas and components with a high degree of uniformity. ANELVA C 7300 consists of two main components: the processing chamber and the magnetron power supply. The chamber is primarily composed of the process chamber, gas box, vacuum pumps and coolant supply, and the magnetron sputter gun. Inside the processing chamber, the magnetron sputter gun is mounted to the chamber wall, allowing the sputter gun to rotate in both clockwise and counterclockwise directions without restriction. Gas is introduced through the gas box on the side of the chamber, while evacuation pumps regulate the pressure inside the chamber. The magnetron power supply, located outside of the processing chamber, is connected to the sputter gun via a high-voltage cable. CANON / ANELVA C 7300 utilizes a highly efficient CMS process, where negative ions accelerated towards the target by an internal field are attracted to the sample, creating a low pressure plasma filled with energized atoms. The resulting bombardment of these atoms on the sample creates a thin, homogenous layer of the desired material. Through the use of shutter arrays, the transport of sputtered material from the target to the surface of the sample can be precisely controlled. C-7300 system is designed to provide precise control over the deposition rate, film thickness, step-coverage, and composition of the resulting thin film. Its user-friendly interface allows for convenient access to unit parameters such as pump speed, pressure, flow rate and power, so that the setup and operation of the machine can be quickly optimized according to the application. For safety, the tool includes temperature and exposure safeguards, as well as a PC-style O/S for immediate access to asset parameters. C 7300 sputter coating model is an ideal choice for the deposition of thin films onto substrates. Its precise control over parameters such as deposition power, gas flow rate and pressure, provide a degree of customization unmatched by any other existing sputter coating equipment. Additionally, its robust design and high-quality components ensure reliable performance and long-term usability.

There are no reviews yet