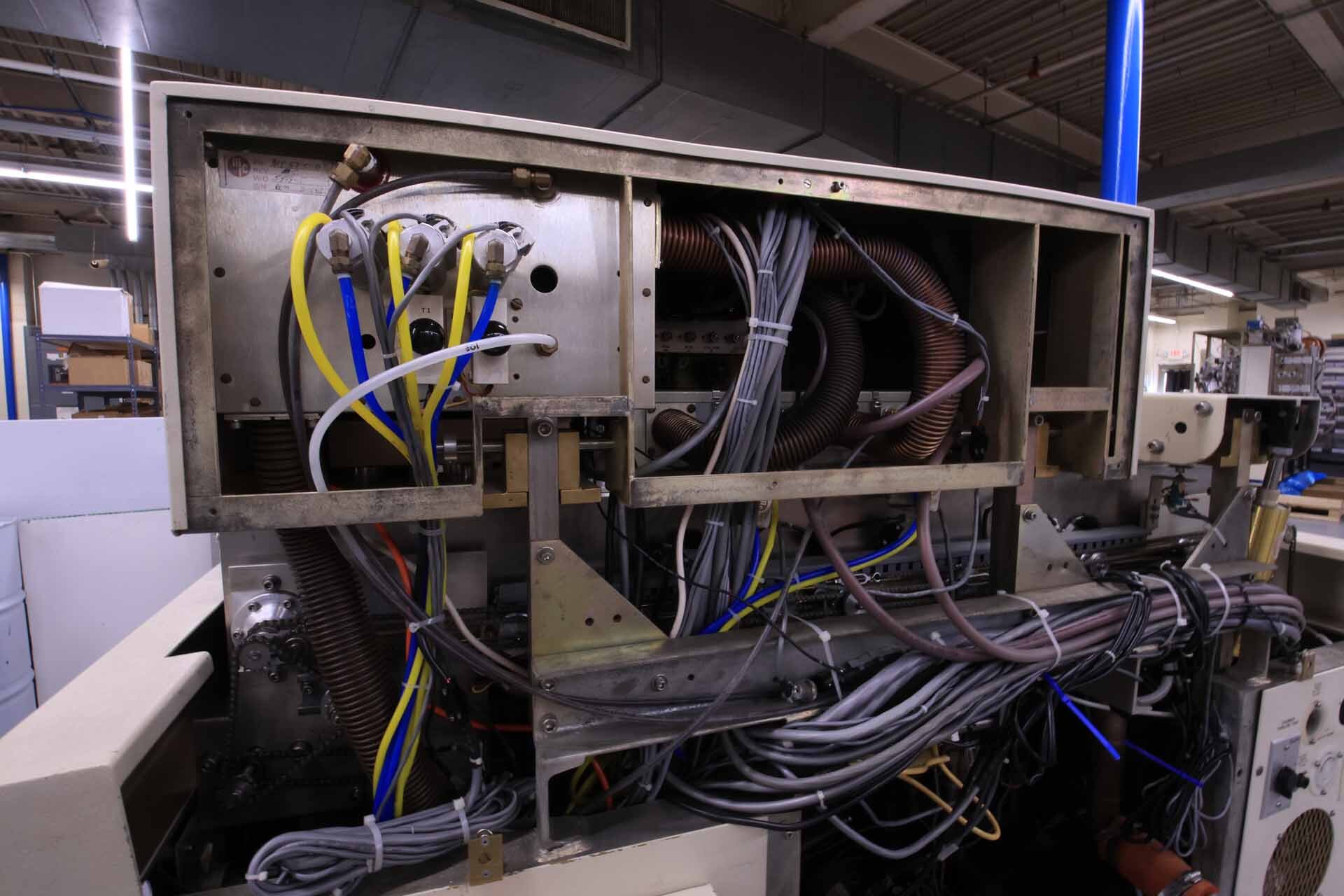

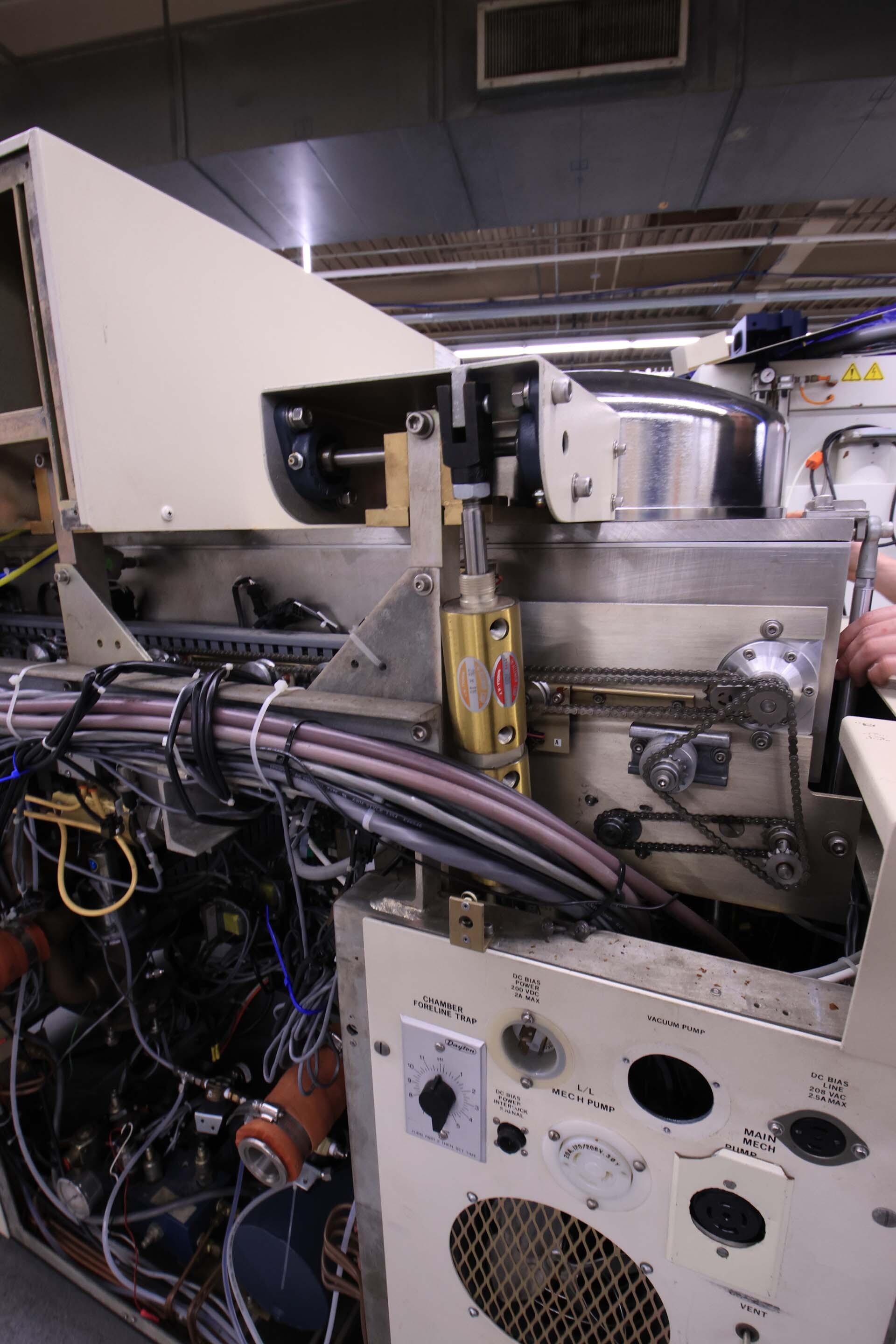

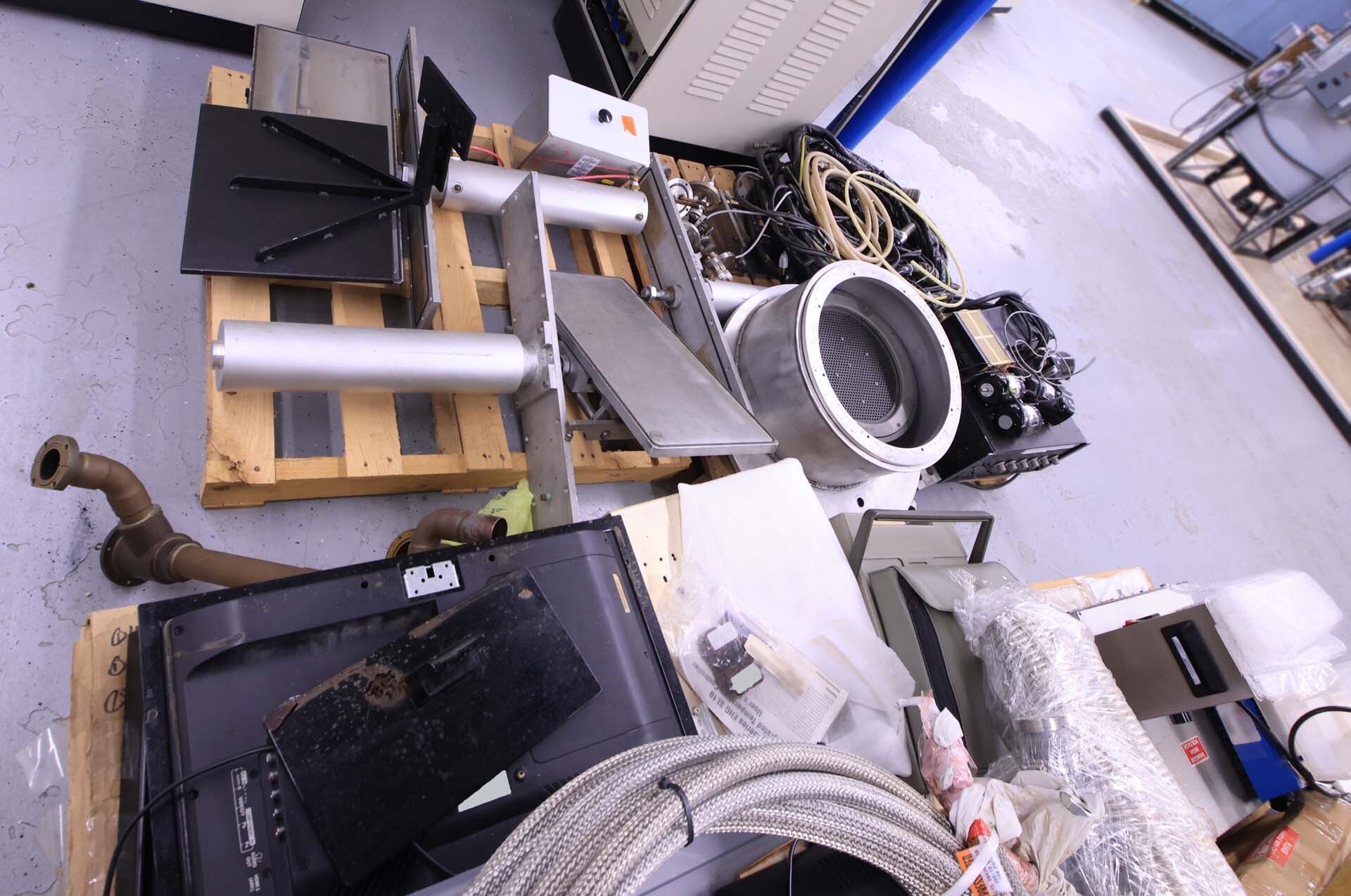

