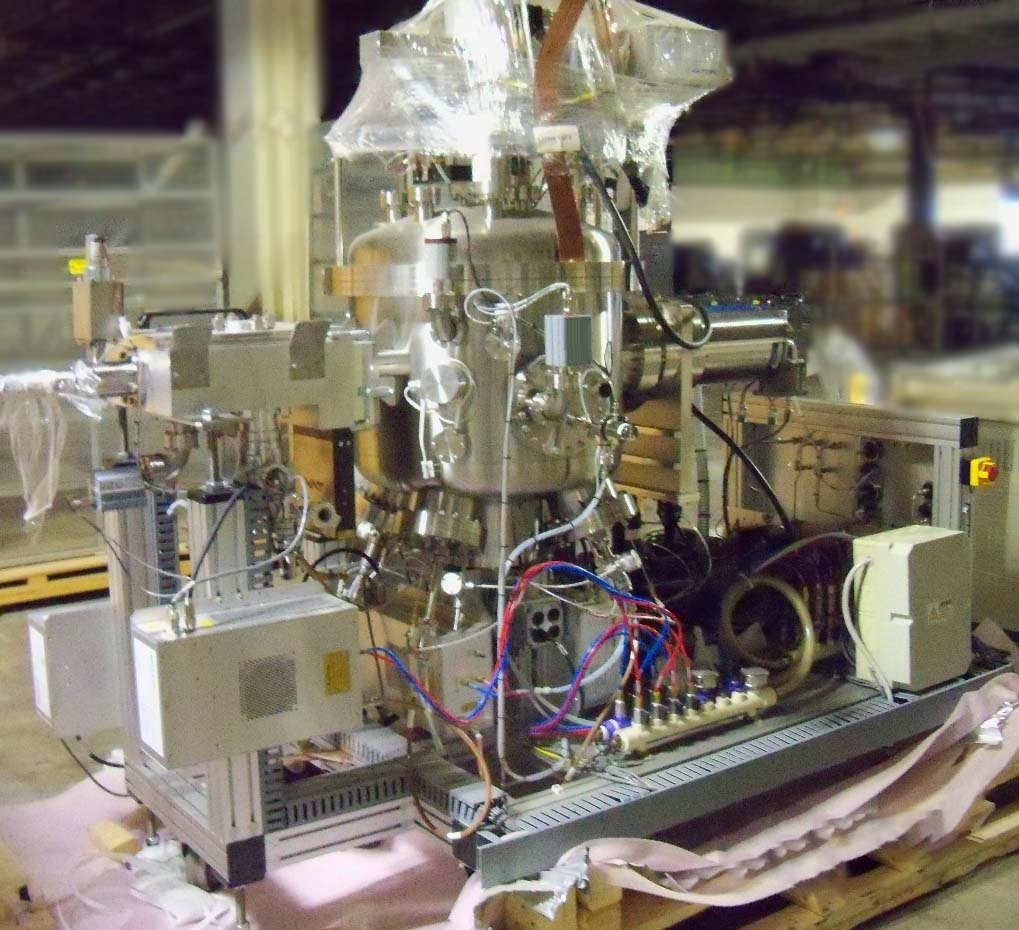

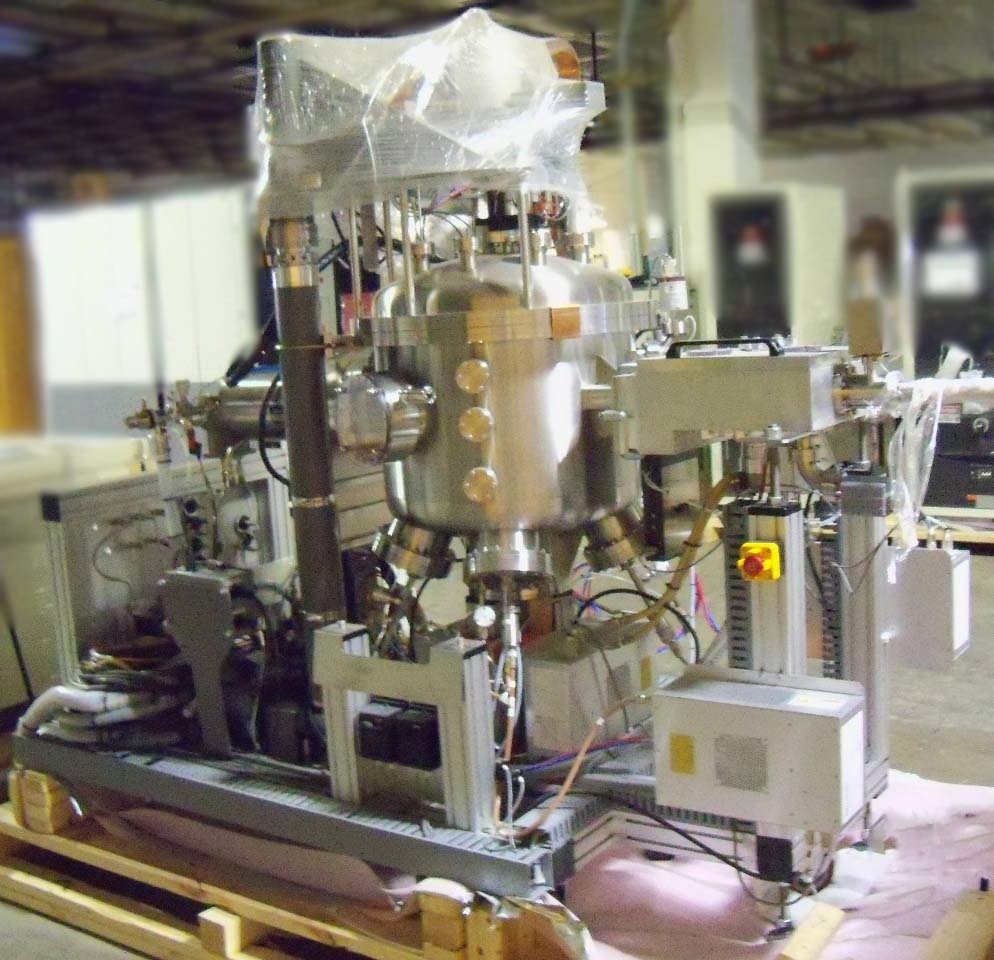

