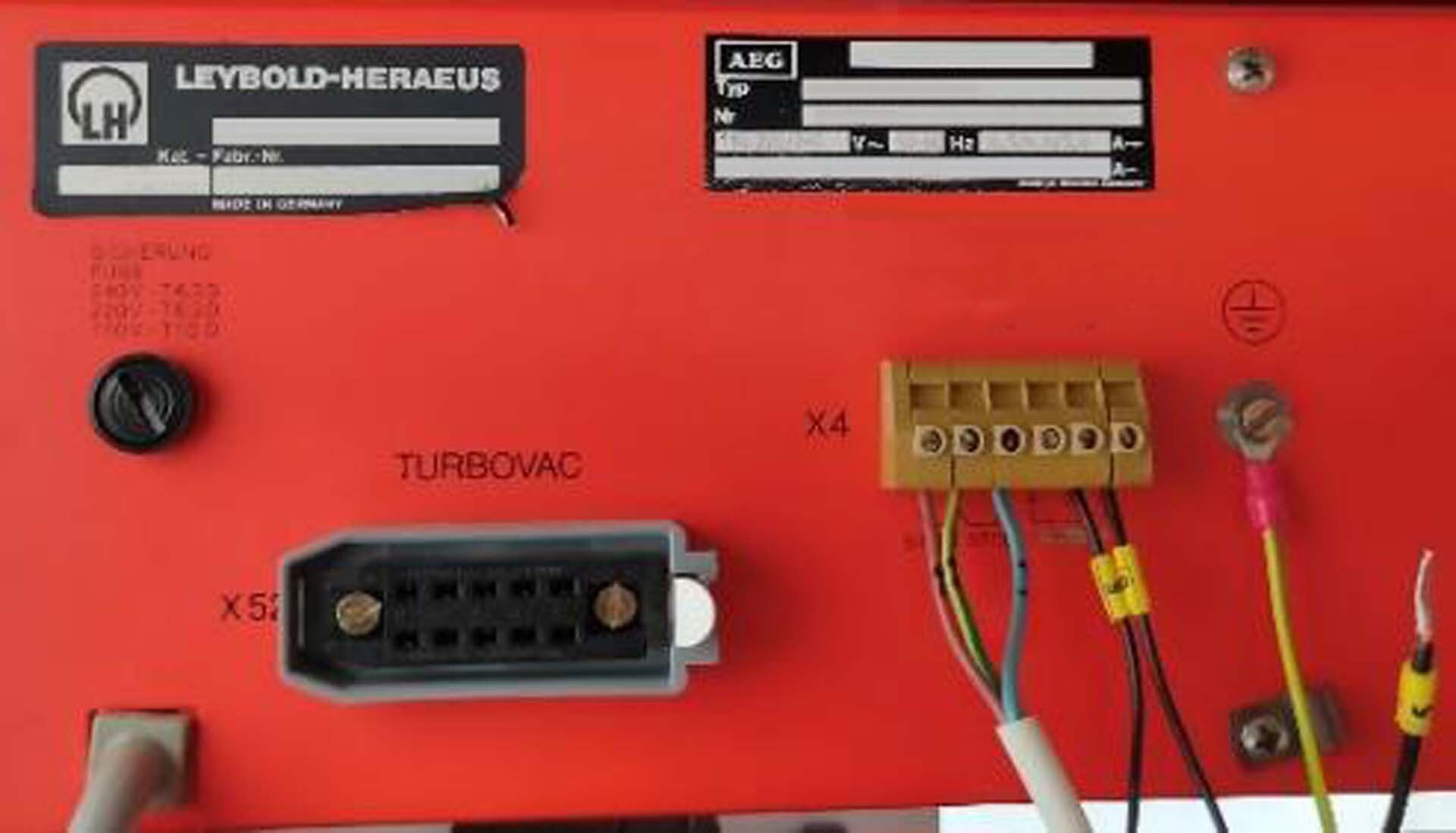

Used LEYBOLD HERAEUS Z400 #9363002 for sale

URL successfully copied!

