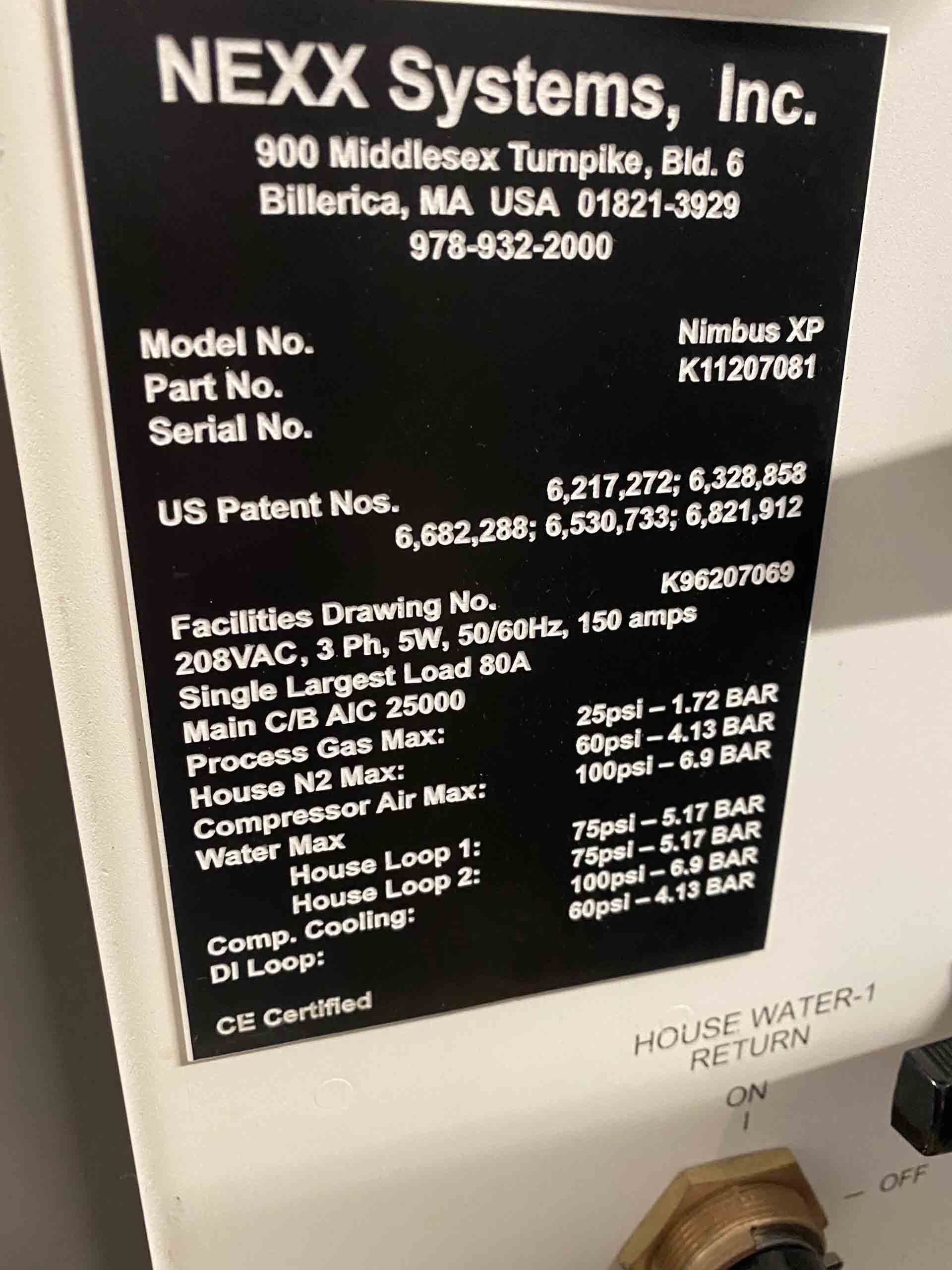

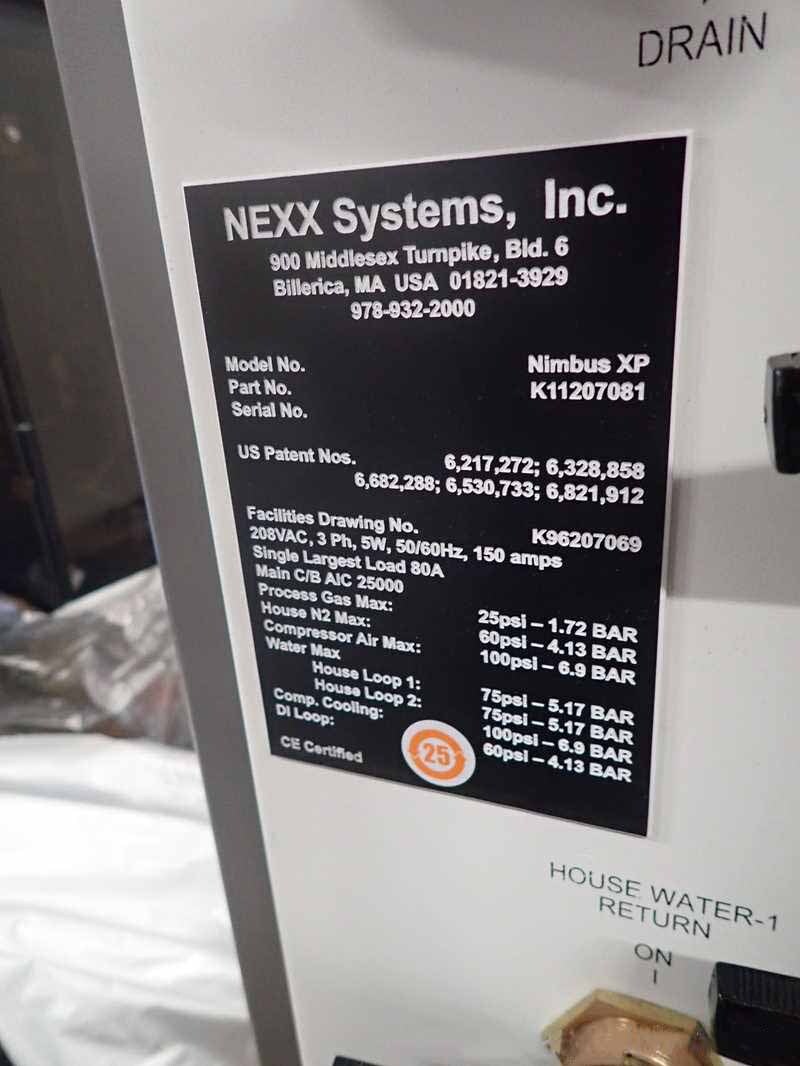

Used NEXX SYSTEMS Nimbus XP #9372726 for sale

URL successfully copied!

