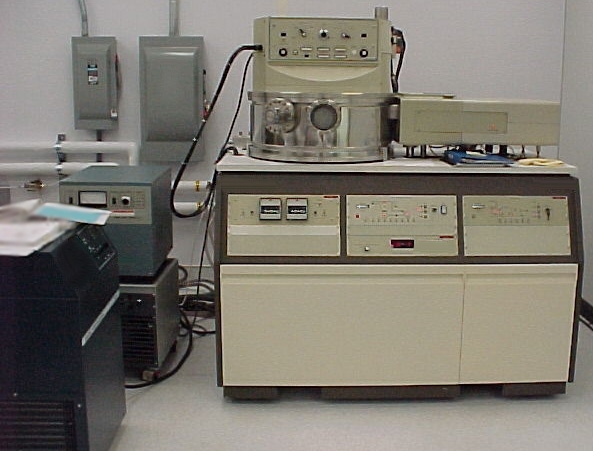

Used PERKIN ELMER 2400 #9215991 for sale

URL successfully copied!

Tap to zoom

ID: 9215991

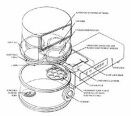

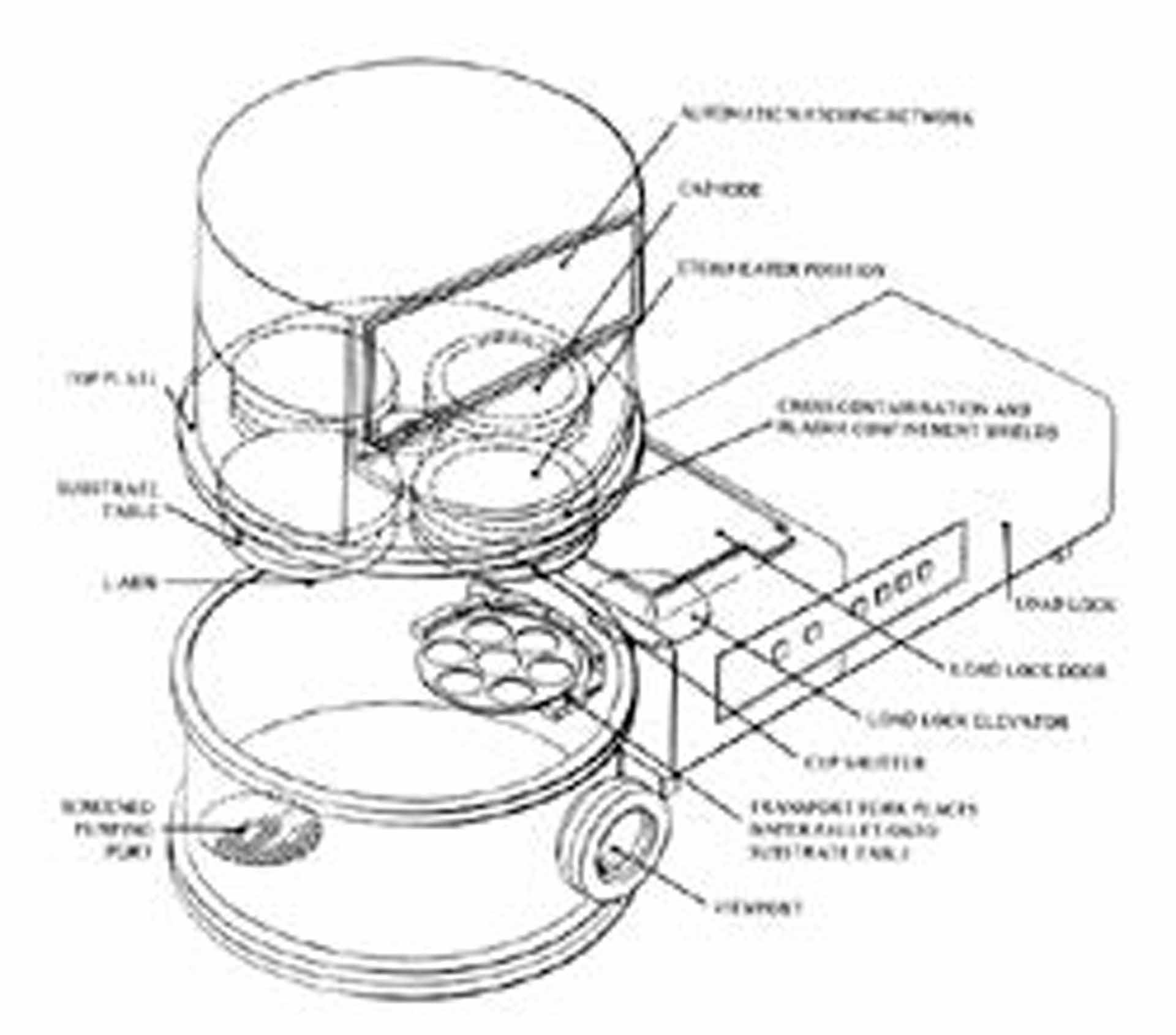

