Used CPA 9900-1 #9173304 for sale

URL successfully copied!

Tap to zoom

ID: 9173304

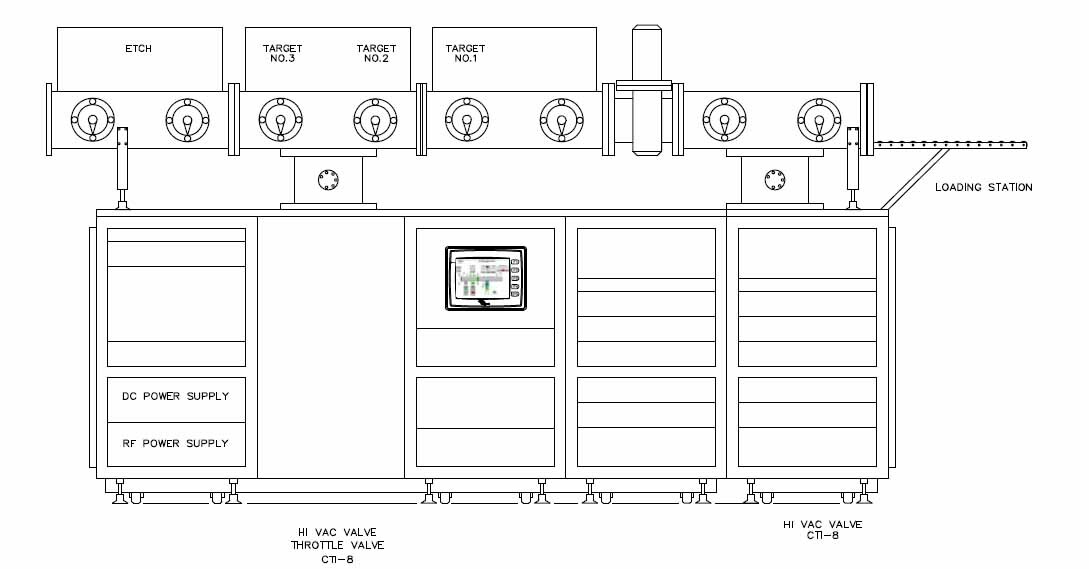

Horizontal in-line sputtering system

Process parameter control ranges:

Sputtering pressure: 5 microns to 30 microns

Conveyor speed: 0.1 to 80 cm.min

D.C. Deposition power level: 100 to 9000 watts

R.F. Deposition power level: 50 to 3000 watts

R.F. Sputter clean power level: 15 to 1000 watts

Substrate heating: Inline heating is variable from ambient to 350°C

Uniformity performance:

(Across 12” sputter zone)

Etch: ±10%

Deposition:

R.F. Magnetron ±10%

D.C. Magnetron ±5%

Vacuum performance:

Ultimate pressure (total system):

2X 10(-7) in 16 hours clean, dry and empty

5 x 10(-7) in 30 minutes

Rate of rise:

More than 6 minutes to 1 x 10(-4) torr clean, dry and empty

Vacuum tight: Less than 5 x 10(-10) standard atmosphere cc helium/second

Optional features:

Multiple cathodes

Multiple power supplies

DC and RF in any mix

With / Without sputter etch

With / Without substrate heating

Turbo pump Hi-Vac

Cryo pump Hi-Vac

Sputter up / Sputter down

With / Without load lock

Various numbers of process gases

Rail bias

Installed RGA

With / Without window shutters

Unequipped chamber for future expansion

Target assembly sizes: 15”, 22”, 35”, and 50”

Utility requirements:

Power:

208 V

100 Amps

3 Phase

50 / 60 Hz

4 Wire delta

5 Wire wye

Water temperature: 50° - 75° F (10-24°C)

Air: 70 to 100 PSIG (6 to 8 ATU) filtered 1 CFM

Sputtering gas: Typically 5 PSIG (1.3 ATU) Argon.

CPA 9900-1 sputtering equipment is a versatile and durable solution for a wide variety of coating and PVD (physical vapor deposition) applications. This sputtering system utilizes high power planar magnetron sputter sources to deposit thin films of target materials onto substrates, offering both high uniformity and excellent target material utilization. 9900-1 is also one of the fastest sputtering systems on the market, enabling up to 300nm per minute deposition rate. The sputtering sources of the unit can be tailored for operations on a variety of substrates, including a broad range of materials from ceramic, glass, silicon, and metal. By utilizing a Turbomolecular vacuum pump and an innovative cooling machine, CPA 9900-1 is capable of achieving high vacuum pressures of 1x10-7 Torr. The tool also features a large work area measuring 10.7x7.2 inches, enabling it to process larger substrates. Furthermore, 9900-1 includes a number of automation features, such as its automatic deposition thickness monitor, capable of measuring deposition thickness in real-time and adjusting parameters accordingly for a higher uniformity. Furthermore, the asset also offers a number of safety features, including emergency stop buttons and a protective chamber in the event of a problem during operation. In conclusion, CPA 9900-1 offers a reliable and consistently powerful sputtering solution for a wide range of surfaces and PVD applications. It is able to handle large substrates and can deposit target materials at a rate of up to 300nm per minute using its high power planar magnetron sputter sources. With its numerous automation and safety features, 9900-1 is an ideal choice for those looking for a powerful and versatile sputtering model.

There are no reviews yet