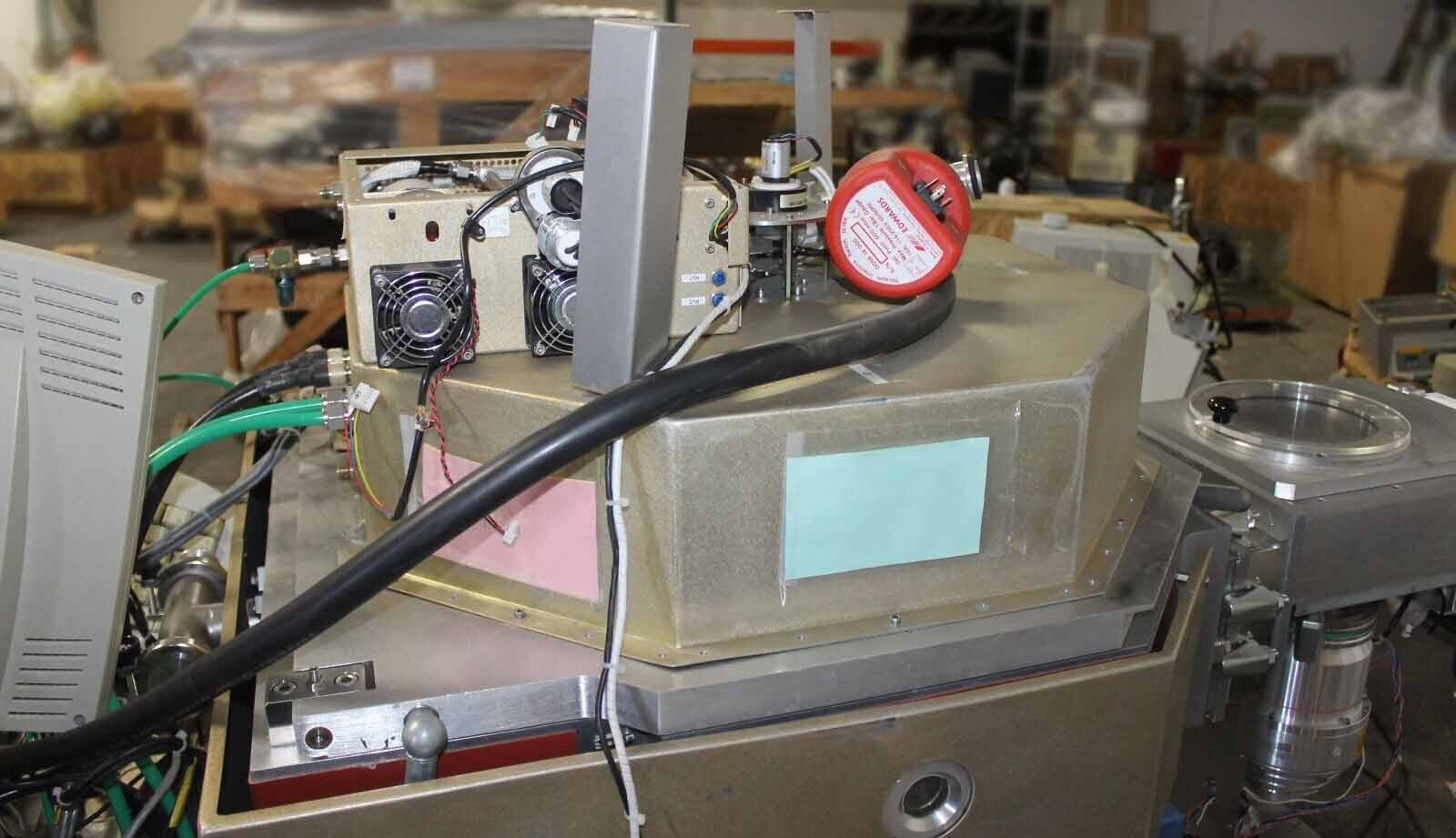

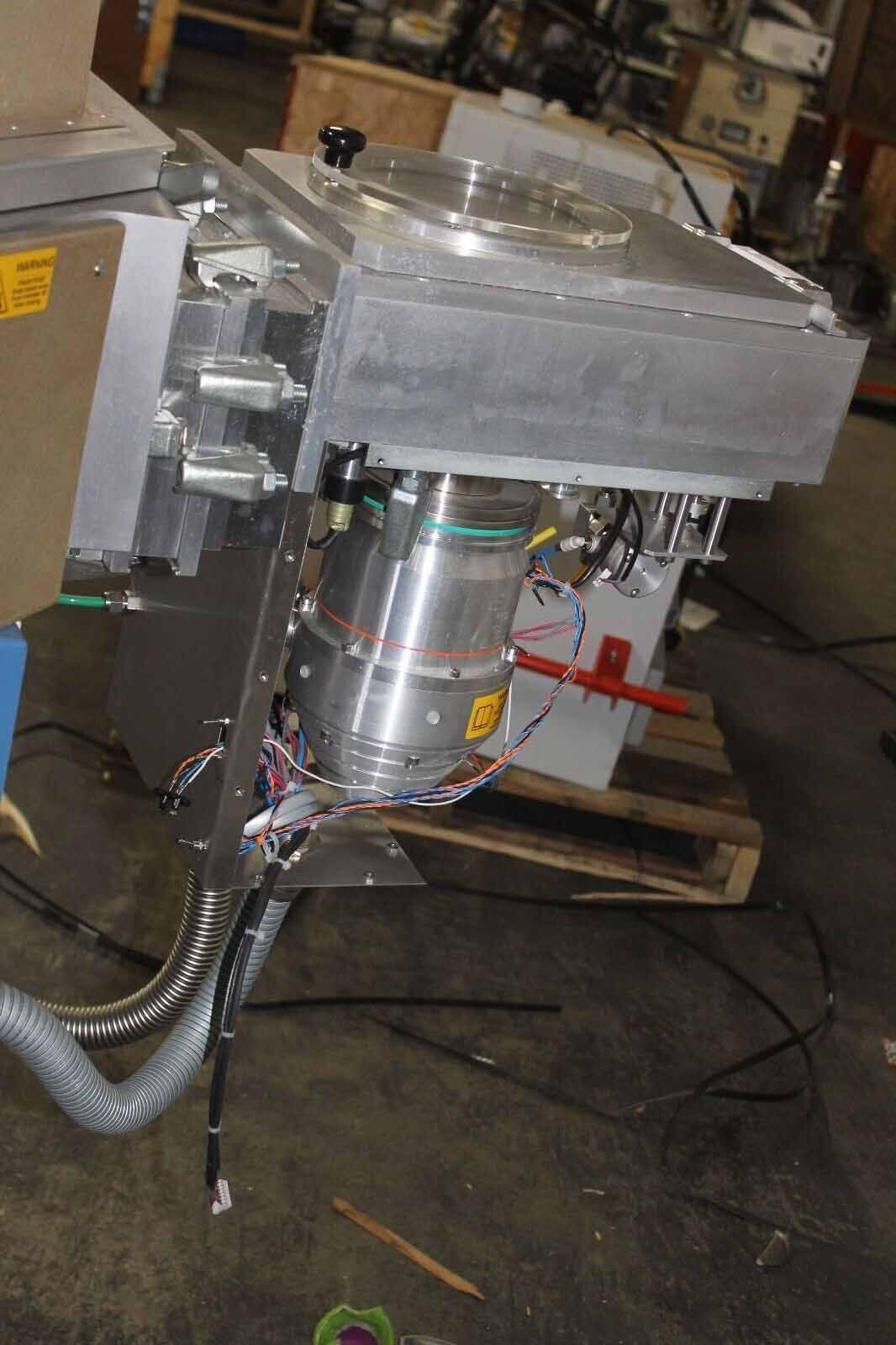

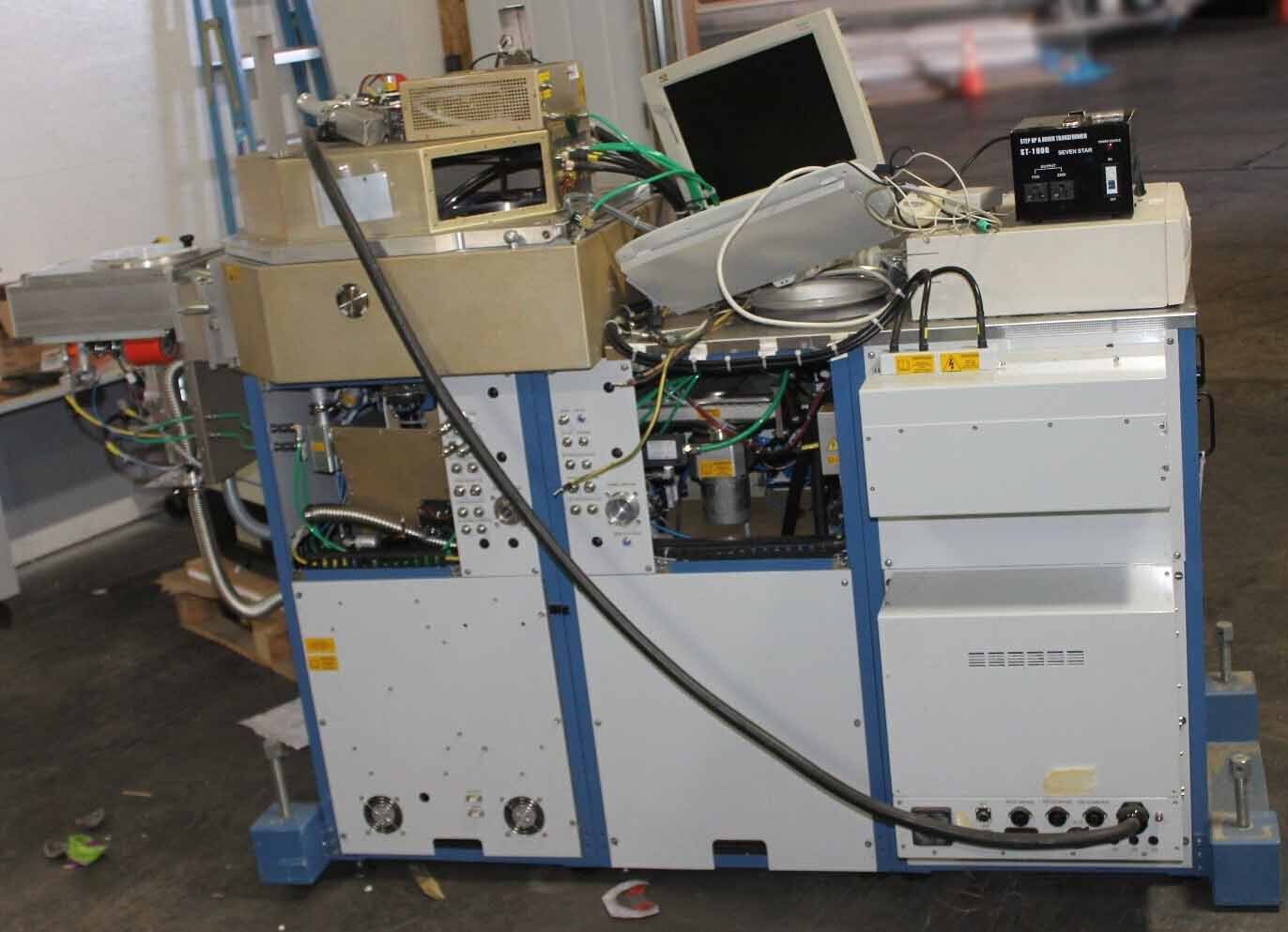

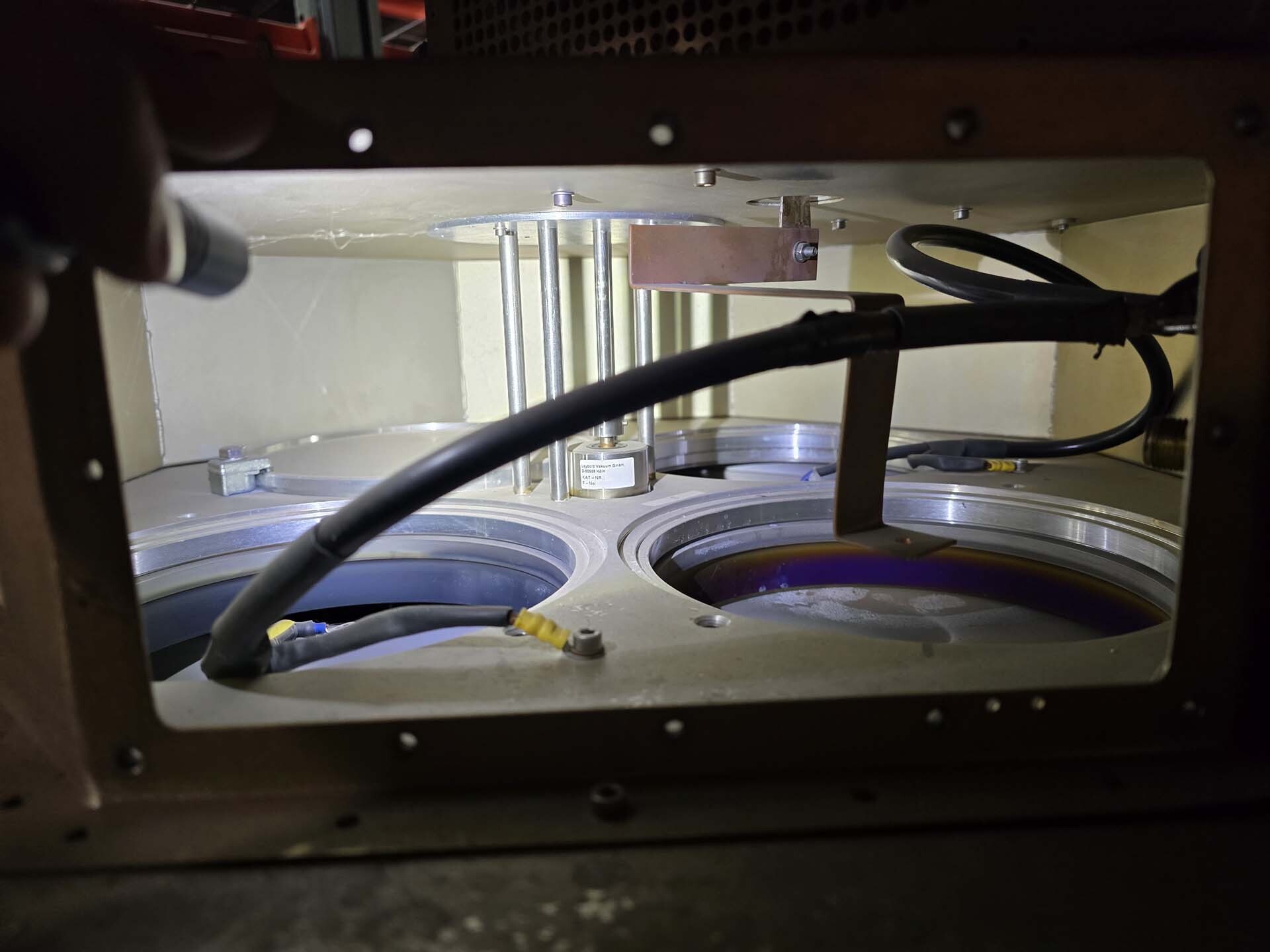

Used OXFORD Plasmalab 400 #9409150 for sale

URL successfully copied!

Tap to zoom

OXFORD Plasmalab 400 is a state-of-the-art sputtering equipment that is used in the production of semiconductor and thin film devices. This high power system offers users a wide range of high quality grade options, including different target orientation, process configuration, and vacuum preparation. Plasmalab 400 is equipped with