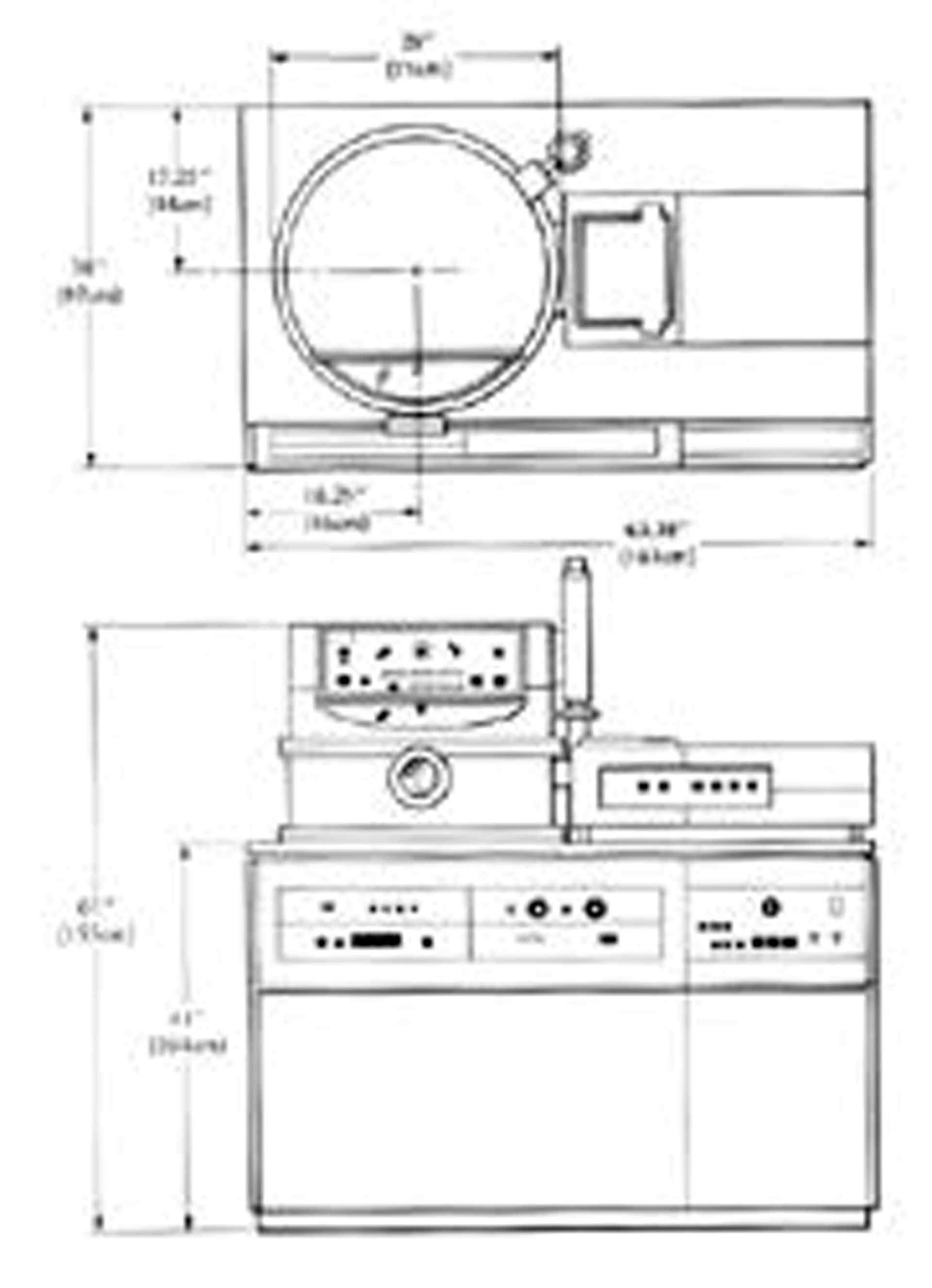

Sputtering system

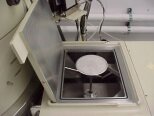

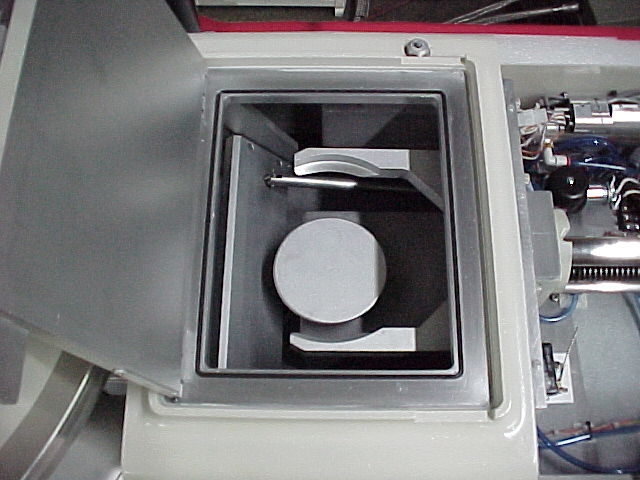

With load lock

Platen optimum, 4.5"-8"

