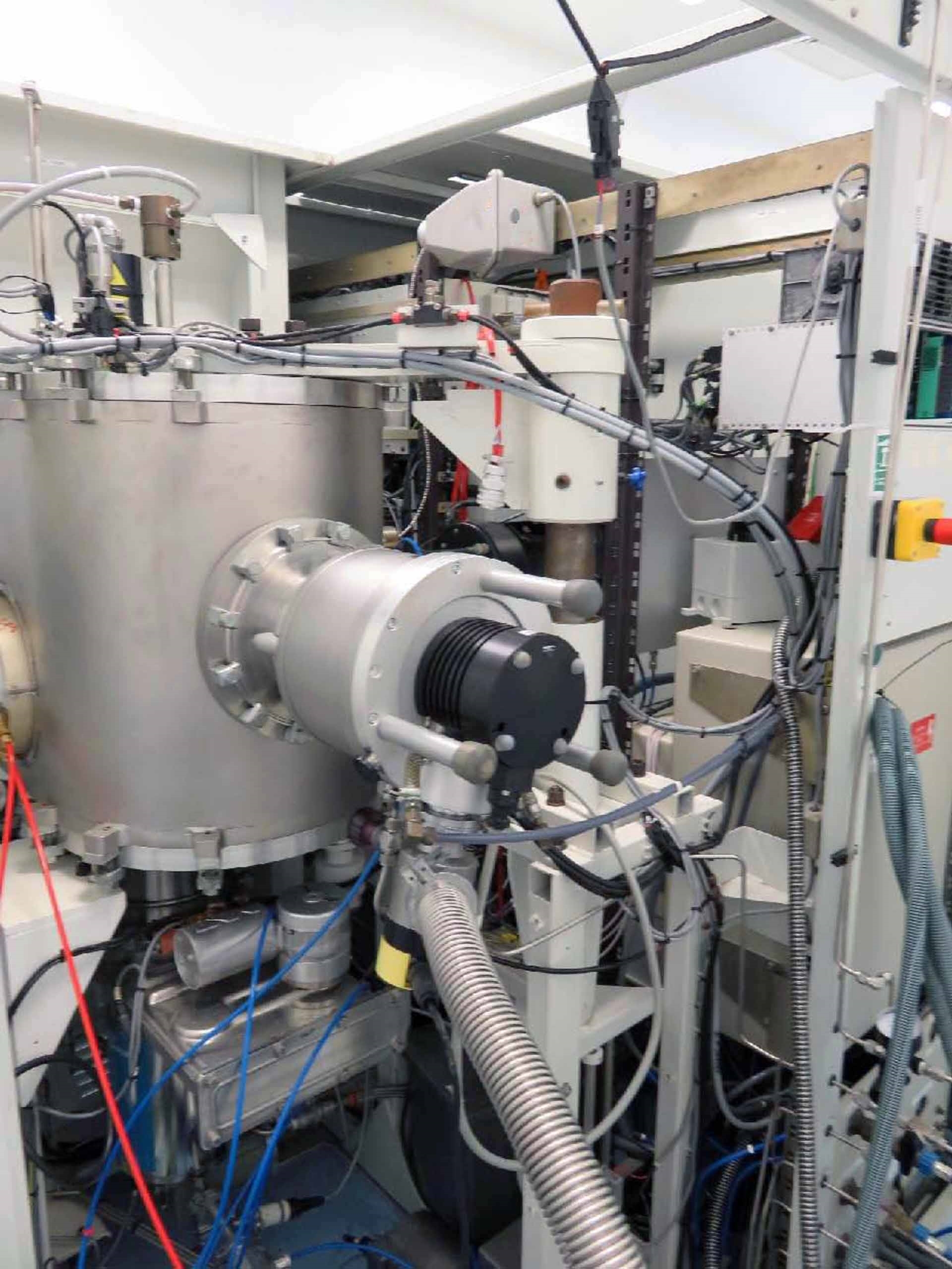

Used NORDIKO 3000 #9228384 for sale

URL successfully copied!