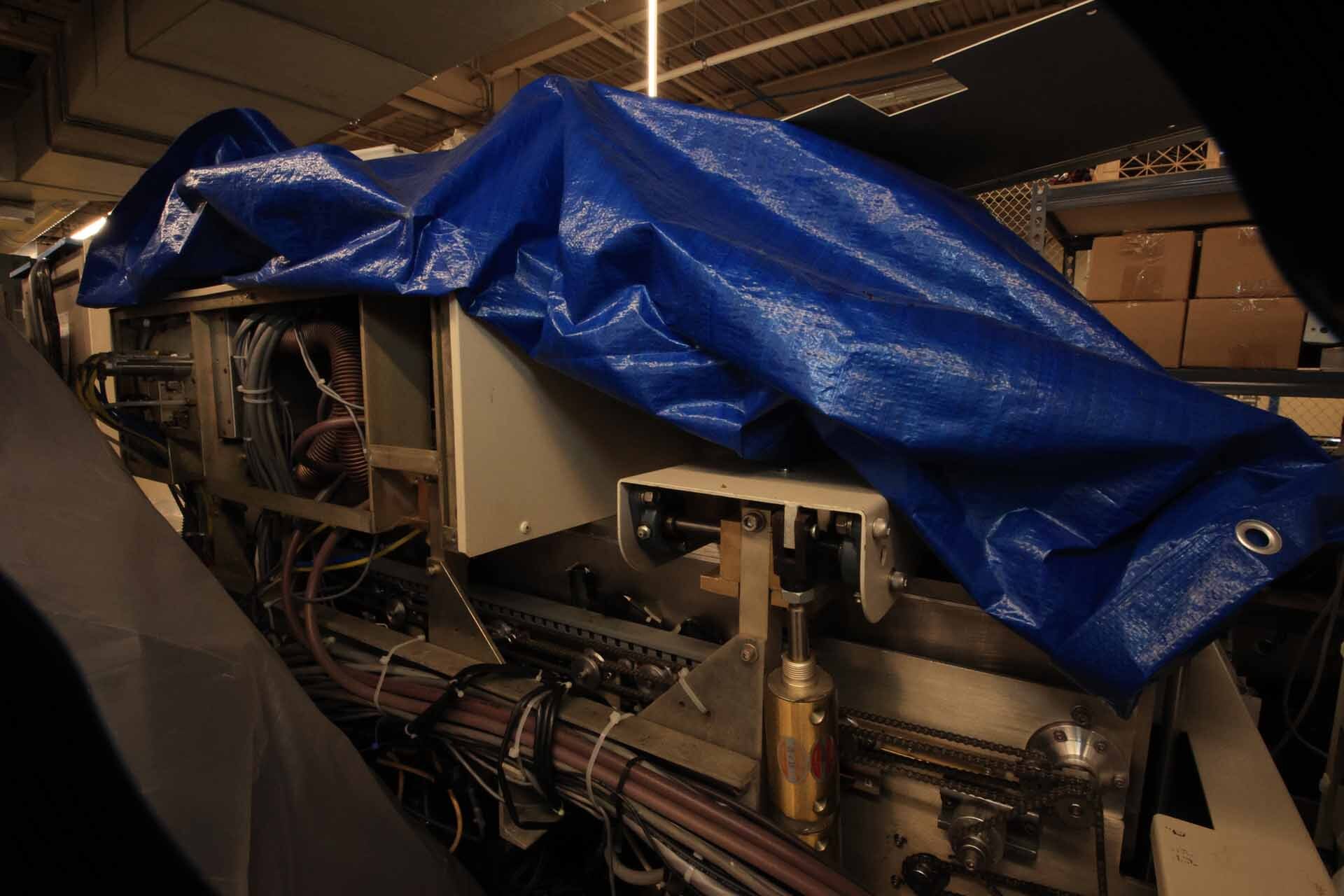

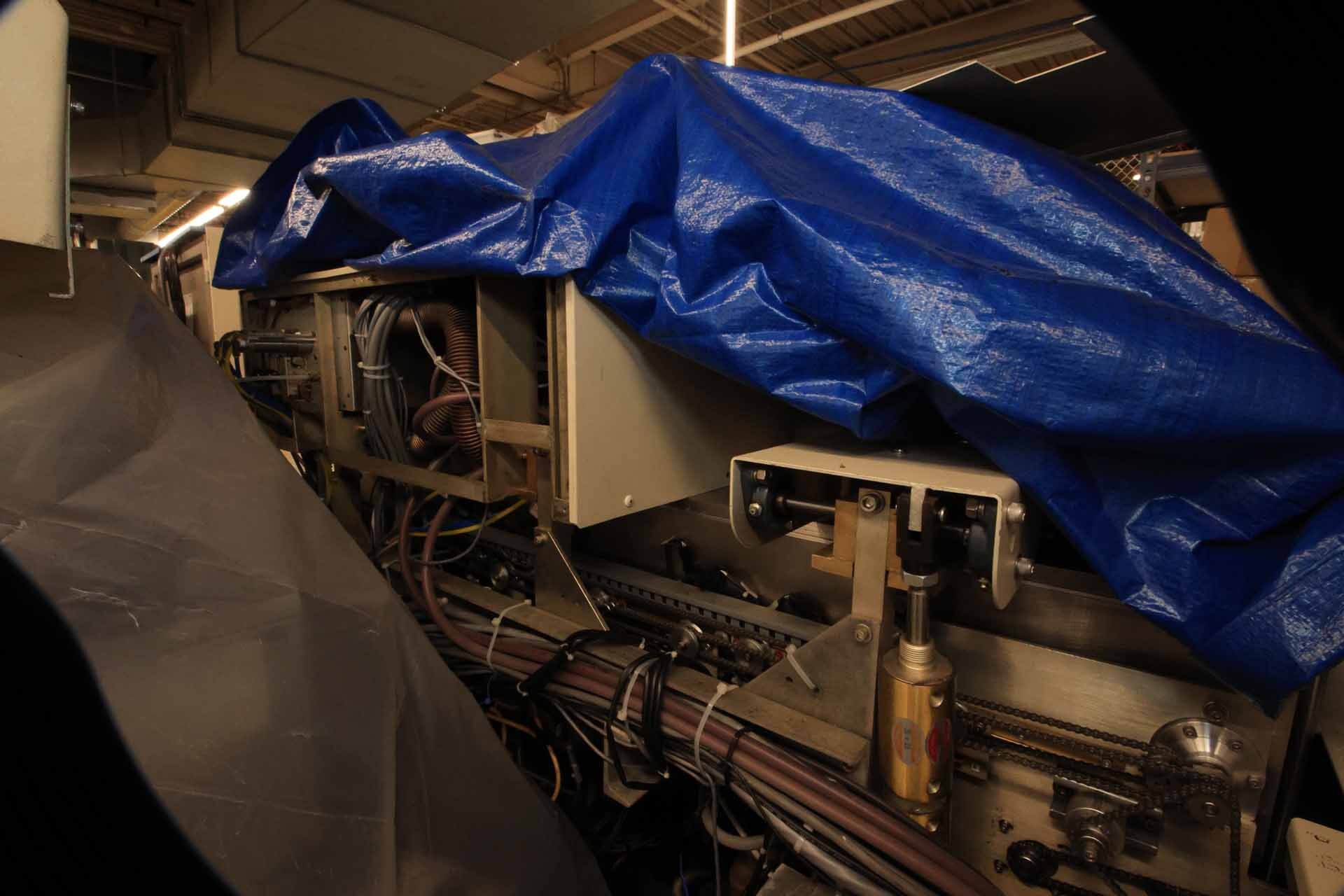

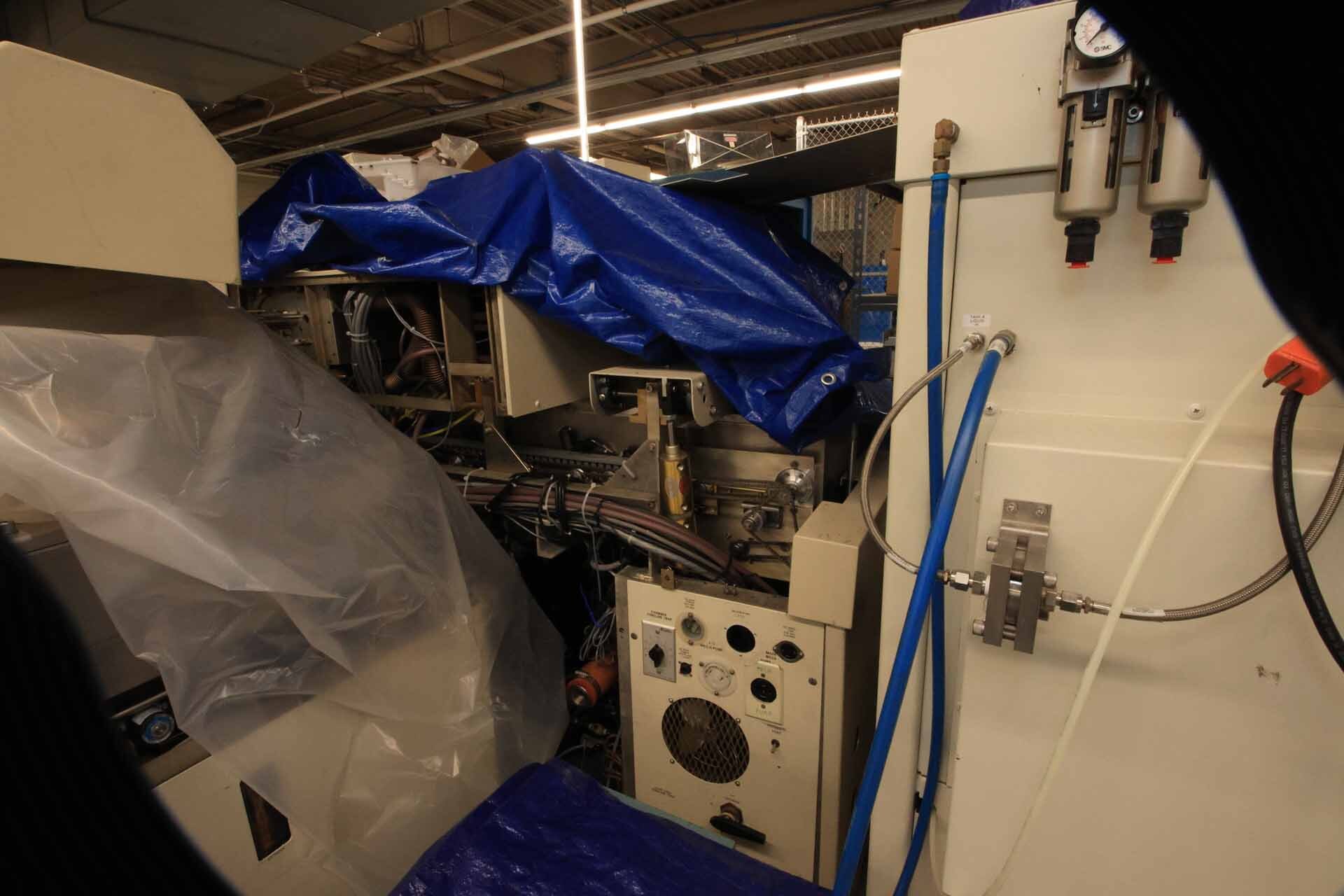

