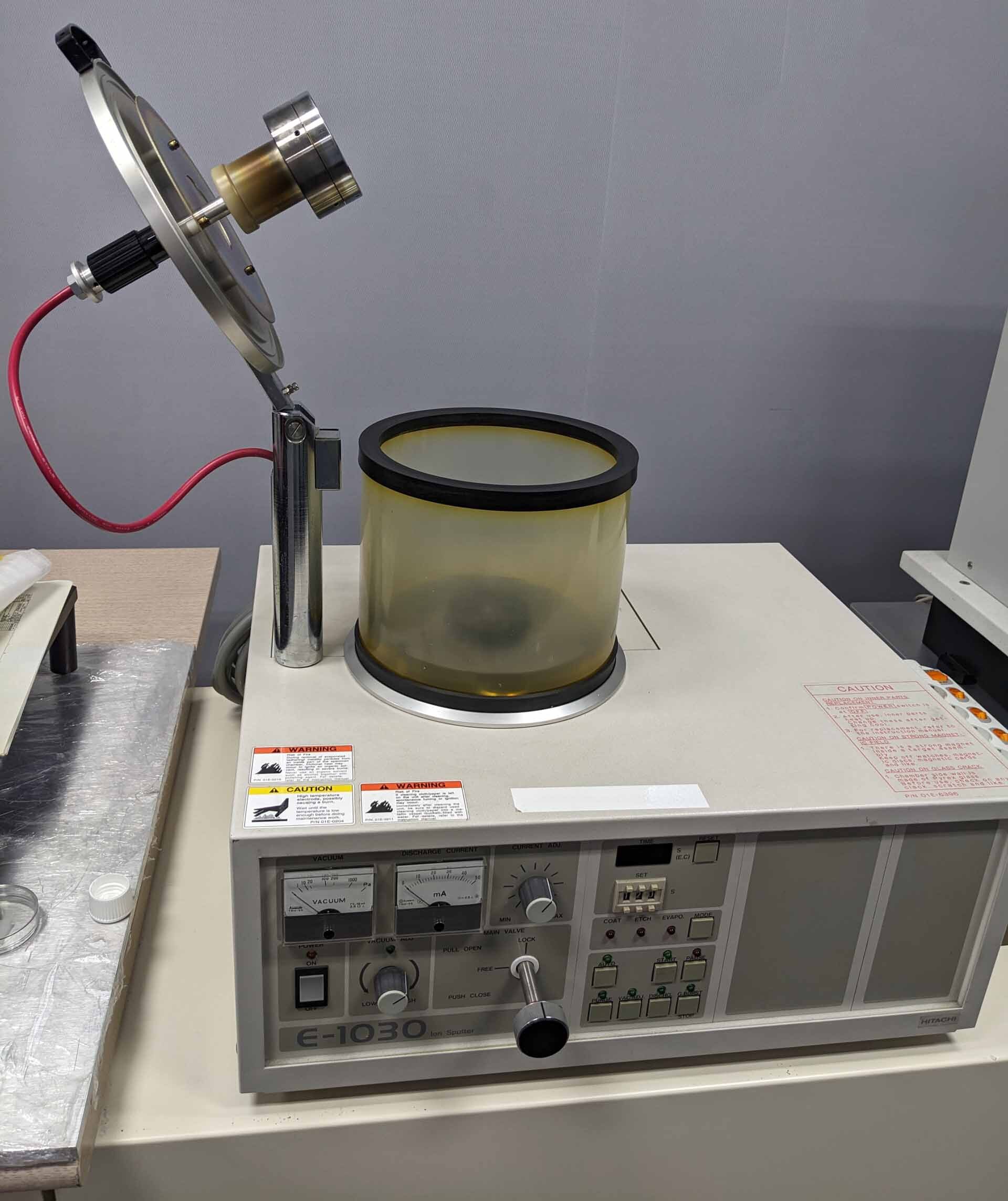

Used HITACHI E-1030 #293671277 for sale

URL successfully copied!