Tap to zoom

ID: 9372726

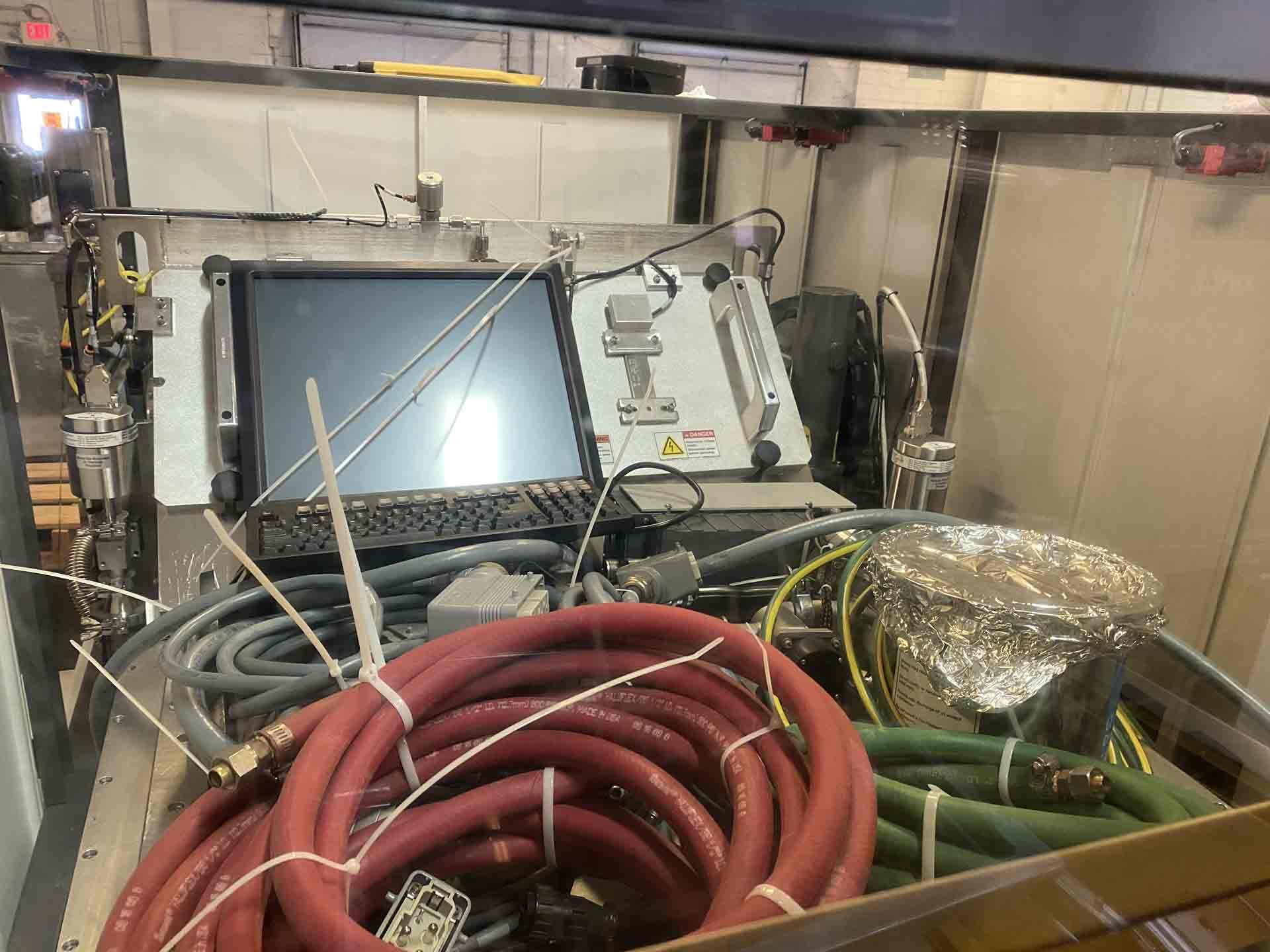

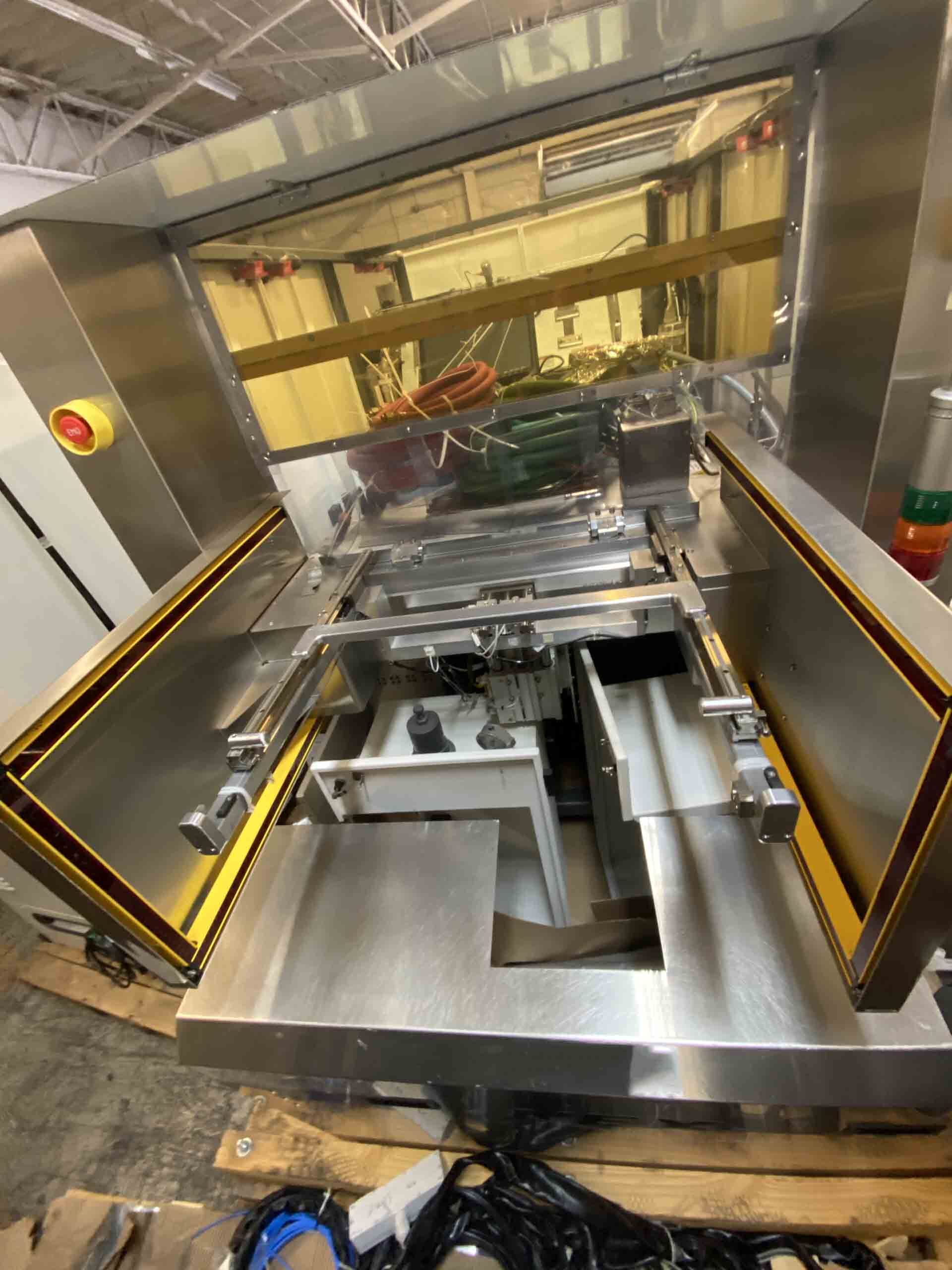

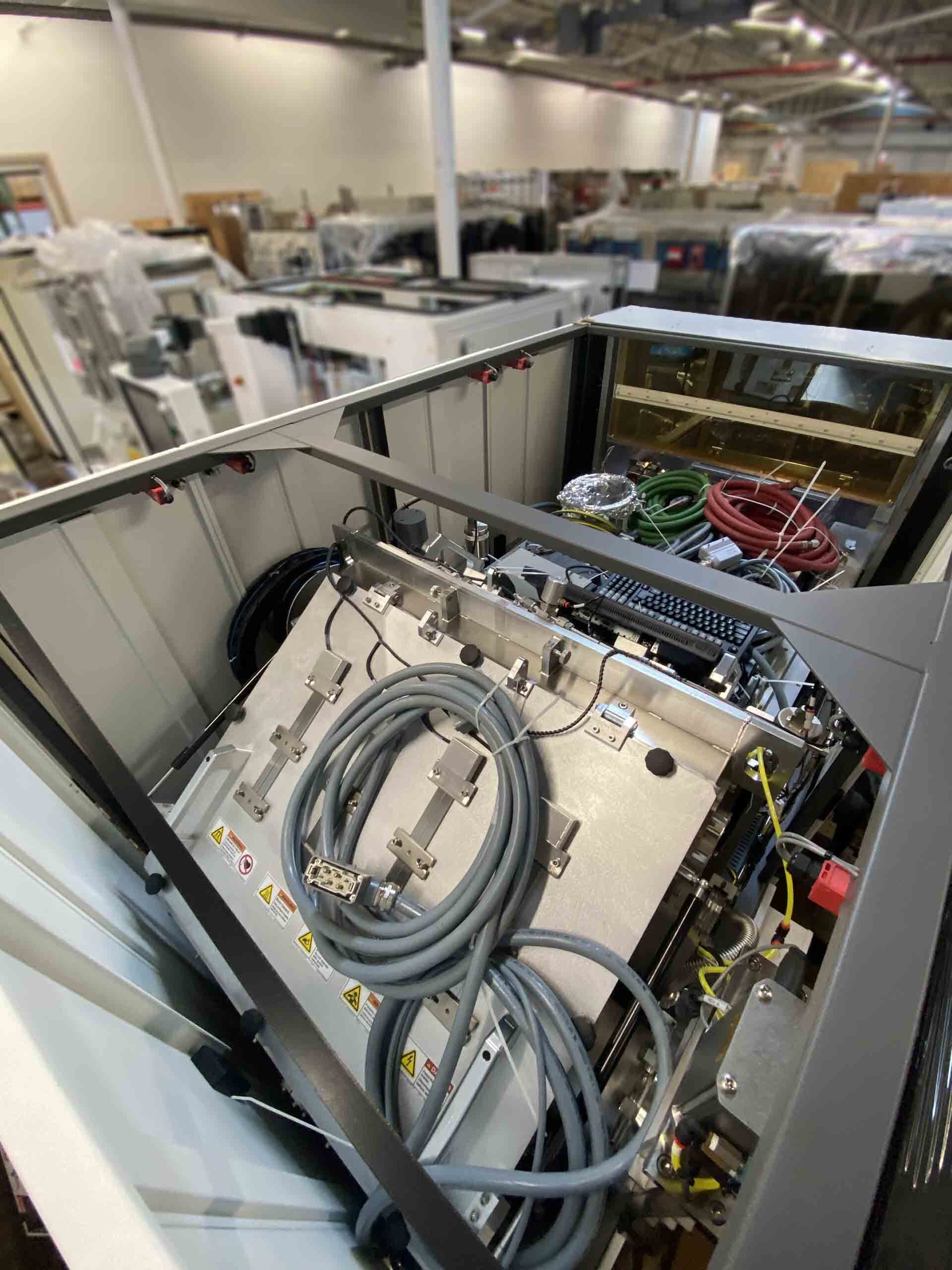

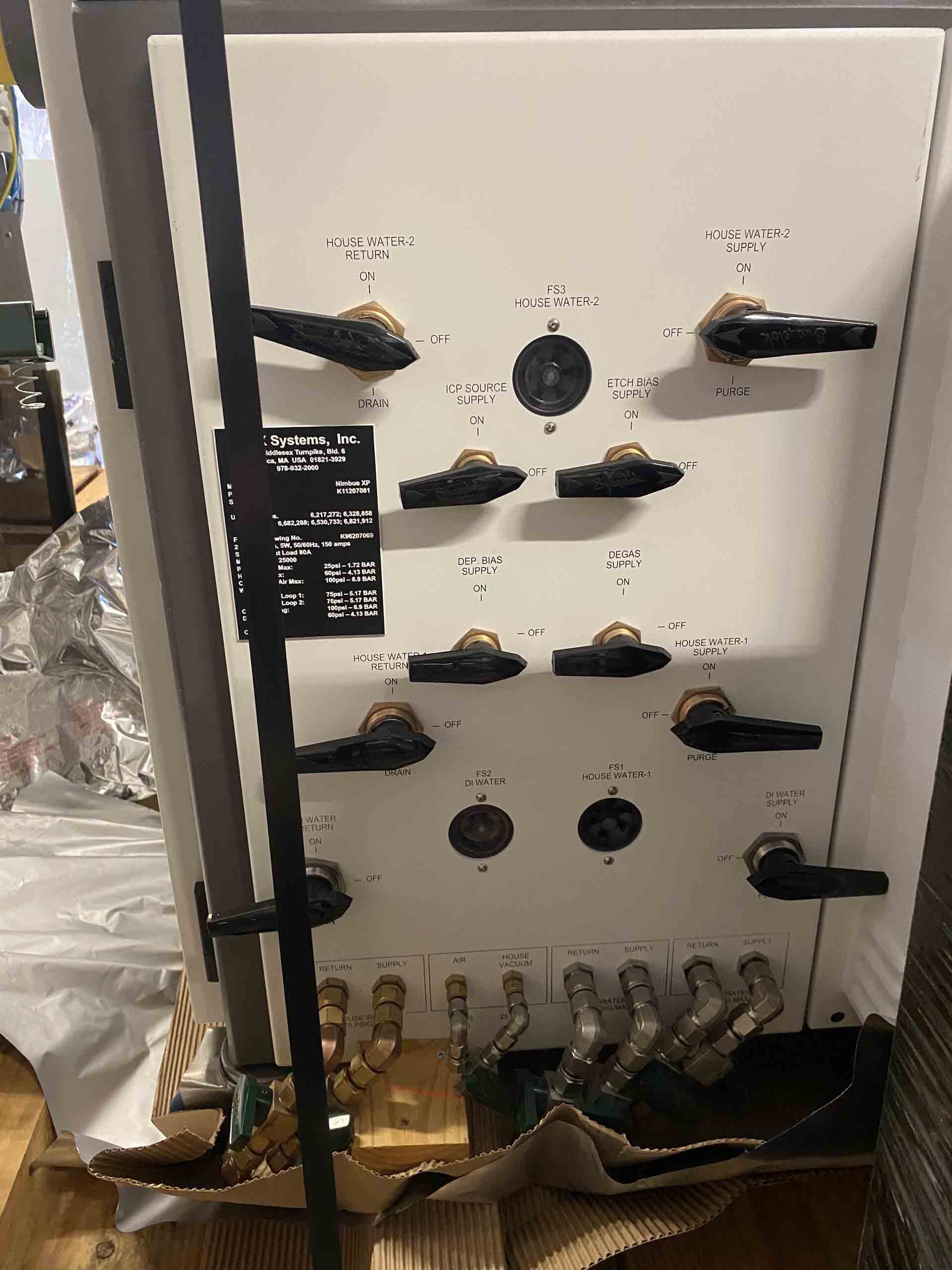

PVD Sputtering system

With NEXX 003 Control panel

Power supply: 208 V, 50/60 Hz, 150 A, 3 Phase.

NEXX SYSTEMS Nimbus XP Sputtering Equipment is an integrated sputter deposition platform designed for research and development of thin film processes. The system utilizes a vacuum chamber and a high-energy plasma source to deposit a range of materials onto a substrate placed in the vacuum chamber. This allows the user to apply thin film layers of various thicknesses and uniformity, as well as deposition rates for a number of materials including metals, semiconductors, and