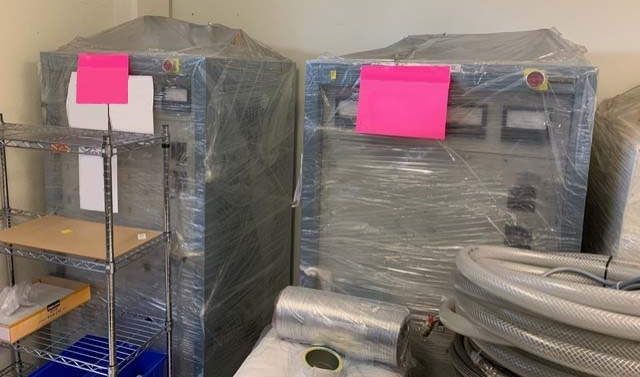

Used MEIVAC / ALCATEL / COMPTECH 2460 #9261538 for sale

URL successfully copied!

Tap to zoom

MEIVAC / ALCATEL / COMPTECH 2460 sputtering equipment is an advanced, versatile and reliable tool for depositing thin films of different materials onto a variety of substrates. It is designed for high-throughput deposition of multiple layers of compounds that result in cleaning, coating and insulating thin films. This tool's modular design is suitable for deposition and characterization of thin films on up to three cooperation targets for a variety of applications such as prints, flat panel displays, sensors and bio-medical devices. MEIVAC 2460 is equipped with a vacuum chamber, consisting of an ultra-high vacuum port with an isolation valve and a turbo-pump. The chamber is also equipped with a gas control system that provides a precisely controlled low-pressure environment. This unit provides active control of the total pressure and allows one to select from a variety of gases used for sputtering and characterizing the thin films. Additionally, the chamber is equipped with an internal water cooling machine for temperature stabilization and a robust target support that offers a variety of possibilities for introducing substrates. The deposition process is controlled by a PC based electronics tool with a user-friendly graphical interface. ALCATEL 2460 features a wide range of sputter sources, including co-deposition sources, high power sources and specialty-designed sources. Each source is precisely matched to the process and substrate in order to optimize performance and ensure engineered quality results. The sputter sources provide a wide range of ion species such as Ar+, Ar++, reaction gas ions and others, allowing fine tuning of deposition rate and uniformity. The Co-deposition source can produce a variety of layered structures with controlled micro-structure. COMPTECH 2460 sputter asset offers excellent performance, reliable operation and customizable configurations. It provides a full range of control over the operating parameters and the deposition process. It allows process monitoring within the vacuum chamber and excellent process control with a wide variety of precision process instruments. It is ideal for creation of films for applications that need resistive, capacitive, optical or magnetic properties and is capable of excellent material deposition at high accuracy and high throughput. 2460 sputter model is an optimal tool for coating substrates with reliable, high-performance thin film layers.

There are no reviews yet