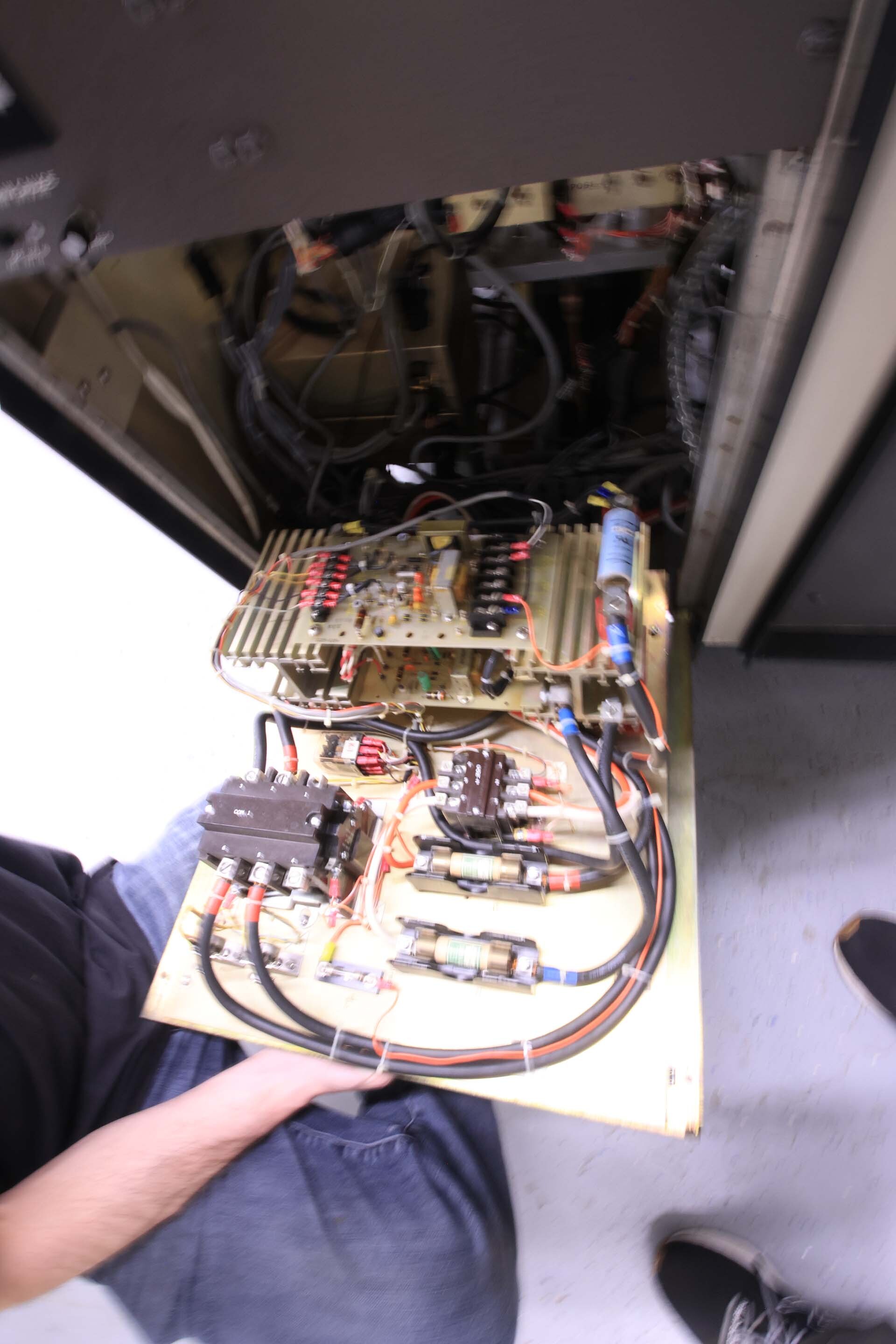

Used MRC 902M #9255814 for sale

URL successfully copied!

