Used MRC / TEL / TOKYO ELECTRON Eclipse Star #9108489 for sale

URL successfully copied!

Tap to zoom

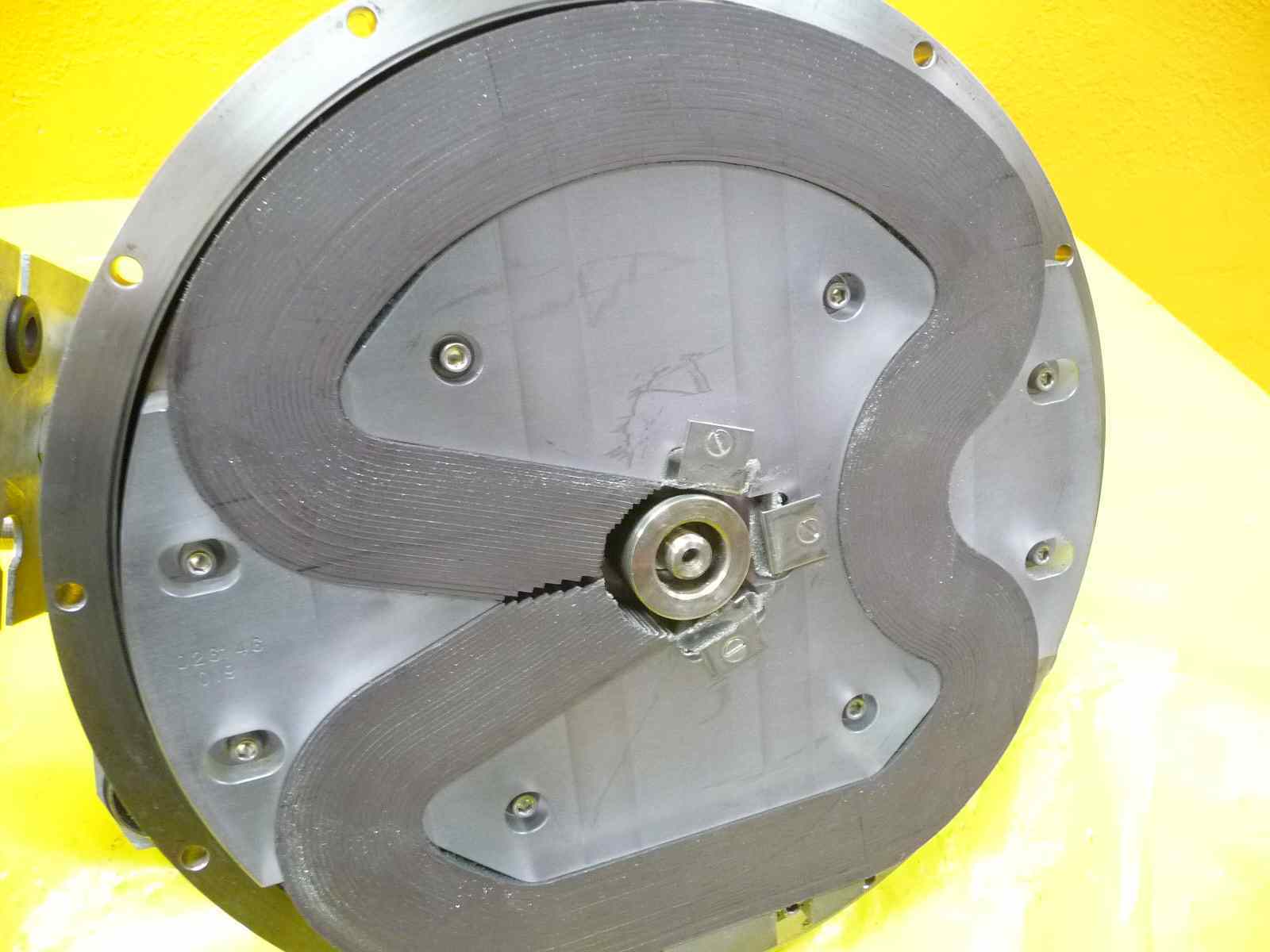

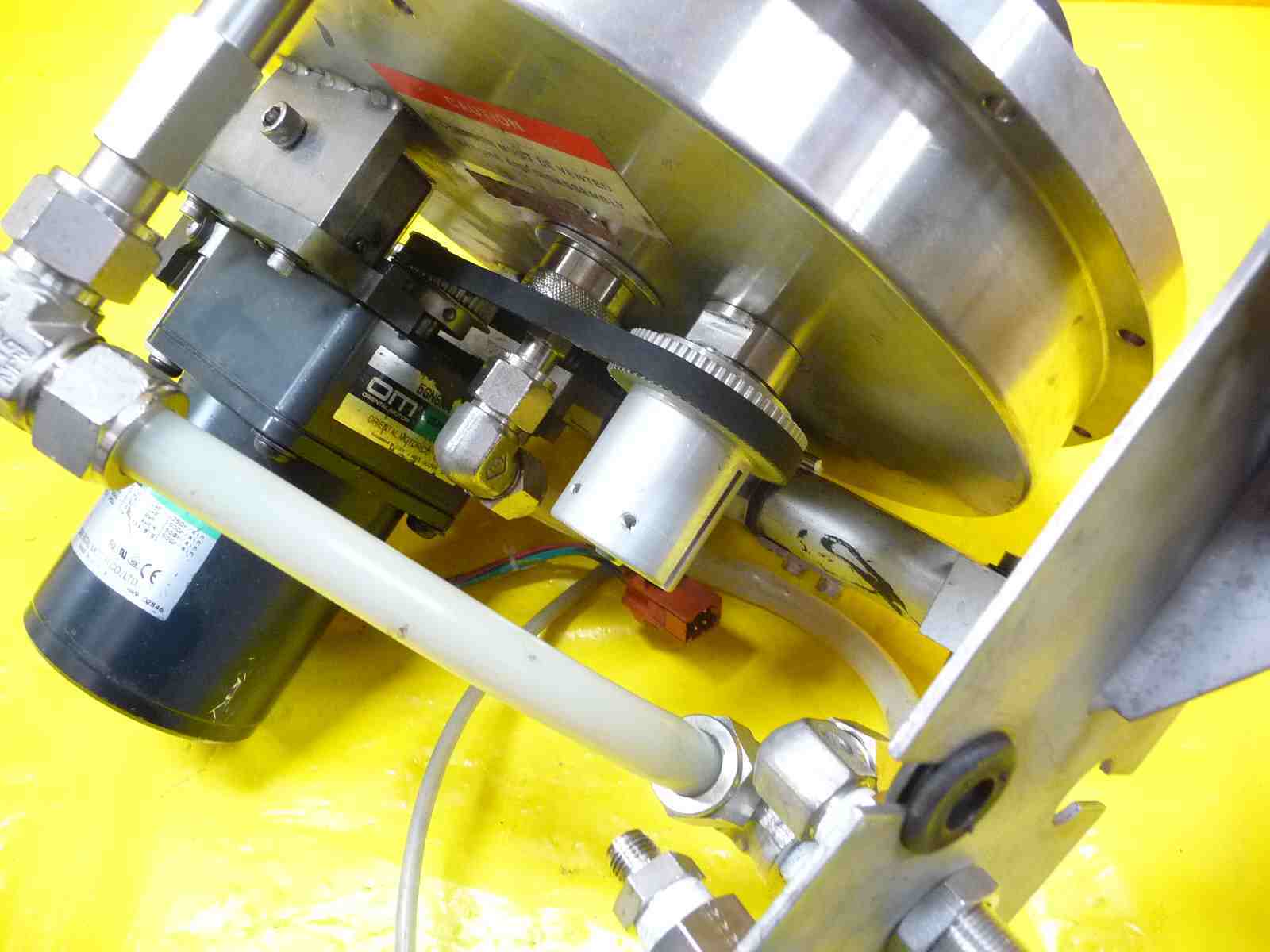

MRC (formerly known as TEL) MRC / TEL / TOKYO ELECTRON Eclipse Star is a robust sputtering equipment that utilizes inert gas to dislodge atoms from a target material and coat the surface of a substrate by depositing them on it. The system's low-energy features include a variable-magnitude ( high- or low-energy) sputter source and a compact chamber with a tightly integrated design for process control. MRC Eclipse Star has a power range of 1-15 kW, and a maximum sputter rate of up to 3 nm/min. It is equipped with two end station operating modes: inline and edge station. The inline mode supports conventional sputtering processes with the sputter source being placed away from the wafer surface. The edge station mode, on the other hand, brings the sputter source closer to the wafer surface to create an edge-defined oxide layer. This sputtering unit offers both thermal and RF application support, accommodating both low- and high-energy coatings. The Electron Cyclotron Resonance (ECR) and Power Feed Forward (PFF) enable full-field plasma control, with advanced process control and feedback algorithms built into the machine. Additionally, the power is regulated by the use of PowerSource modules that can adjust RF signals up to 500 kHz. TEL Eclipse Star can operate with multiple gas sources, up to four mass spectrometers, and a maximum wafer size of 200mm. The pre-installed wiring ratchet prevents over-torquing and its SCARA robot offers faster loading, unloading, and wafer handling speeds. The tool's advanced feature set also includes a multi-target sputtering chamber, which enables multiple different materials to be deposited on a single substrate. Eclipse Star is also capable of in-situ diagnostics and asset monitoring. Its advanced diagnostics feature extends beyond visual inspection, with an extraction port for in-situ chemical analysis of the layer being deposited. These features enable TOKYO ELECTRON Eclipse Star model to deliver a high accuracy and repeatable, reliable, and 100% repeatable results. The equipment is also capable of advanced capabilities such as closed-loop process control, fast wafer end point detection, precise etch control, and fully automated operation.

There are no reviews yet