insulators. The unit is capable of small area samples as well as production sized wafers up to 8". Nimbus XP utilizes an in-vacuum rotation feed and lift mechanism to ensure uniformity of larger deposited areas. This mechanism was designed with a sloped bottom in order to minimize contamination buildup. Additionally, the magnetic levitation of the turntable results in low friction and highly uniform deposition rates. The machine also makes use of an in-vacuum transfer which allows for samples to be placed in the chamber without the introduction of contamination. The controller utilizes an intuitive menu-driven design and is integrated with all the necessary software modules needed for automated operation. This includes software for target surface optimization, particle flux measurement, data logging, process control, and parameter tracking. For manual operation, the controller has a touch-screen LCD display with microprocessor-controlled rotary switches and menu items. Additionally, the tool has two separate interlocked plasma sources, each of which can be tuned to precisely the correct substrate deposition parameters. The asset's performance is closely monitored by a sophisticated vacuum and in-chamber monitoring model. This includes temperature, flow rate, and gas species to ensure optimal process conditions. Additionally, the equipment features a built-in ion source and has the ability to measure the flux of positive ions in the vacuum chamber. This allows users to quickly and accurately monitor the in-chamber process. In order to accurately reproduce thin film deposition processes, the system also features a number of safety interlocks. This includes automated ground fault interlocks, cabinet interior exhaust ventilation, as well as hardwired protective shielding. Additionally, the unit features an integrated energy saving mode, allowing users to save up to 50% on their energy costs. Overall, NEXX SYSTEMS Nimbus XP Sputtering Machine is a state-of-the-art platform that provides users an integrated solution for precise and uniform deposition of thin films on substrates. With a multitude of safety features, highly intuitive controller, and automated operation capabilities, Nimbus XP is the perfect solution for accurate and controlled thin film deposition.

There are no reviews yet