Tap to zoom

ID: 9255814

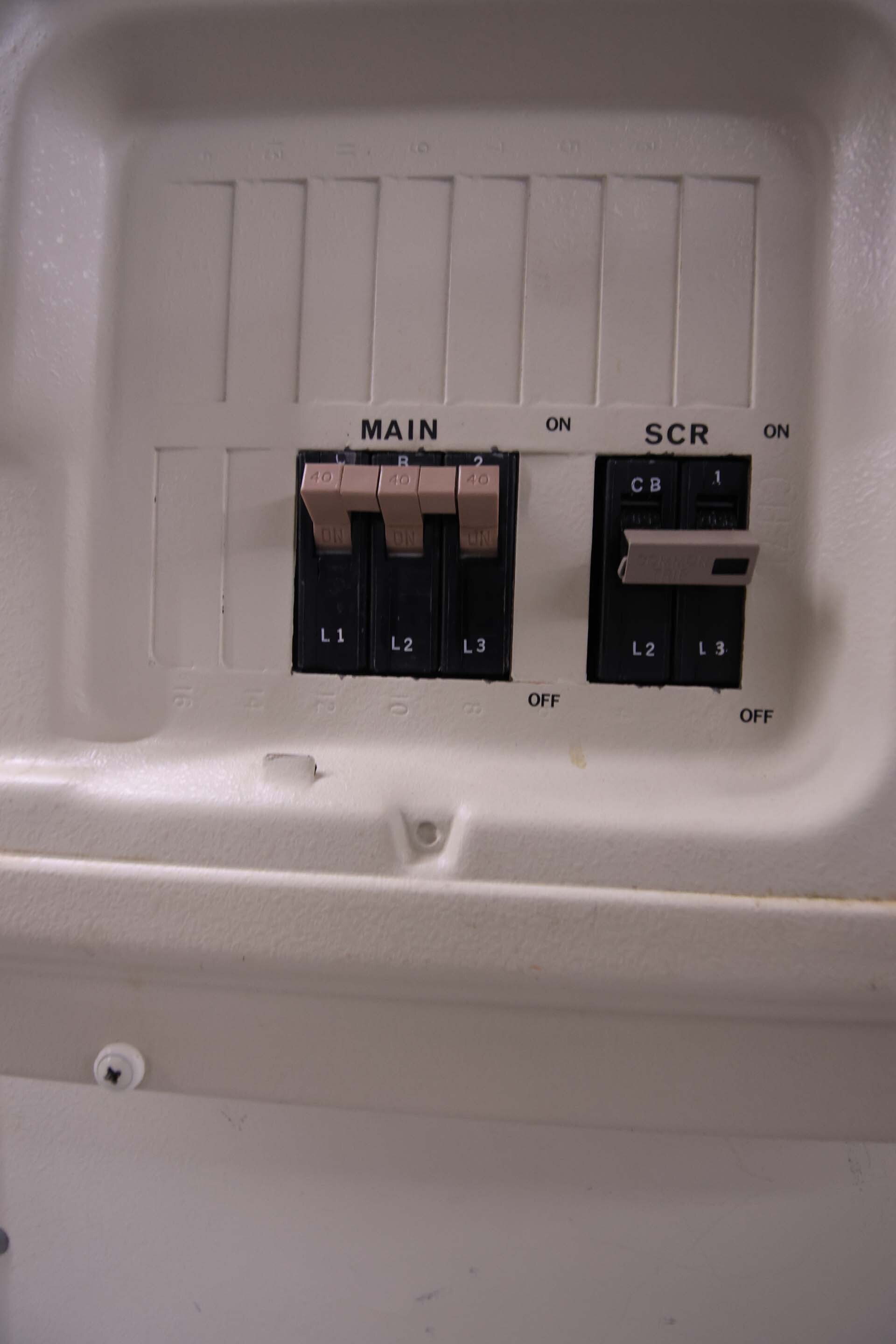

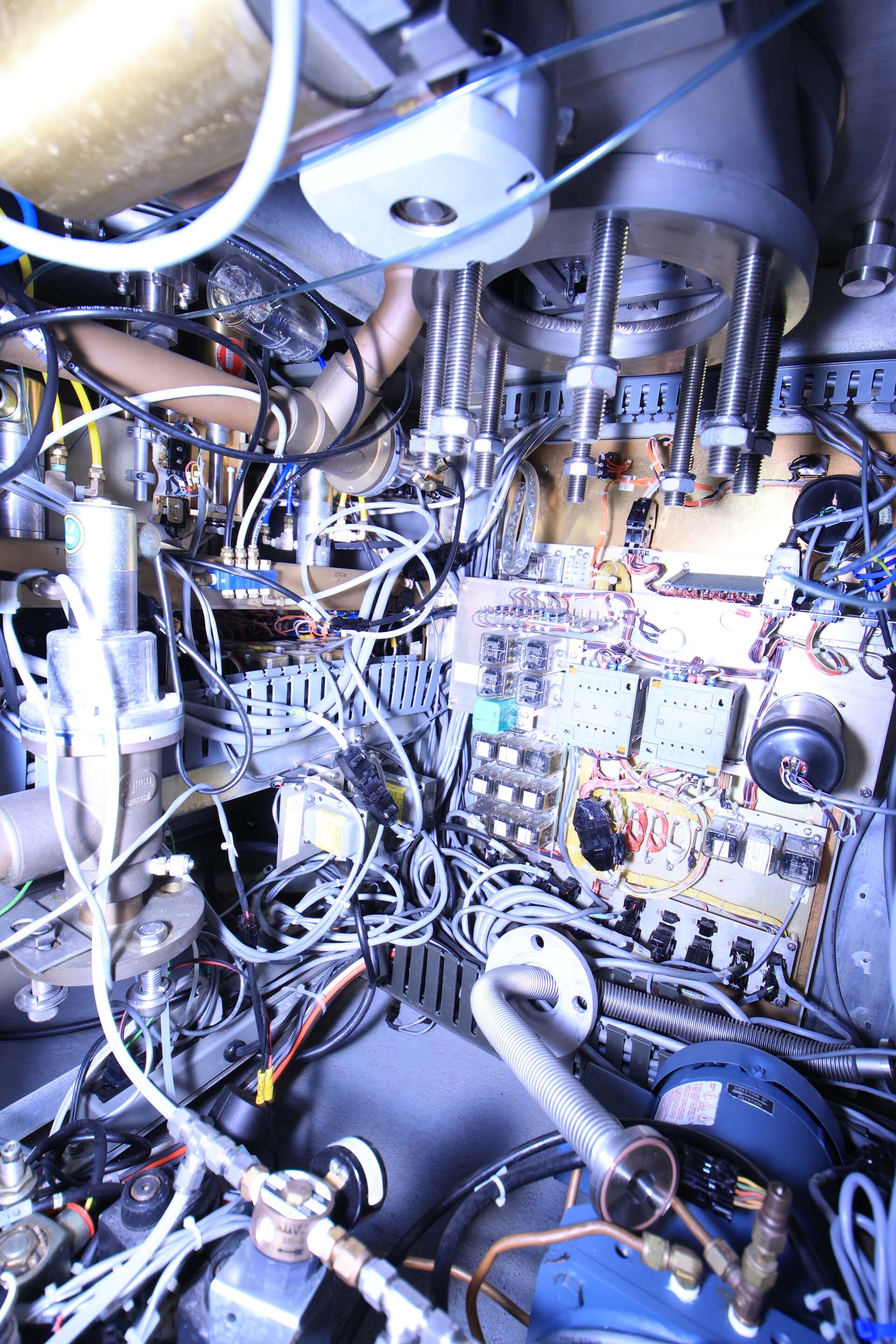