Tap to zoom

ID: 9363002

Vintage: 1982

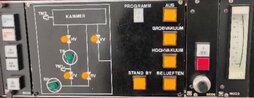

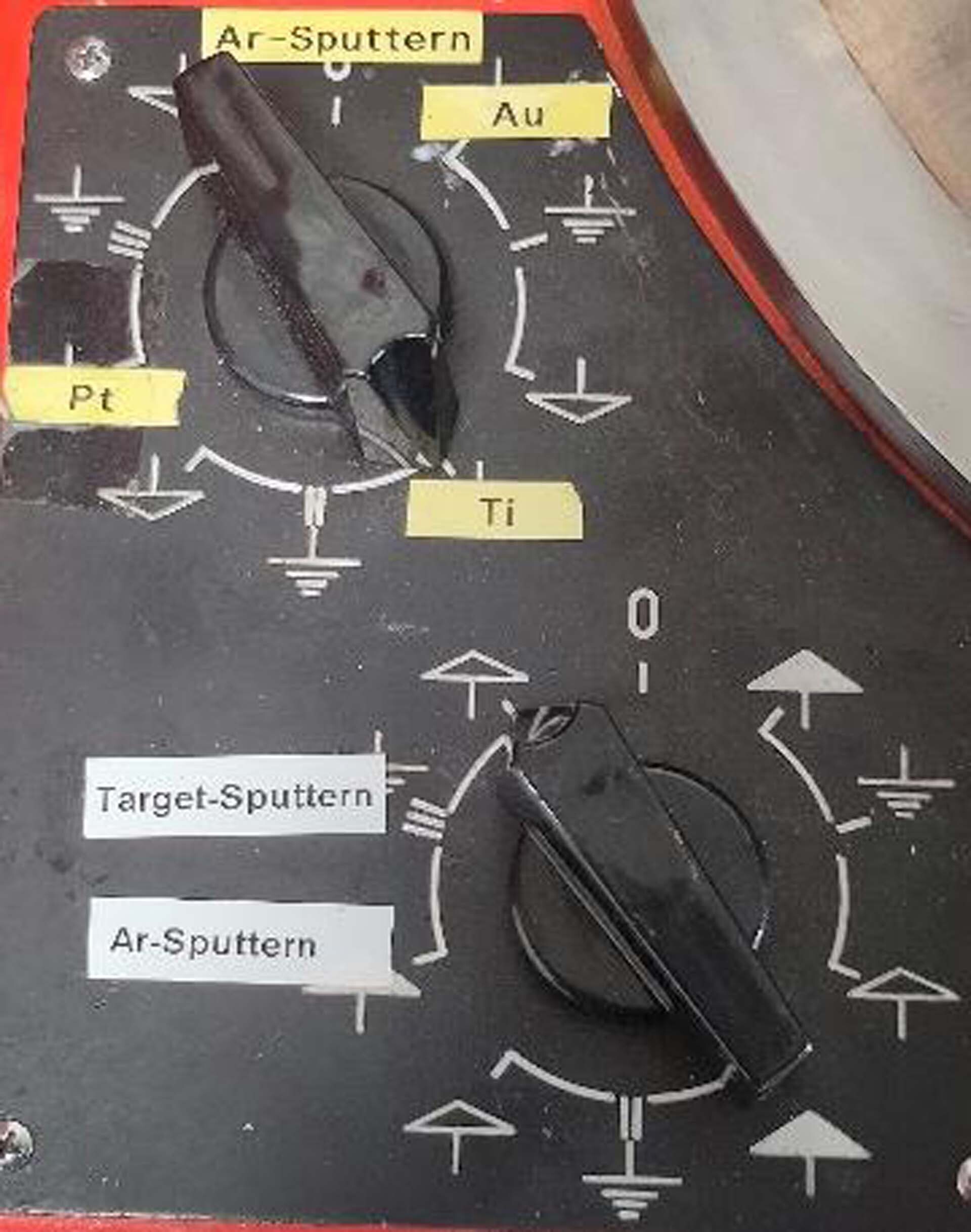

Sputtering system

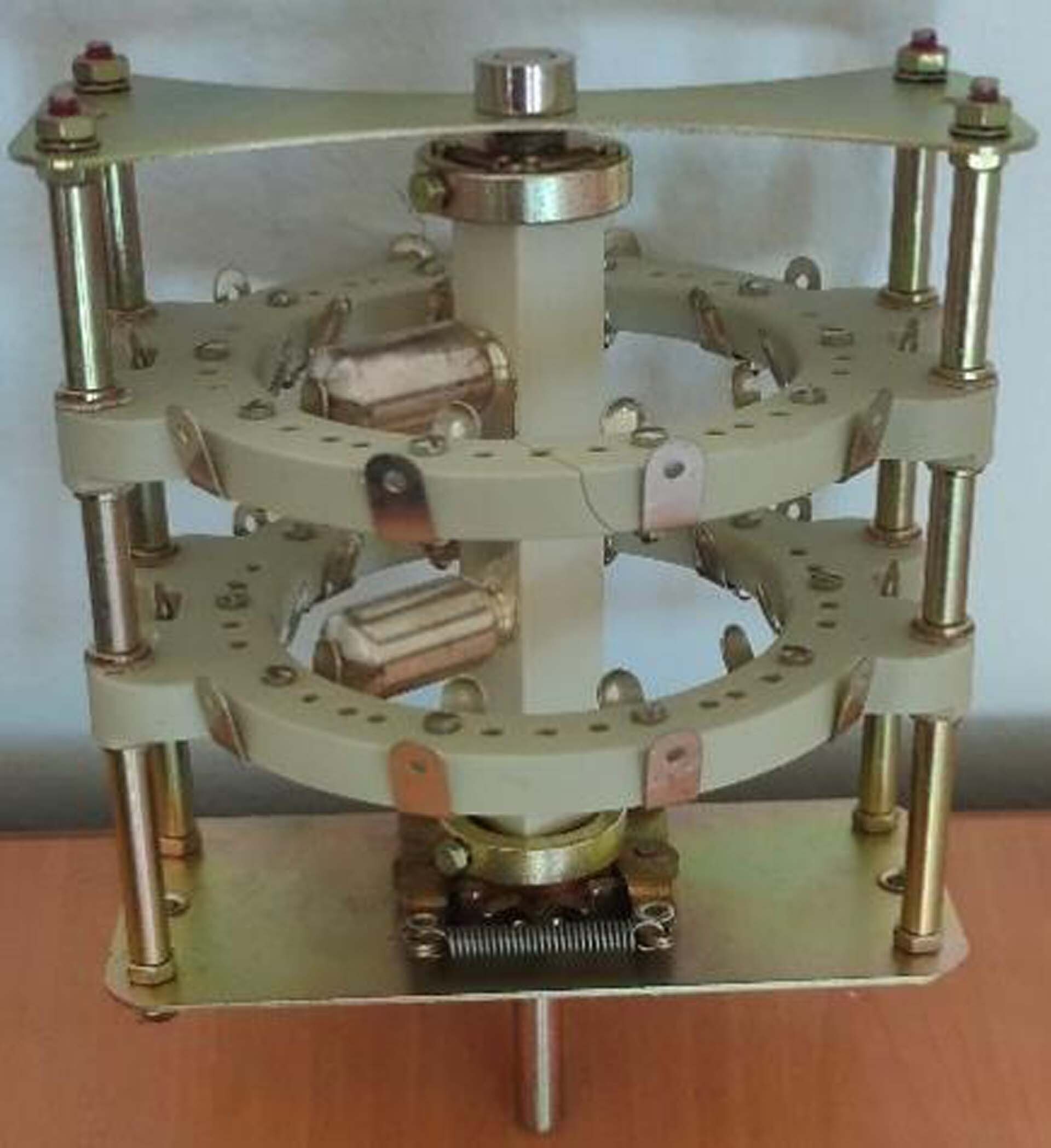

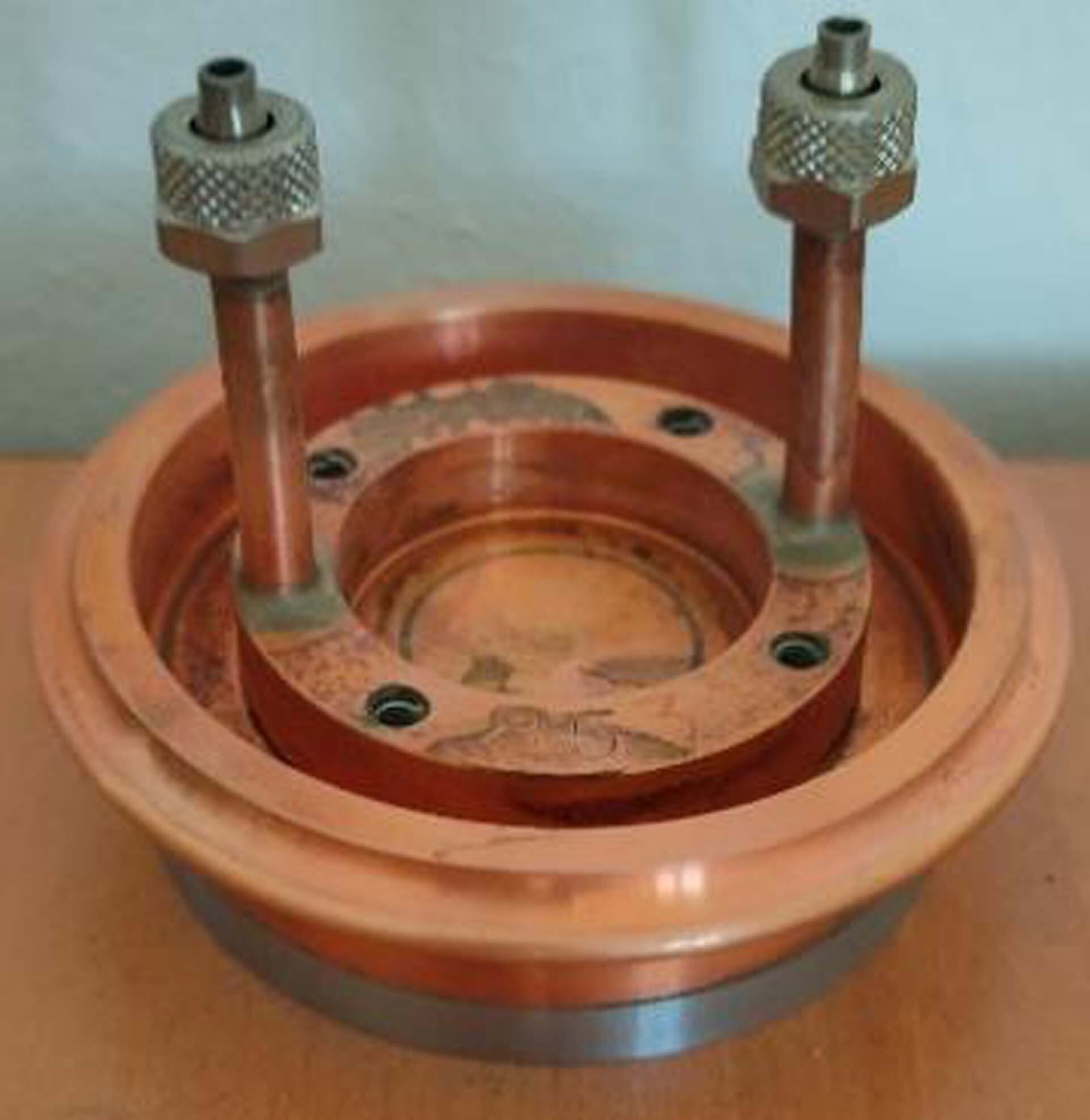

(3) Cathodes

RF Mode

Maximum sample size: 3"

Number of targets: 3

Reactive gases: Ar, O2

Compressed air pressure: 7 to 9 Bars

Water pressure: 4 to 7 Bars

Substrate bias: Maximum -150 V

Substrate heater: Maximum 500°C

Base pressure: <2 x 10^-5 mBar

Generator:

Type: IGD 0.5/13500

Power: 0.5 kW, 220 V, 50 Hz

DC Power supplies: 500 W

RF Power supplies: 600 W

Power supply: 220 V, 50 Hz, 25 Amps

1982 vintage.