Tap to zoom

ID: 9228384

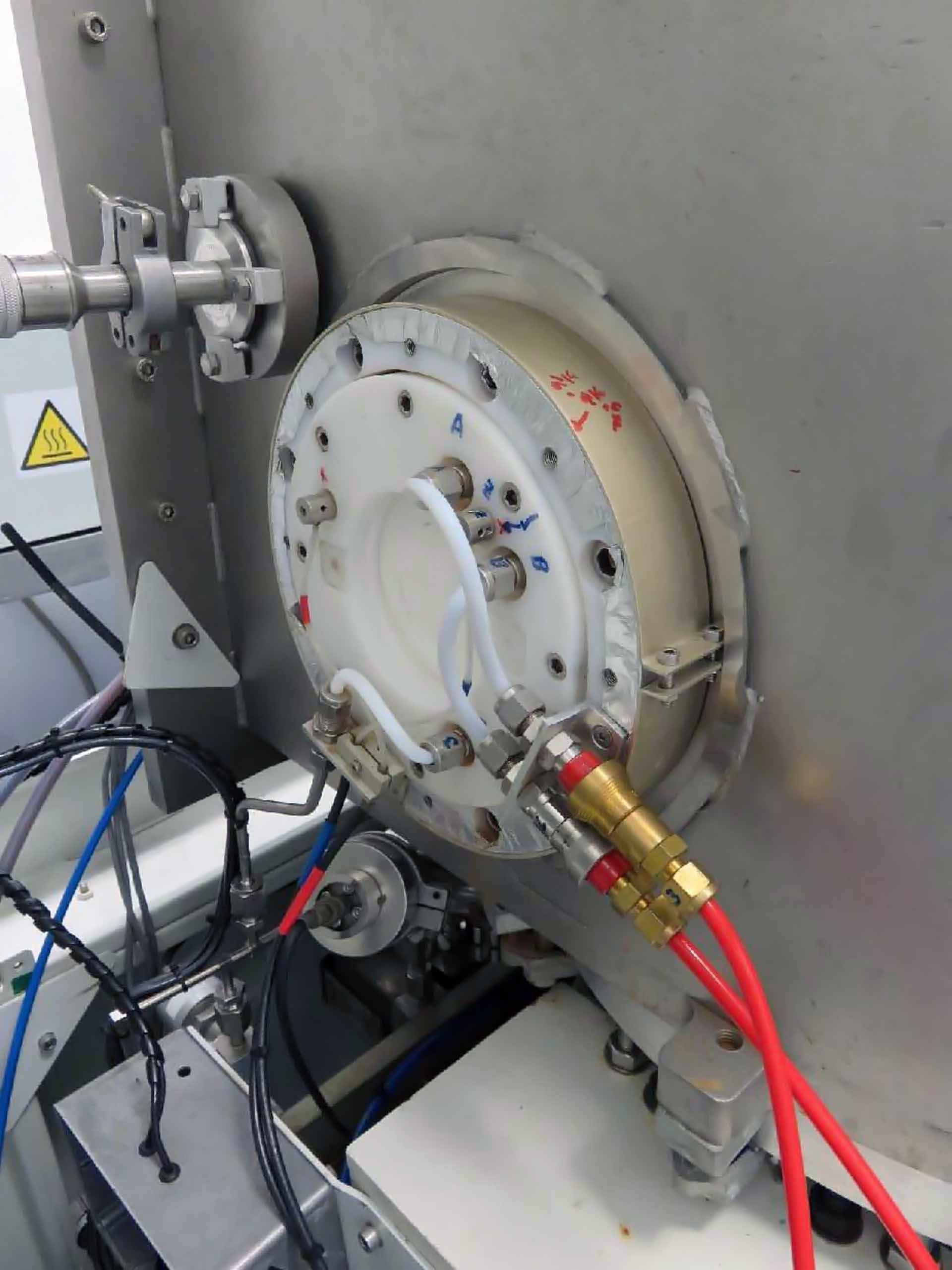

Dual ion beam sputter coater

Al203 RF Coupling ceramic window have been replaced

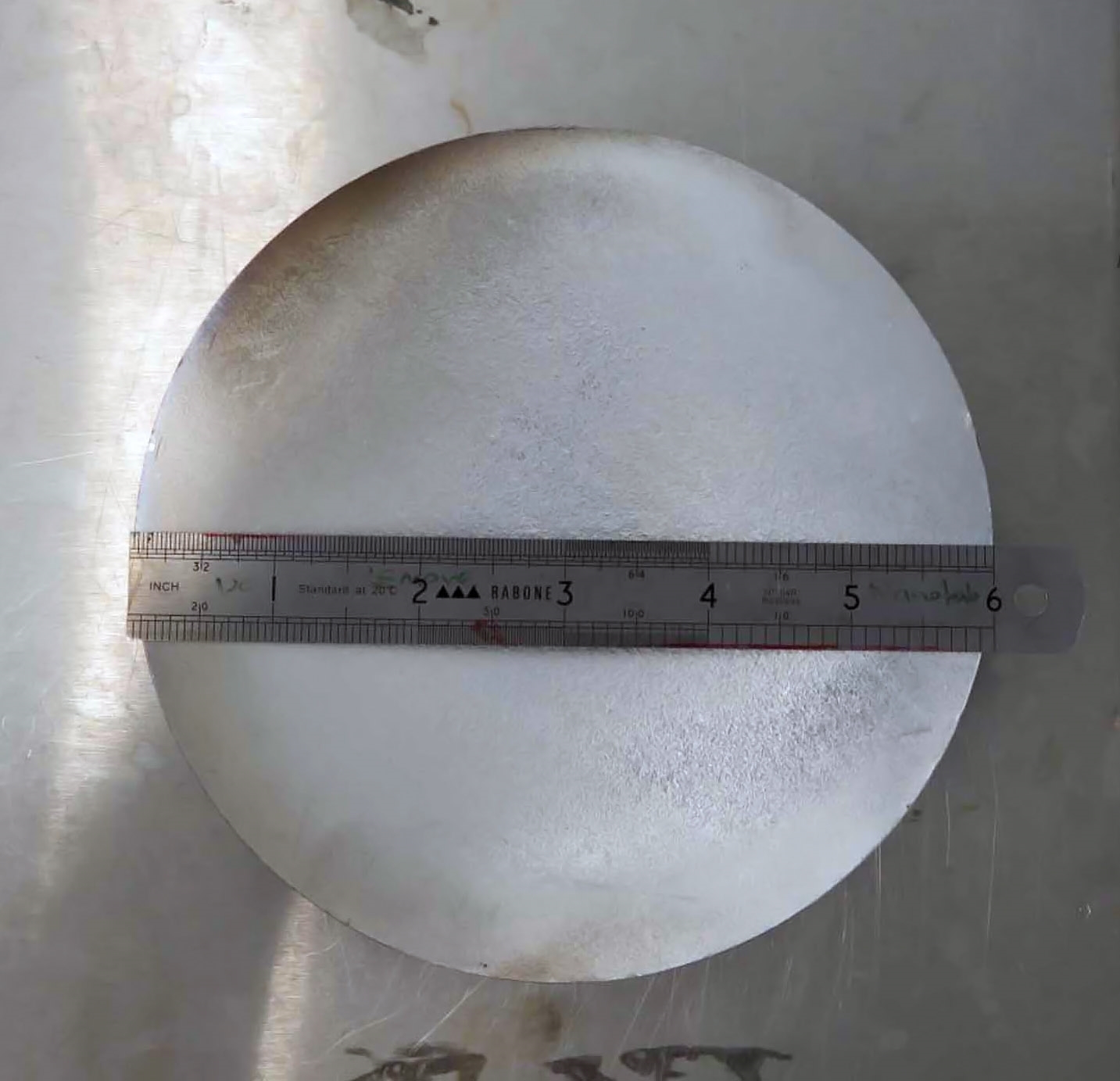

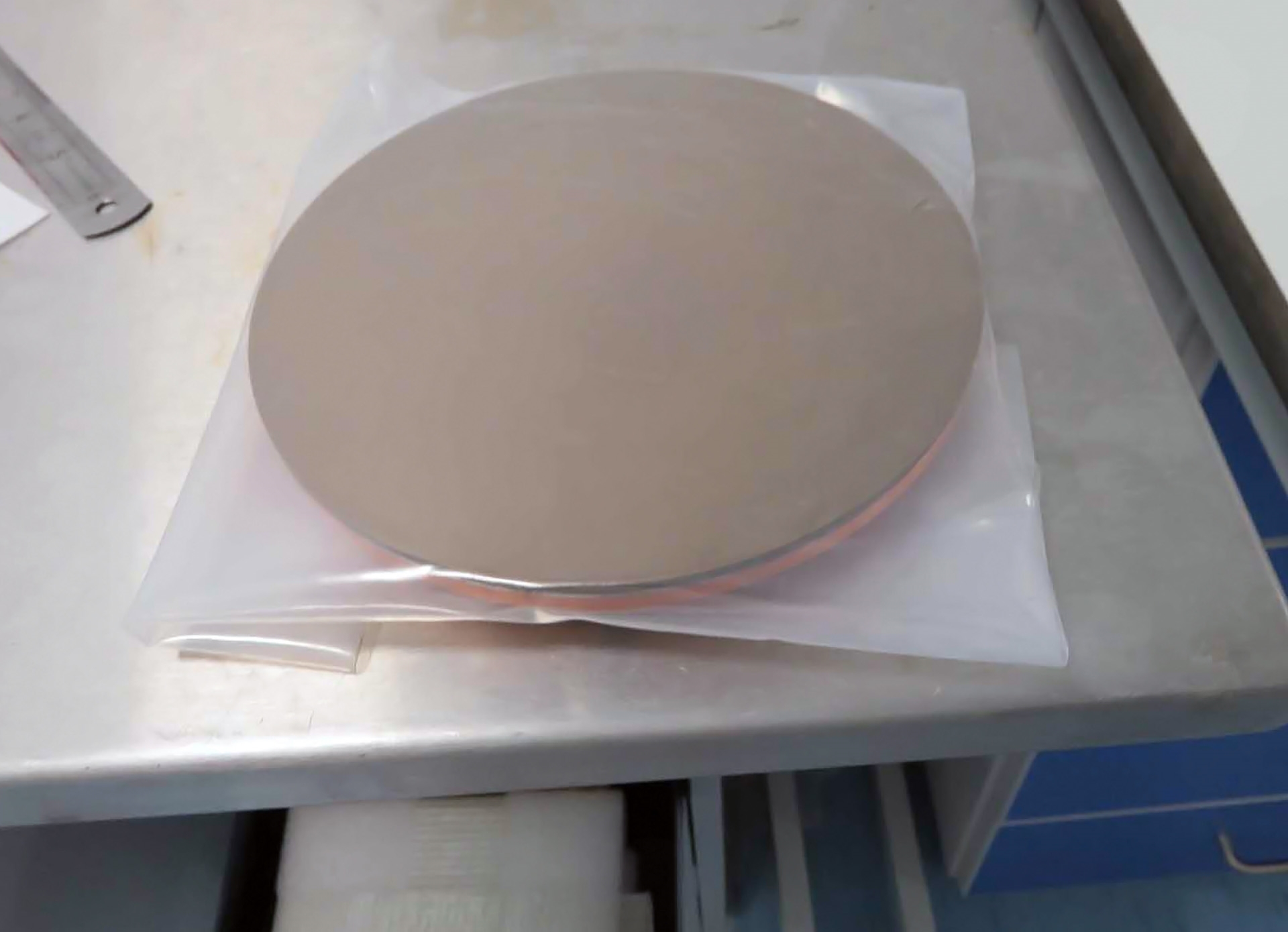

(14) DIBS Targets, 6"

Al, TiN, Zr, Ni, SiO2, Mg, Si, Yt, ITO, Cr, Hf, Zn, AlN, Mo

Spare parts:

Qty / Make / Model / Description / Part no

(1) / LEYBOLD / Trivac D40 BCS PFPE / Roughing pump / 11389B

(1) / LEYBOLD / TurboVac 100C / Turbo pump / 85535

(1) / LEYBOLD / Turbotronik NT1000/1500VH / Turbo controller / 40-2461-8

(2) / RF PLASMA PRODUCTS / RF5 / RF Controllers / -

(2) / SORENSEN / DCS 600 1.7 / Neutralizer power supplies / 1210

(1) / HELIX CTI CRYOGENICS / Cryo Torr 8 / Cryo pump / 8033179

(1) / CTI-CRYOGENICS / 8300 / Compressor / 8052000

(1) / GLASSMAN HIGH VOLTAGE INC / PS / ER OIR 300-220 / DC Power supply / -.

