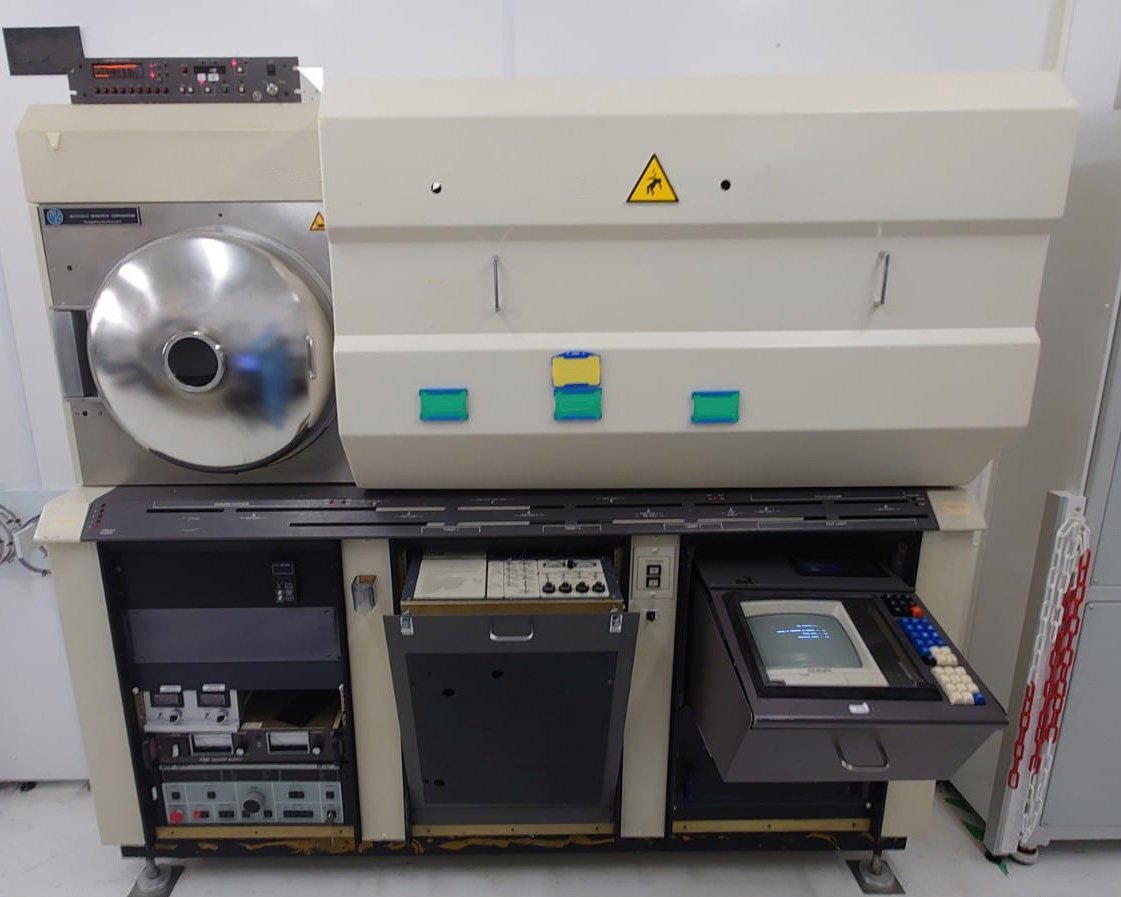

Used MRC 603 #293667099 for sale

URL successfully copied!

