Used ENERJET KJL-HV-268-A #9122382 for sale

URL successfully copied!

Tap to zoom

ID: 9122382

Sputtering system

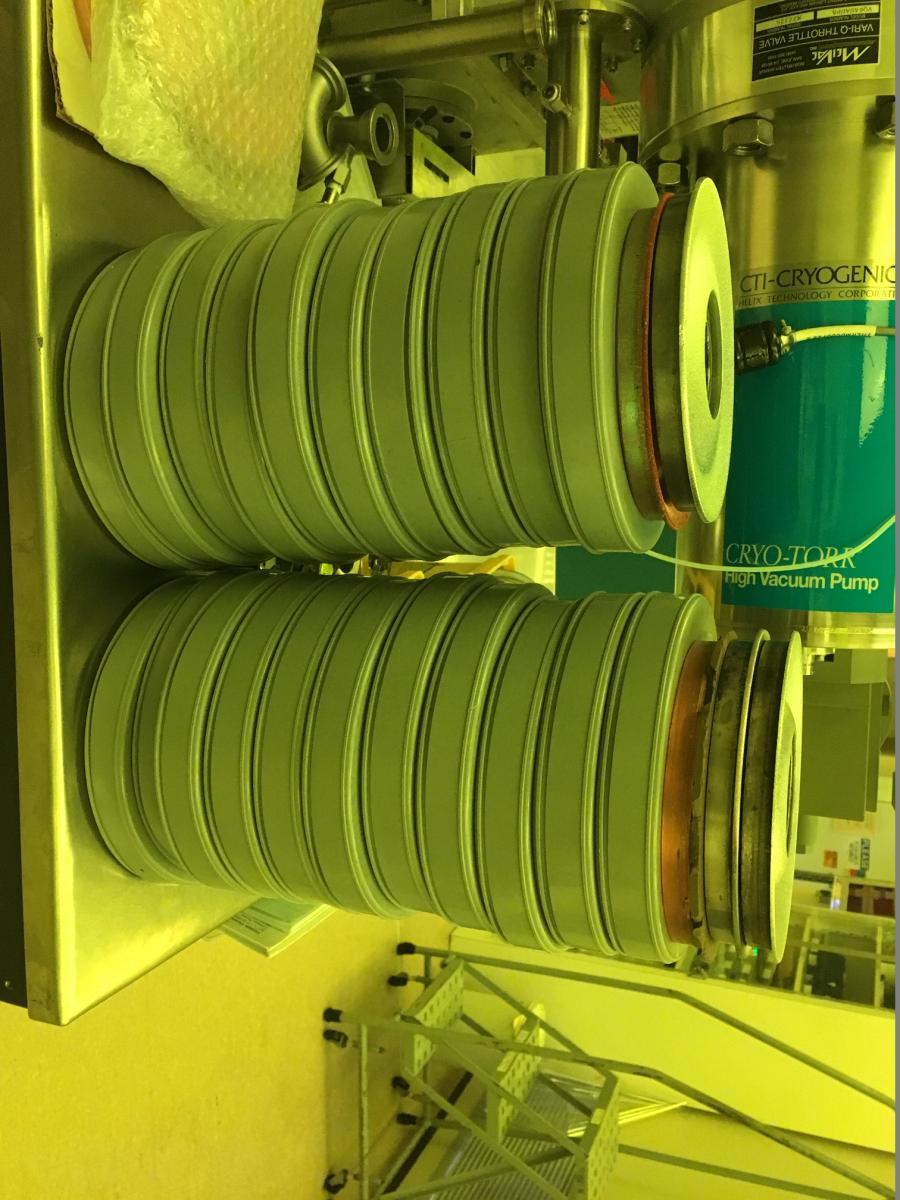

