Used CANON / ANELVA ILC-1012 #9215758 for sale

URL successfully copied!

Tap to zoom

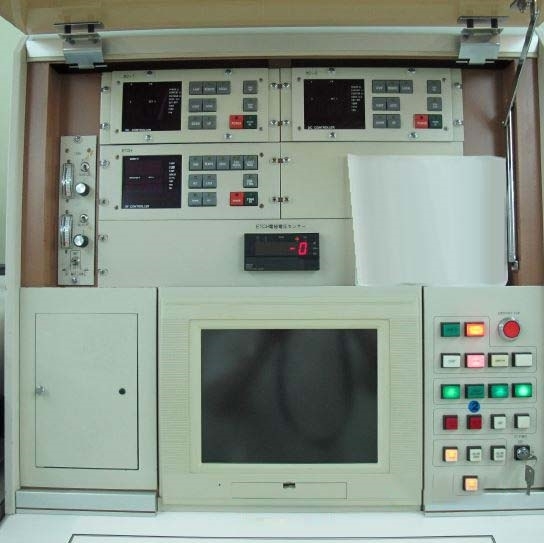

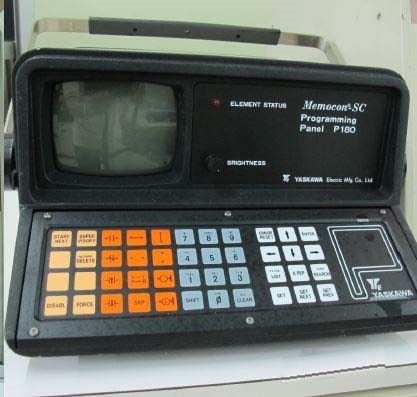

CANON / ANELVA ILC-1012 Sputtering Equipment (hereinafter "the System") is an advanced coating unit for applications in fields such as precision engineering, semiconductor, and electronics. Its primary purpose is to create thin films of materials by sputtering them onto various substrates, a process in which a material is ejected as microscopic particles from a source pellet due to a combination of ion bombardment and elevated temperatures. The Machine is comprised of an IH vacuum chamber, a power supply, and an aimer head. The vacuum chamber allows users to introduce the desired material into a working chamber with a vacuum pressure of 1000-30000 Pa. It is designed to be compatible with both Forward- and Reactive-Sputtering processes, allowing users to sputter onto substrates almost any material of choice. The power supply allows for precise control of the materials' work-function, sputter angle, and sputter rate, while the aimer head provides fine control of the direction of the sputtered particles. The entire tool is supported by an industrial-grade controller with a simplified user interface, allowing for quick and easy operation and modification of process parameters. This is aided further by the Asset's ability to save and recall up to sixteen user-defined recipes for repeatable, high-quality processing. The advanced engineering of the Model provides for extra-fine and uniform sputtering of thin layers down to a width of 0.1 μm, which is important for high-precision electronic applications where a tight tolerance in layer thickness is required. About this, the Equipment allows for a control over sputtering parameters satisfying the requirements of the most advanced electronic industries. The process control is further assisted by a number of supplementary features, such as the End Point Detector. With this system, users can set a sputtering target thickness and the process will automatically stop once the desired thickness is achieved. Additionally, the Unit includes a Vacuum Sensor, allowing operators to monitor chamber pressure while sputtering. The Machine also has an emergency stop tool that will shut off the asset in the event of an emergency or abnormal operation. In summary, CANON ILC-1012 sputtering model is the ideal choice for precise coating of materials onto electronic components or substrates. It has a wide range of features, such as process-control options, a user-friendly interface, and advanced engineering, which ensure it will remain a trusted and dependable tool for many years to come.

There are no reviews yet