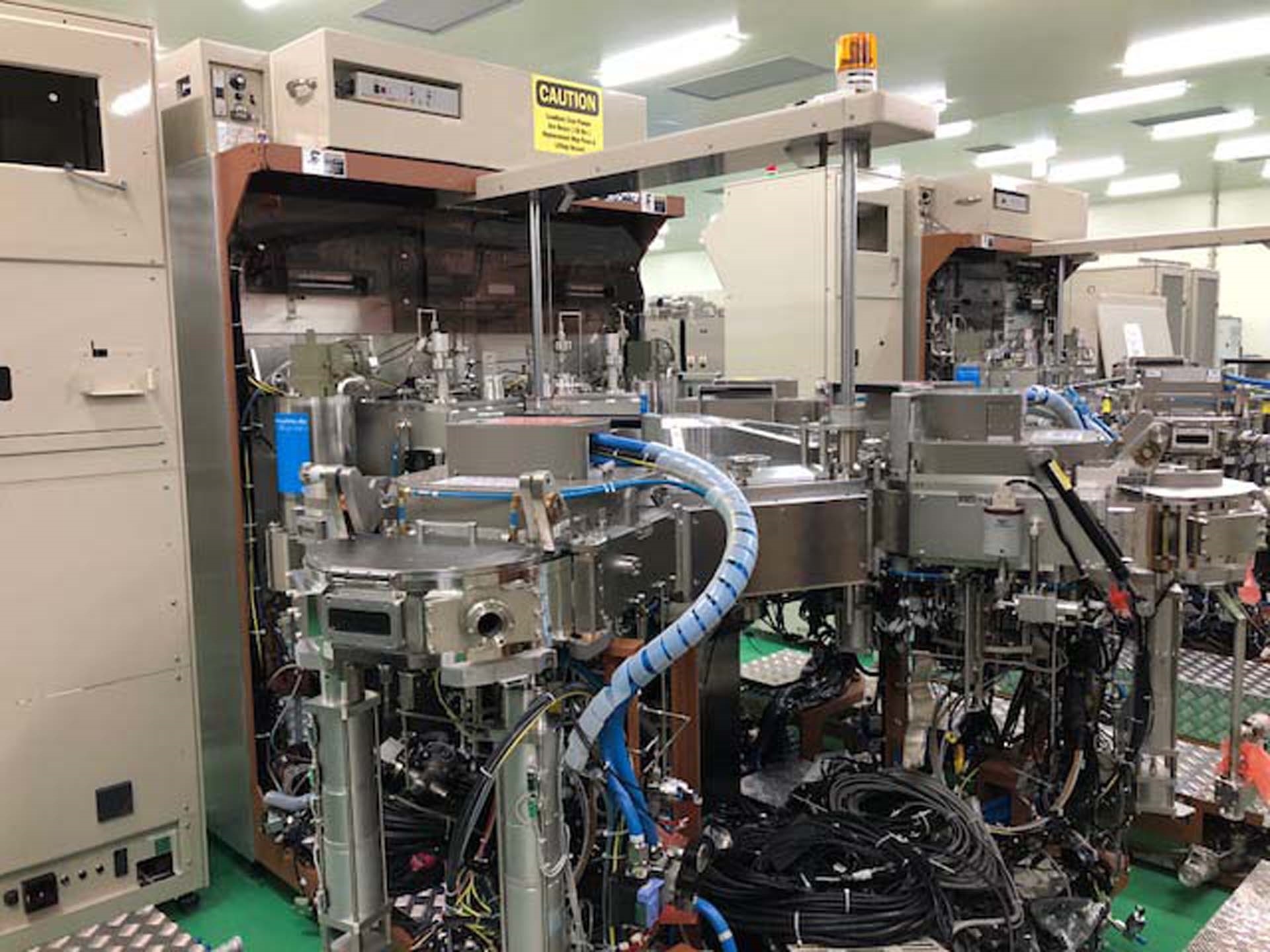

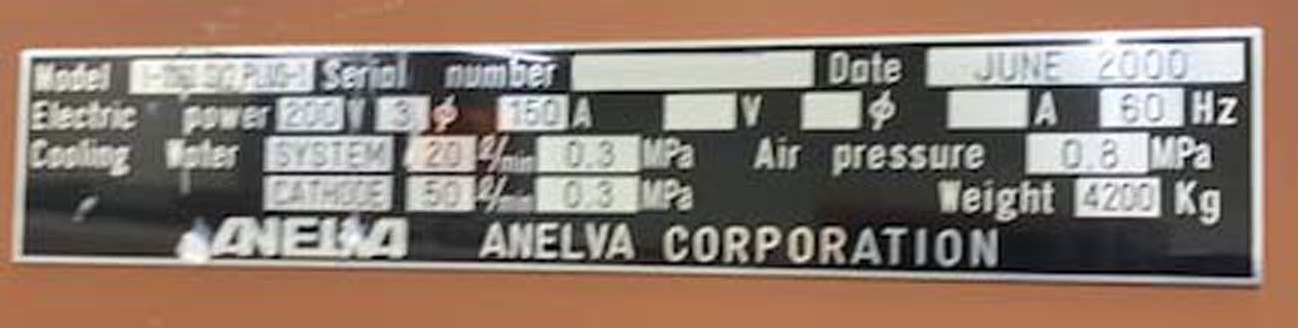

Used CANON / ANELVA ILC 1060 #9248133 for sale

URL successfully copied!

