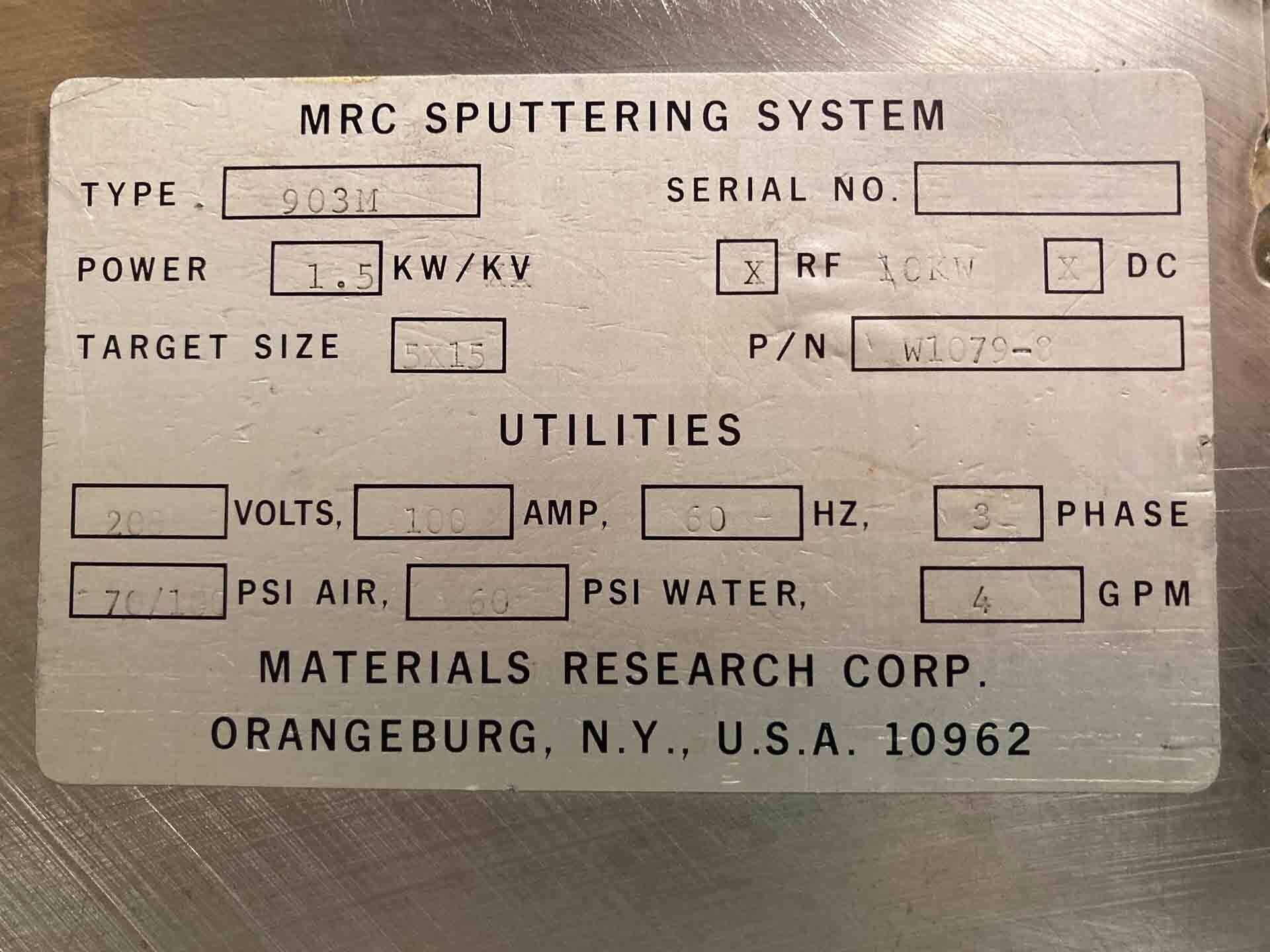

Used MRC 903M #9166595 for sale

URL successfully copied!