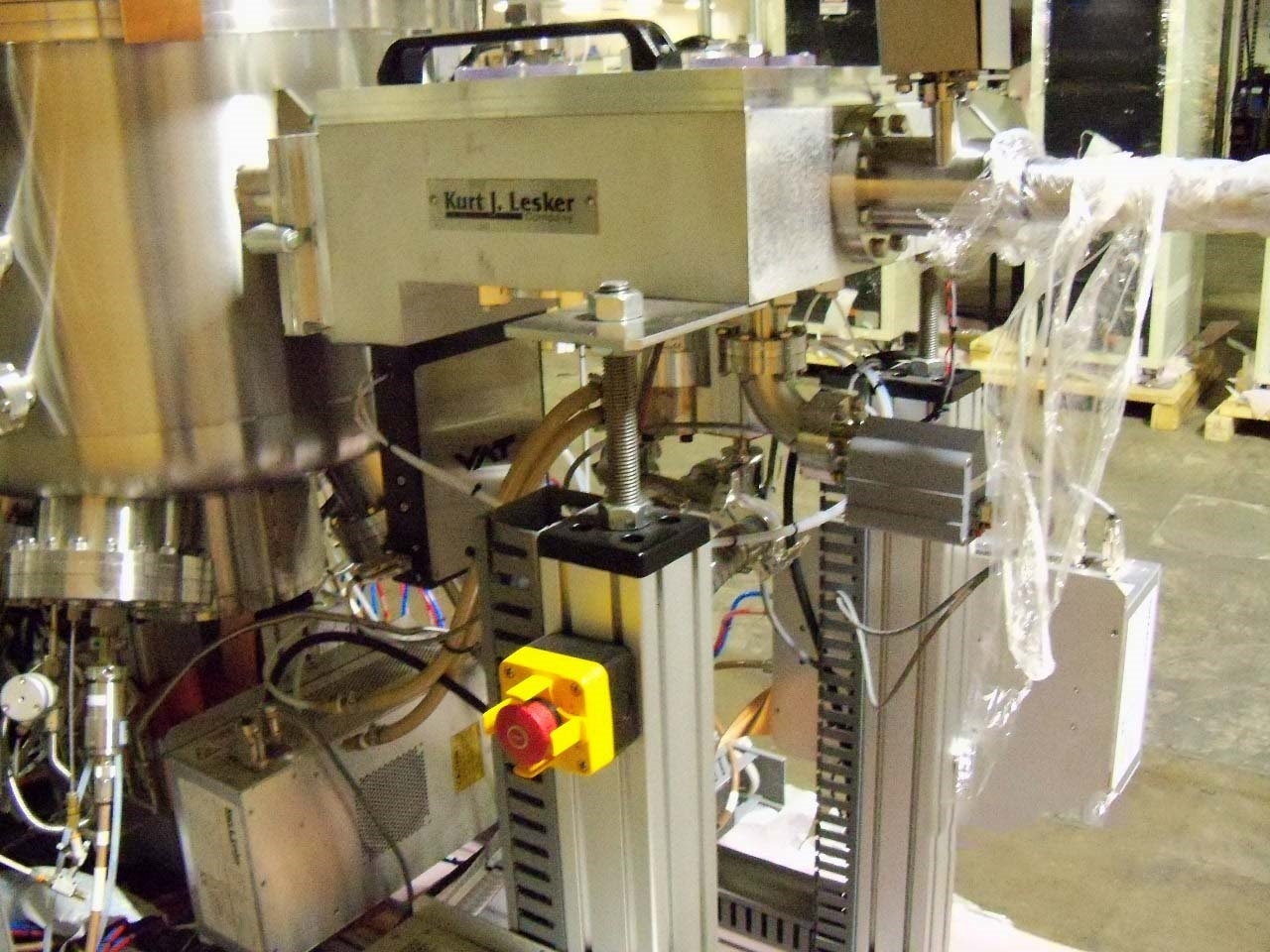

Used KURT J. LESKER CMS-24 #9235982 for sale

URL successfully copied!

