Used CVC 601 #9046395 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

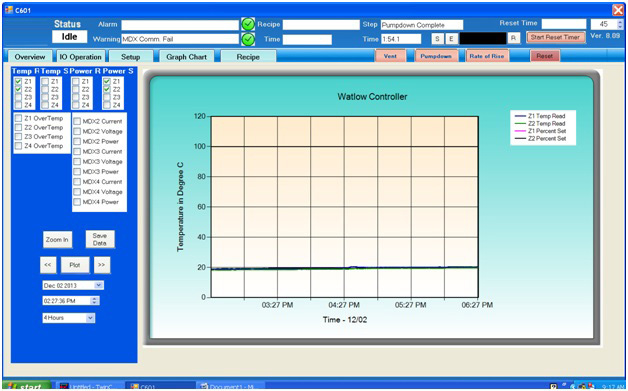

CVC 601 is a sputtering equipment designed to deposit various thin film materials onto a substrate. It features a unique structure in which the deposition target and the sample substrate are mounted on separate turntables—each adjustable to a multitude of angles. This allows for an even deposition of thin films on either curved or curved surfaces, making it an attractive choice for many vacuum deposition applications. The system consists of a process chamber, high-vacuum rotary pump and rotary joints, which provide the vacuum tight connections from the chamber to the sputtering sources. The target material is magnetically mounted to the target stand, which is adjustable to varying angles, allowing the target to be rotated for even deposition of films. The sample substrate is then mounted to a substrate holder, which is connected to the sample turntable. An adjustable turntable allows the sample to be rotated for even and uniform deposition of the films even on curved surfaces. In operation, the unit will pump down the process chamber until a predetermined vacuum level is reached. The sputter sources will then be powered and sputtered onto the substrate, creating the desired thin-film. The target angle and turntable speed can be adjusted to control the thickness and homogeneity of the deposited film. 601 also features a wide range of control and monitoring devices. These include a sample pressure monitor to monitor the process chamber pressure, and an emission monitor to monitor the level of carbon contamination in the sputter process. Other features include over-current protection, a digital readout of pump pressure and film thickness, a programmable timer, and manual override control. CVC 601 machine has been designed for use in many thin-film deposition applications, such as the production of optical filters, semiconductor devices, dielectric coatings, and diamond-like carbon coatings. Its unique design allows it to provide uniform, controlled deposition of thin-film materials without the need for complex post-processing. By providing reliable results and efficiency in a cost-effective design, it is an attractive choice in the thin-film deposition industry.

There are no reviews yet