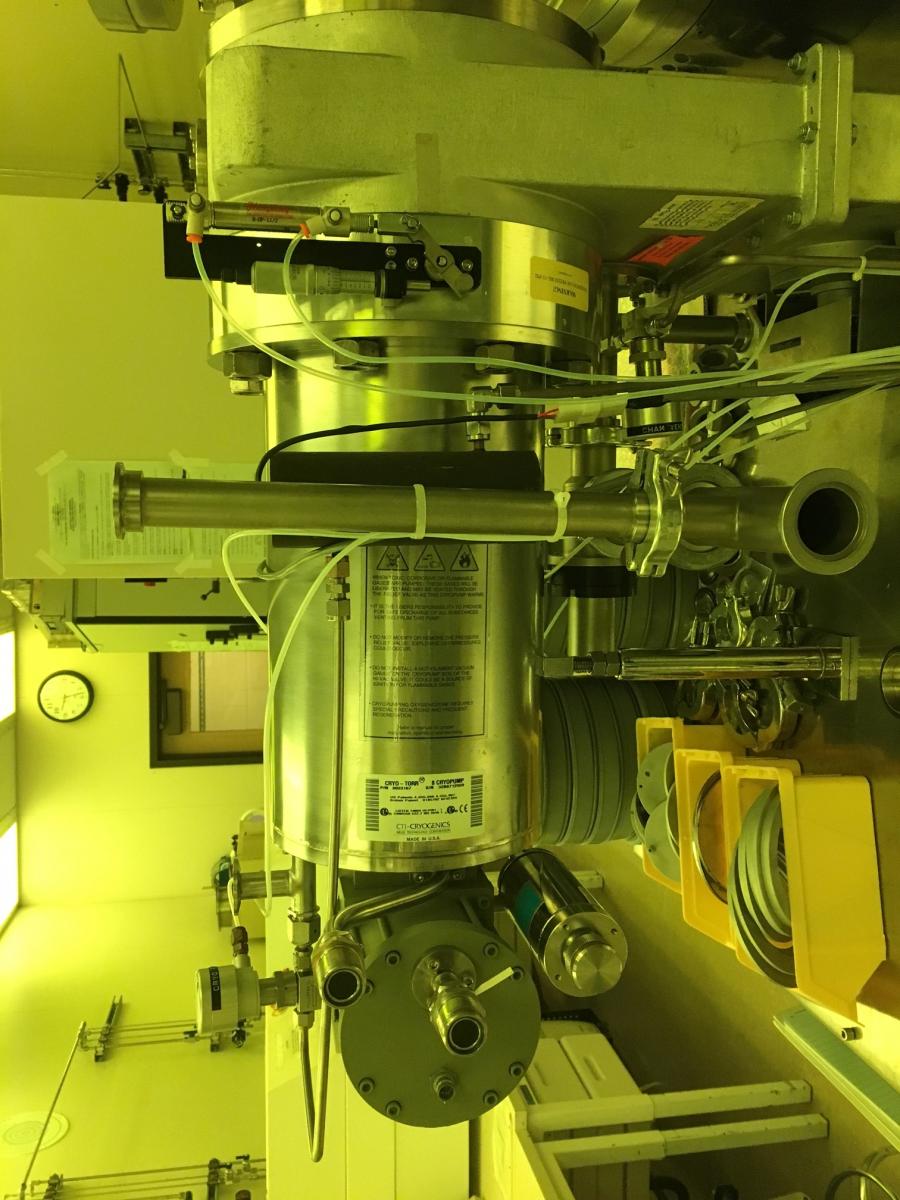

Targets: Torus-10

Chamber: ~28" round vacuum, 14" H

(4) Ports in floor of chamber (3 filled with Torus-10 sputtering sources)