Tap to zoom

ID: 9235982

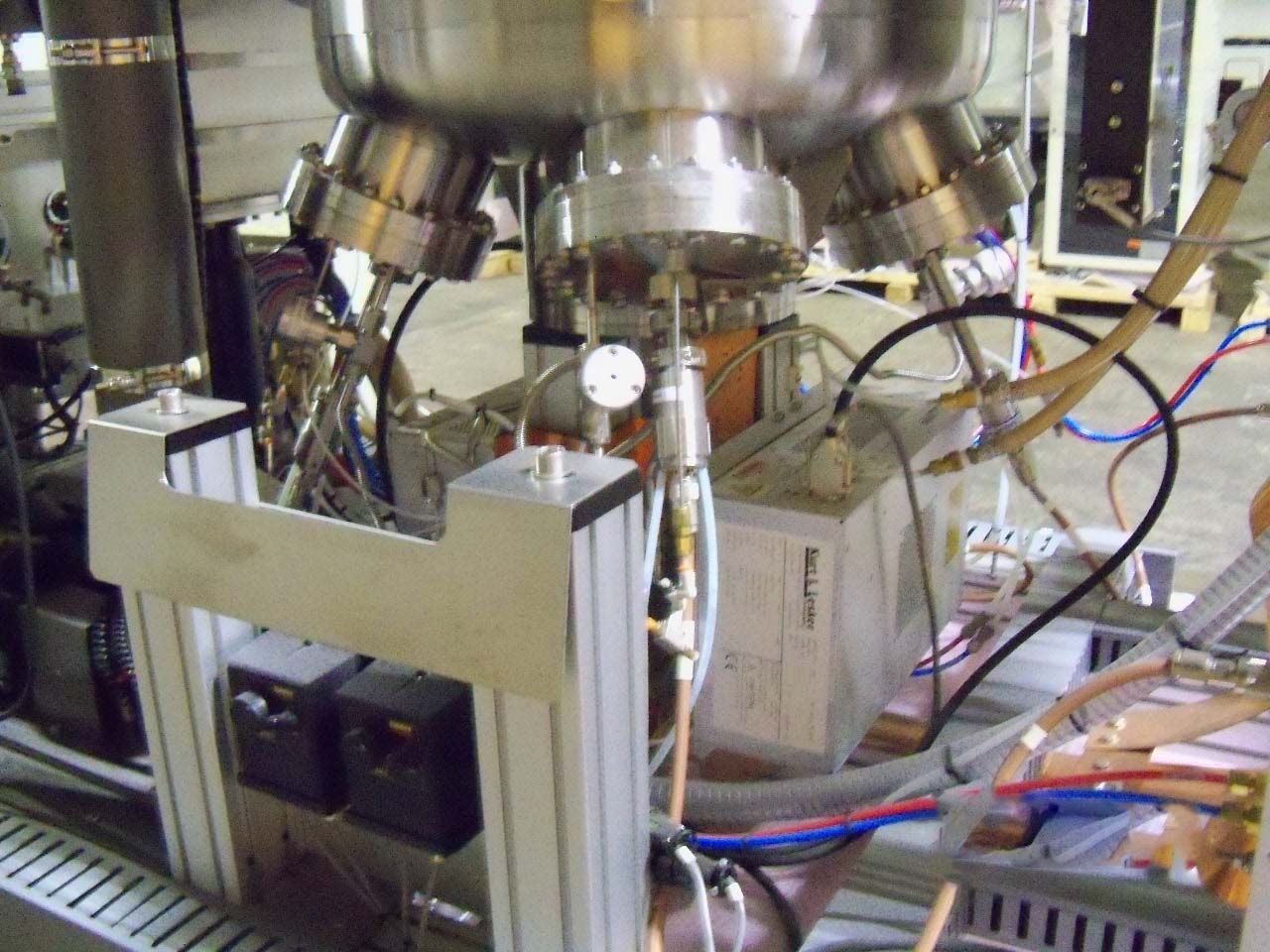

