Used DENTON VACUUM DESK II #9224511 for sale

URL successfully copied!

Tap to zoom

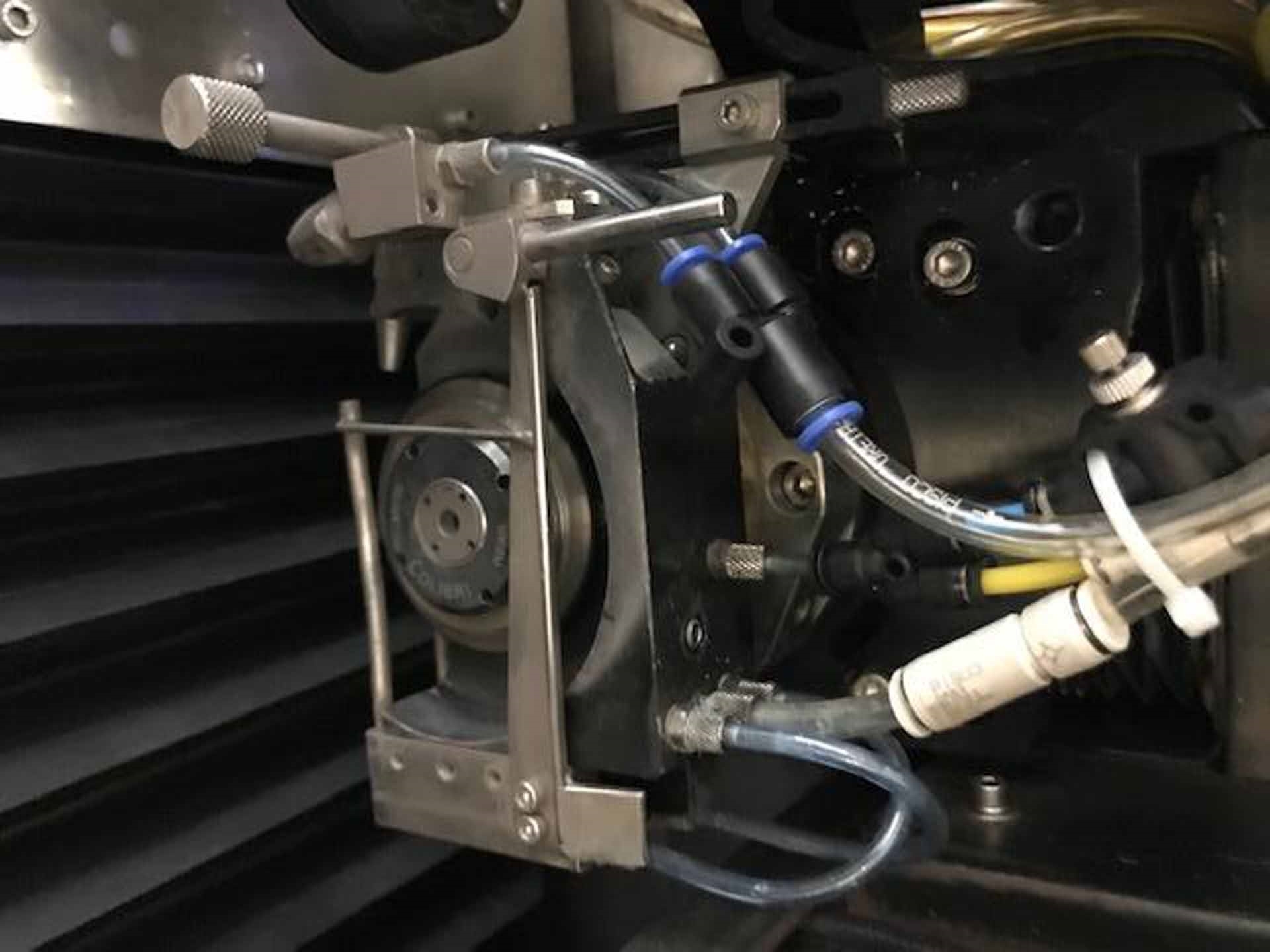

DENTON VACUUM DESK II (VD2) is an automated vacuum chamber sputter deposition equipment designed for intricate thin film deposition on a variety of substrates. This system is a valuable tool for performing application-specific coating processes, as it is ideal for precision thin film deposition work with unparalleled accuracy and reproducibility. The VD2 is constructed of three main modules: a control station, a source chamber, and a process chamber. Each of these modules is designed with user safety and ease-of-use in mind. The control station allows for session setup, graphical job mapping, and the ability to monitor the deposition in progress. This station utilizes a touchscreen interface that is easy to operate, allowing the user to operate the unit with minimal training. The source chamber contains two cylindrical chambers connected through a vacuum feedthrough; one chamber houses a source of inert gas such as Argon, while the other is used for substrate heating. A single rotatable substrate holder is used to transport individual specimens through the vacuum feedthrough chamber. The process chamber consists of a cylindrical chamber containing two independently-controlled electrostatic gun sources, two magnets, and a single RF sputtering source. These components are engineered to maximize the uniformity of the thin layer composing the film deposited onto the substrate. The process chamber also includes a cooled substrate holder to maintain process temperatures, as well as a quartz crystal pressure gauge for real-time monitoring of the machine pressure, allowing the user to make necessary adjustments for correct operation of the tool. The VD2 enables the user to generate high-quality thin films with features as small as 0.1 μm. This versatility makes it suitable for a range of applications, from device fabrication and nano-scale patterning to medical diagnostics and metrology. The asset is also equipped with a variety of source gases, making it suitable for a range of materials, such as metals, semiconductors, polymers, oxides, and nitrides. The VD2 also offers the advantage of highly repeatable deposition processes, maintaining process quality and reproducibility across a large scale of substrates and applications. This ensures reliable, consistent end-product quality, essential for precision thin film deposition tasks. The VD2 is an advanced, user-friendly sputtering model that can easily be integrated into any prototyping or research laboratory. With its advanced design and wide range of options, this vacuum deposition equipment provides superior accuracy and repeatability in thin film deposition technology.

There are no reviews yet