Tap to zoom

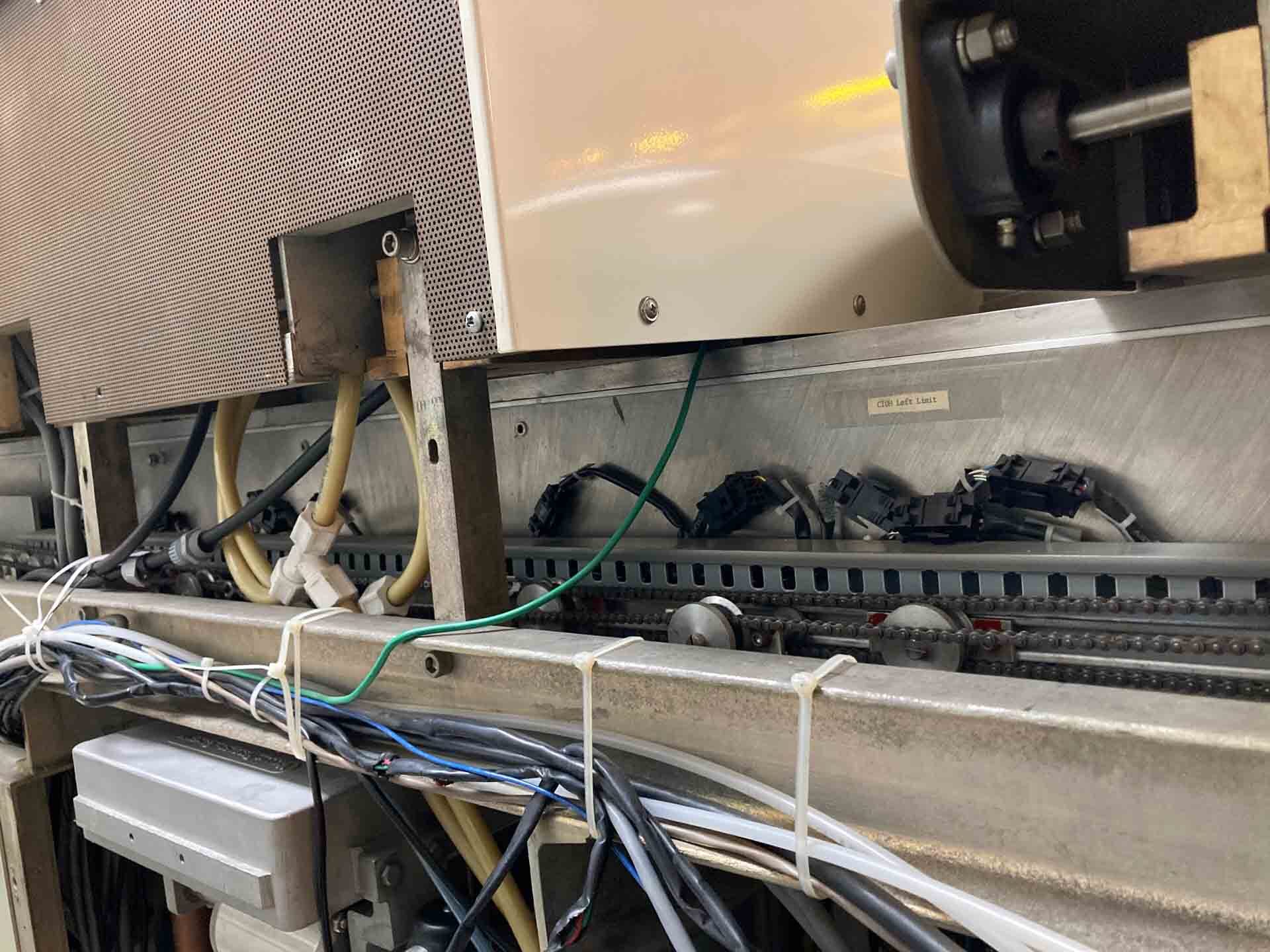

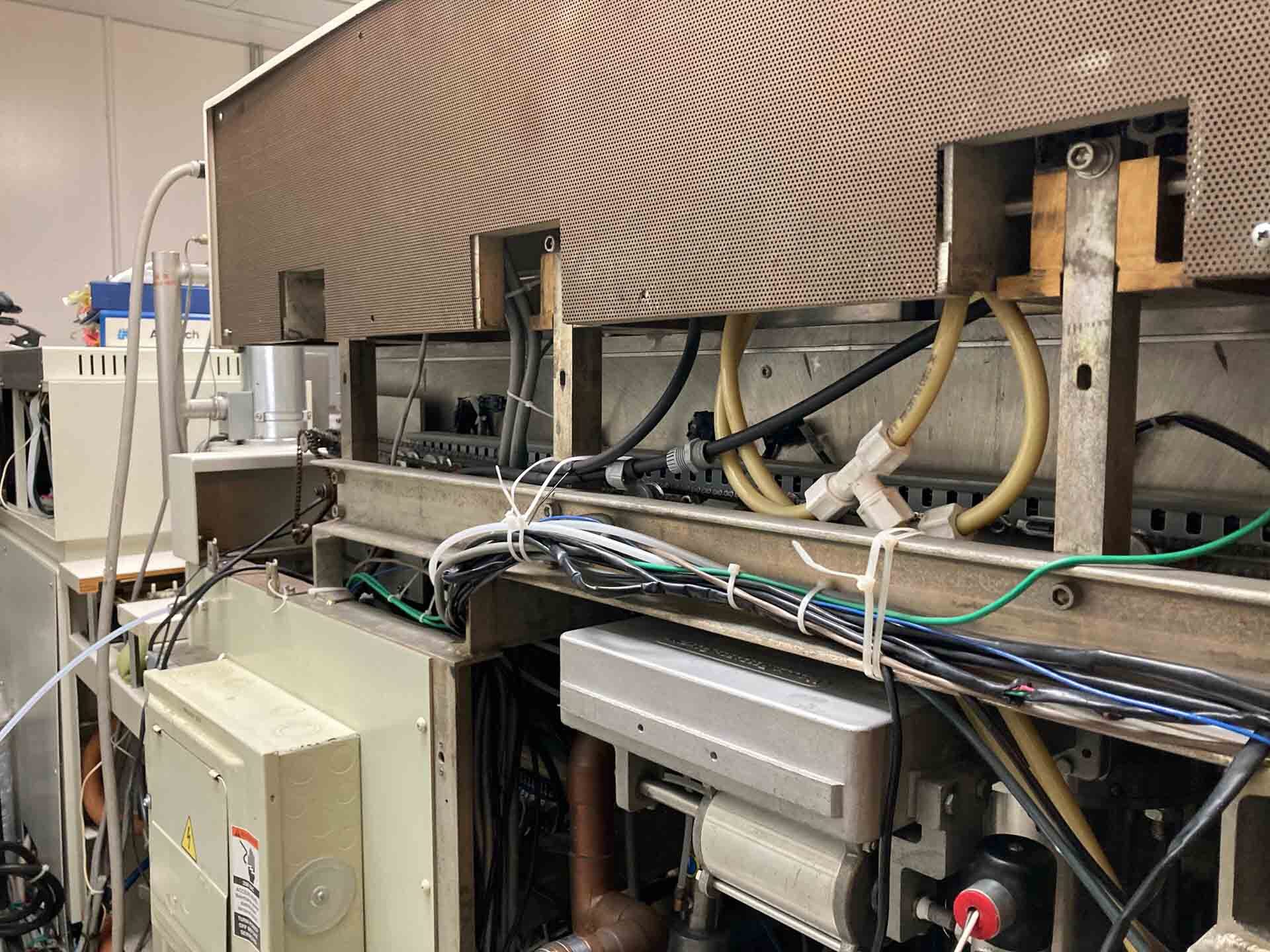

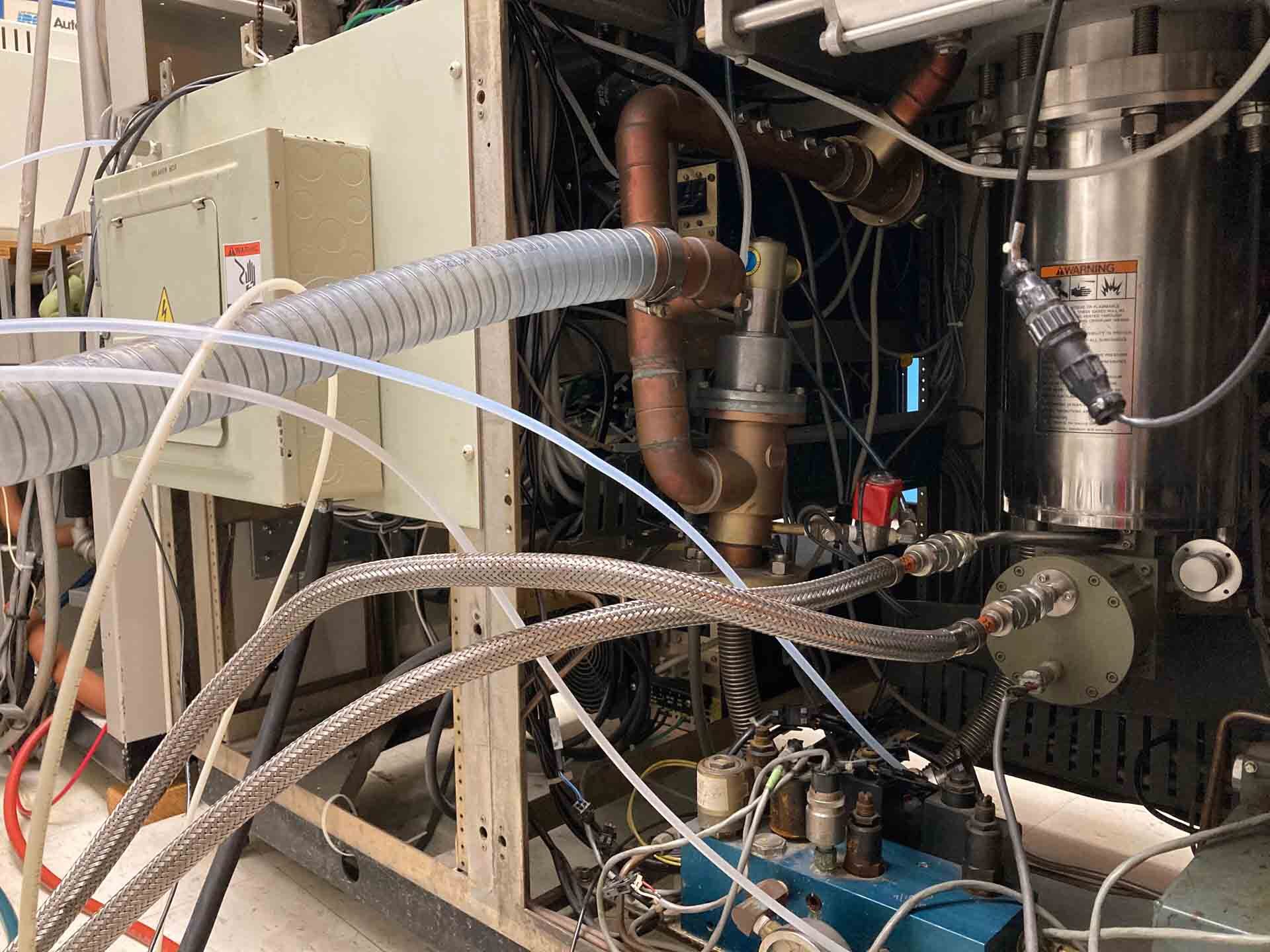

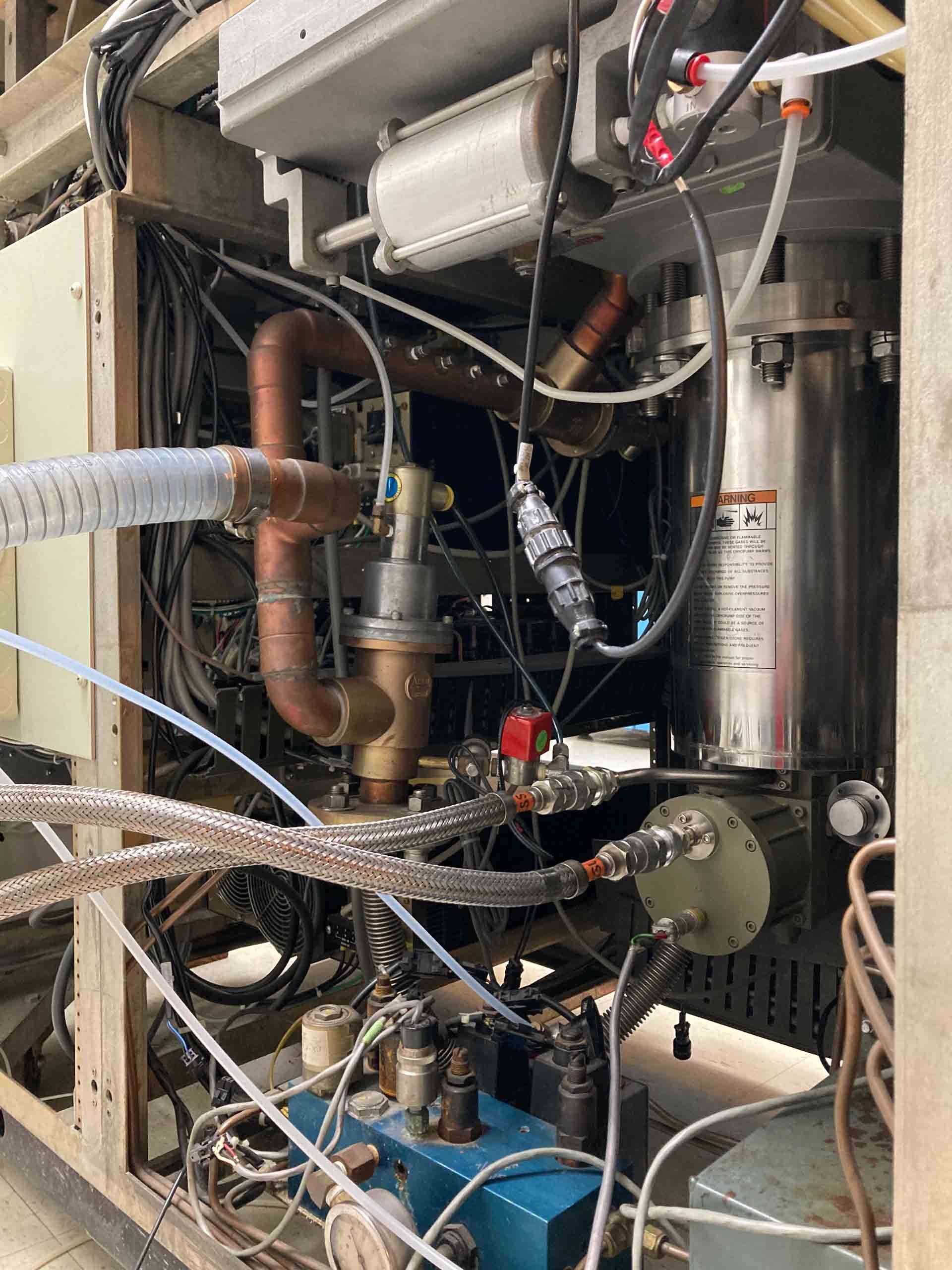

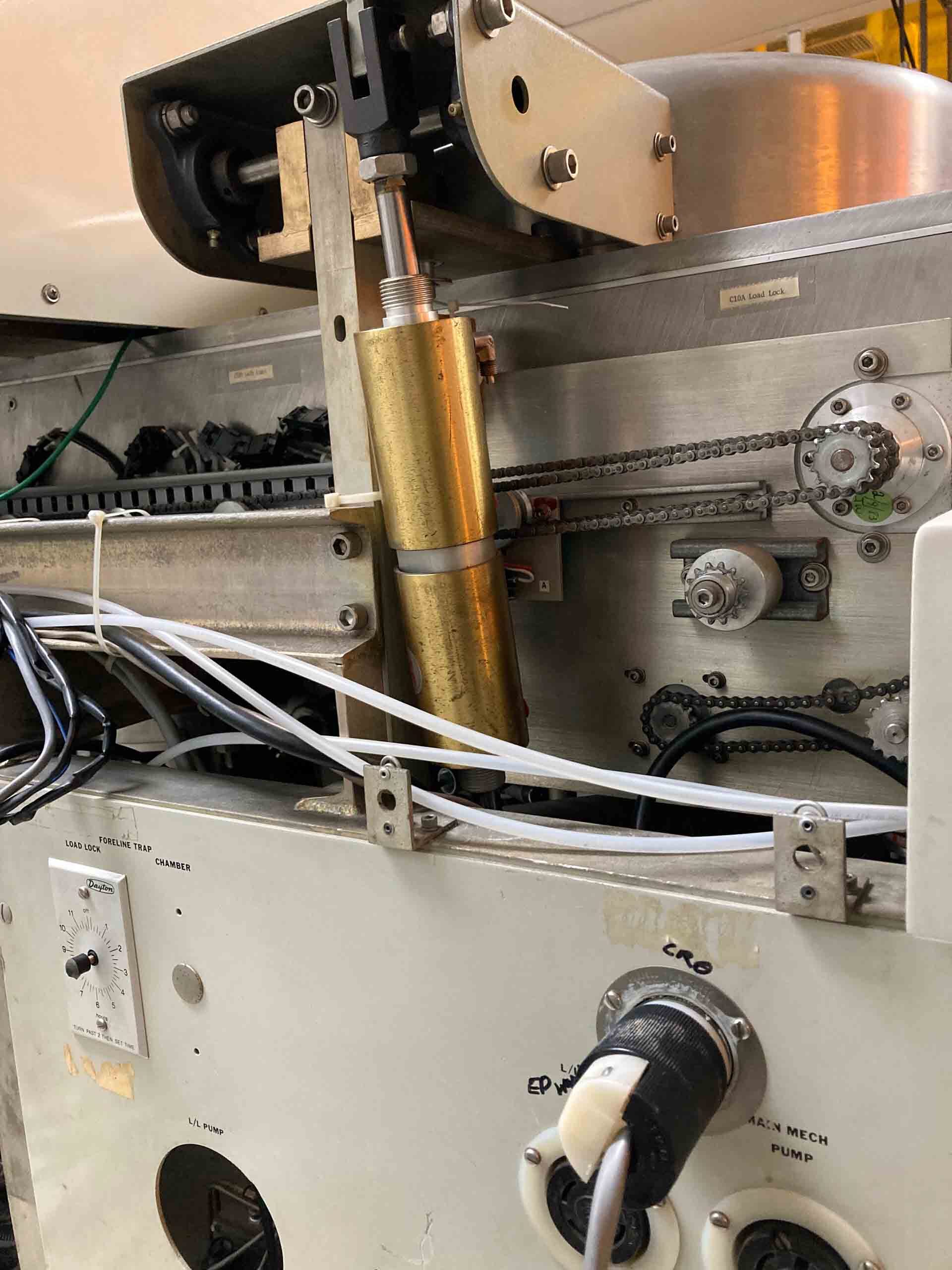

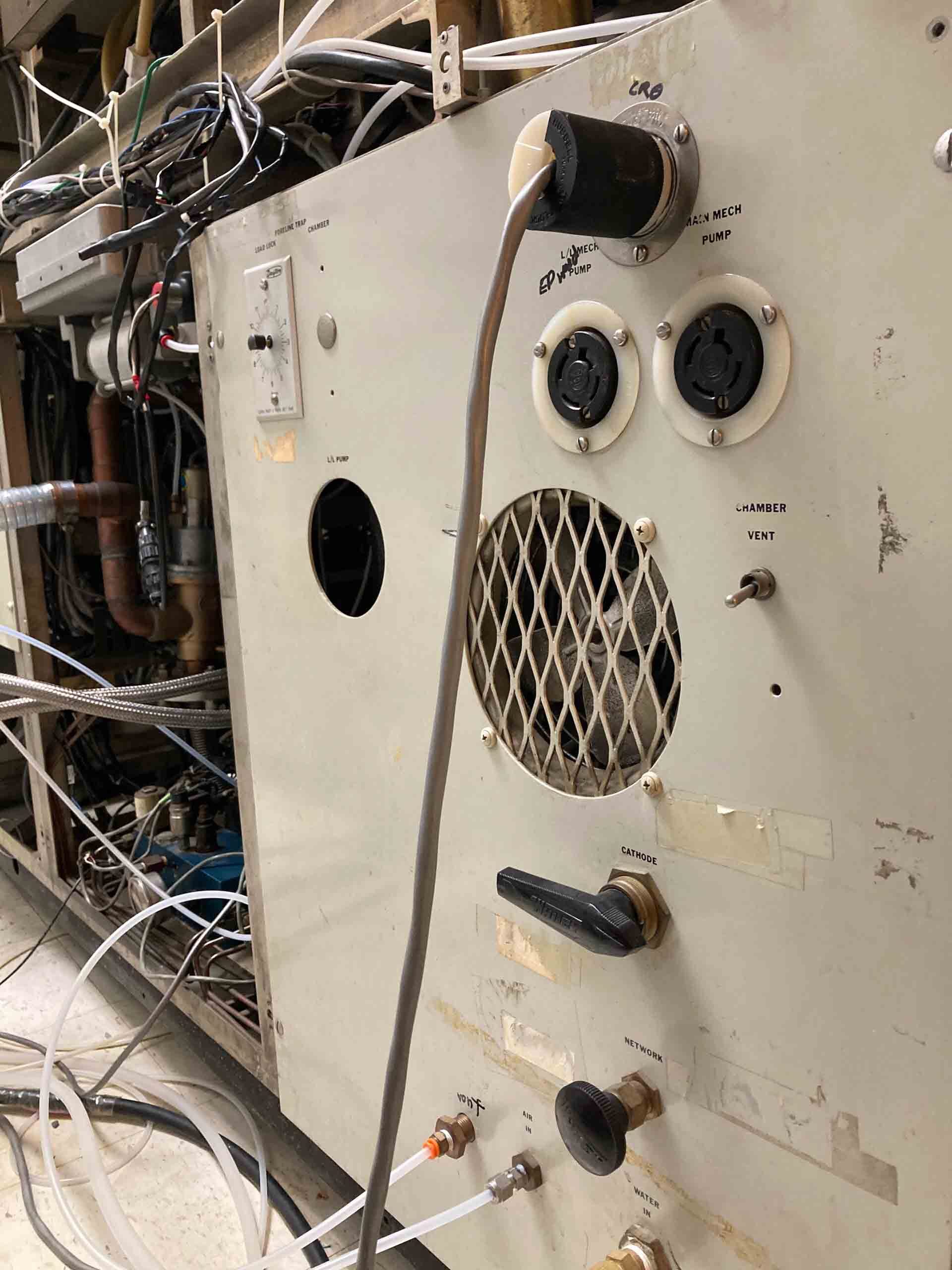

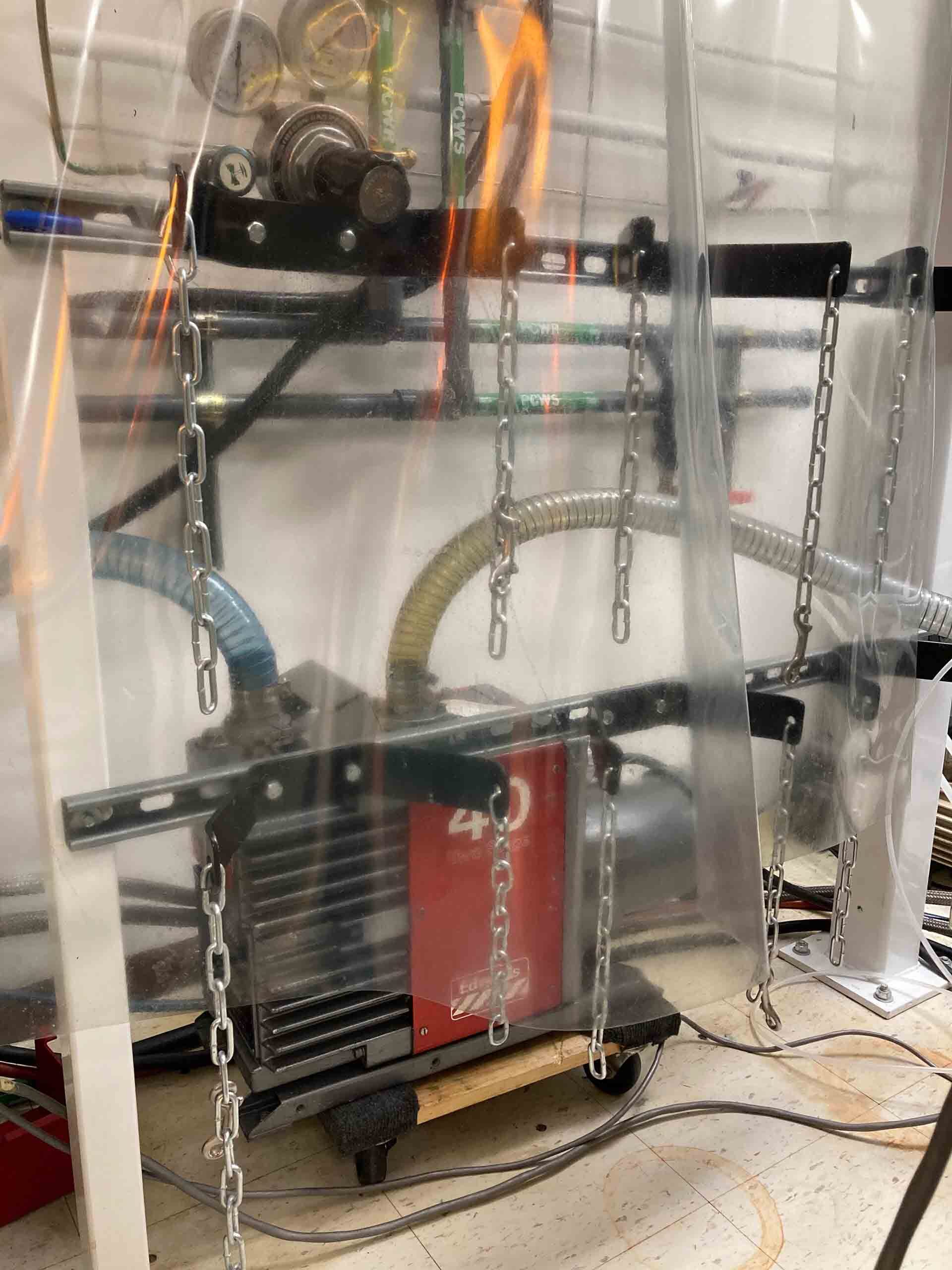

MRC 903M is a highly versatile and reliable sputtering equipment