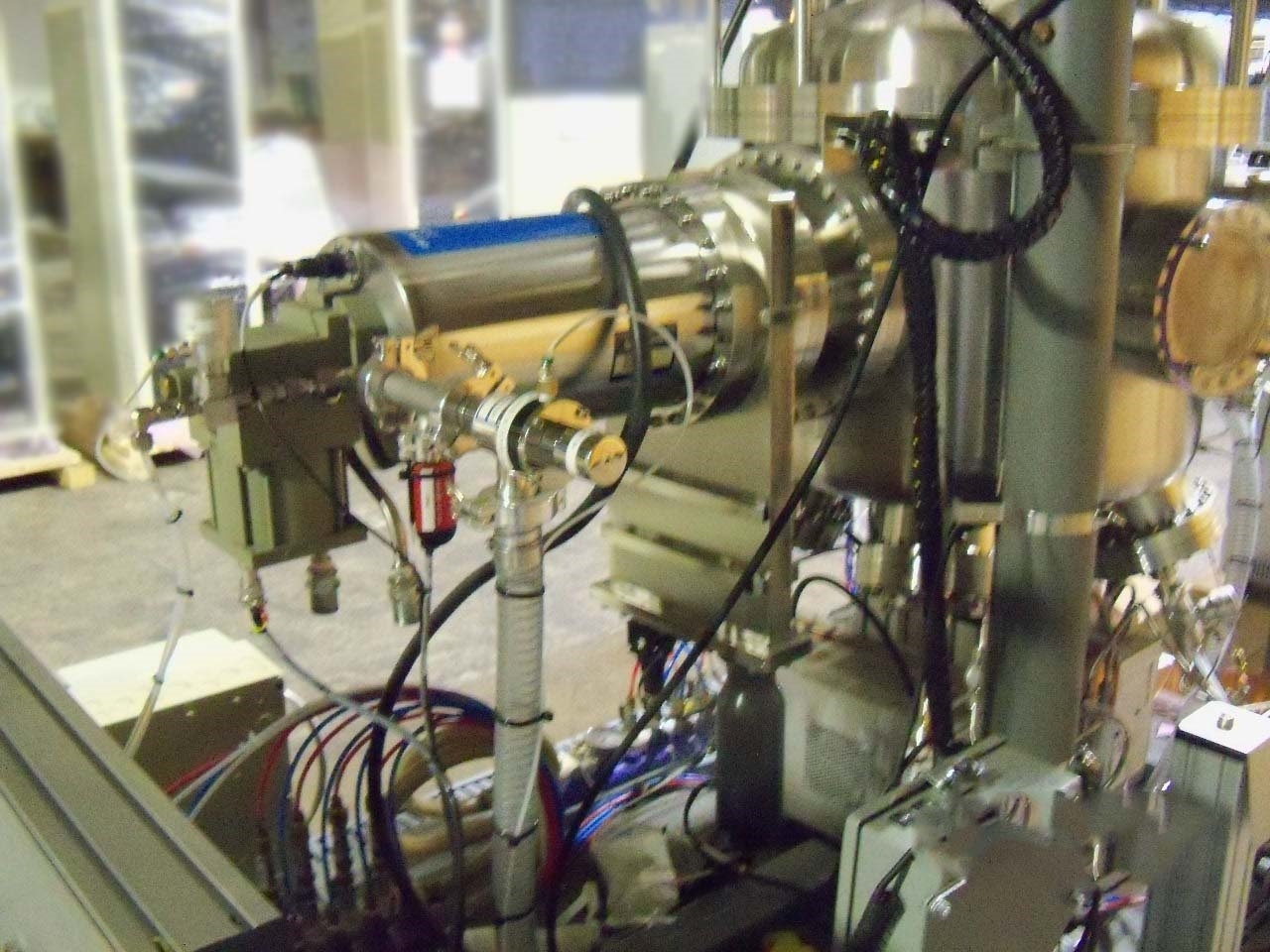

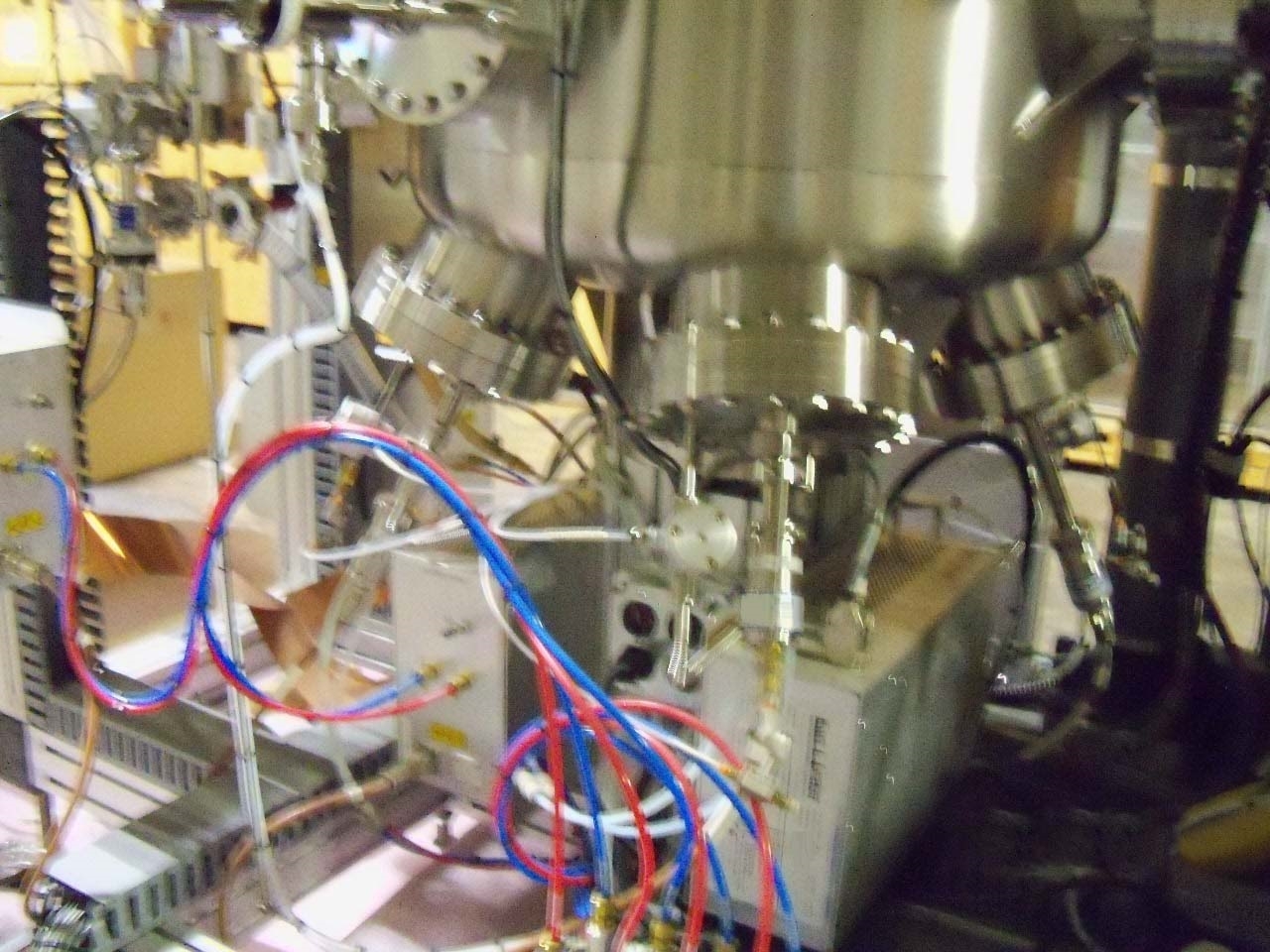