Gun, 2"-3"

With PLC control

PLC / PC With data logging

W-10

Remote access

Load lock reduces pump down time

Anode / Cathode spacing remotely adjustable

Heat / Cool substrate table

Automated for high production throughput

Optional heat / Cool table: 600° With rapid cool down

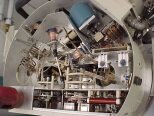

(3) Cathodes diameter, 8"

Round targets, 8”

Vacuum station: Turbo molecular / Diffusion-pump

Tuning: Randex Servo-match automatic tuning

LEYBOLD 450 Turbo pump

No mechanical pump

No RF generator

Substrate table:

Water-cooled, 8" diameter

Etch / Bias operations:

Up to 1 kW Etch

Variable bias: 0 to 50%

Shutter:

Stainless steel cup

Vertical and radial adjustment

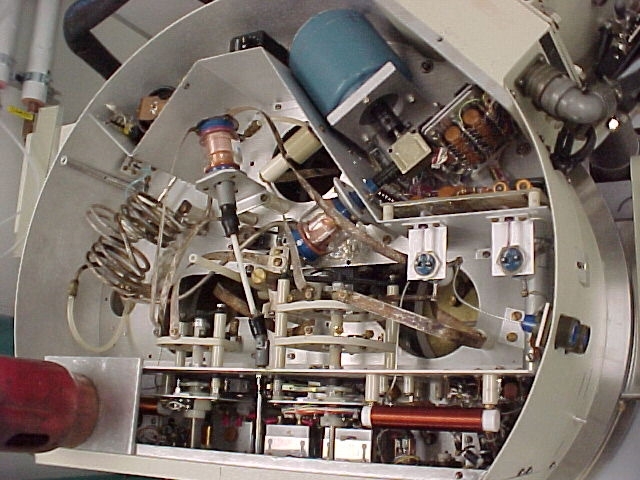

Control & meters:

Manual override toggle switches for load and tune controls

Target selector

Mode selector

Shutter position switches

Bias adjust potentiometer

RF Power adjust control

RF Power ON / OFF push button

Table bias

Forward power

Reflected power meter

RF Power supply: 1 & 2 kW Controlled remotely from sputtering module.

PERKIN ELMER 2400 is a high-end sputtering equipment designed to deposit thin layers of sputterable material onto a substrate. It is capable of producing thin uniform coatings at high deposition rates and can be used for various applications such as optical, surface-sensitive, and magnetic devices. The system offers advanced sputter-coating capabilities through its two- and four-source systems, which employ separate configurations depending on the type of material being deposited. In either case, the unit utilizes a high-throughput, high-vacuum platform, allowing for ultra-thin layer deposition without excessive heating or oxidation. 2400 employs an automated process, allowing for precise repeatable coatings ranging from 20 Angstroms (A) to 5000 A. The machine comes with a choice of two or four sputter sources, each of which can be individually adjusted to provide greater control over the deposition process. It also features an integrated inert gas atmosphere that incorporates an argon or other noble gas to maintain a consistent charge instead of ambient air. The tool also has advanced controls for monitoring and regulating process parameters like temperature, gas mixtures, and power levels. The four-source configuration allows the user to easily alternate between different sputterable materials during a single coating process, giving them access to the wide range of possible coating compositions. When it comes to substrate processing, PERKIN ELMER 2400 can accommodate both planar and curved substrates, with various shapes and sizes. Using its adjustable and easily detachable bell-seal, the asset ensures an even-flow of material and consistent thin-film results. In addition to sputter-coating functionality, 2400 also offers advanced analytical capabilities such as X-ray fluorescence (XRF) and Auger Electron Spectroscopy (AES). XRF scans the surface of a sample for chemical compositions while AES provides fingerprints of molecular structures found within the coating material's surface. Both allow researchers to conduct further investigation and adjust their deposition parameters if necessary. Overall, PERKIN ELMER 2400 is designed to provide the ultimate coating solutions for research facilities, laboratories, and other industrial applications, allowing users to easily deposit thin-film material for various projects. With its automated controls, wide range of settings, and advanced analytical capabilities, the model is a reliable and versatile sputtering equipment capable of fulfilling the needs of any experimental or development environment.

There are no reviews yet