designed and manufactured by MuRata Machinery Ltd. It is an advanced sputtering tool suitable for precision cleaning, etching, deposition, and thin-film processing applications on a wide range of substrates such as silicon, copper, glass, polymers, and low-k materials. It consists of three main components: a precisely controlled vacuum chamber, a specially designed gas manifold, and a robotic sample-stage motion-control system. MRC 903 M vacuum chamber is designed to achieve a high degree of mechanical, thermal, and vacuum stability, with an ultimate pressure of 1x10-6 Torr. Temperature-controlled heating components can maintain uniform temperatures between -25 Celsius to +150 Celsius. The chamber also features a high-purity, low-outgassing Non-Evaporable Getter Pump (NEG) which removes non-condensable gases and prevents sample contamination. 903M is certified to be compatible with a wide range of process gases, including high-purity Ar, He, O2, N2, NF3, CF4, and other specialty gases. The gas manifold unit efficiently controls the flow, composition, and pressure of different gases used in the sputtering process. There are separate chambers for the argon and inert gas, and a bypass valve for adjusting the pressure. Gas control valves are accurately positioned to enable precisely adjustment of gas flow. This enables 903 M to precisely control the deposition profile and layer thicknesses for different substrates. MRC 903M robotic sample stage is pre-installed with a two-axis sample holder and mechanical clamping machine. It features a high-precision linear motor in X- and Y-axis motion, allowing for precise positioning and a very smooth motion pattern. Additionally, the sample holder can be rotated up to 180 degrees for different step coverage angles to achieve better coating uniformity. In conclusion, MRC 903 M sputtering tool is a highly versatile and technologically advanced tool designed for precision thin-film coating applications. It includes a precisely controlled vacuum chamber, a dynamically-balanced gas manifold, and a high-accuracy robotic sample-stage motion-control asset, making it ideal for high-precision cleaning, coating, and etching processes.

There are no reviews yet