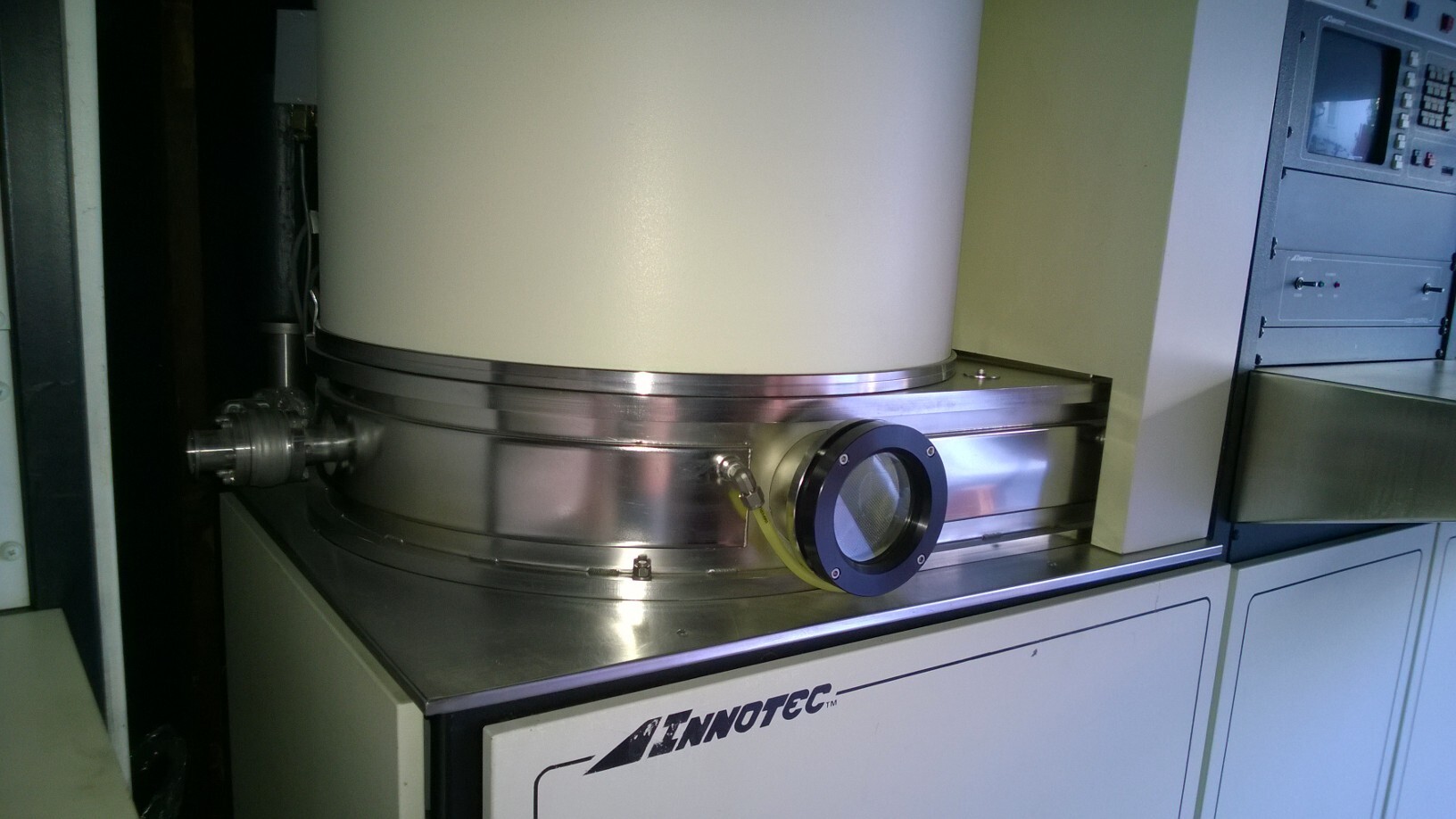

Used INNOTEC VS-24C #9097901 for sale

URL successfully copied!

