Used MRC 822 #9039130 for sale

URL successfully copied!

Tap to zoom

ID: 9039130

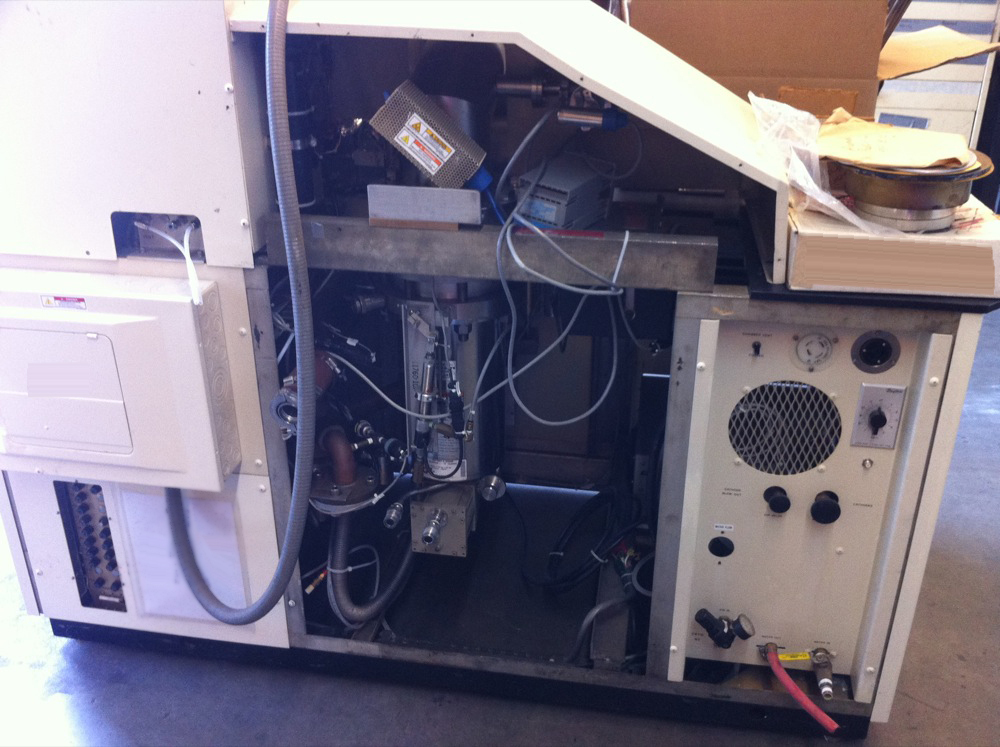

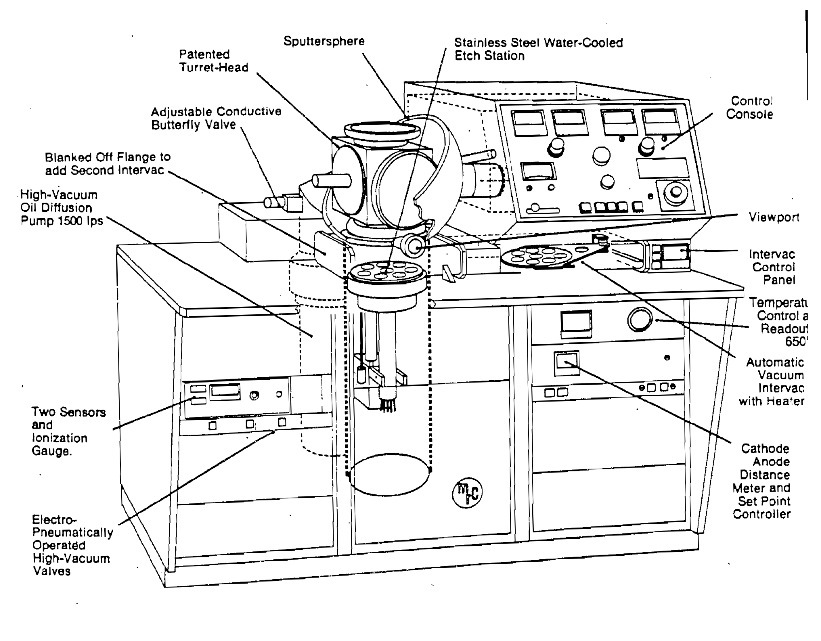

Sputterspheres

With load lock

Includes:

(3) Diode targets, 8"

Spherical chamber, 19"

