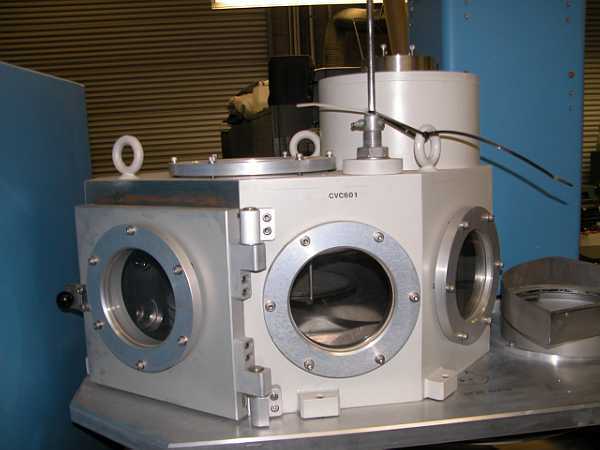

Used CVC 601 LL #135391 for sale

URL successfully copied!

Tap to zoom

ID: 135391

Vintage: 1980

Load lock with RF Etch

For conversion of CVC 601 sputtering system to load lock

Specifications:

Chamber top plate assembly and hoist

Heavy duty hoist

Load lock chamber with cassette

Roughing manifold

RF Etch assembly with matchbox

Rotostrate titanium table with pallets

1980 vintage.

CVC 601 LL is a vacuum sputtering equipment that is built for a variety of thin-film deposition applications. It is mainly used for depositing metals, dielectrics and nitrides, as well as oxide and other compounds. It has all the features necessary for complex thin-film applications from research and development to small- to medium-scale production. 601 LL utilizes a high-end diamond-like-carbon (DLC) coating system with advanced multi-source sputtering and rapid thermal annealing. It has a distributed power architecture with an advanced digital sputtering power supply that has adjustable steering capability to provide a continuous plasma concentration while allowing the material composition to be precisely controlled. It utilizes an efficient low-power arc-suppression circuit that detects arc-like conditions and suppresses them immediately. The main chamber of the unit is made of aluminum-alloy and is designed for easy operation even in extreme conditions. It is equipped with a high-vacuum chamber for high-quality thin-film deposition and quick pump-down times. An integrated encoder is placed on the door for precise control of argon flow and closing of the chamber. It is also fitted with an OLED display to monitor the chamber conditions and make real-time adjustments. CVC 601 LL offers unique features such as an advanced arc detection machine, an adjustable power range with a peak current up to 20A, and an automatic substrate holder position control for evenly distributed coating. The tool offers a wide processing window for a variety of materials ranging from aluminum to gold and other exotic alloys. 601 LL has a lateral gas delivery asset that allows deposition of highly reactive materials such as oxides and nitrides. It offers a large area-coverage and uniformity control model to produce high-quality thin-films with minimal waste. In addition, CVC 601 LL is a reliable equipment that is backed by an innovative optical-acoustic system capable of visually and audibly providing accurate process control conditions, as well as on-board diagnostics and a hardware data logger. It also has an enhanced sputter cleaning unit and a hydrogen-free resistor coating for superior performance.

There are no reviews yet