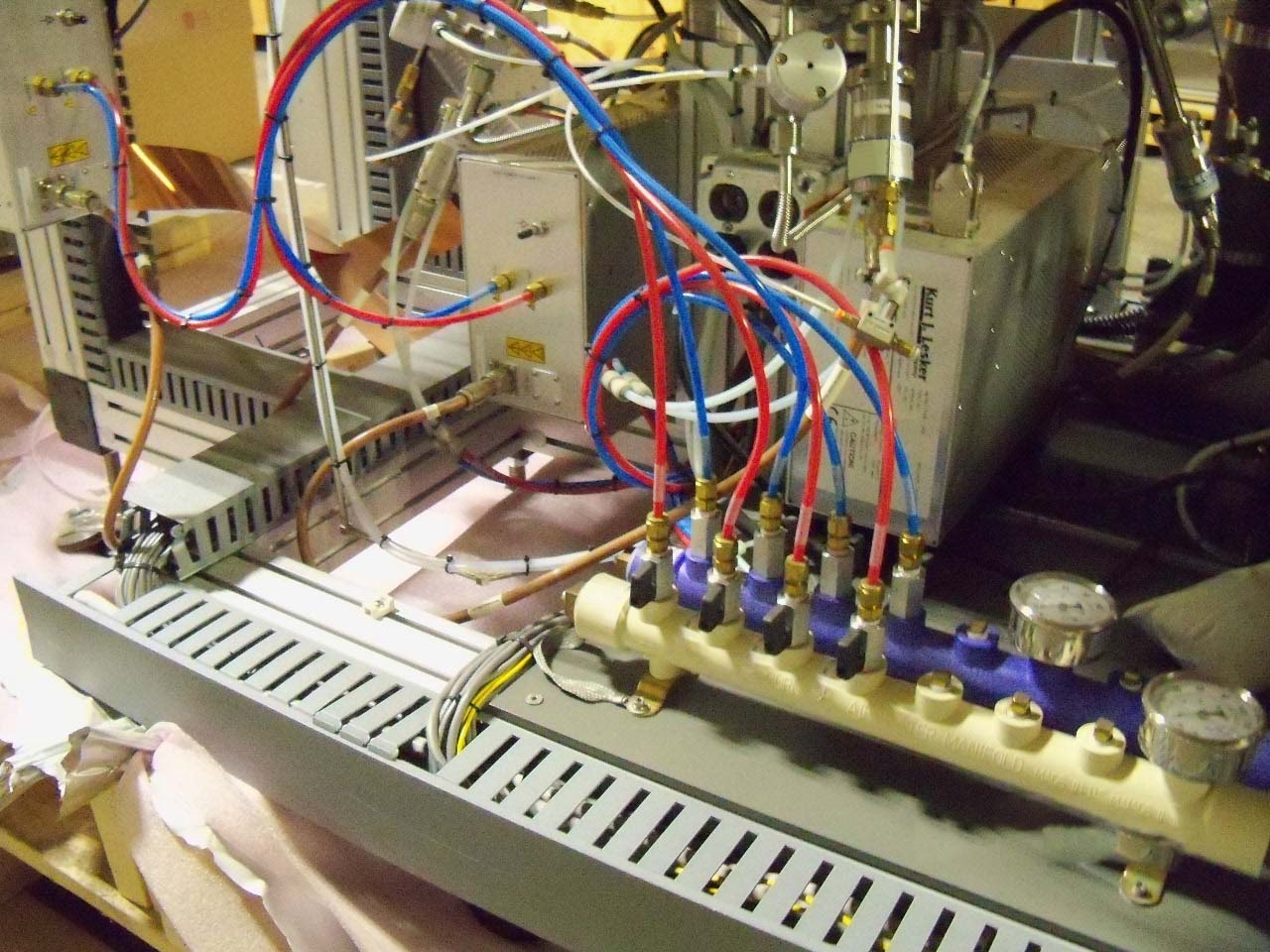

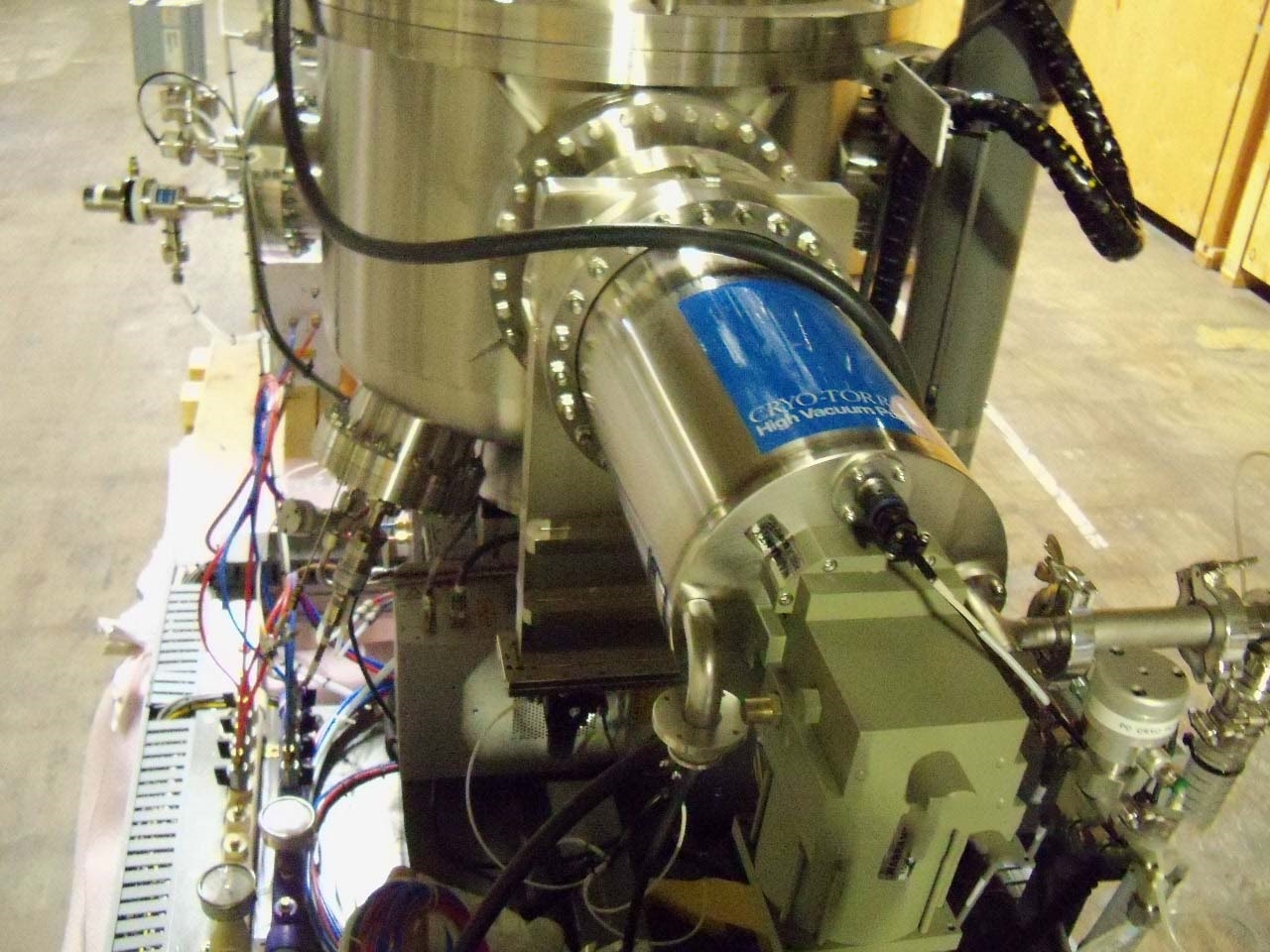