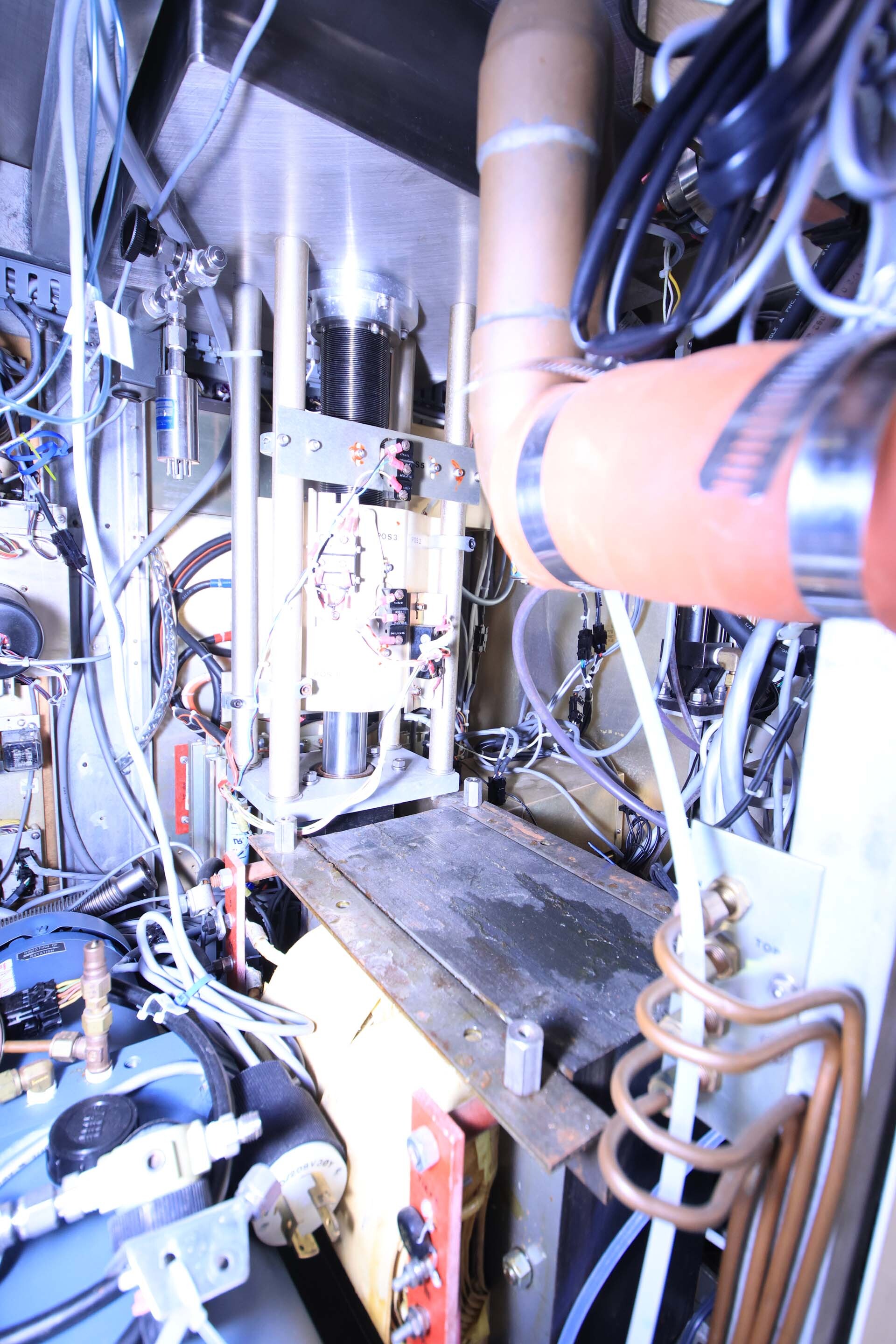

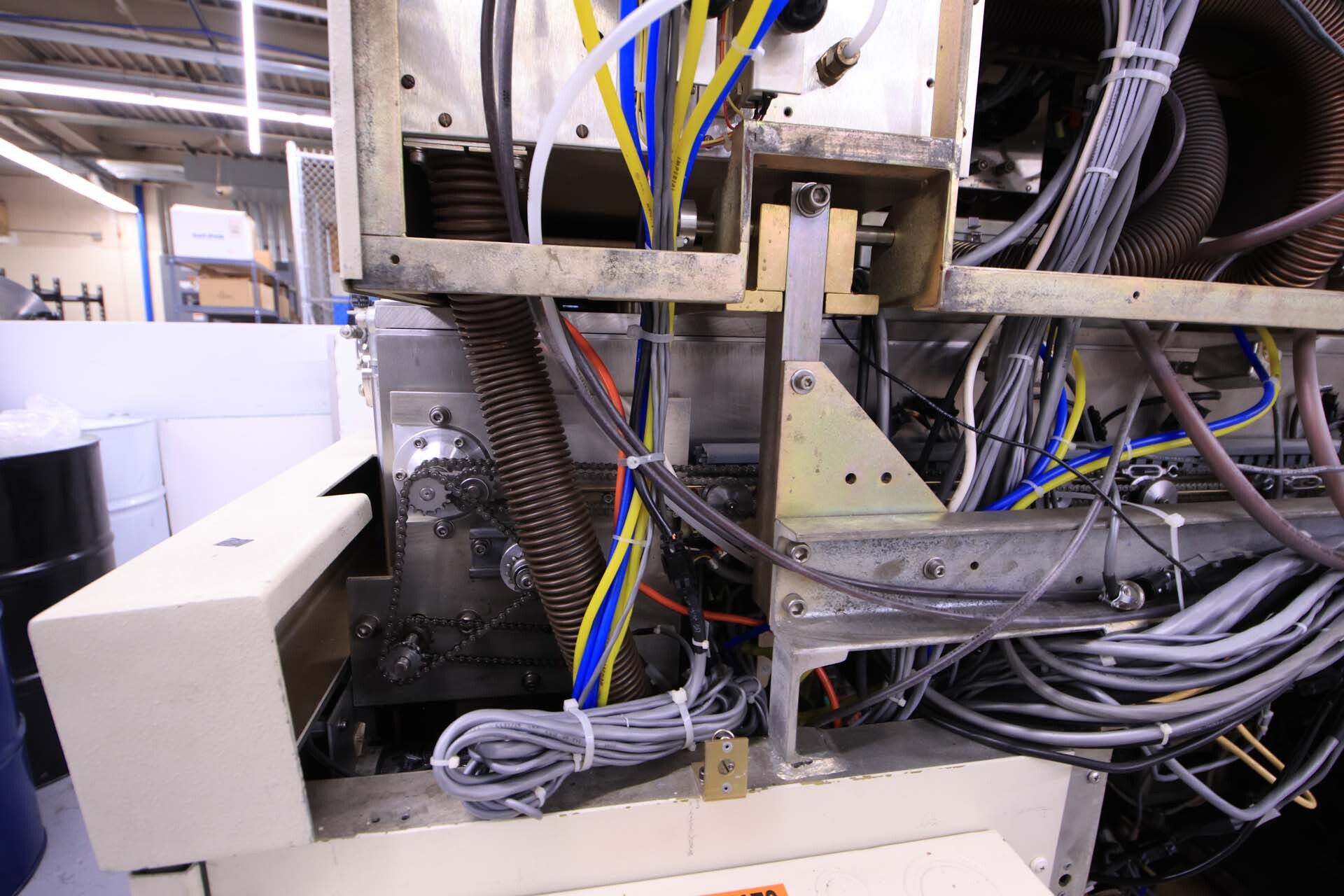

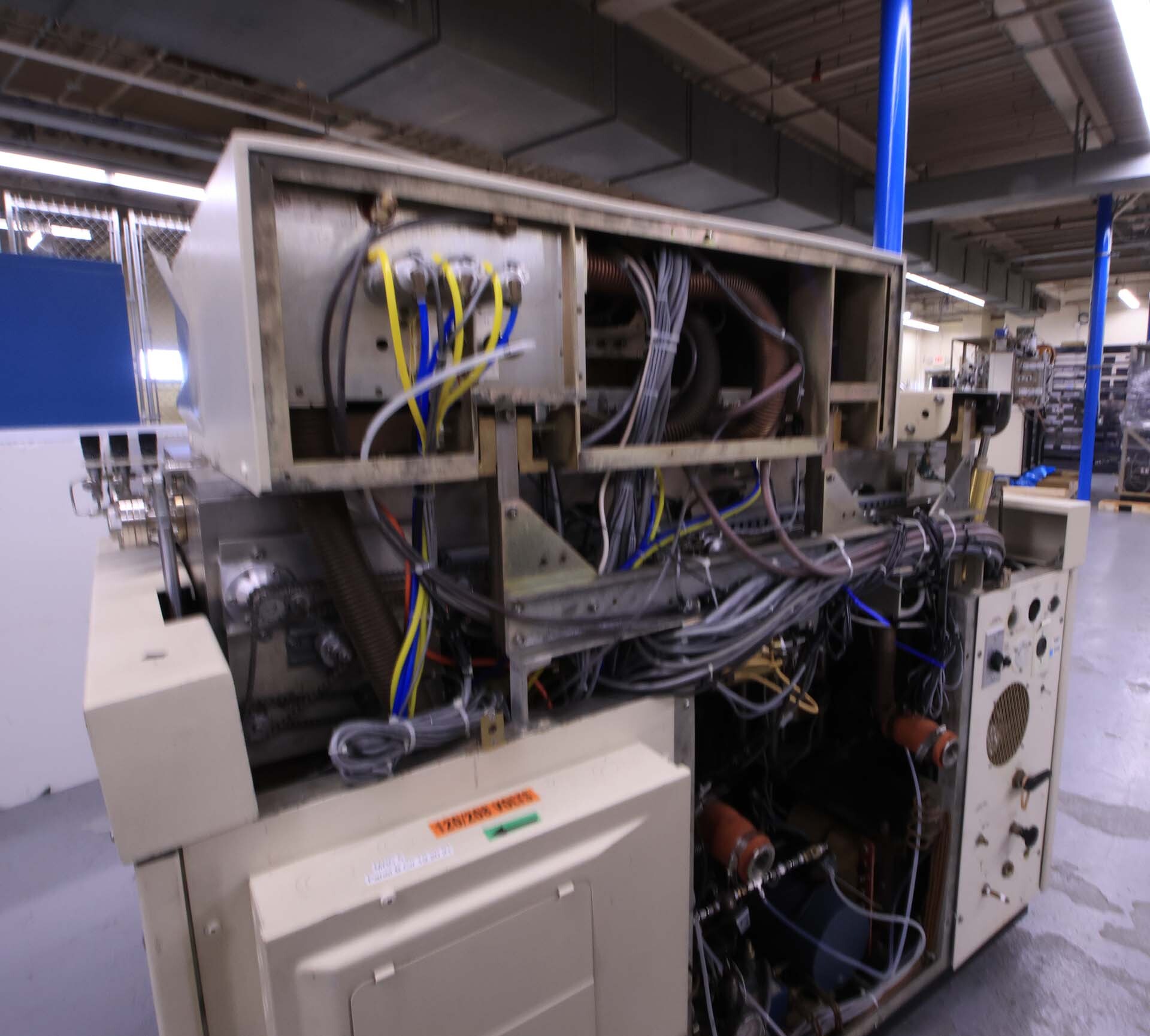