Tap to zoom

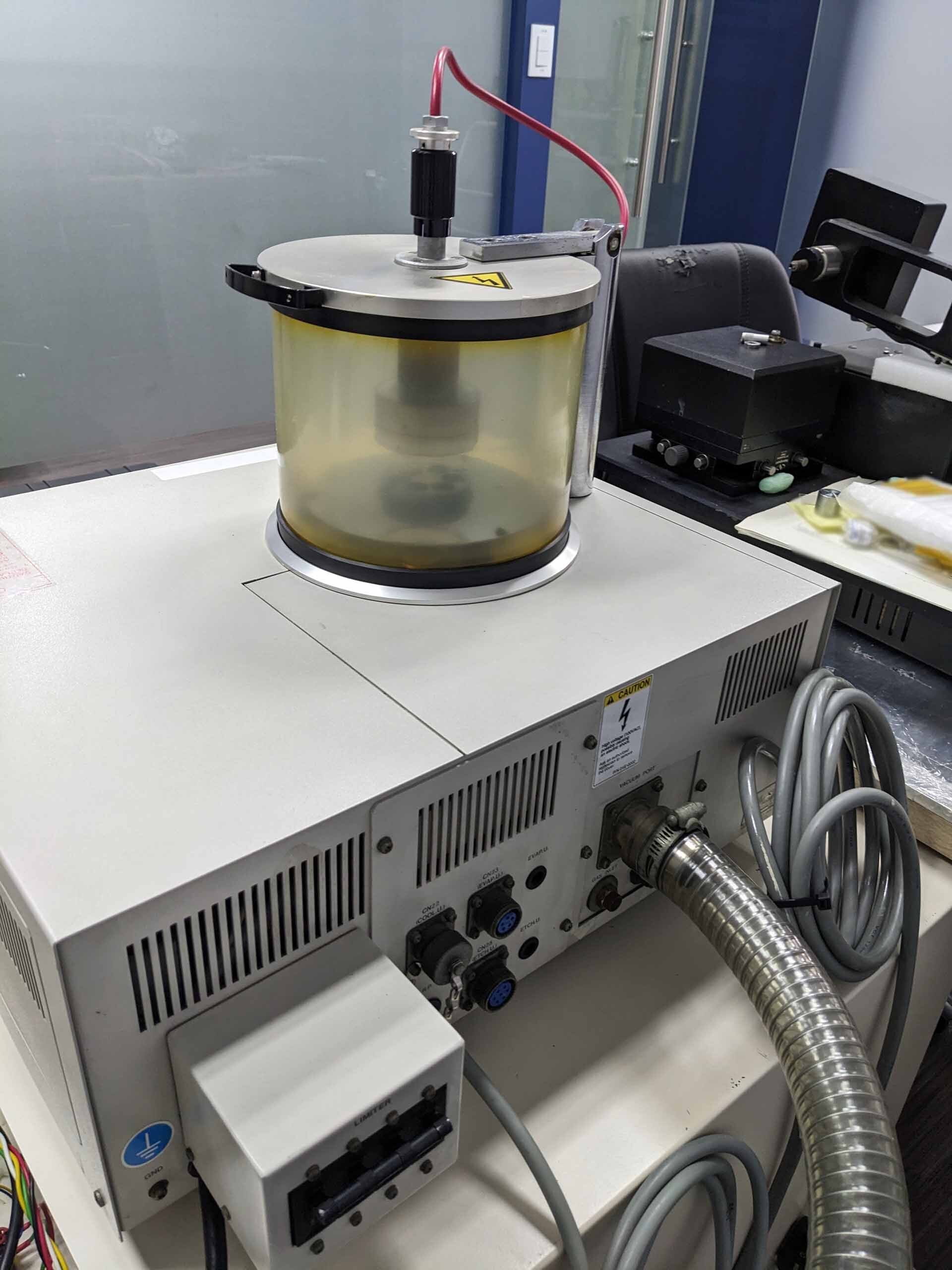

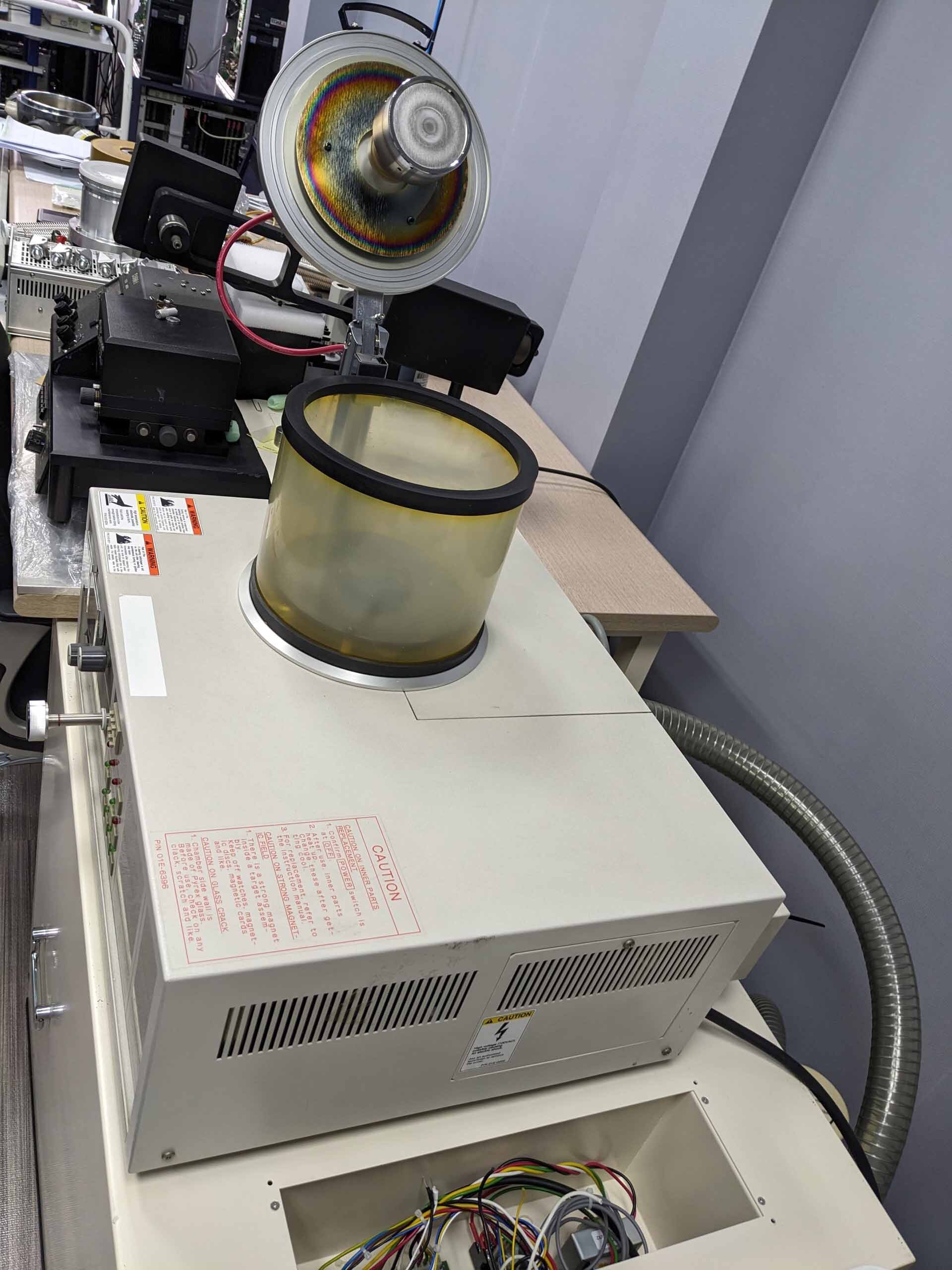

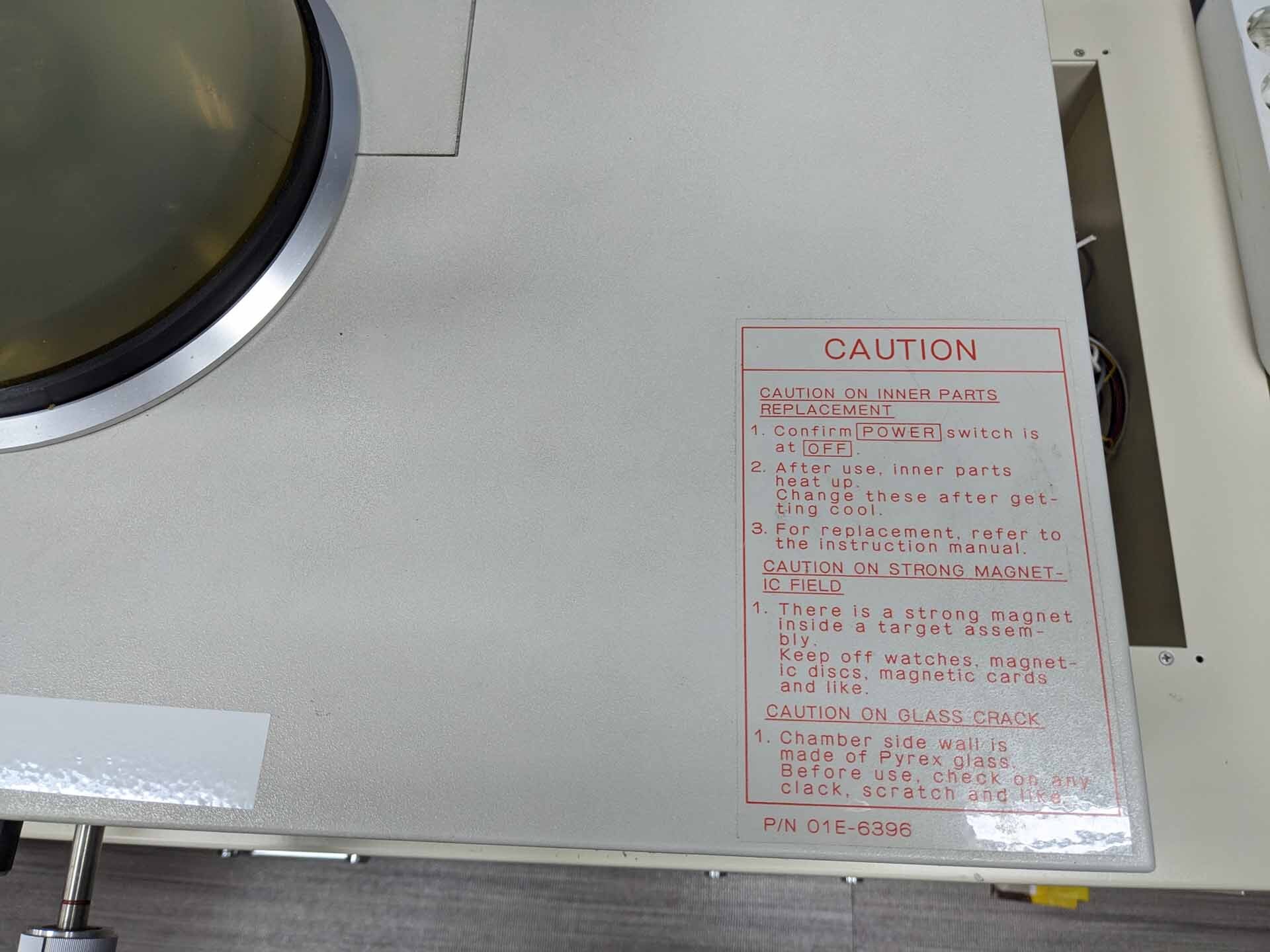

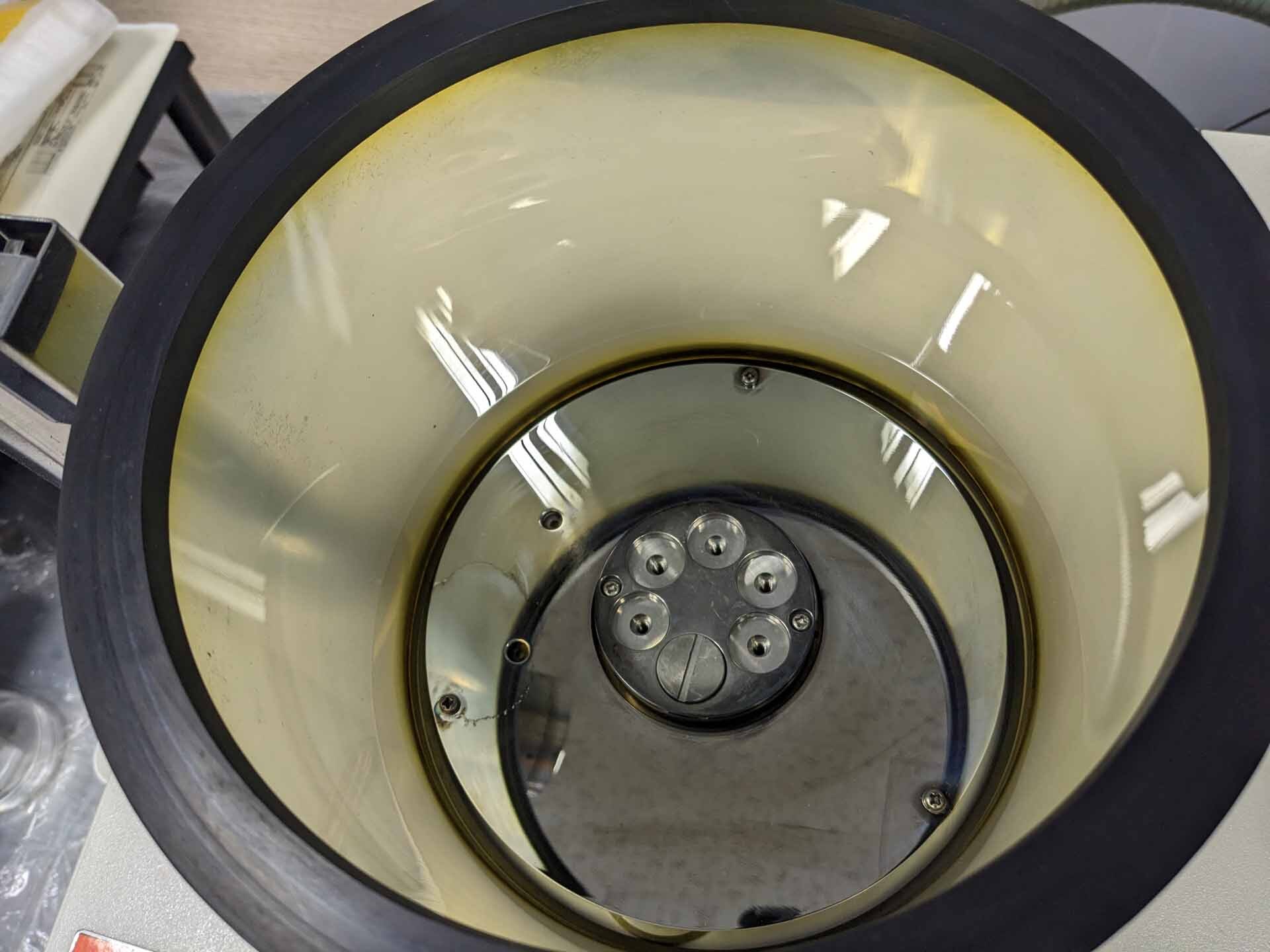

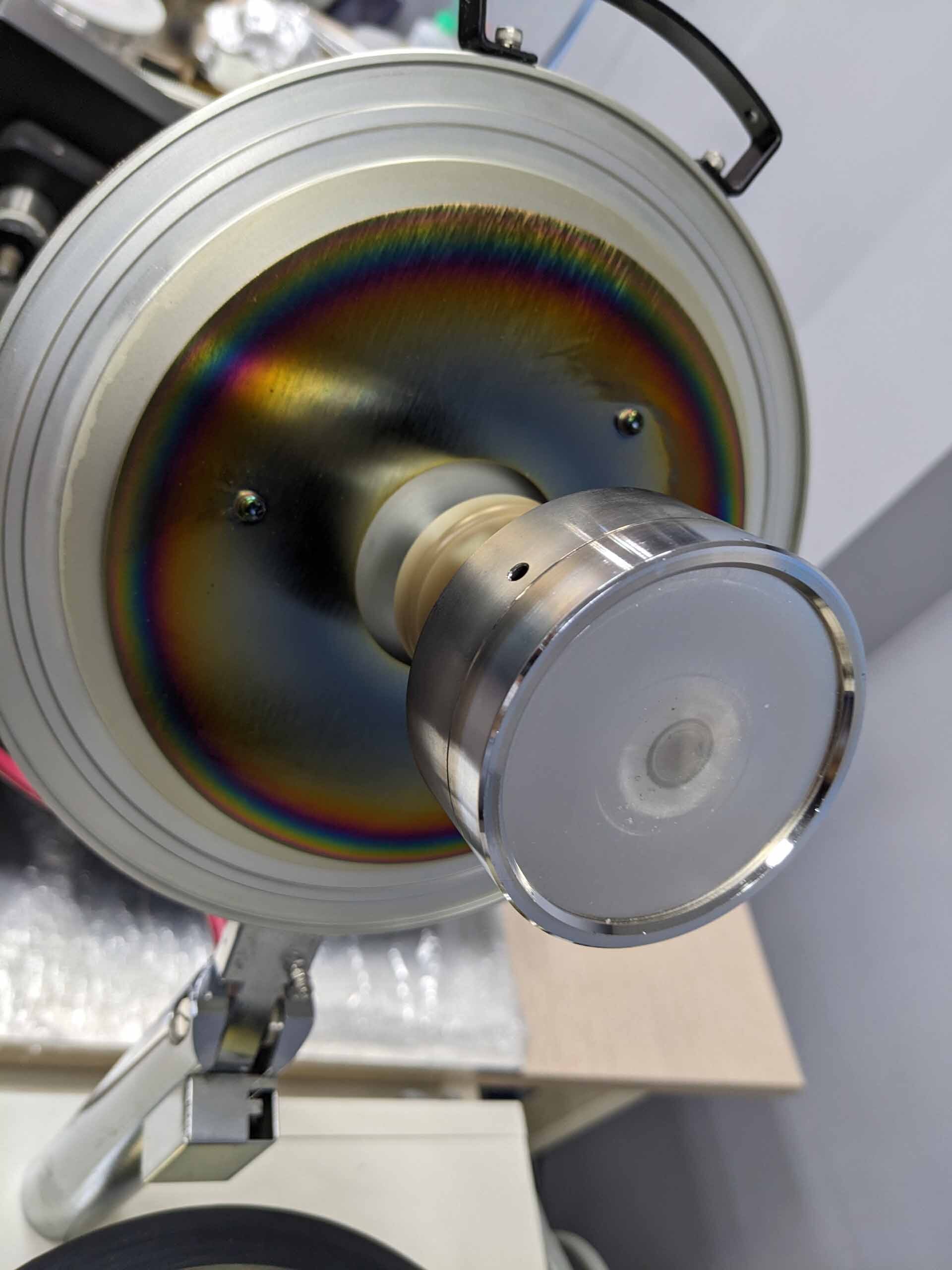

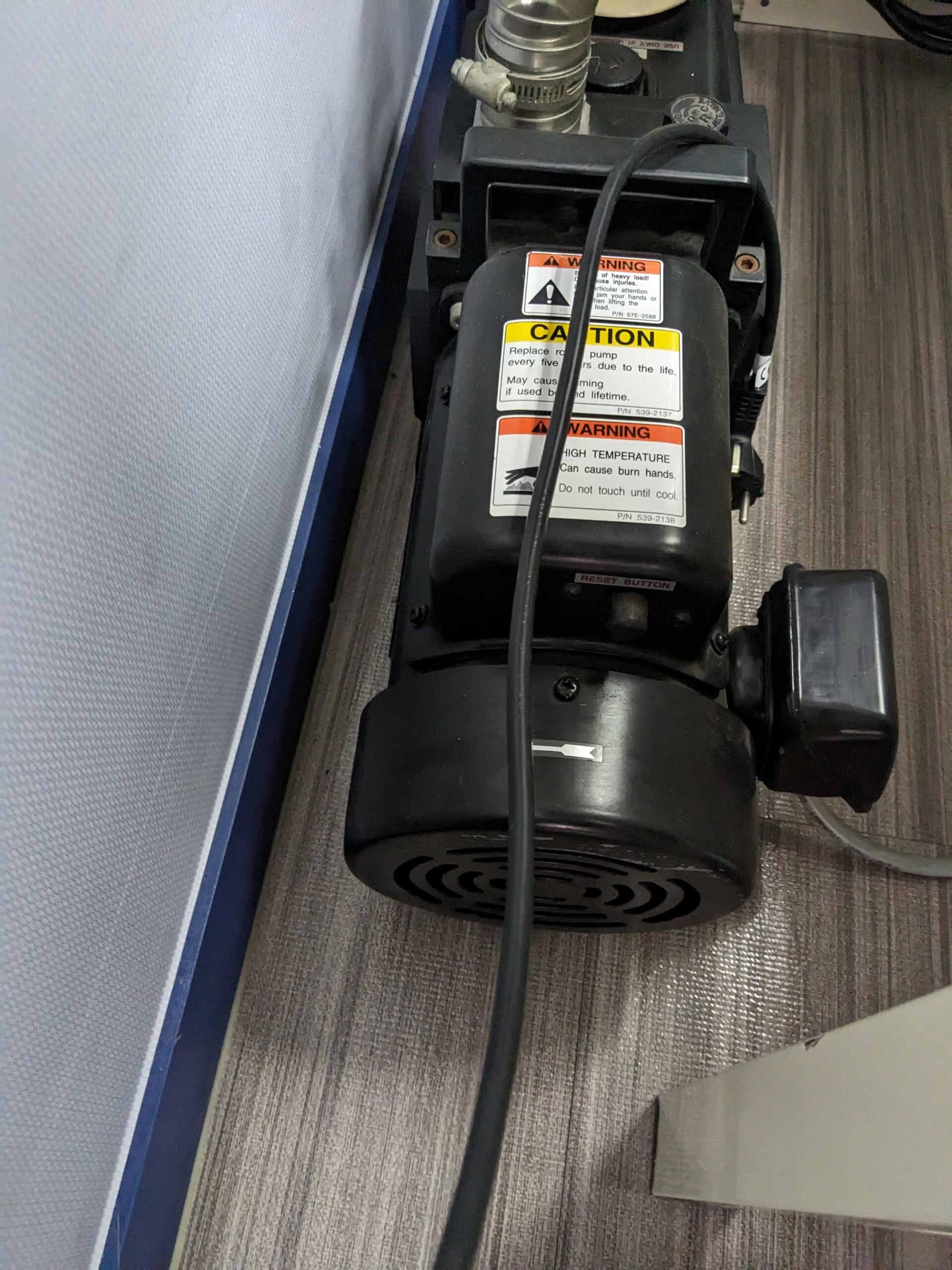

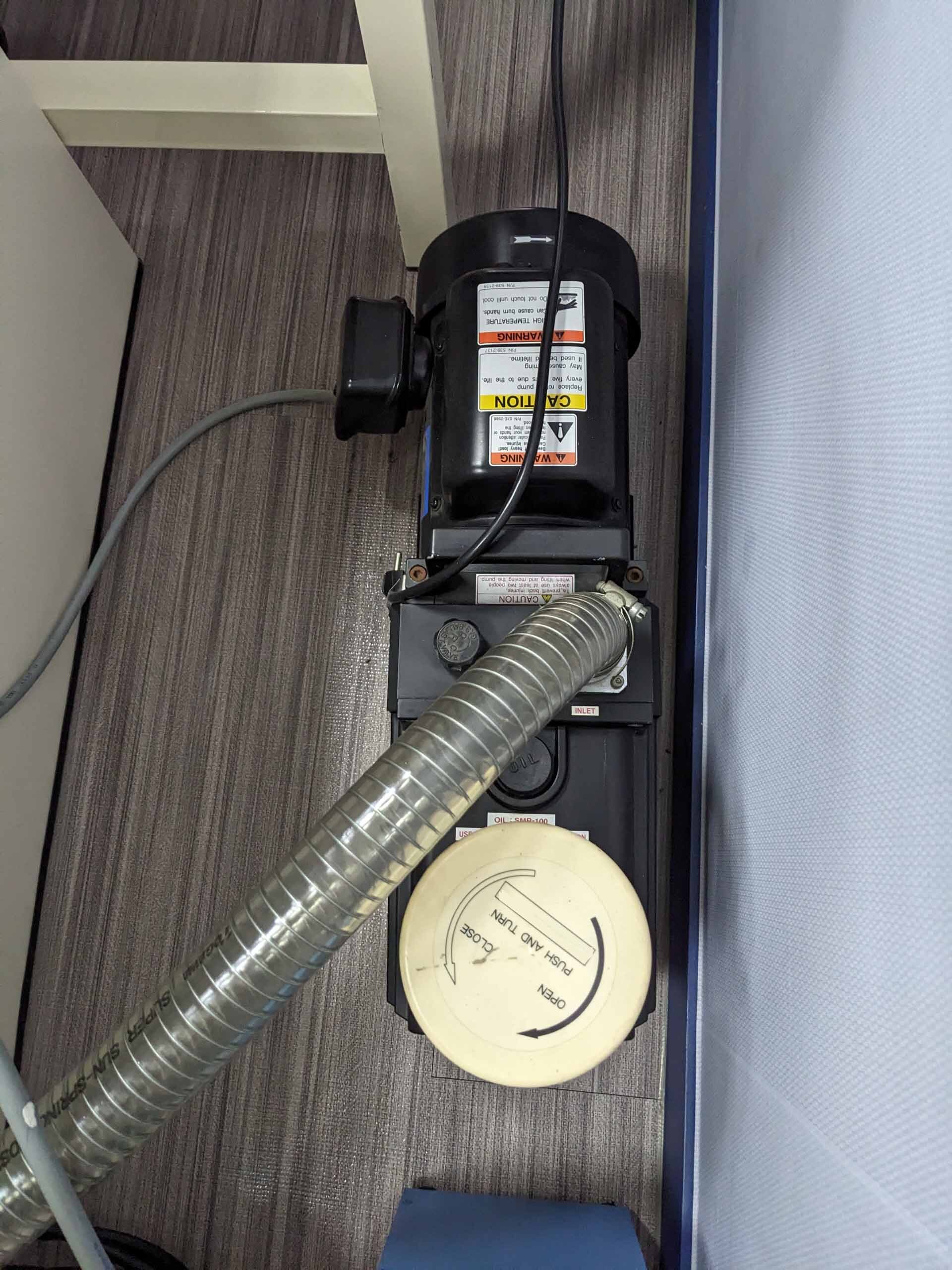

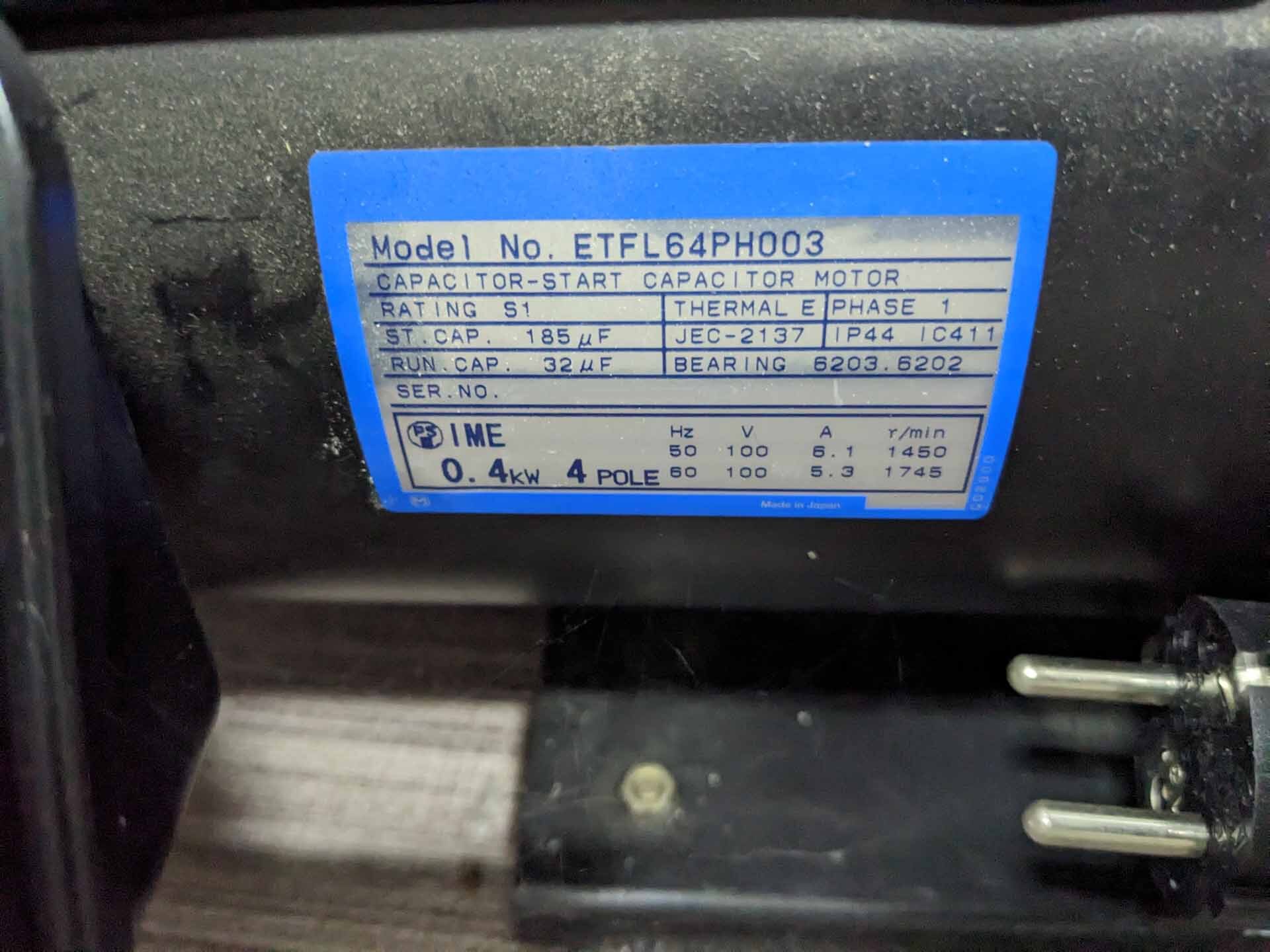

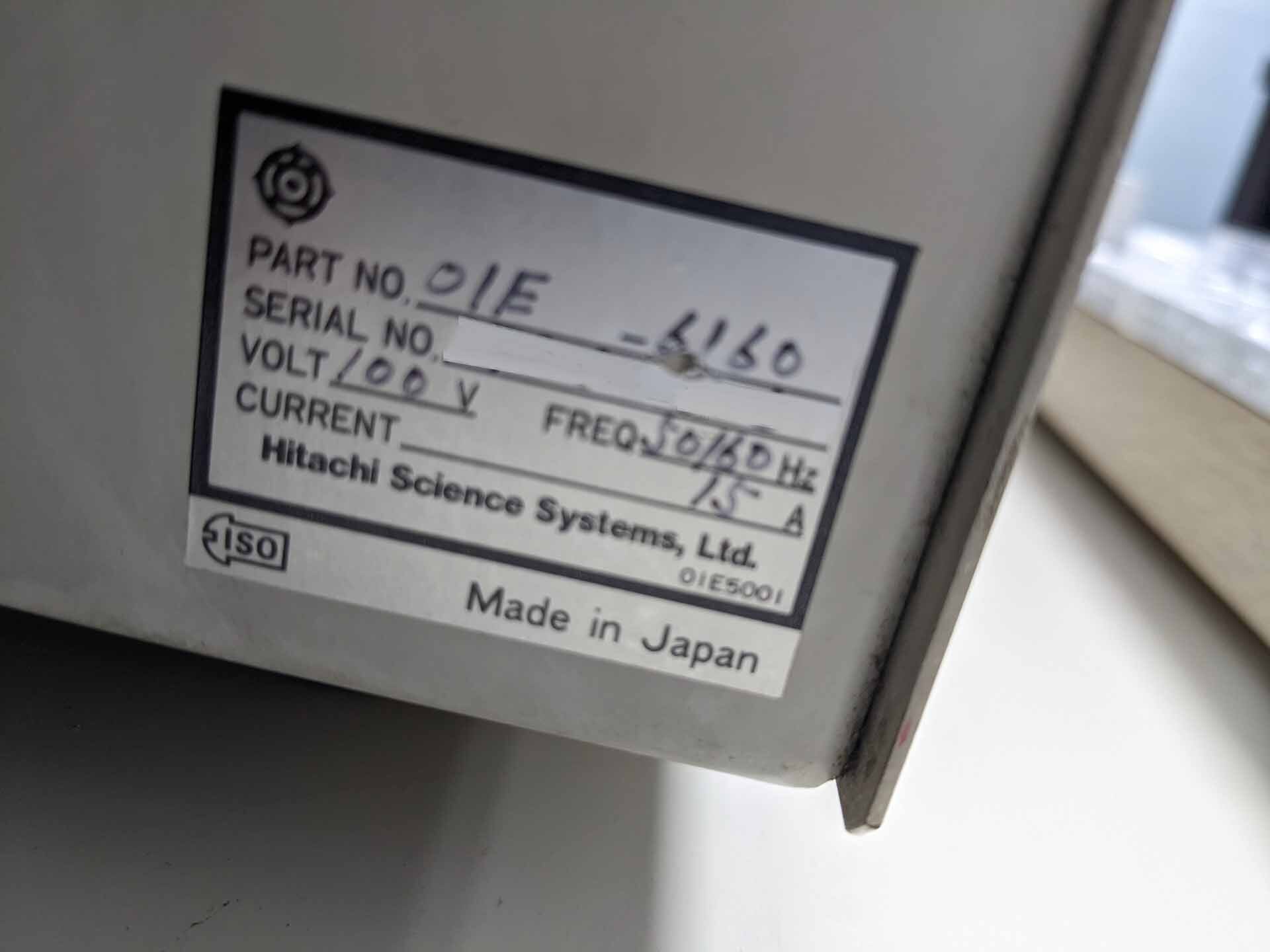