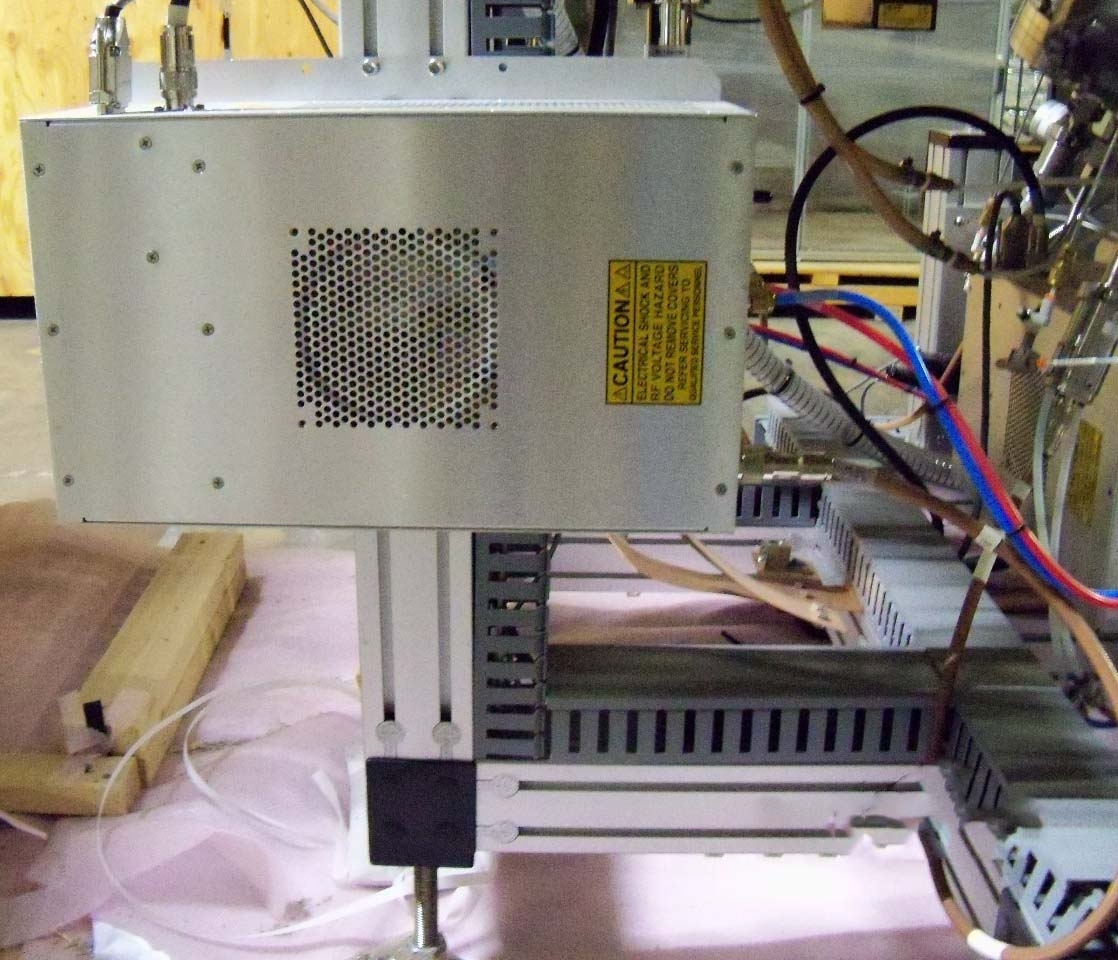

Physical Vapor Deposition (PVD) system

Includes:

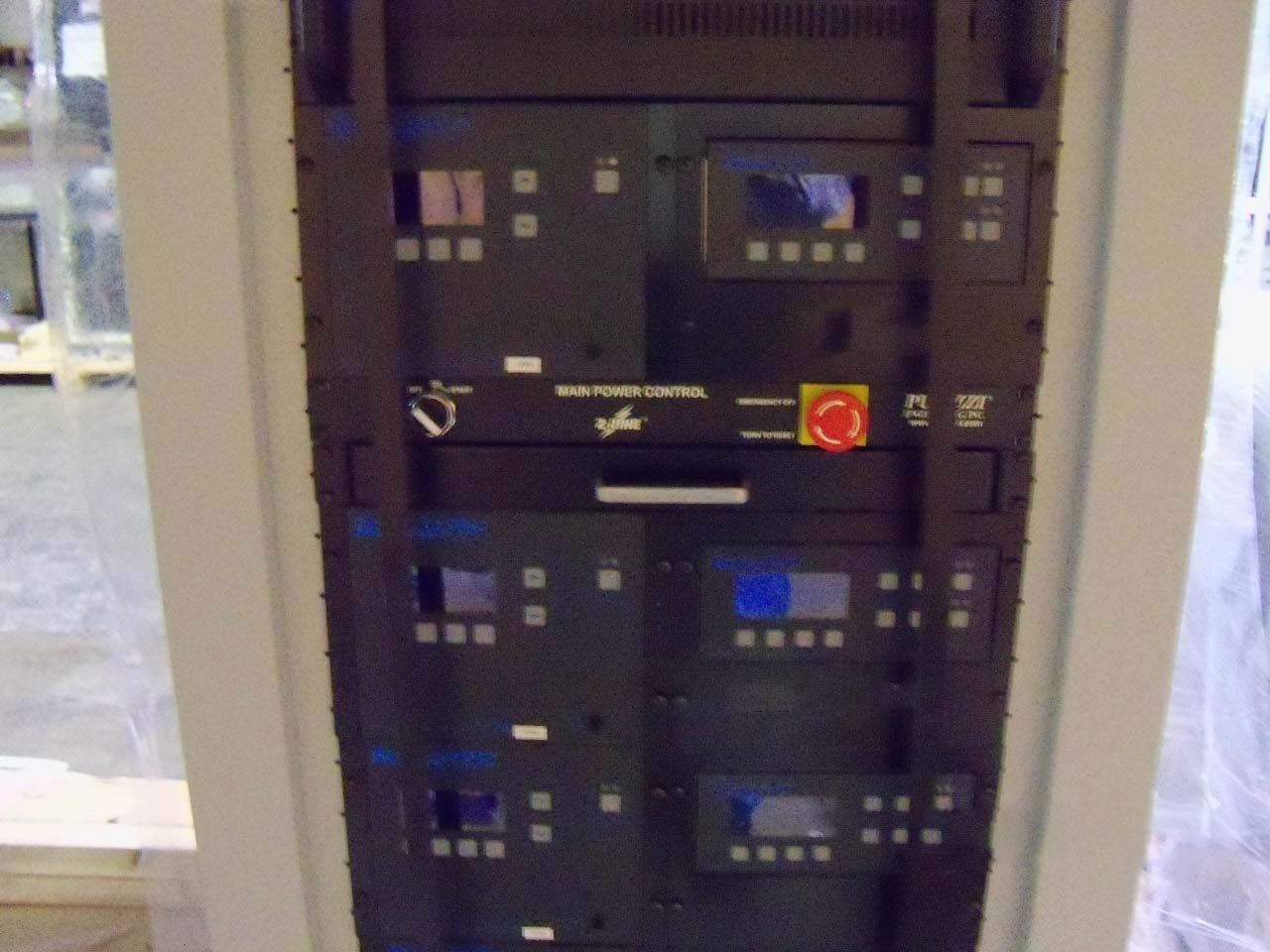

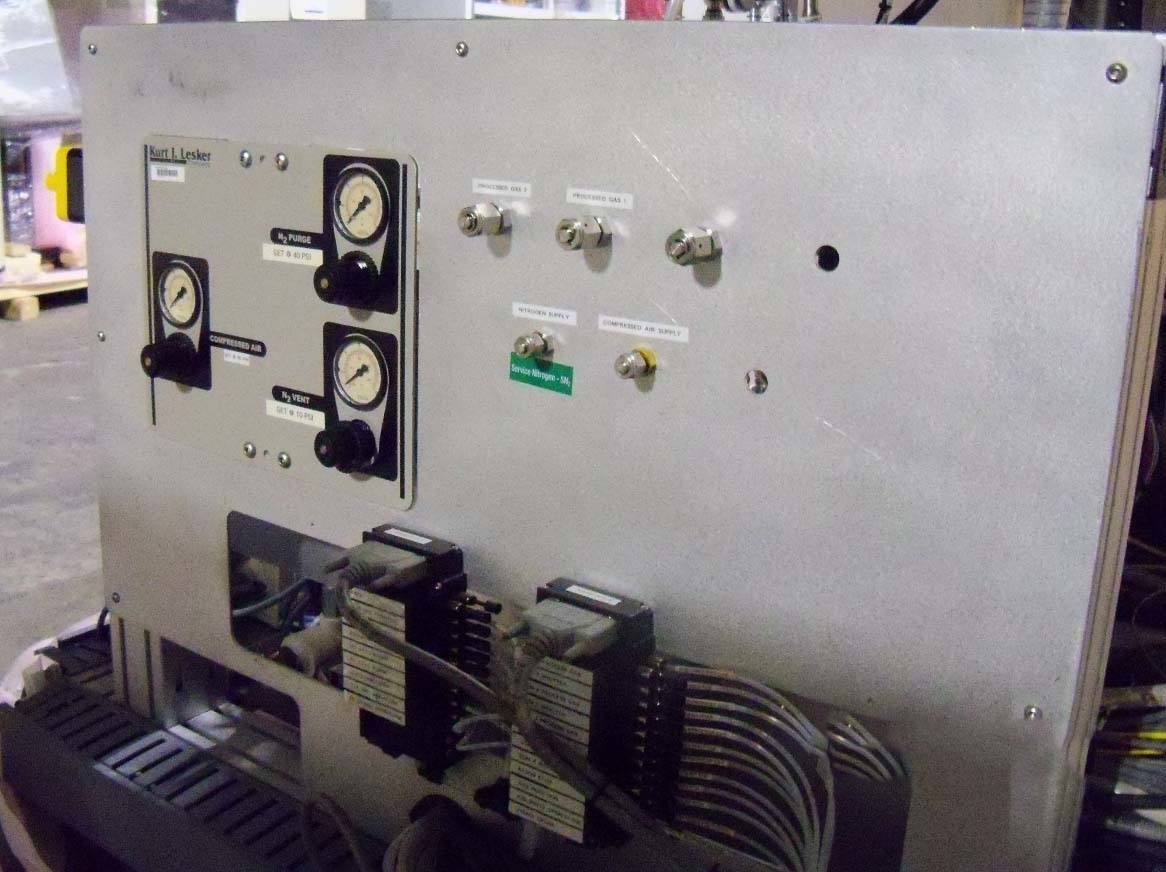

Control cabinet

TEK-TEMPERATURE INSTRUMENTS TKO-100 Chiller

CTI-CRYOGENICS 8200 Compressor

Manuals

Schematics and CD.

