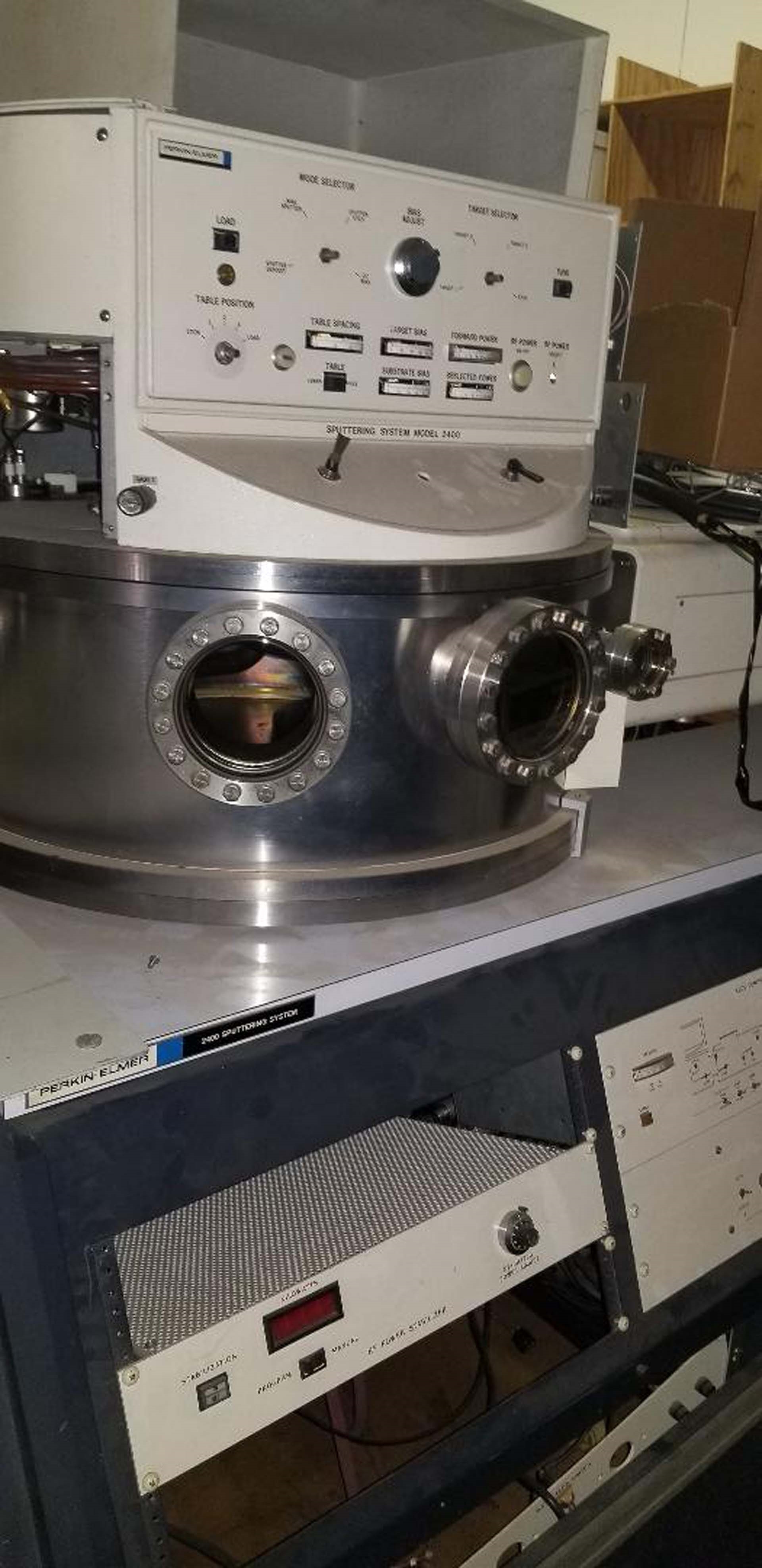

Used PERKIN ELMER 2400 #9152162 for sale

URL successfully copied!