HITACHI E-1030 is a sputtering equipment designed to enable the deposition of thin-film materials, such as metals, oxide, nitride, and diamond-like carbon (DLC), onto substrates in order to create thin-film devices such as optical coatings, data storage media and electronics. The system consists of a vacuum chamber, a sputter gun, an electron beam gun, a nitrogen precursor source, a gas inlet unit, and a mechanical pump machine. The vacuum chamber of E-1030 is oval-shaped and is coated with nickel and aluminum. It is fitted with a four-way viewport for observation and cleaning purposes. The chamber contains an array of electrodes and an inflatable bag to hold the substrate. The substrate can be heated through resistive heating and has a range of temperatures from room temperature to 1,000 degrees Celsius. The sputter gun of the tool works by bombarding the substrate with argon ions. These ions bombard the substrate, causing atoms of the target material to be ejected. This process is known as sputter sputtering and is widely used for the deposition of thick films. The gun also offers an anodic arcing process which is useful for increasing the uniformity of the film deposition. The electron beam gun of the asset is designed to enhance the sputtering process. By sending a beam of electrons at the substrate material, the gun helps to increase the total deposition rate of the film while minimizing film thickness non-uniformities. The nitrogen precursor source is designed to add nitrogen to the film being deposited in order to create a nitrogen-rich nitride film. This film is highly desirable in the electronics industry because it has higher dielectric strength and resistance to corrosion. The gas inlet model of HITACHI E-1030 is designed to allow for the introduction of various gas species into the chamber. The equipment consists of two gas inlets and two separate lines for each gas. This allows for different gas mixtures to be accurately mixed, allowing for the creation of specialized films. The mechanical pump system of the unit is designed to maintain the chamber's desired vacuum level during the entire deposition process. The machine uses two rotary vane pumps and a backing pump in order to achieve the desired vacuum level. The backing pump is used to maintain the pressure, while the rotary vane pumps are used to evacuate the chamber and maintain the required vacuum level. E-1030 is a reliable and efficient sputtering tool, allowing for the deposition of highly uniform thin-film material onto substrates. Its combination of sputter gun, electron beam gun, nitrogen precursor source, gas inlet asset, and mechanical pump model make it an ideal tool for the deposition of thin-film structures.

There are no reviews yet