Tap to zoom

ID: 293667099

Sputtering system

Bias with TCR Generator

Etching

RFPP 2 Generator

ADVANCED ENERGY MDX-10K Generator

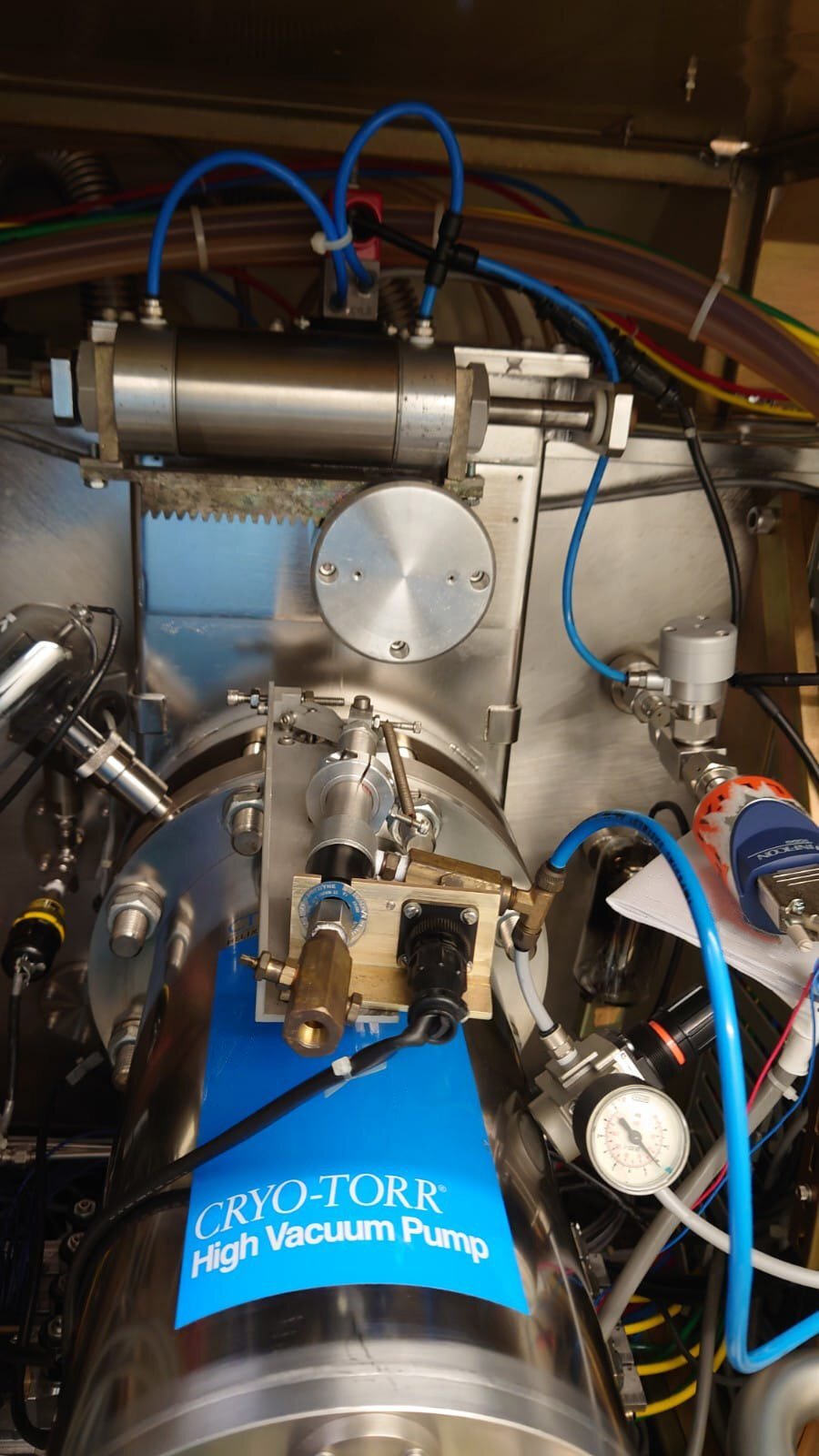

CTI-CRYOGENICS CT-8 Cryo pump

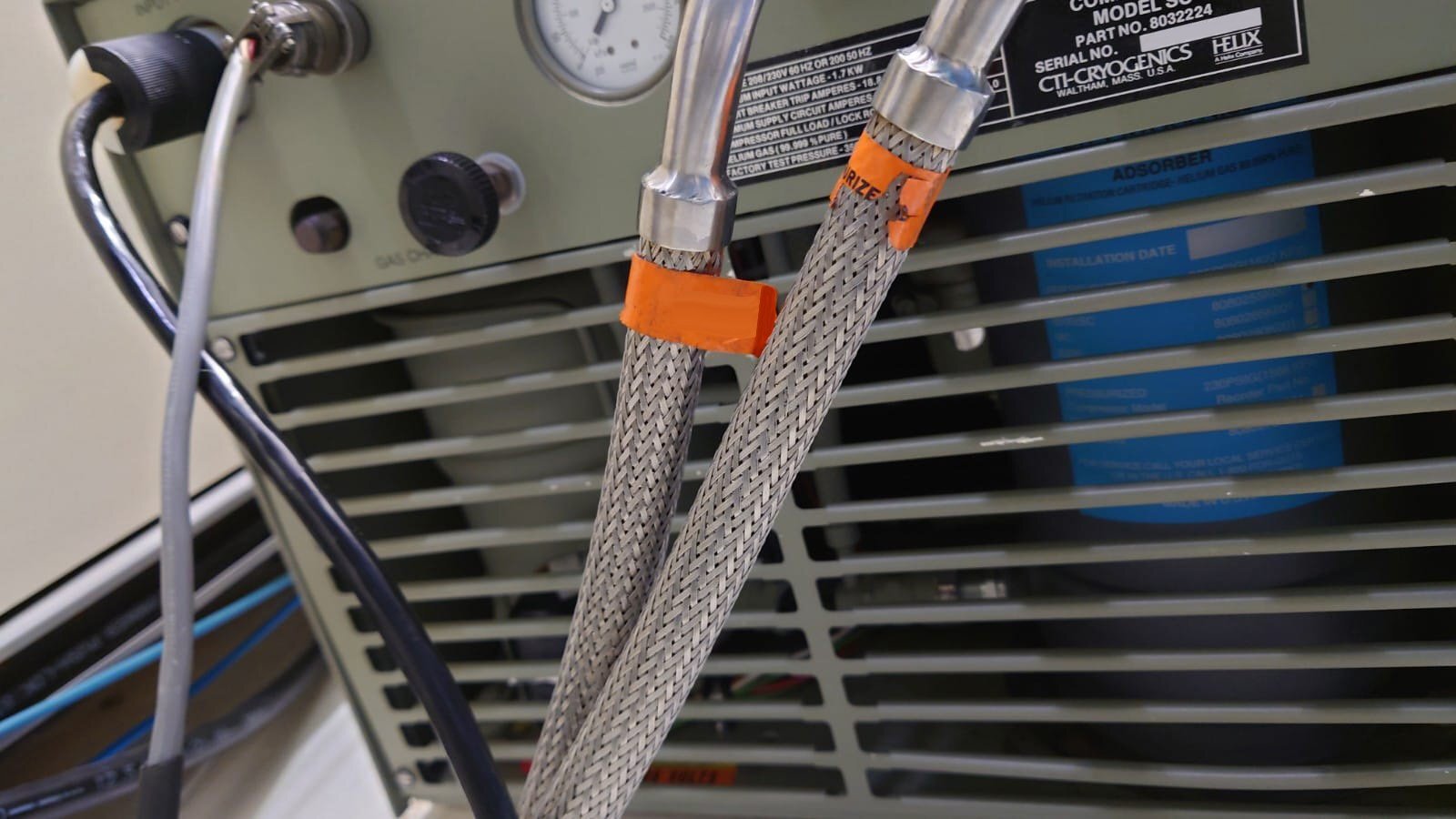

CTI-CRYOGENICS SCR Compressor.