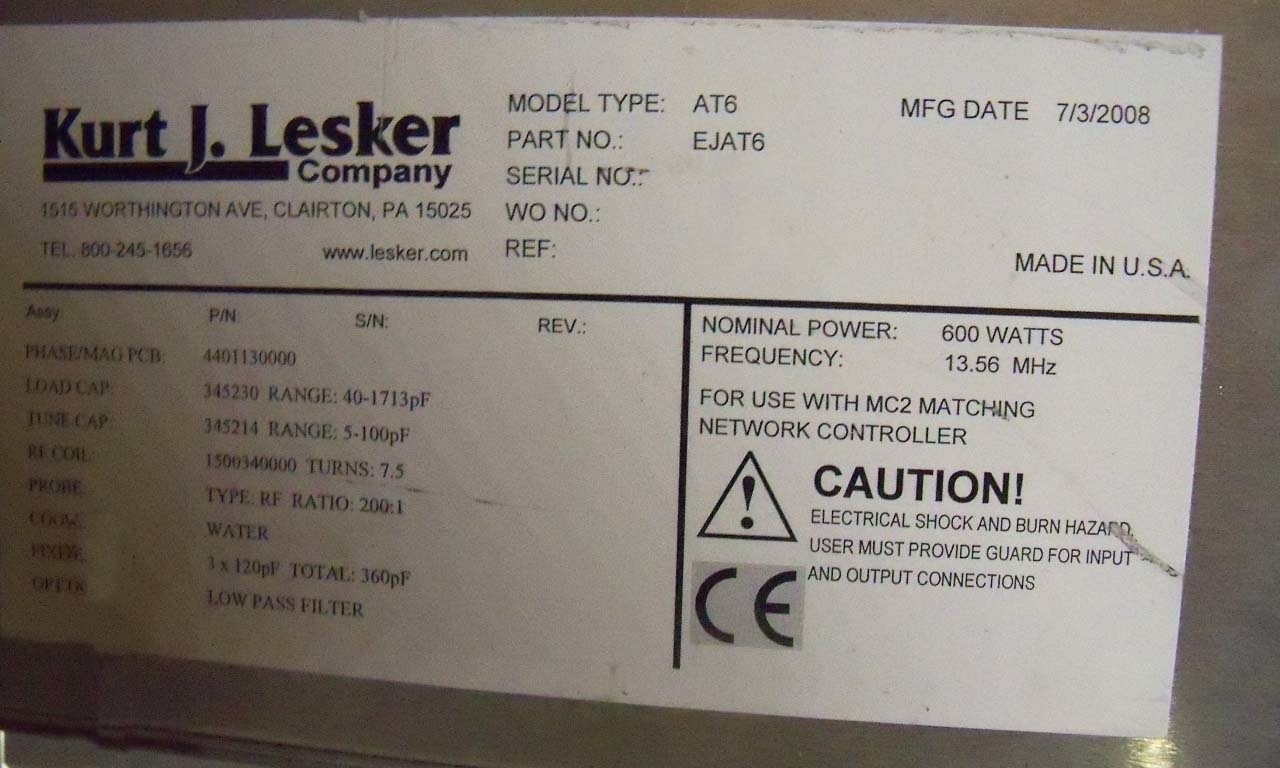

KURT J. LESKER CMS-24 is a powerful high-speed sputtering equipment designed to precisely deposit thin film materials with excellent adhesion and uniformity characteristics. The system features several components, including a vacuum evaporation source, a high-power radio frequency (RF) sputtering source, a precision two-axis automated stage, and an automated in-situ wafer daisy loading/unloading unit. The vacuum evaporation source 3Hybrid assists in thin film deposition by heating a crucible containing a material that is then evaporated and deposited onto a substrate. The crucible is heated to a set temperature by a high power induction heater, allowing users to precisely control the source temperature and end-point deposition rate over a wide range. The RF sputtering source is based on a chemically inert cathode substrate, which operates at high power and deposition rate over a wide area. The source is capable of producing thin films with excellent adhesion, high uniformity, and low micro-bumping characteristics. This ensures optimal uniformity of the thin film material deposited onto the substrate. The Precision Two-axis automated stage offers precise robotic positioning of the substrate and evaporation source, while monitoring temperature, position, and deposition rate. The machine is capable of precise alignment of the sources, enabling accurate thin film deposition. In addition, the automated in-situ wafer daisy loading/unloading tool increases wafer handling efficiency, enabling quick and easy setup and loading of panels or carriers without having to manually enter and align wafers. The asset also automatically screens wafer substrates to ensure they are within specific size tolerances. CMS-24 sputtering model is a powerful tool for precise thin film deposition, allowing users to produce high-quality materials that are uniformly deposited with excellent adhesion characteristics. With robust features and an automated in-situ wafer daisy loading/unloading equipment, the system provides efficient and reliable film deposition capabilities for the most demanding industrial requirements.

There are no reviews yet