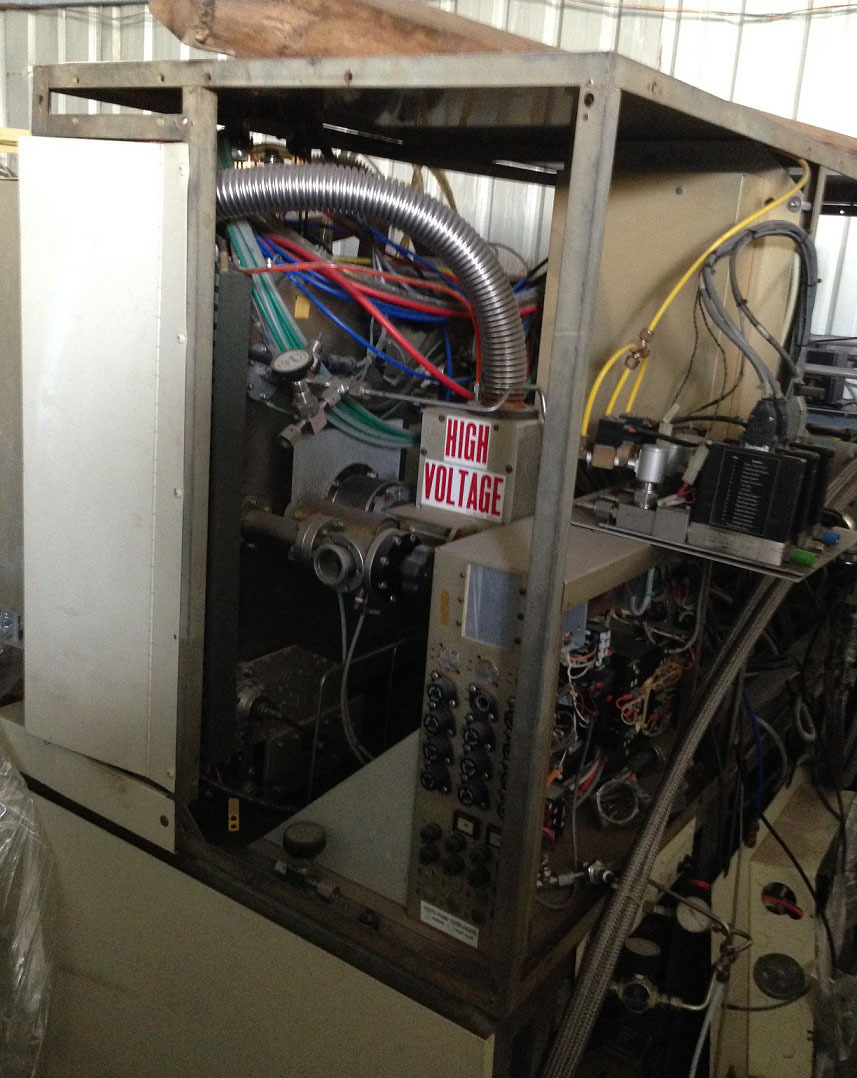

Used MRC 603 #9160654 for sale

URL successfully copied!

Tap to zoom

MRC 603 is a DC magnetron sputtering equipment designed to deposit thin films on substrates for a range of applications. The system operates by using a combination of a DC magnetron, power supply, process chamber, and vacuum unit. The magnetron provides electrons and ions necessary for sputtering processes, with the power supply regulating the output of the magnetron. The process chamber is typically a small cylindrical chamber, with the substrate holders mounted in the center. The process chamber has a port for pump-down and gas control machine, as well as another port for the magnetron. The vacuum tool helps maintain the necessary pressure for sputtering processes. 603 asset is a particularly versatile sputtering model, as it is capable of various RF, DC, Ar/O2, and reactive sputtering configurations. In RF sputter deposition, the magnetron is coupled with a high frequency power supply to create a high frequency field between the magnetron and substrate electrode. This field causes ionization of the sputter gas, resulting in sputtering. DC sputter deposition involves both a DC power supply and DC magnetron, creating a DC field between the magnetron and substrate. The DC field creates a negative bias voltage on the surface of the substrate, raising the sputter ionization energy. Ar/O2 sputter deposition takes advantage of an oxygen rich environment, monitored and regulated by a gas control equipment. The oxygen combines with Argon to make Ar+ ions, resulting in the sputtering of the target material. Reactive sputter deposition combines DC sputter deposition with reactive gases, such as nitrogen or carbon. By introducing the appropriate gases, a thin film of the reactive material can be deposited, such as nitride or carbide films. MRC 603 is a robust and reliable sputtering system designed to meet a variety of thin film deposition needs. Its versatile configuration options make it a great choice for a variety of applications. The unit operates at high power levels, with the magnetic field sealed and enclosed by a vacuum feedthrough. The power supply control allows the user to modify power levels for various sputtering configurations, providing for greater control and accuracy of the process. 603 machine is an excellent choice for creating high quality films on various substrate materials.

There are no reviews yet