Front viewport

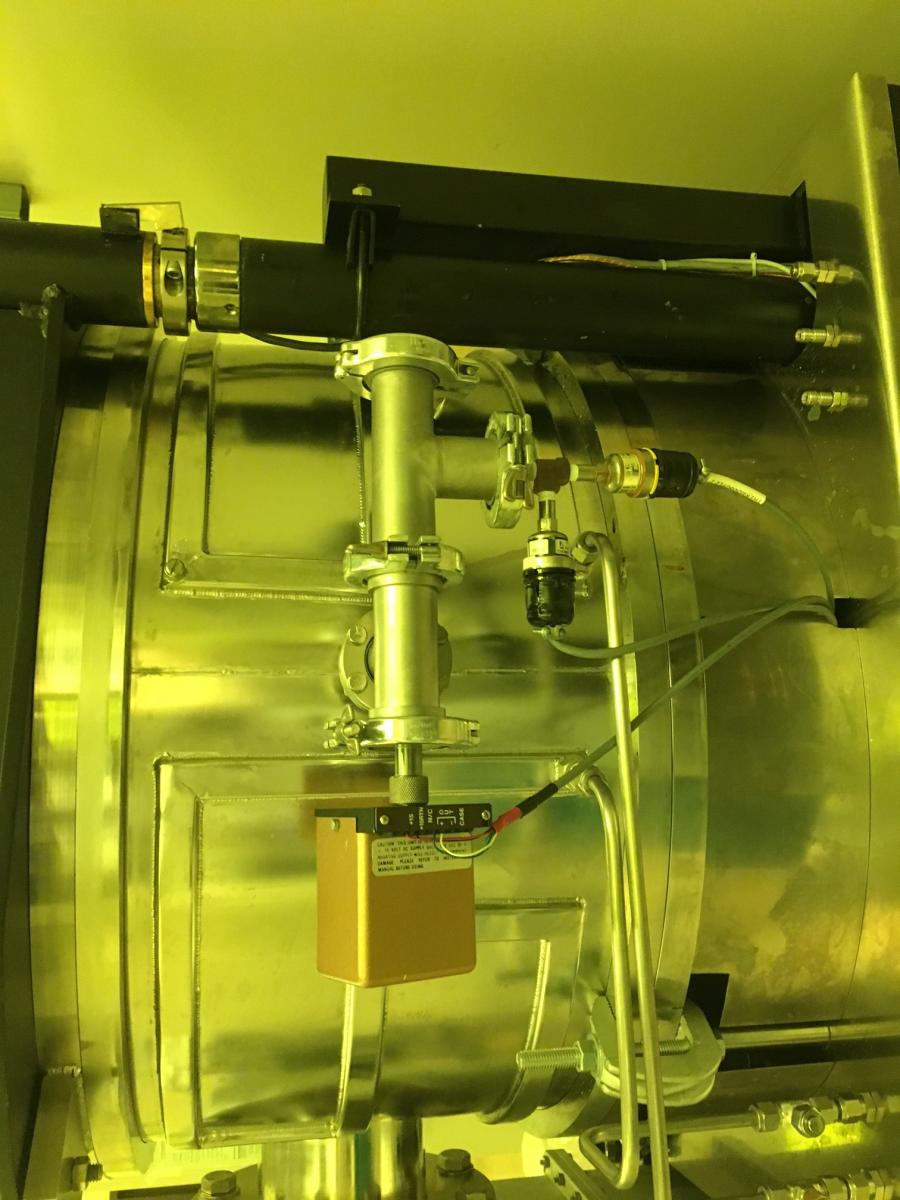

Rear connections for rough lines and gauges

Side mounting for cryo pump

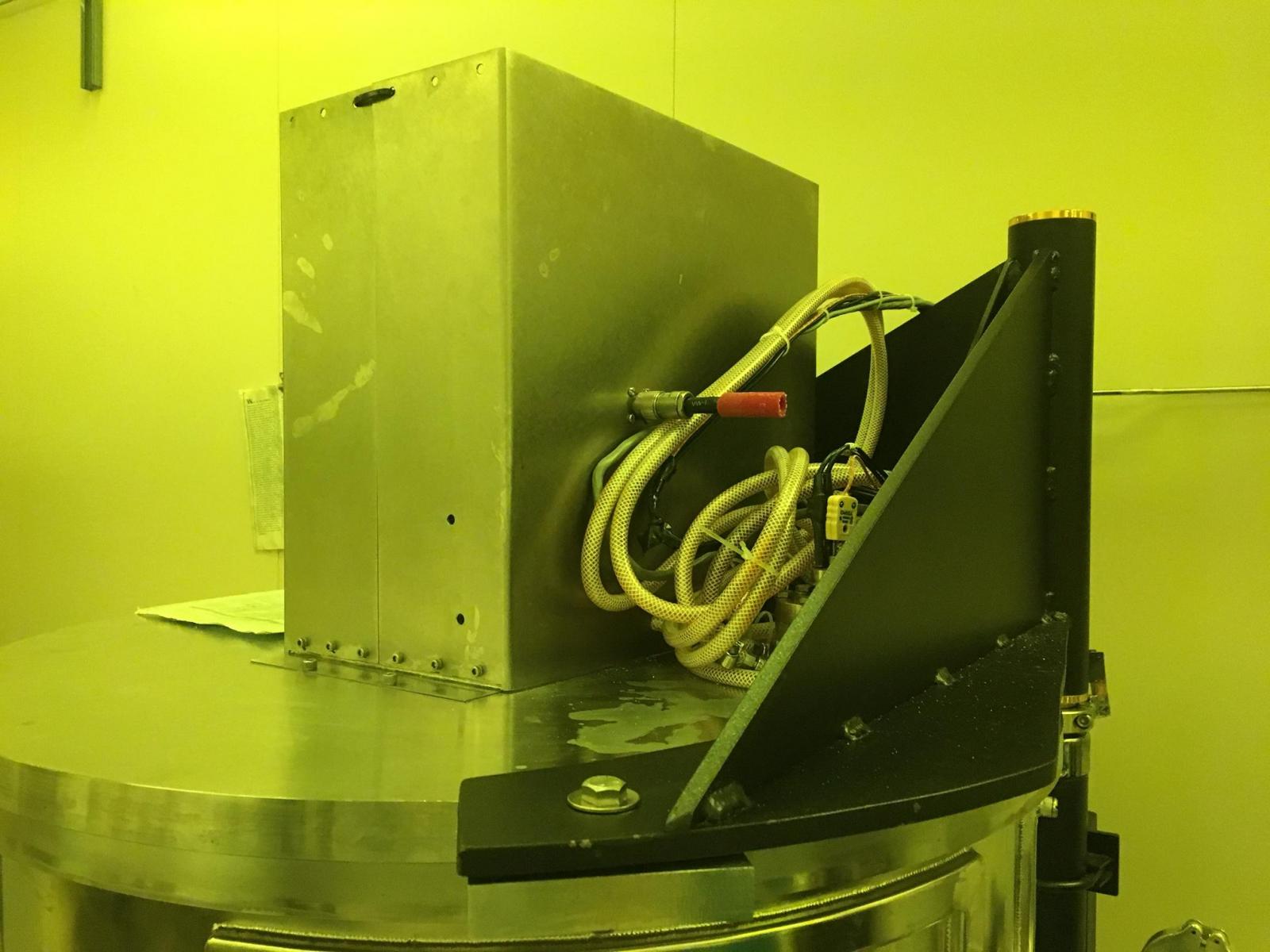

Chamber lid with lifter has a 8 x 4" wafer plate mounted to it on a rotary feedthru

Motor connected to motor controller that spins at 0-24 RPM

CTI-8 Cryo pump

Compressor not included (cables & hoses included)

Tool pumps to 8x10-6 in 2 hours, upper 10-7 overnight

Cryo has a gate valve and a conductance control valve (multivane, micrometer at stop to throttle back pumping)

(3) Sputter sources

(1) Connected to DC power supply: (1) Eratron

(1) RF: not connected

Targets available: Al, Al/Si (0.5, 1, 2%) C, Cr, Cu, Mo, Si, SiO2, Si3N4, Ta, Ti, TiN, W, W-Ti, WC and Y in various states of use

Tool has systems to run:

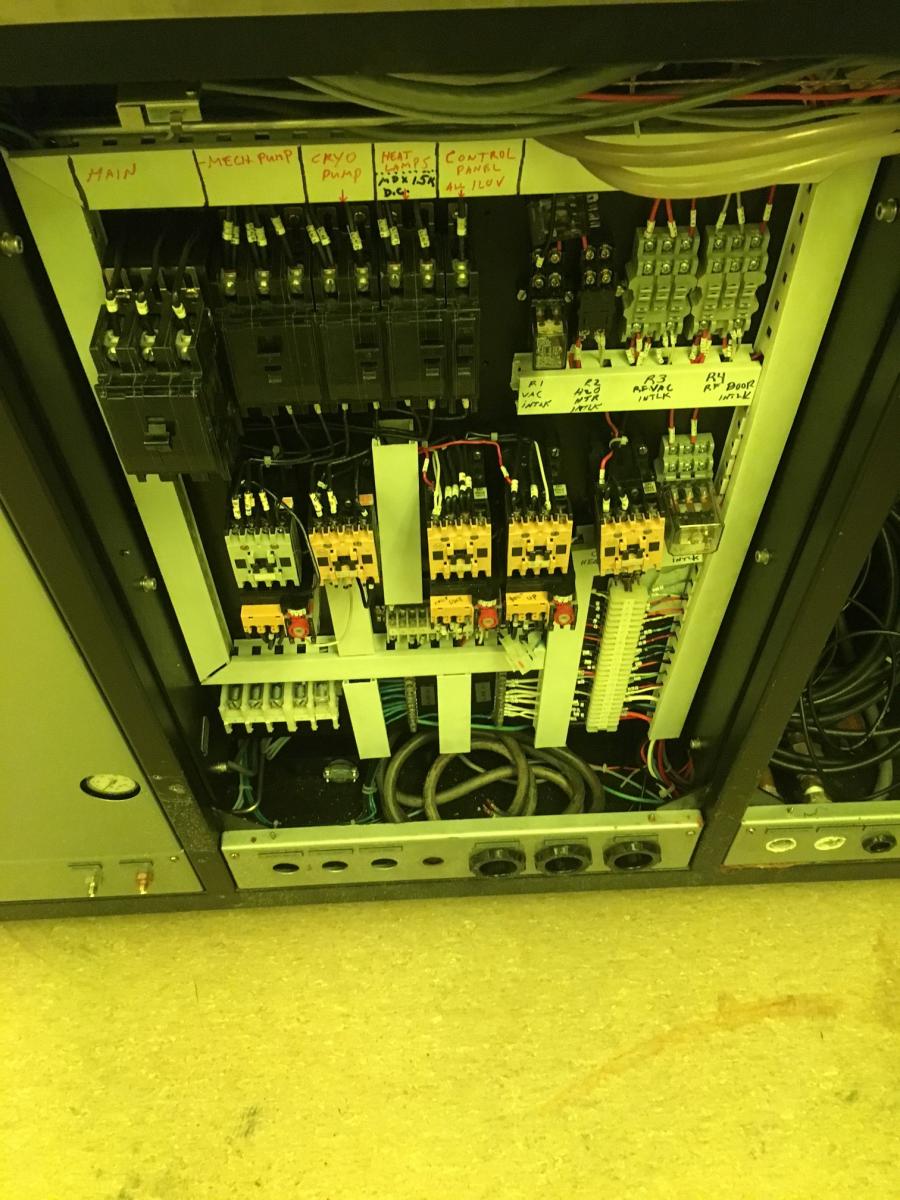

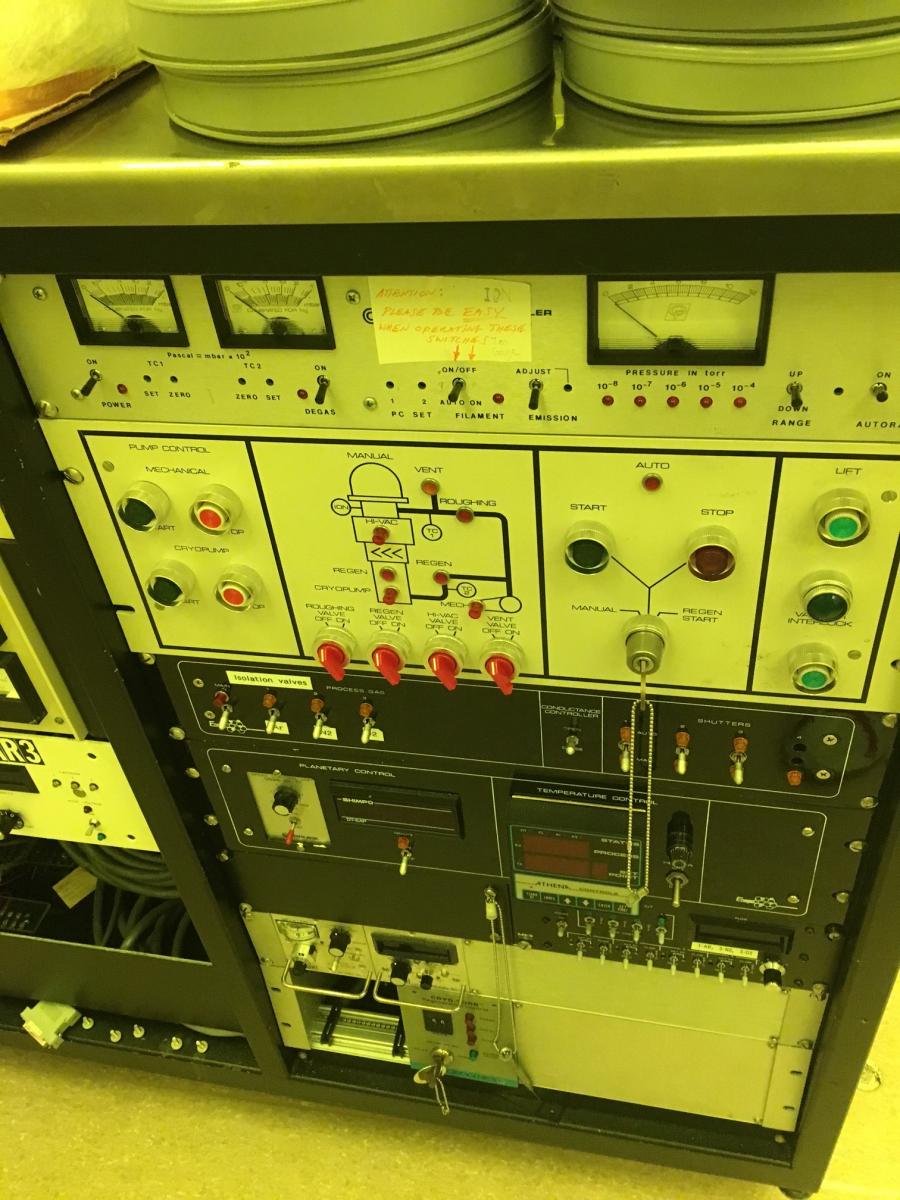

Pump controller to control power to pumps and crossover to high vac

Gauge interface and baratron, convection and ion gauges

Flow controller for MFCs (100 SCCM Ar, O2, N2) that can be slaved to pressure or ratio'd

Cryo controller and cryo temperature gauge

Heater controller but heating element has been moved

Rotation controller

Water flow system, valves and flow switches

Interlocked cabinet

Fixturing for 4", 3" wafers

(2) Chamber shields that can be cleaned (floor of chamber is only part that is not cleaned)

Currently in cleanroom.

ENERJET KJL-HV-268-A sputtering equipment is a high-performance sputtering device designed for the deposition of thin films of atoms and molecules on surfaces. The system consists of a three-source multi-cathode sputtering gun, combined with a high vacuum chamber with an integrated pressure regulation unit for controlling the machine's working environment. The gun has a built-in chamber to deposit sputtered films with an adjustable substrate holder that permits a wide range of applications. The tool features an innovative and advanced high-vacuum chamber that is designed to be efficient, safe, and easy to use. It utilizes a magnetic levitation asset, which dynamically balances the pressure inside the chamber and ensures uniform film deposition. A built-in chamber pressure regulator allows the user to precisely and reliably control the working environment. The sputtering cathodes deliver uniform, low-energy ions to the surface to be sputtered, preventing the production of contamination and eliminating the need for burning-in and initially cleaning the substrate. KJL-HV-268-A sputtering model is ideal for the deposition of a wide range of metals, alloys, oxides, and other materials. Thanks to its variable geometry and pulse frequency, the equipment can be used to layer or etch materials down to a thickness of a few angstroms. The substrate holder is adjustable and can accommodate substrates up to 12" x 12" in diameter. It is also capable of sputtering layers at different angles, allowing for the production of multi-layered films. The system features a convenient digital control interface, with inputs for external control. This makes it easy to automate the unit and integrate it into existing systems. The high-vacuum chamber is water cooled, saving on operating costs, and has a safety crosslock, locking the door when the vacuum chamber is in operation. It also has diagnostic alarms and controls so that the user can pay attention to safety protocols while running the machine. ENERJET KJL-HV-268-A sputtering tool offers the ultimate in productivity, speed, and precision. With its advanced features and reliable performance, it is an excellent choice for high-quality sputtered thin-film deposition.

There are no reviews yet