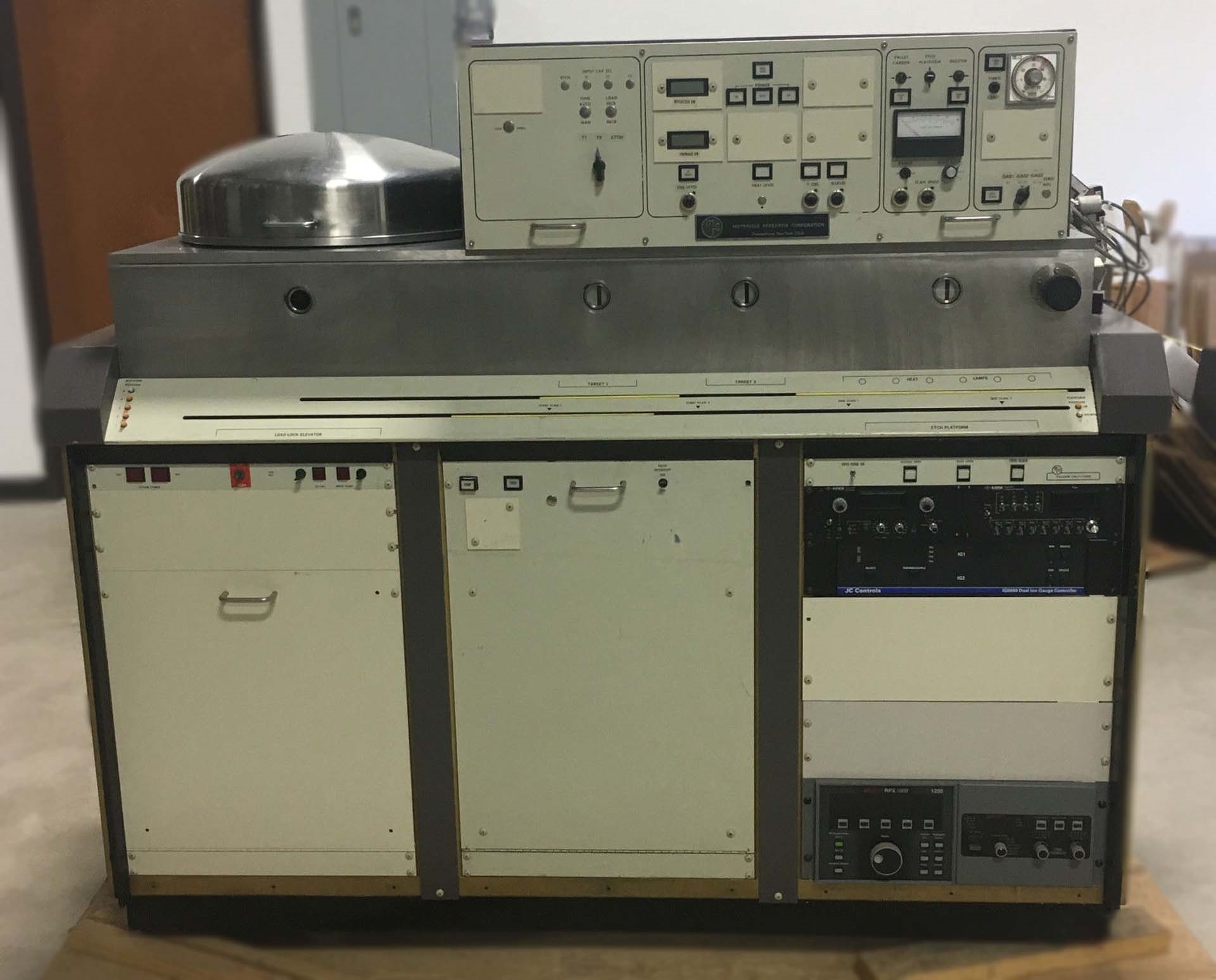

Used MRC 902 #9229738 for sale

URL successfully copied!

