Used DENTON VACUUM Desktop #9070115 for sale

URL successfully copied!

Tap to zoom

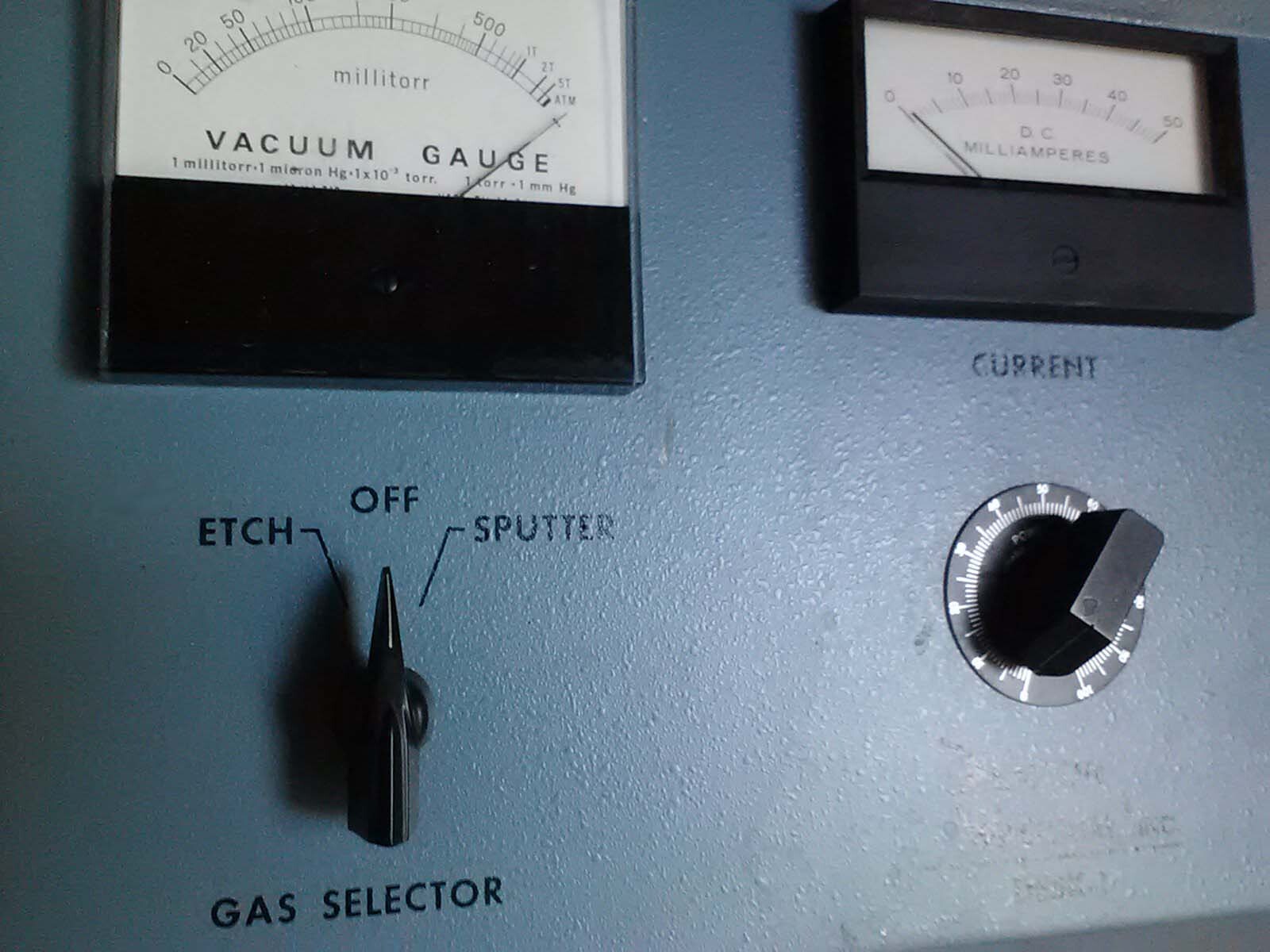

DENTON VACUUM Desktop (DVTD) is a sputtering equipment designed to facilitate a complete vacuum thin film coating process. It can be used in applications such as thin film electronics, hard coatings, optical thin films, and many more. DVTD consists of a sputtering chamber, a cathode assembly, and an adjustable target. The sputtering chamber is made of stainless steel and features an innovative double wall design. This design creates a durable, high-vacuum static atmosphere, providing an optimal sputtering environment. The chamber is also equipped with a vacuum gauge to measure the pressure, a safety valve, and an exhaust outlet. The cathode assembly is a critical component of the sputtering process and is made of a copper mesh material. This allows it to provide a uniform distribution of magnetic field that is essential for uniform sputtering. It is connected to a power supply that can be controlled to adjust its intensity and is equipped with a magnetic shield to protect the target from possible magnetization. The adjustable target ensures a uniform thickness of material deposited on the substrate. It is made of stainless steel and is designed to be easily moved up and down in order to adjust the distance between the cathode and the substrate. The target can also be shifted in an "L" shape, which allows it to be turned in any direction for easy control over the direction of the flux. To ensure good coating performance, DVTD is equipped with a number of protective features. It is provided with a water-cooled system to ensure efficient heat transfer and prevent thermal damage. The unit is also designed with ground fault and over-current protection, as well as an emergency switch to shut off the power in case of a hazardous situation. Overall, Desktop is an effective sputtering unit that facilitates the entire vacuum thin film coating process. Its innovative design provides a durable, high-vacuum static atmosphere, suitable for uniform sputtering, while its adjustable magnetic shield enables precise control over the direction of the flux. The numerous protective features incorporated into the machine also ensure that the coating process runs both safely and efficiently.

There are no reviews yet