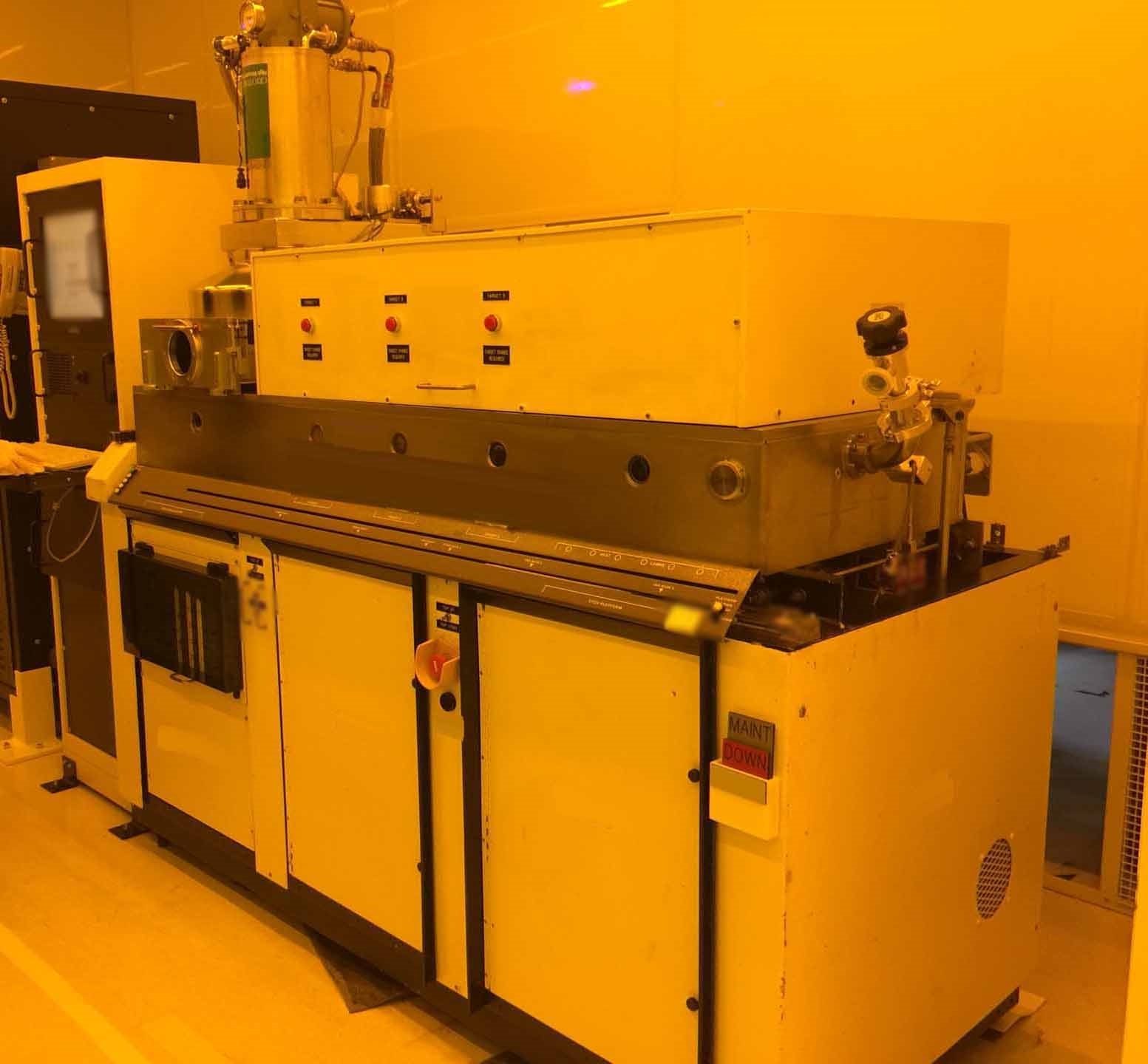

Used MRC 943 #9199346 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9199346

Sputtering system

Compressor

Mech pump

System hardware:

MRC Load lock assembly

CTI CT-8 Cryo pump:

Load lock

Process chamber

(3) SIERRA Scientific planar 5"x15" cathodes

(3) Target shielding sets

ADVANCED ENERGY MDX-10 DC Power supply: 10 kW

MRC Hivac valve

With MRS throttle valve assembly

(3) MKS MFC

MKS 390 Baratron assembly

MRC Hydraulic system

ENI OEM-12A RF Generator

ENI Matchwork 10 RF Matching unit

Rack hardware:

GOULD / MODICON PLC Controller

GP-303 IG Controller

MKS 252 Throttle valve controller

MKS 247 MFC Controller: 4 Channels

(5) GP-275 Convectrons

TCR DC Voltage power supply (MRC Rail bias).

MRC 943 is an advanced D.C. Magnetron Sputtering equipment which is used for research and development of thin film coating applications. It features a large, reliable magnetron gun and extensive deposition rate control capabilities. The system is equipped with an advanced high-frequency resonant-cavity plasma generator to ensure uniform plasma in the deposition chamber for improved performance and accuracy. 943 includes a multi-chamber configuration that allows for incorporation of up to four target materials simultaneously in the process. The integrated process control unit of MRC 943 features closed-loop control of process parameters, including the ability to adjust the power level, gas flow rate, and gas pressure in an effortless way. This machine offers the ability to perform a wide range of sputter coating step sequences, as well as to monitor and adjust exposures to ensure accurate and repeatable deposition results. In addition, on-board cooling fans help reduce operating temperatures and improve the tool's reliability and lifetime. In order to perform deposition onto numerous substrates at high accuracy, 943 includes two separate independent cathodes, which can be remotely adjusted to choose between either planar or cylindrical magnetic fields. This feature allows for precise control of the electron flux and uniform deposition over a wide range of substrate sizes and shapes. The asset is operated from an easy-to-use control tilting display, including preset coating recipes to save on time and energy. It also has an automatic end-of-run diagnostic feature for troubleshooting. Additionally, users can monitor the entire deposition process and adjust recipes in real time using a visual interface displaying information such as deposition pressure, temperature, and process parameters. MRC 943 includes a comprehensive software package for recipe loading, deposition control & monitoring, feedback and reporting. Additional features such as the ability to control several MRC systems in parallel, data logging capability, and programmable hardware are also supported. In short, 943 is a powerful, easy-to-use, and reliable sputtering model that offers rapid deposition at high precision with precise uniformity and control over the entire process. It is perfect for research laboratories, scientific labs, and industrial processes alike.

There are no reviews yet