Tap to zoom

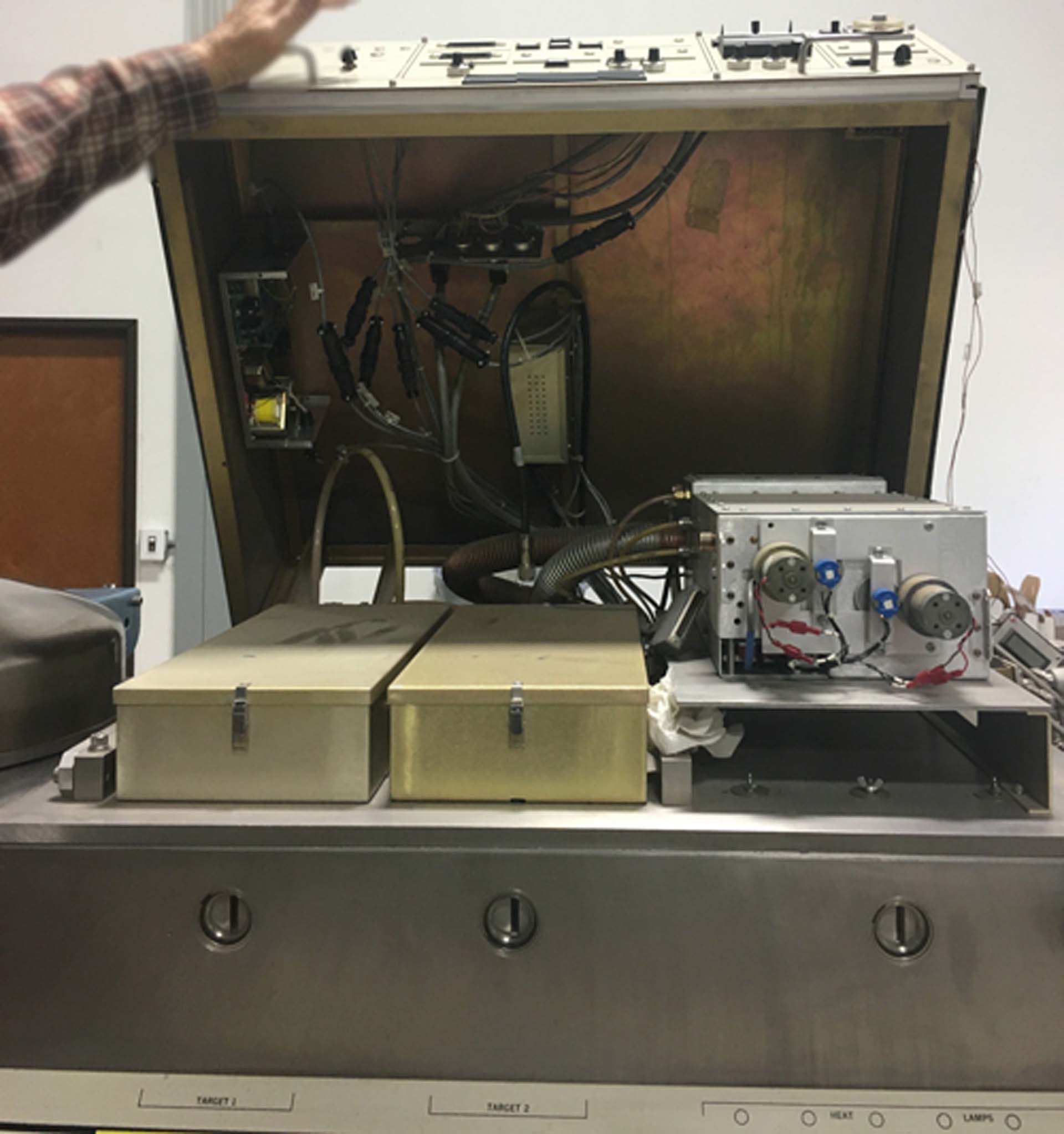

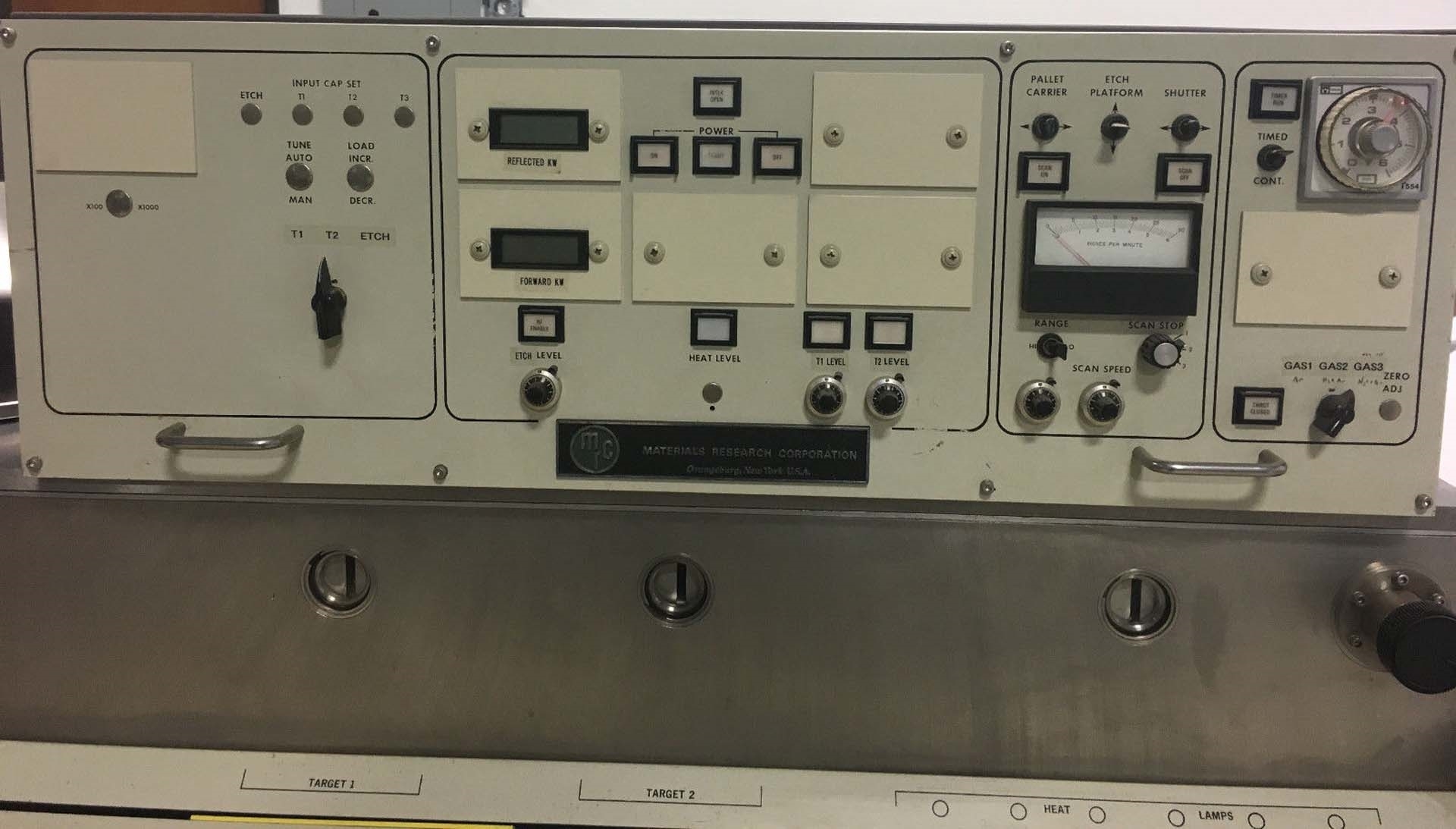

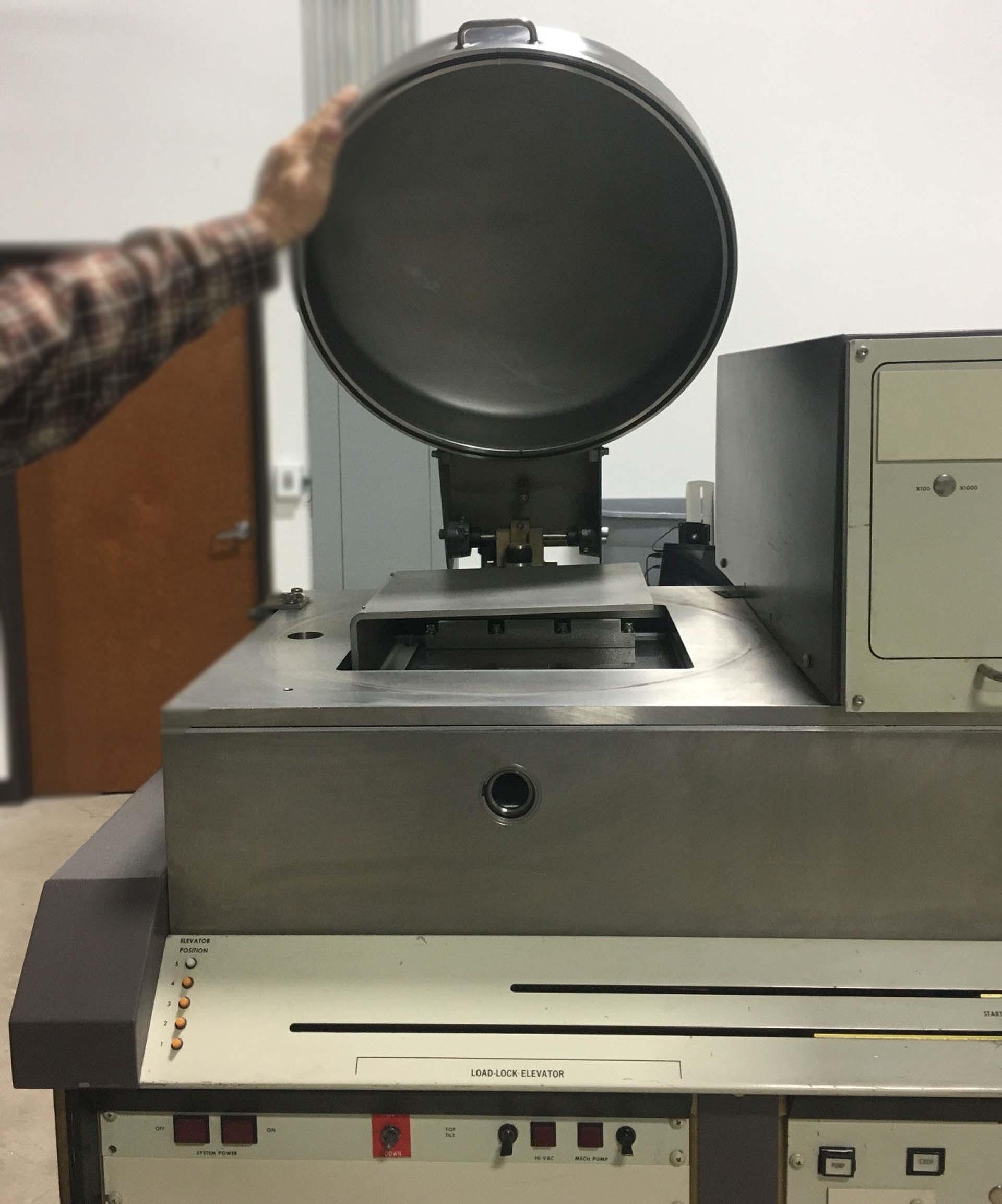

MRC 902 is a general-purpose magnetron sputtering equipment designed for the deposition of thin films. This system is capable of depositing dielectric, metallic, and transparent conductive oxides onto a variety of substrates including: silicon wafers, flat surfaces, and 3D objects. The unit features a permanent magnet DC magnetron sputter source to provide a homogeneous sputter distribution over the target surface. The magnetron source is capable of sputtering alloys and compounds with adjustable power and gas pressure rate. Its adjustable power and gas pressure rates enable users to achieve control over the overall process at different deposition rates and target materials. Additionally, the rotatable source in the machine allows for uniform coverage over large or complex substrates. 902 also offers a precise, versatile control over the deposition rate and thickness. The thickness can be adjusted between 0 - 100nm, allowing for the deposition of films with exact desired thickness. In addition, it is equipped with an automated pressure controller, allowing users to quickly change process parameters such as gas pressure and power levels. MRC 902 is designed to be easily adhered to a variety of substrates through an external vacuum chamber. This short cycle time reduces the overall deposition time from minutes to seconds allowing for high deposition rates which increase the deposition rate per hour. Additionally, the tool is highly automated, allowing for precise control and process repeatability. In terms of safety, the asset features a built-in process gas monitor that helps to avoid contamination. It also features a target monitor, which helps to detect any changes in the target material throughout the process. Moreover, it features an RF interfacing unit providing additional safety against unwanted RF interference. To sum up, 902 is a highly reliable, efficient, and accurate sputtering model suitable for a variety of thin film deposition applications. With its adjustable gas pressure and power levels, precise film thickness control, and automated pressure control, it can help to improve the quality of thin films and increase deposition rate per hour. All in all, MRC 902 is a great option for any lab creating thin film products.

There are no reviews yet