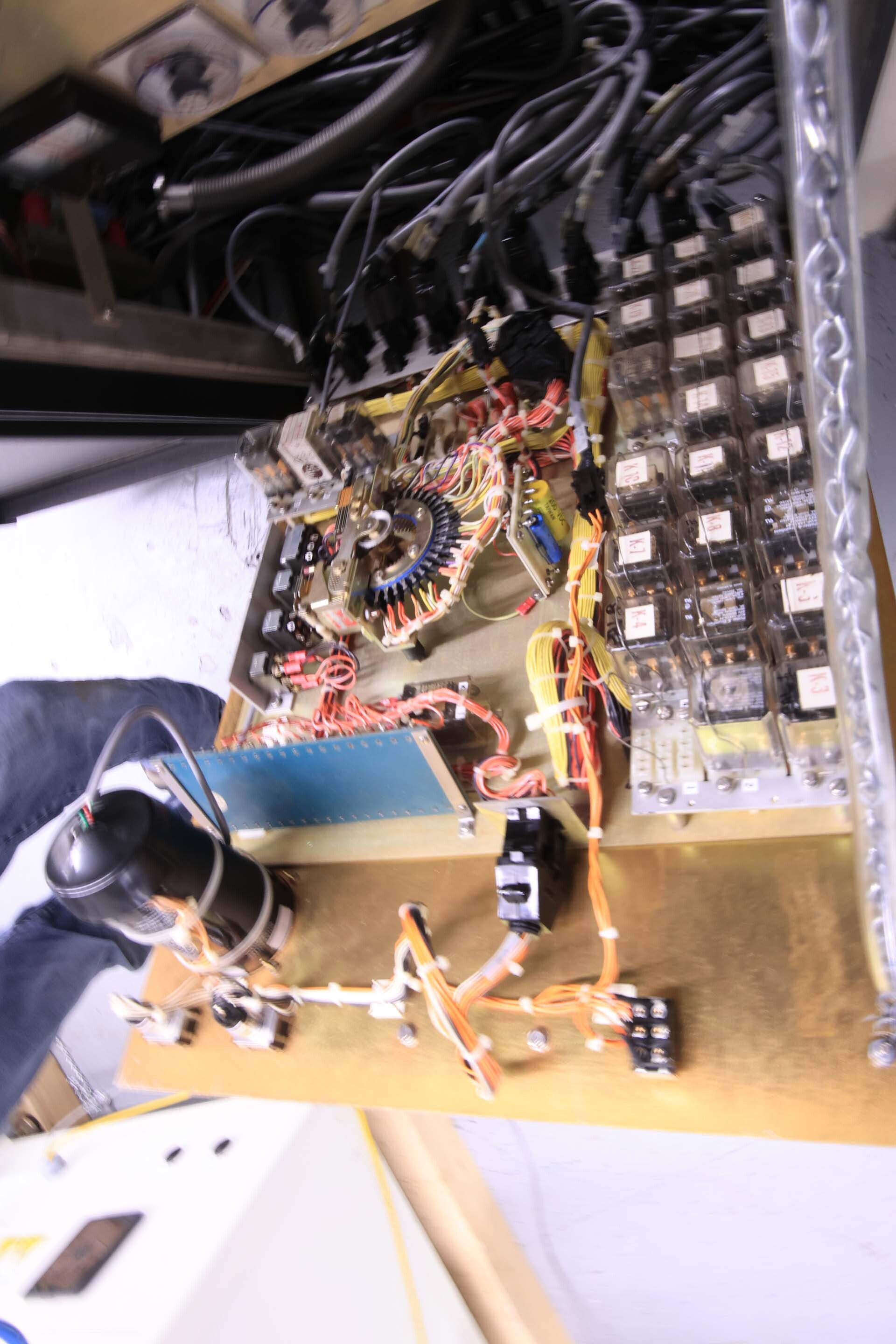

Sputtering system

(2) Standard rectangular targets

Sputter etch

Pallet size: 12" x 12”.