Tap to zoom

ID: 9097901

RF Magnetron deposition systems

Chamber: 24" dia x 12" H

Dual 19" instrument rack

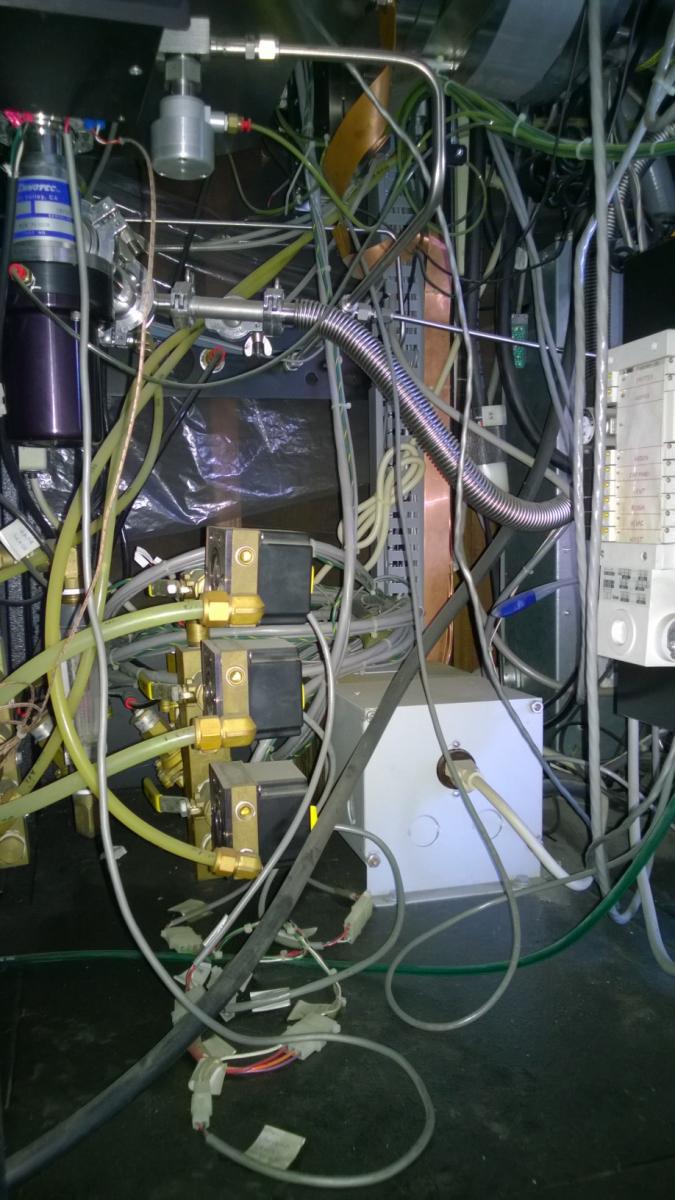

CTI Cryo-Torr 8 cryopump

Side mounted

High conductance valve

CTI 8300 Compressor with 8001 controllers

RF Power supply: 2kW Matching system as bias

(1) 14" Magnetron source with R match system and Al2O3 target

MKS Vacuum gauges valve and process control systems

Temperature and thickness control

Electro pneumatically actuated valves

VCS Vacuum system controller

VSC Sense analog and digital signals RS-232

Load lock system not included.

INNOTEC VS-24C is a high-performance sputtering equipment used in thin film coating applications. It is designed to provide uniform films over large areas and has the capability to deposity thin films on a wide range of materials including metals, oxides, nitrides, and alloys. The sputter gun consists of an anode electrode, an enerVac vacuum port, an insulation coating, and a target holder. A high-voltage pulse is applied to the anode, which energizes and generate ions from the target material and accelerates them towards the substrate. The ions strike the substrate and deposit the target material as a thin film. The sputter gun can be operated in either DC (direct current) or RF (radio frequency) mode. In DC mode, the ions are accelerated continuously, while in RF mode, the ions are accelerated in a pulsed fashion. The system has a patented ion source with magnetic field assisted uniform plasma distribution, which has improved the uniformity of the thin films. The RF source size can also be adjusted according to the size and shape of the application to further improve the uniformity of the thin films. The unit is equipped with a load lock and supports a range of substrates up to 8" in diameter and 4" in height. It has a 4" target holder with an option of front or rear loading. The substrate holder can be heated up to 200°C. The machine is designed with thermally controlled walls to reduce heating of the substrate, reducing thermal stress on thin films. It also has an emergency stop tool to prevent asset damage due to extreme power surges. VS-24C is a modular model and can be easily integrated with other modules for plasma etching, ion cleaning, and other plasma-related processes. It is well suited for thin film coating applications in automotive, medical, and electronic industries.

There are no reviews yet