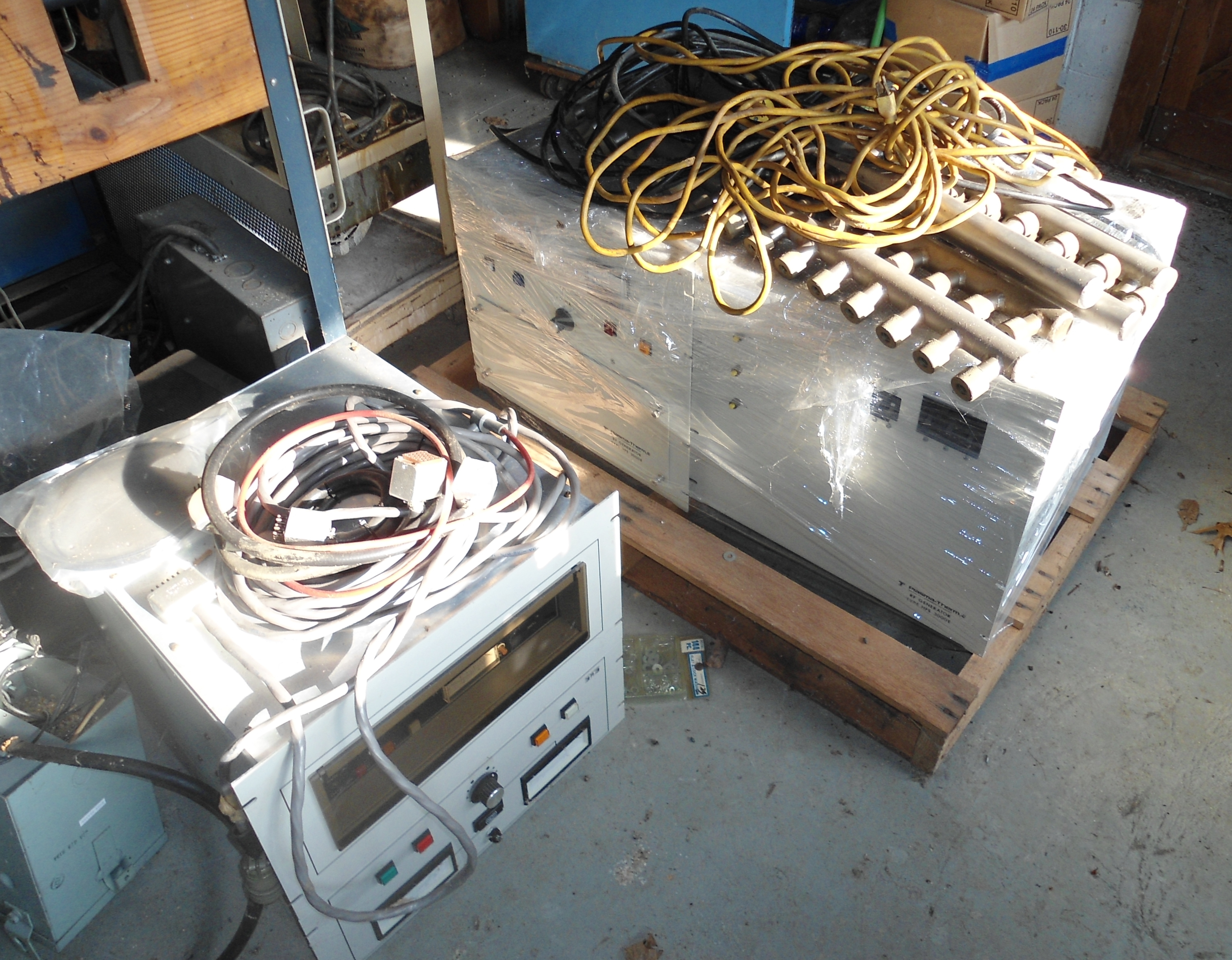

Used CVC 601 #78715 for sale

URL successfully copied!

Tap to zoom

ID: 78715

Sputtering system

Load lock

Chamber top plate assembly and hoist

Main pump chamber

Heavy duty hoist

Loadlock chamber with cassette

Roughing manifold

RF Etch assembly with matchbox

Rotostrate titanium table with pallets

Missing parts:

Center hub

Matchbox missing bias pickup.

CVC 601 is a reactive sputtering equipment used to deposit thin films of material onto a target surface. It uses cathodic arcs to generate dense plasma which, in turn, is used to create an ion bombardment on the surface of a substrate to be coated. The ions created during the sputtering process penetrate the surface of the substrate material and cause the atoms of the target material to attach to the substrate material. The result is a thin film of deposited material on the target substrate. 601 utilizes a dual target to generate a wide range of ions over a relatively large area. It has the ability to produce a greater deposition rate than single target systems due to its configuration employing both positive and negative electrode targets. The targets are composed of a base/constraint material and a coating material in a fractional arrangement. This unique arrangement allows for effective heat regulation and uniformity of deposition rate. CVC 601 also features an eddy current power supply (ECPS) system. This unit provides an in-situ control of the sputtering environment, allowing the user to fine tune the ion particles providing the target materials. This machine can also be used to maintain a given target temperature, assuring a superior deposition rate and uniformity of deposition. Another feature of 601 is its robust substrate architecture. The surface of the substrate is designed in a way to ensure a better cohesion of the deposited material with the substrate, as well as providing superior heat dissipation and uniformity of deposition. Furthermore, the substrate materials are designed to resist physical damage and contamination. CVC 601 is a highly efficient and reliable tool. It is capable of producing very uniform deposits with precise control of film thickness and uniformity of deposition. This asset is an ideal choice for deposition of materials on a variety of substrates. It is increasingly being used for precision coating of metals, semiconductors, oxides, and a wide range of compounds. Furthermore, its flexibility in controlling deposition rate and film thickness makes it a valuable tool for research and development.

There are no reviews yet