NORDIKO 3000 is a complete sputtering equipment which consists of deposition chamber, vacuum pump, power supply and control unit, as well as necessary components. The chamber is designed to have an in-vacuum electrical feedthrough, which allows a DC voltage to be supplied to the substrates for thin film deposition. The vacuum pump and control unit allow for an optimal vacuum in the chamber. The power supply is for operating the magnetron, and provides energy for the sputtering process. 3000 is equipped with a magnetic suspension and pulsed DC sputtering technology. This enables the deposition of highly adherent metal films with very good homogeneity, uniformity and excellent adhesion of the deposited metals onto the substrates. The magnetic suspension helps maintain a very uniform, high-quality sputtered film feature, even on rather large substrates. NORDIKO 3000 features adjustable power and frequency to play a key role in controlling the rate of deposition and composition of the metal layers of the sputtered film. Adjustable pulse frequency also increases the deposition rate while offering improved uniformity, as non-uniformly heated nodes from the pulse are eliminated. As a result, 3000 can produce both dense and porous thin films, which are highly adherent to the substrates. The multi-chamber design of NORDIKO 3000 system enables two substrates to be processed simultaneously, thus increasing throughput. It is also very energy efficient, offering reduced process time, better uniformity, and improved repeatability. Additionally, the unit is able to provide good environmental protection due to its multiple sealing-off machine. Overall, 3000 sputtering tool offers excellent performance and is suitable for many different thin film deposition applications. It can provide excellent uniformity, repeatability, and adhesion for metals and other materials, allowing great control over the deposition process.

There are no reviews yet