Used PERKIN ELMER 4400 #9201790 for sale

URL successfully copied!

Tap to zoom

ID: 9201790

Wafer Size: 6"

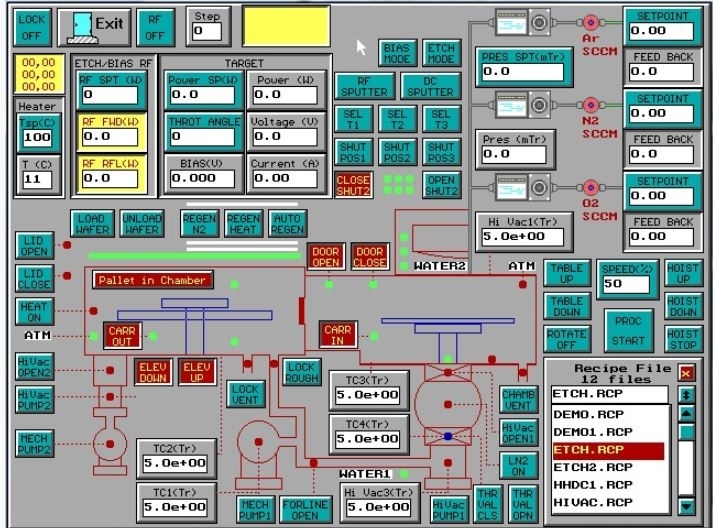

Sputtering system, 6"

Wafer loading: Manual

With load lock

Cathodes: Circle shape, 8″ & 4 max

Sputter methods: RF / DC

Diode / MAGNETRON

Gas lines: 1~3 MFC

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration 4400 4410 / 4450

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

4400 4410 / 4450

DC Power 5 kW 5 kW / 10 kW

RF Power 1kW / 2kW 2 kW / 3 kW

Pulse DC Power 5 kW 5 kW / 10 kW

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Replaced obsolete controls:

Auto pump down controller

Load lock controller

Digital clock timer

Table raise / Lower control

Throttle valve control system

Pressure control system

Sputter head controls

Gas line with MFC

Ar, 200 SCCM, customized

Power box: AC 380 V / 208 V / 3 Phase.

PERKIN ELMER 4400 is a state-of-the-art sputtering equipment that has become a common versatile tool for thin film vacuum deposition. This sputtering tool is a multi-source system, allowing for sputtering any metal or dielectric material in its three-chamber design with its custom-engineered end-mount wafer holder. 4400 can achieve precision deposition thickness down to 1 angstrom and thin film uniformity down to 1 nanometer. This precision measurement is made possible with the patented copper target protection method that also ensures process repeatability as well as long cycle production times. Using TRIO-MIM^TM sealed magnetron technology guarantees non-contamination of the chamber during deposition of the thin film materials. The TRIO-MIM^TM sealed magnetron technology heats the sputtering target and thus additional potential to vary process parameters is opened. This allows for performance of high density, high conductivity films as well as more complex organic materials which require a higher substrate temperature during deposition. PERKIN ELMER 4400 is a reliable and easy to operate unit. This sputtering equipment offers flexibility in terms of the size of the wafer holder and the ability to adjust the sputtering parameters with real-time software control for greater process precision. Machine calibration is easily carried out using the built-in Auto-Calibration feature. It is also a robust enough tool for UL certified operation in production environments. In addition to its general deposition applications, 4400 is often used when creating advanced device components. It implements mechanical polishing of substrates to ensure smooth surfaces while the sputtering process creates fine micro-scale features on the devices. PERKIN ELMER 4400 is a reliable and efficient sputtering asset, offering partial and full-chamber sputter sputterings with optional in-situ deposition and annealing. The model's features allow for production of the highest quality thin films while controlling the cost of production.

There are no reviews yet