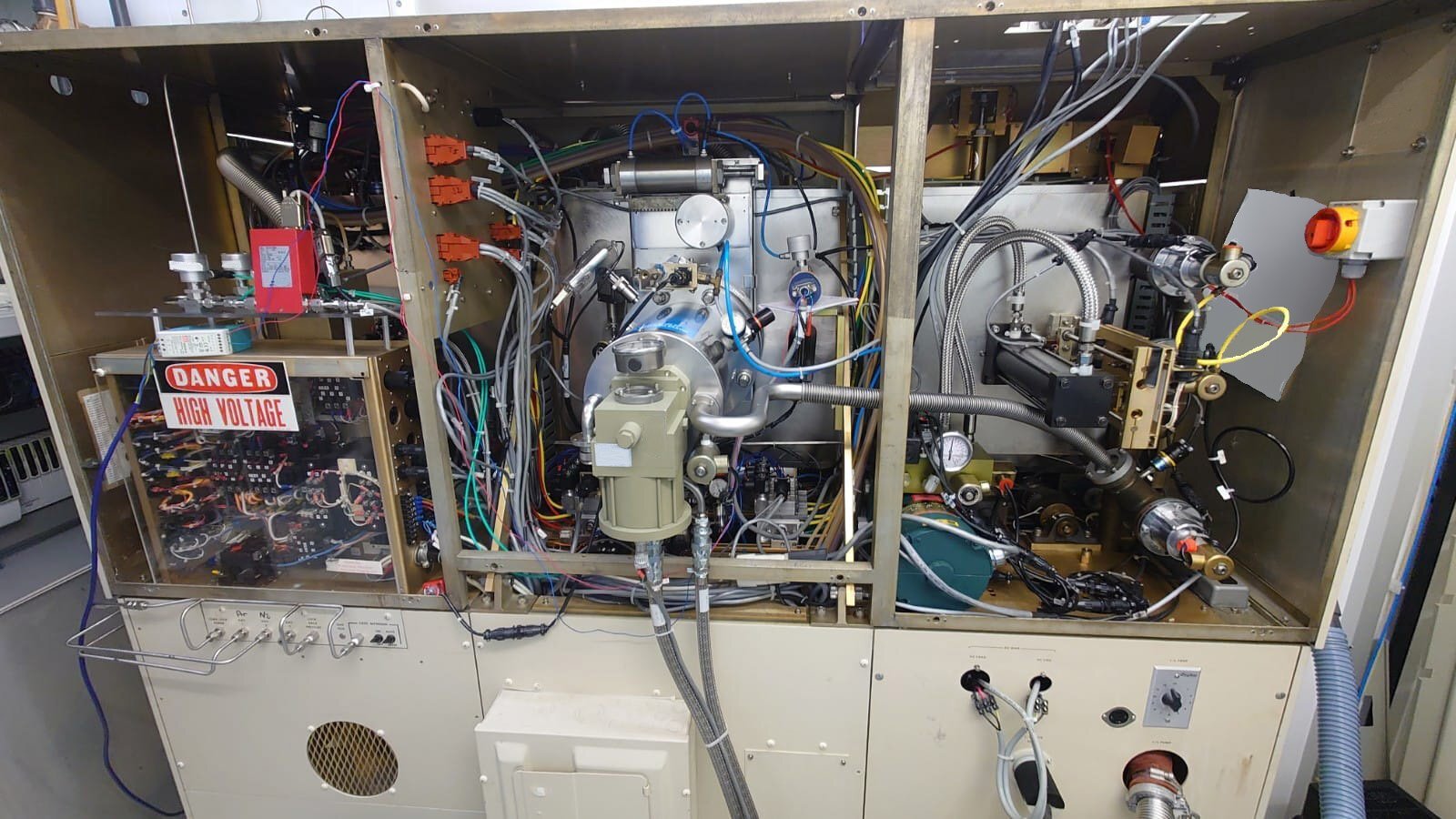

MRC 603 is a sputter deposition equipment designed for deposition in a vacuum environment. The system consists of a sputter source, an ion source, a sample holder, a vacuum chamber, and a power supply. The sputter source is composed of a direct current (DC) cathode and an anode which are charged with a high voltage, typically between -400 and 1000 Volts. This charge causes a bombardment of positively charged gaseous ions, which results in sputter deposition of the material contained in the source onto the sample holder. The ion source is used to neutralize any positively charged ions that are generated during the sputtering process. This ensures that the particles that are sputtered are of uniform size, reducing the risk of sample contamination. The sample holder is composed of a rotating drum and has the capacity to hold up to seven samples. This allows for repeatable and high-quality deposition in the same conditions. The vacuum chamber is the main component of the unit and is designed to sustain a constant pressure of 10-5 Torr. To sustain this pressure, a rotary pump is installed in the machine and is used to evacuate the chamber. The pressure is carefully monitored and controlled from the chamber LCD display. In between depositions, the chamber is cleaned using a high-nm cleaner cartridge, used to remove any built-up material from the walls of the chamber. The power supply is the final component of the sputter tool and is used to control the current, voltage, and time of the sputtering process. It is capable of controlling up to three sources simultaneously, allowing for simultaneous deposition of additional materials. The power supply also includes a timer, enabling a precise and repeatable sputtering process. In summary, 603 sputter asset is designed to provide uniform and consistent coating of part surfaces in a vacuum environment. The model allows for simultaneous deposition and is easy to operate, allowing for reliable results.

There are no reviews yet