Tap to zoom

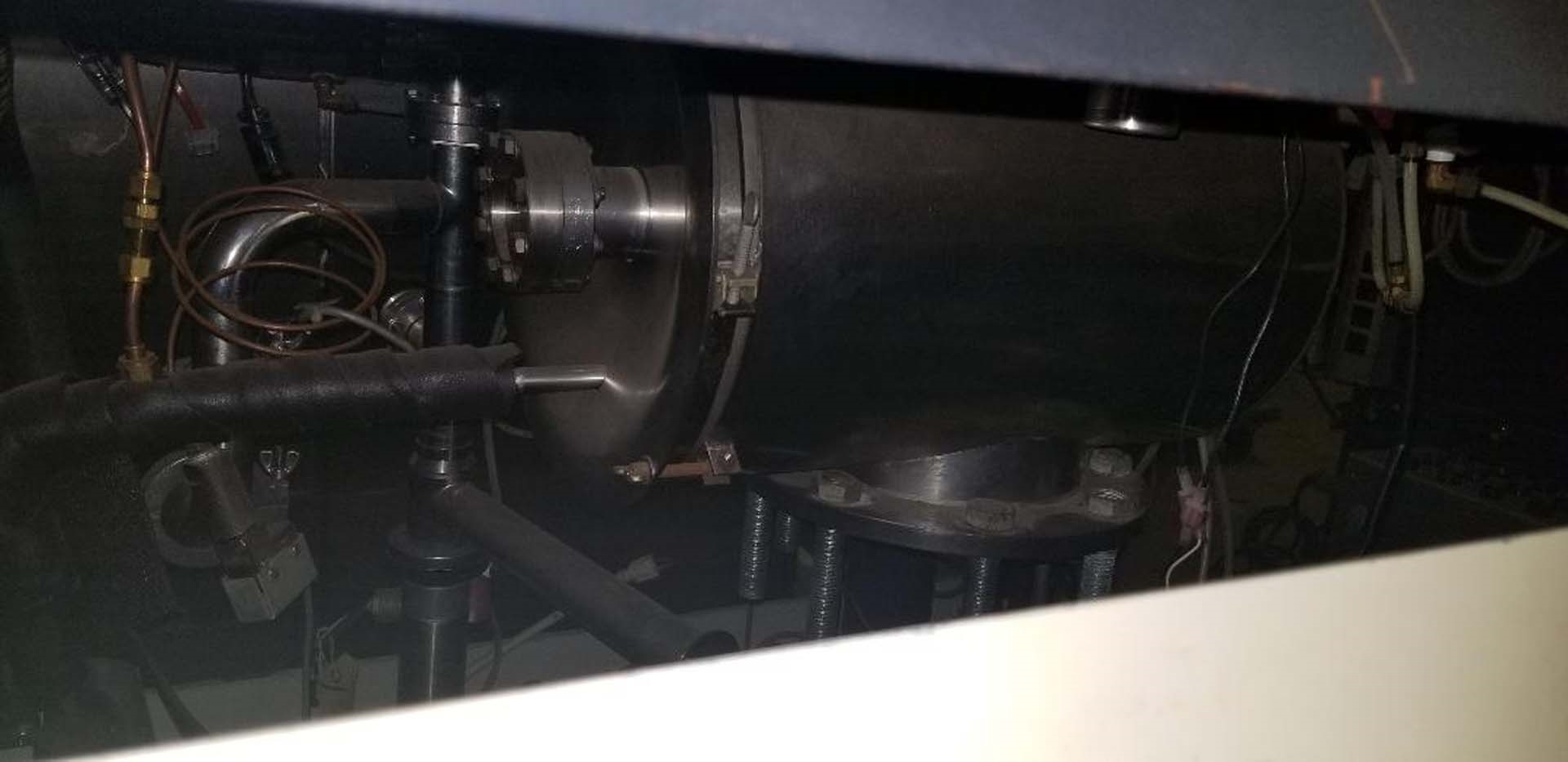

PERKIN ELMER 2400 is a means of depositing various materials on a substrate surface in thin film form. It is classed as a sputtering equipment, that is, a system which uses low voltage plasma to sputter atoms from the source material and onto the substrate in a controlled environment. 2400 is driven by a direct current (DC) power supply which allows the unit to deposit materials at a higher efficiency than an equivalent alternating current (AC) machine. It is supplied in a single or dual magnetron configuration, giving it both sputtering and etching capability in one tool. The dual magnetron configuration also offers Azimuthal rotation of up to 90 degrees, allowing a much greater range of materials to be sputtered. The asset allows pre-programming of deposition processes and is capable of maintaining a wide range of gas pressure during operation. It also has automatic gas flow control and a single button start and stop mechanism to ensure a consistent deposition process. PERKIN ELMER 2400 is well suited to preparation of samples for a variety of different applications, such as photoelectronic devices, optical coatings, thin film resistors, thin film capacitors, and other thin film deposition processes. It offers a very stable and reliable sputtering environment and has very low maintenance and operating costs compared to other sputtering systems. 2400 is capable of sputtering materials onto substrates with high precision and as such, is useful for complex fabrication processes. It is a cost effective solution for depositing a variety of materials with accurate levels of deposition. The model has an optional chamber monitor alarm which allows for detection of out of tolerance conditions, and is upgradeable with many options to ensure that sputtering processes can be optimized for a particular application. In summary, PERKIN ELMER 2400 sputter equipment is an effective, cost-efficient solution for creating thin film circuits for a variety of applications. It is extremely reliable and precise, with low operating and maintenance costs, thanks to its easy-to-use pre-programming capability and gas flow control feature. All in all, 2400 is an excellent solution for thin film deposition needs.

There are no reviews yet