Sputters up to (3) materials without breaking the vacuum

CTI 8 Cryo pump with SC compressor

LEYBOLD D-60 Mechanical pump

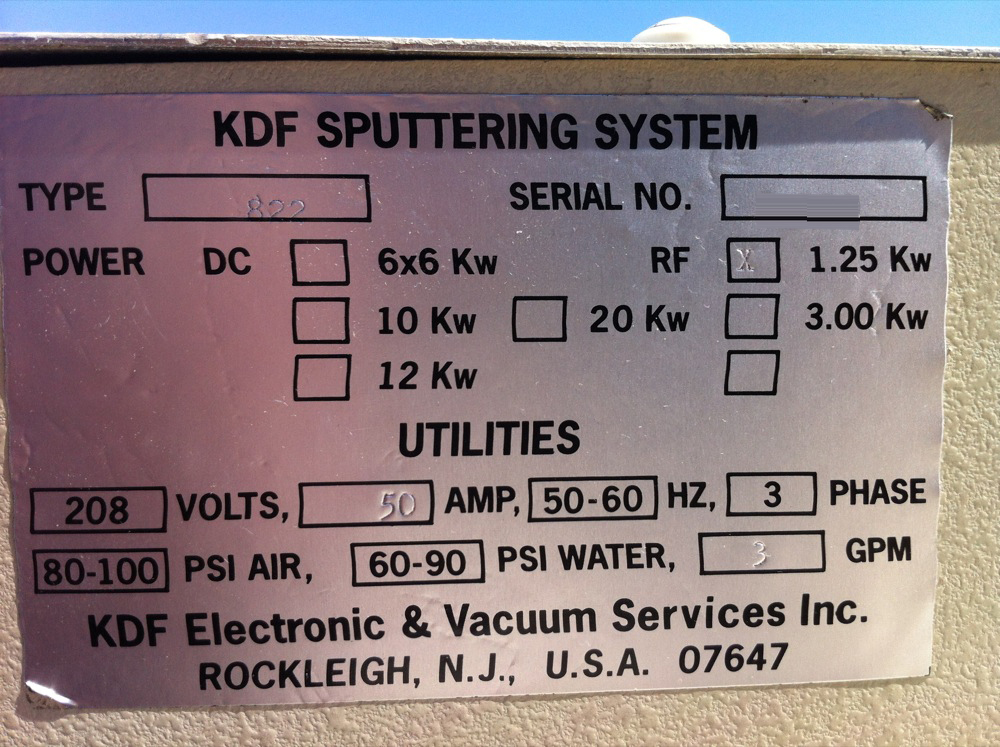

ENI OEM-6 RF Generator, 1.25 kW

Sputter etch

GP-280 IG controller

VARIAN TC controller

Load locked system

Pallet, 8"

Complete set of manuals

Eye-level control console:

Forward and reflected power meters

Two peak-to-peak meters

Remote power control

Multi-range sputter timer

Sputter button

Pirani gauge

Modes of operation:

Diode deposition: RF Diode, RF Bias

Magnetron deposition: DC and RF

Reactive sputtering

Sputter etching

RF System:

Voltage stabilization

RF Matching network

Auto tuning

Vacuum

Dual loadlock: two pallet mode, three pallet mode

Semi-automatic operation speeds

DC Magnetron power supply: Model: S3016

80-100 psi air, 60-90 psi water, 3 GPM

208 V, 50 Amp, 50/60 Hz, 3 Phase.

MRC 822 is a high-energy ion beam sputtering equipment using a high-current ion source for processing materials. This advanced sputtering technology is used to deposit thin films onto a variety of substrates. 822 system is a computer controlled machine with a user-friendly control interface which allows for process control and monitoring of sputter parameters. MRC 822 unit utilizes both a vacuum chamber and an ion beam source in order to process the substrate. The vacuum chamber is composed of stainless steel and is designed to maintain a low vacuum level, typically in the range of 10-5 to 10-6 Torr. Inside the chamber, an inner vacuum machine is also employed to maintain the target at a stable pressure. A Faraday cage surrounds the target, providing electrical isolation and shielding for the tool components. The ion beam source is comprised of a high-power linear accelerator, which enables a high level of control for controlling sputting parameters such as beam energy and particle size. The accelerator generates particle energies in the range of 100-200 keV and particles sizes ranging from 1-10 nm. The ion beam sources can accomodate an electron gun, allowing for a wide range of possible beam shapes. Additionally, the ion source can be used for etching applications, allowing for selective etching of specific targets. 822 also has an in-situ substrate bias feature which allows for deposition of films onto non-conductive substrates. This feature is ideal for films requiring a depth of penetration or material layering, such as MEMS and other thin film coating applications. The asset is capable of ultra-fine film deposition, with resolutions as low as 2-3 nm achievable with the low energy ion deposition process. Overall, MRC 822 is a powerful and versatile high-energy ion sputtering model. The computer controlled user-friendly interface allows for accurate and reliable sputter processing parameters to be inputted with ease. The step-by-step process control and monitoring allows for precise film deposition and etching applications on nearly any substrate. The combination of high-power linear accelerator and electron gun provides the user with the capability to deposit films with resolutions as low as 2-3 nm.

There are no reviews yet