unique base and high-frequency power supplies that work together to ensure consistency in sputtering processes. This unit can operate at up to 400 kW, allowing it to be utilized for a variety of processes, including high power arc-spray, standard RF sputtering, pulsed DC or RF sputtering, and step-tuned substrate heating. The base power supply provides ultra-low DC power for the start-up and tuning of the sputter process. This is also used for ion bombardment and ion sputter etching. The HF power supply features a frequency control range of 400 kHz to 60MHz, meaning that it can be used for a variety of advanced processes, including step-tuned substrate heating and pulsed RF sputtering. OXFORD Plasmalab 400 has a robust chamber design that can accommodate four magnetron cathodes to allow higher power density and uniformity. The innovative load lock design offers a vacuum barimetric pressure automatically, with an adjustable maximum pressure. This allows users to easily modify the vacuum environment and modify the chamber parameters. The machine offers an intuitive user interface with advanced control functions, and can be operated through a web-based control platform or an OxR framework relying on the object-oriented programming language Python. This control software gives the user full control over plasma parameters, tool functions, and processes. Finally, Plasmalab 400 includes a built-in safety locking asset. This provides process monitoring and interlock protection functions to ensure full safety when operating the model. It also features an active process monitoring equipment that monitors the process parameters of the chamber, allowing the operator to intervene in case of errors or faults.

There are no reviews yet