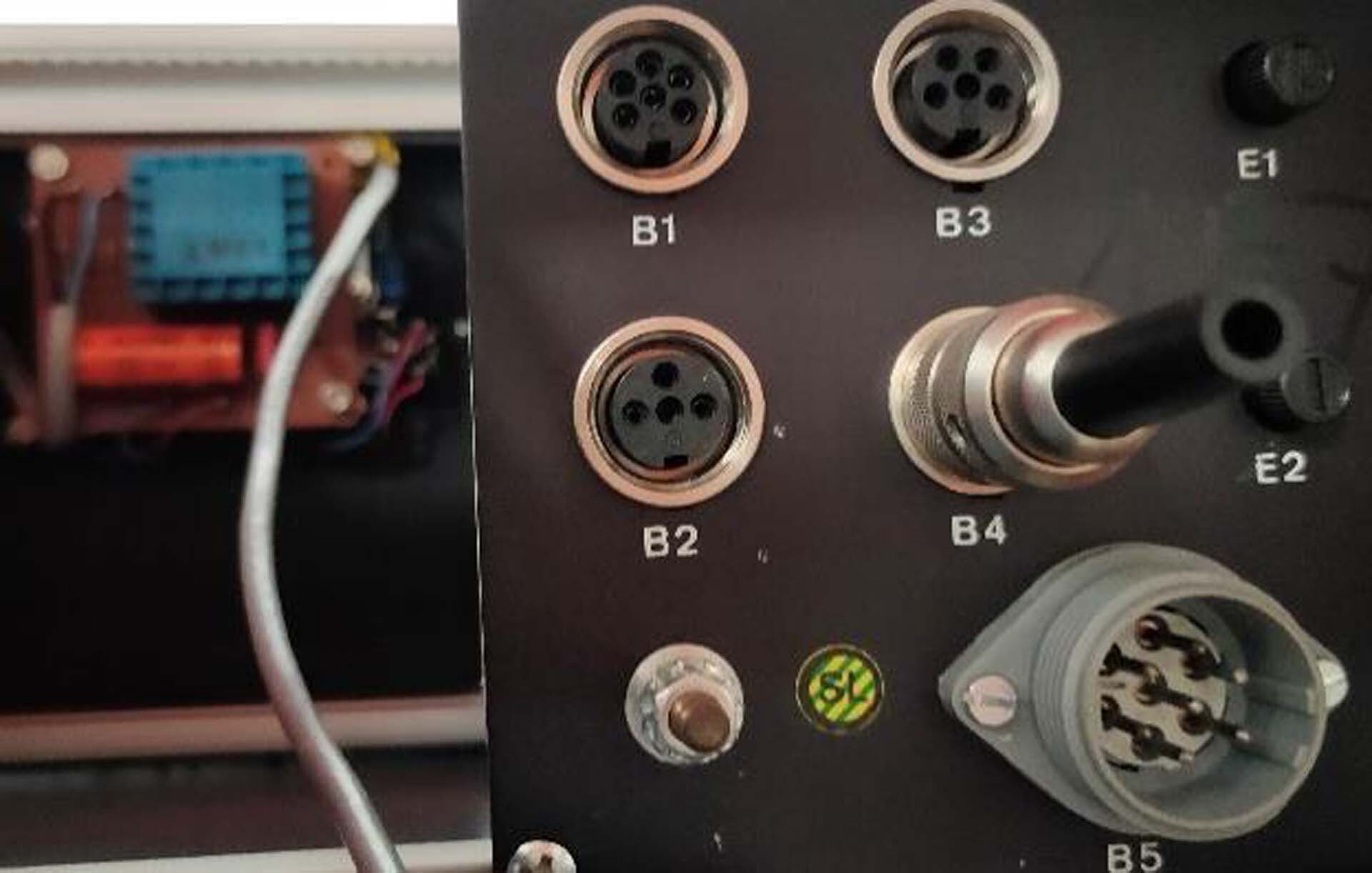

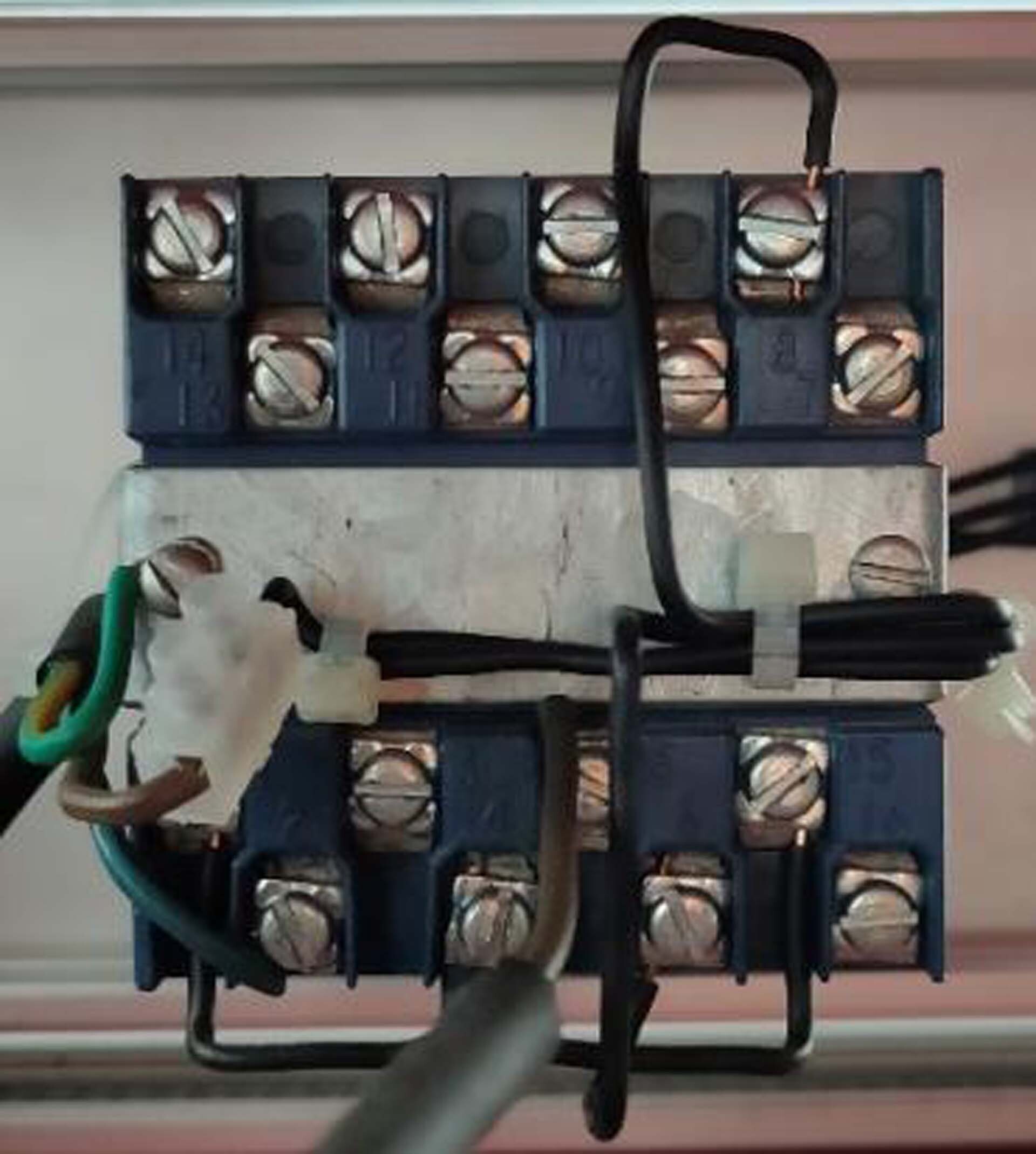

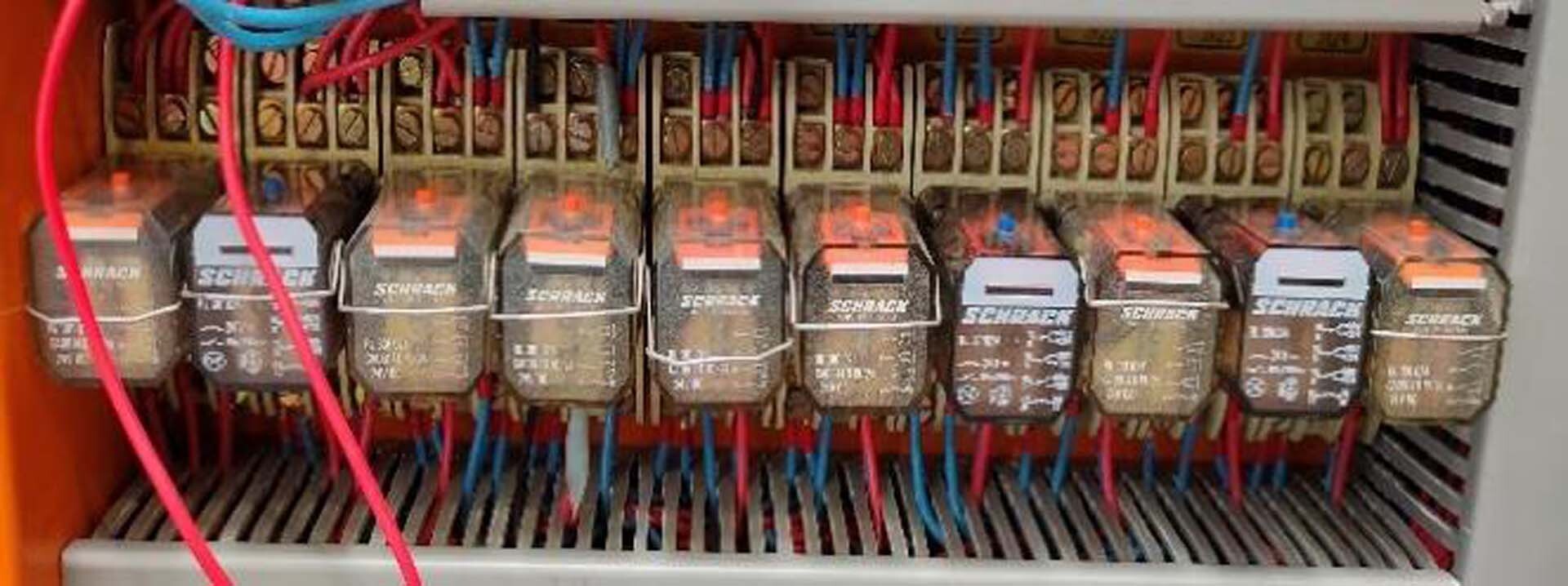

LEYBOLD HERAEUS Z400 sputtering equipment is a highly specialized piece of equipment used in a variety of different industries. It is a vacuum deposition system commonly used in the production of thin films, such as those used in the production of microelectronic components, solar cells, and other thin-film technologies. Z400 is unique in its ability to achieve high-density deposits with a uniform thickness and doping, while also having excellent process control and reliability. LEYBOLD HERAEUS Z400 is composed of three main components: the power supply, vacuum chamber, and deposition source. The power supply includes two high voltage outputs, one for direct current (DC) and the other for alternating current (AC). The DC output is used to drive sputtering with Ar or Xe while the AC output is used to drive ion bombardment, also known as ion assisted deposition. The high voltage potentials and frequencies associated with each output are adjustable, allowing for greater process control and manipulation. The vacuum chamber consists of an interface between the process gas and the deposition source. This is where the vacuum level is maintained while allowing for the introduction of both reactive and non-reactive gas into the chamber. This section also contains the port necessary for introducing target materials into the unit. The deposition source is where the target material is placed and sputtered onto the substrate material below. On Z400, a rotating drum sputtering machine is used to achieve high-density, uniform deposition. This tool also contains quartz windows which allow for an accelerated source burn-off capability, while the chamber lid is equipped with an electron gun asset for substrate cleaning and ion bombardment processes. LEYBOLD HERAEUS Z400 is an advanced, reliable sputtering model, offering unparalleled process control and equipment performance in the deposition of thin films for a wide range of applications. Its combination of rotating drum sputtering, ion bombardment, and extensive process control make it an ideal tool for producing optimal film deposition.

There are no reviews yet