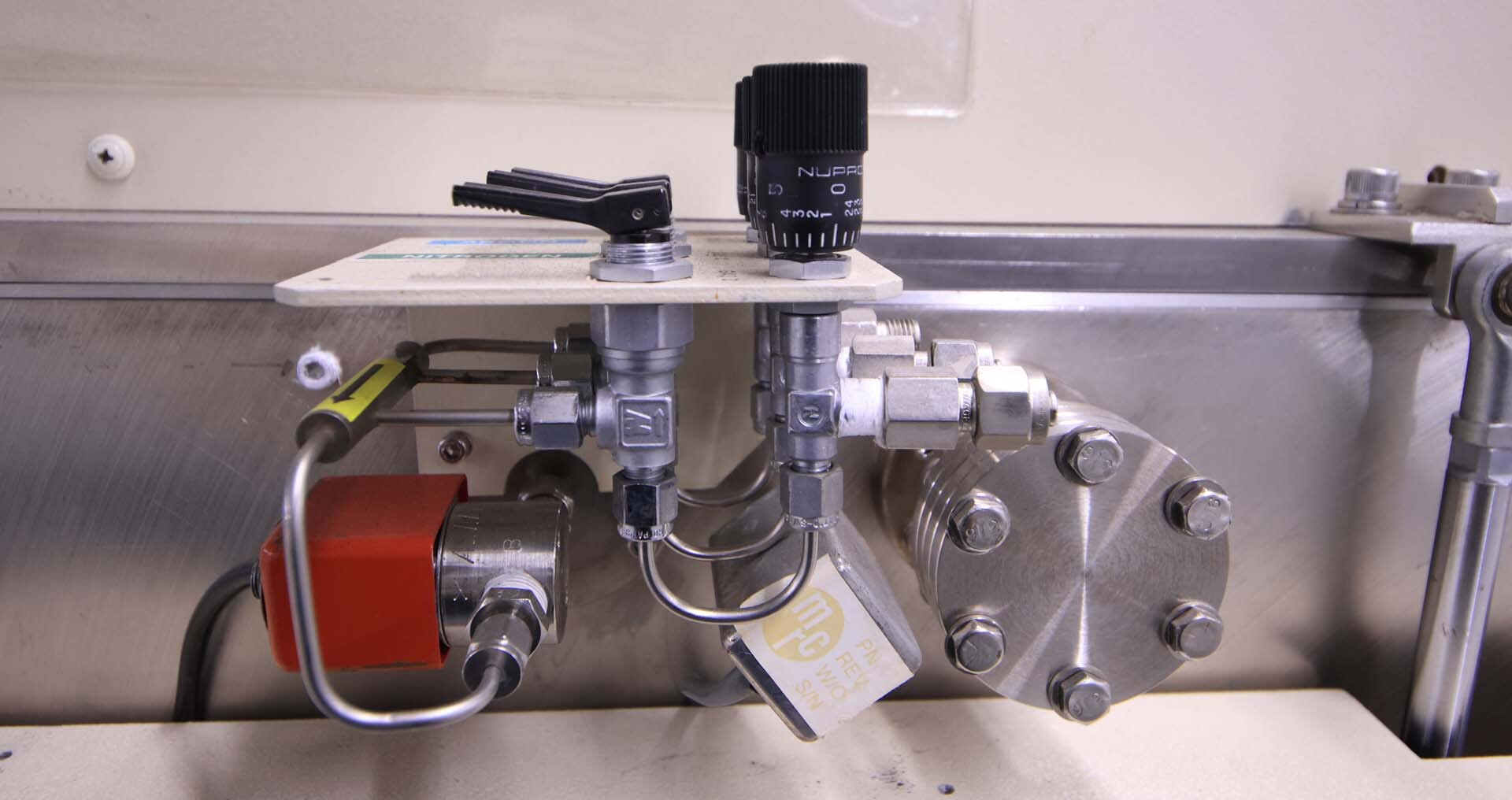

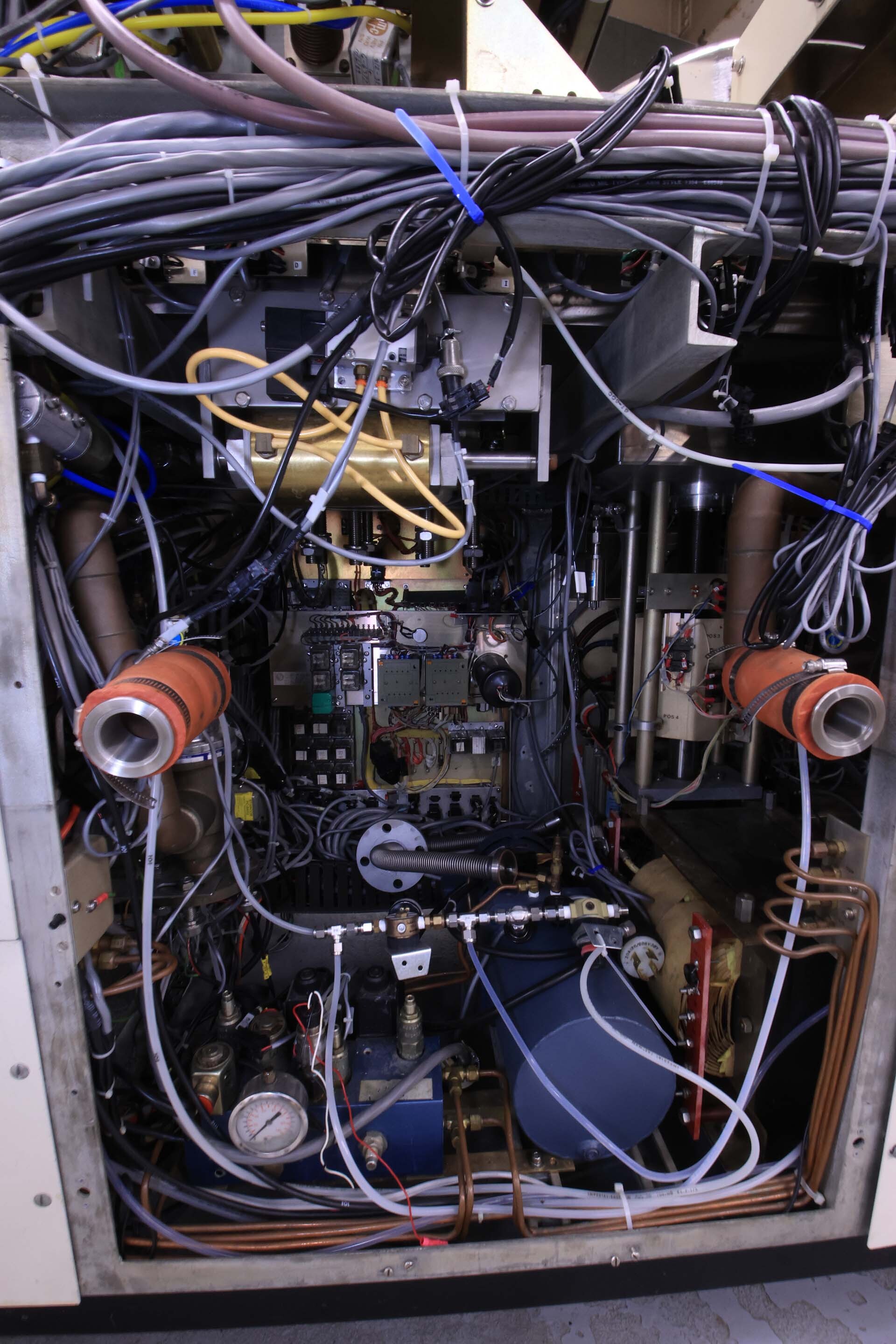

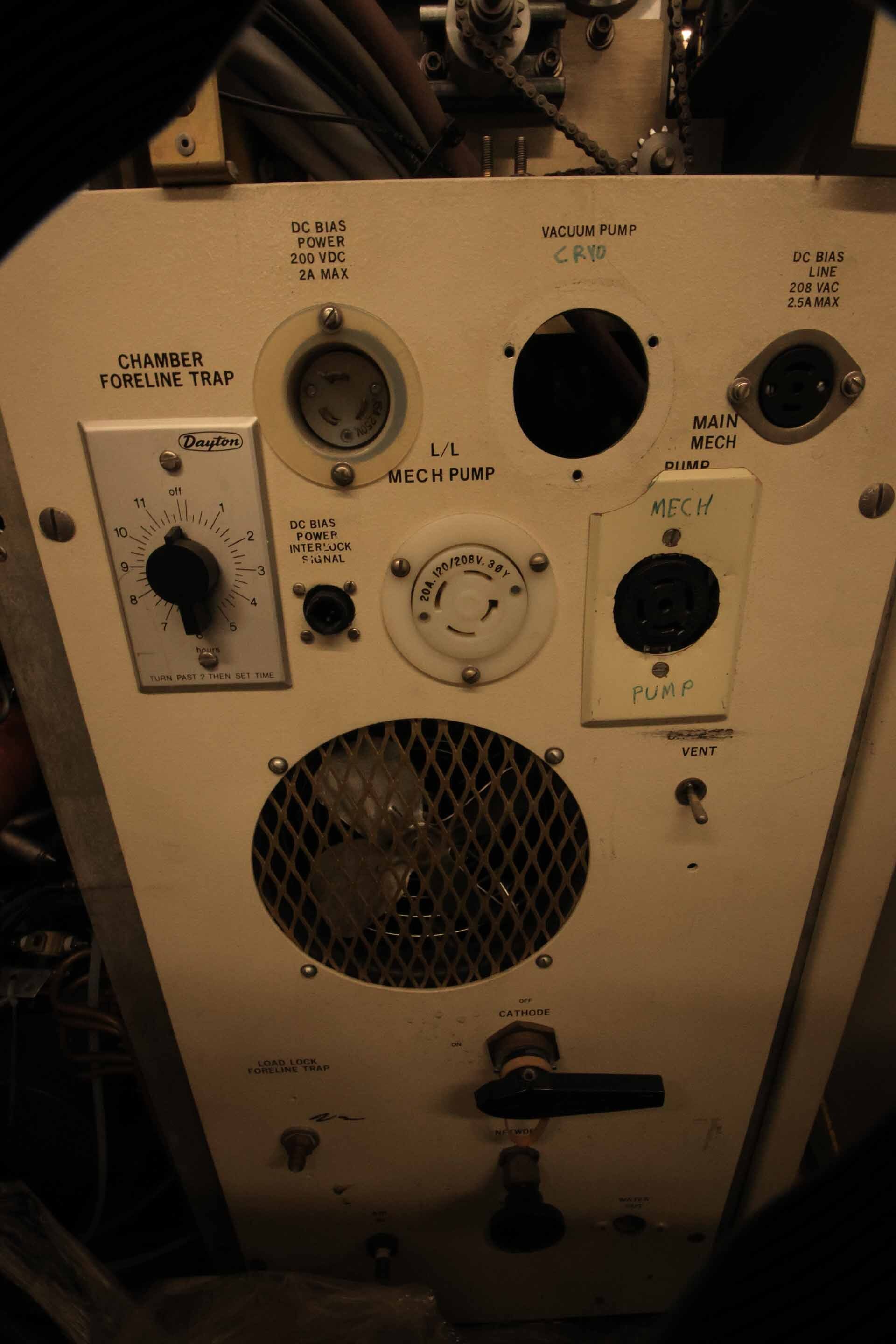

MRC 902M is a sputtering equipment used in the thin film deposition process. Sputter deposition is a physical vapor deposition (PVD) process where a thin film of material is applied to a substrate. This deposition process relies on kinetic energy developed in a vacuum chamber to remove thin layers of a target material and deposit them on the substrate. 902M system features a hybrid direct-current/pulsed-dc power source, which allows for precise control of the sputter deposition process. It includes dual high-efficiency, segmented, linear 7.5-kW magnetrons with physical shield/water-cooling functionality for multi-chamber operations. An advanced substrate-rotation unit also allows for deposition uniformity on large substrates. MRC 902M sputter includes a wide range of process gas capabilities, allowing the user to sputter a variety of materials. Specifically, it allows for reactive sputtering with Oxygen, Nitrogen and Argon, making it ideal for depositing oxides, nitrides and silicides. The machine also features a wide range of pressure/process parameters that can be precisely adjusted, allowing for a full range of process control. 902M provides high-quality, low-cost sputtering deposition of thin-film materials in a single chamber. Its advanced substrate-rotation tool provides highly uniform and repeatable deposition, while its advanced process gas capabilities allow for reactive sputtering of a variety of materials. Its robust, high-efficiency power source and precise process parameters provide application-specific thin-film deposition, making it a powerful asset for a variety of thin-film deposition applications.

There are no reviews yet