Tap to zoom

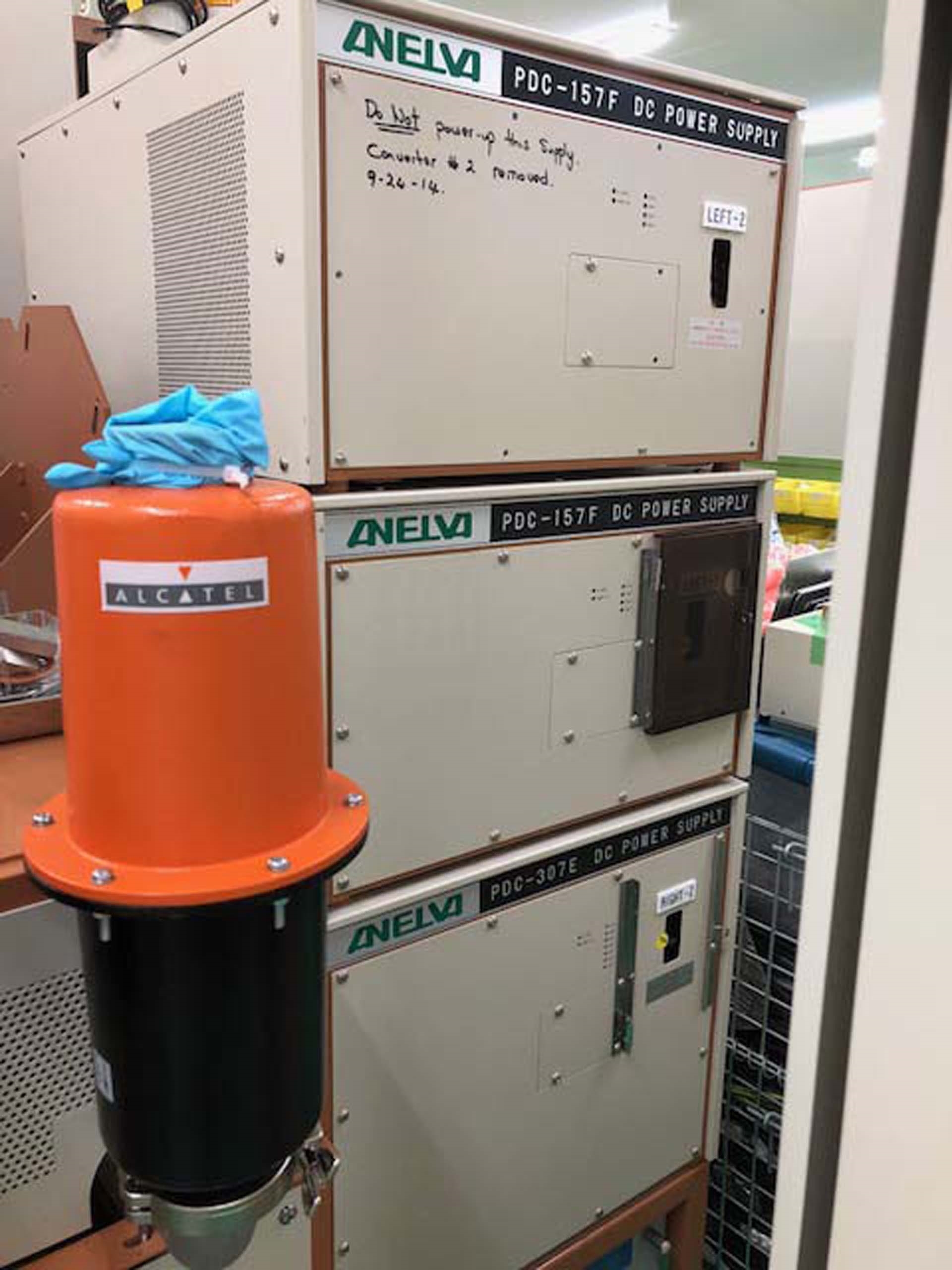

CANON / ANELVA ILC 1060 is a sputtering equipment designed for use in a variety of scientific and industrial applications. It is a computer-controlled, vacuum-based system that employs physical vapor deposition to deposit thin, uniform layers of material onto a substrate. CANON ILC 1060 is highly adaptive and can be programmed to precisely manipulate sputter target composition and current, deposition rate, fluence, substrate bias, and other variables. Its modular design enables high production throughput, and its superior process control and automation permit repeatable, predictable results. ANELVA ILC-1060's primary components include a rotary sputter source, a substrate holder, and a rotatable target. The rotary sputter source employs two guns, each capable of arc and dc discharge. The substrate holder, which can accommodate substrates up to 450 mm in size, is capable of holding up to four substrates at once. The rotatable target sputtering face can hold sputtering targets up to 200mm in diameter. An optional angle-mounted target and platen are available for extended target area coverage. ILC-1060 offers a variety of sputter processes, including argon plasma and reactive gas sputtering, and its process control is highly adjustable to meet the needs of various end users. A primary control module can be programmed to precisely manipulate sputter target composition and current, deposition rate, fluence, and substrate bias. The optional secondary control module enables the manipulation of such process parameters as reactive gas flow rate, chamber pressure, and layer thickness. This module can be locked out to prevent unauthorized manipulation. CANON ILC-1060 is both flexible and economical, making it an attractive choice for numerous applications. Its compact footprint and energy-efficient design minimize space requirements and maximize cost savings. High-level safety systems and automatic statistical process control maintain production quality and reliability. At the end of the process sequence, a post-process vision unit inspects the completed parts for potential process errors and ensures accuracy. Overall, ILC 1060 is an industry-leading sputtering machine that is well-suited for a wide array of scientific and industrial applications. Its reliable performance, superior process control, and adjustable settings make it an excellent choice for precise, efficient deposition of thin layers of material onto substrates or wafers.

There are no reviews yet