Used PERKIN ELMER 4410 #9201791 for sale

URL successfully copied!

Tap to zoom

ID: 9201791

Wafer Size: 8"

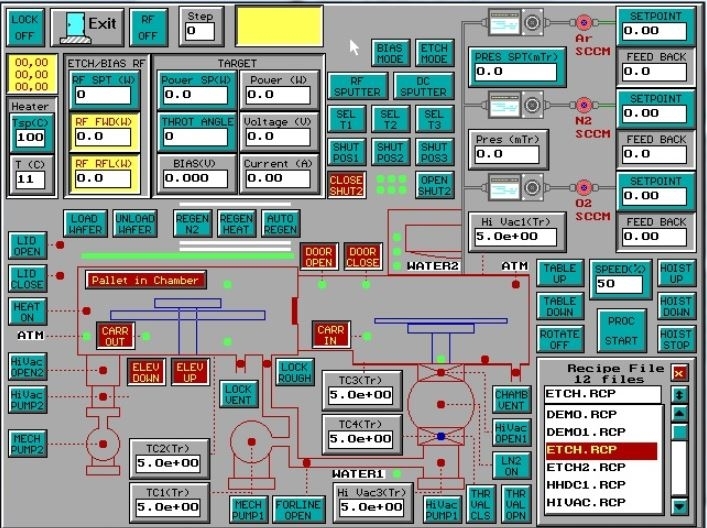

Sputtering system, 8"

Wafer loading: Manual

With load lock

Cathodes: Delta shape, 3 max

Sputter methods: RF / DC

Diode / MAGNETRON

Gas lines: 1~3 MFC

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration 4400 4410 / 4450

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

4400 4410 / 4450

DC Power 5 kW 5 kW / 10 kW

RF Power 1kW / 2kW 2 kW / 3 kW

Pulse DC Power 5 kW 5 kW / 10 kW

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Replaced obsolete controls:

Auto pump down controller

Load lock controller

Digital clock timer

Table raise / Lower control

Throttle valve control system

Pressure control system

Sputter head controls

Gas line with MFC

Ar, 200 SCCM, customized

Power box: AC 380 V / 208 V / 3 Phase.

PERKIN ELMER 4410 is a sputtering equipment designed with a highly versatile feature set, making it a popular choice for electrical, microelectronics and semiconductor applications. This highly capable system consists of two primary components; the sputter gun, and an integrated chassis that houses the control and power components. The sputter gun at the heart of 4410 has an adjustable power supply ranging between 40 to 350 Watts. This allows the user to tailor the unit's deposition rate to match the needs of their current project or application. Additionally, the sputter gun design is highly modular enabling it to use a variety of different sputtering targets including evaporated, magnetron and diode designs. The integrated chassis of PERKIN ELMER 4410 is where the control and all power components reside. The control unit facilitates automated operations as well as manual mode options. This includes a preprogrammed course of action where parameters like pressure and temperature can be specified, as well as manual operations to fine tune the sputtering process. The power unit consists of a number of transformers and rectifiers needed to convert the incoming AC power up to the required DC power for the sputter gun. 4410 is designed to be used in cleanroom-type environments and has been engineered with safety in mind. It contains an emergency shut-off button to enable quick shutdown of the machine in case of emergency, and its exhaust is vented outside to ensure minimal exposure of hazardous materials. In summary, PERKIN ELMER 4410 is a versatile, high-performance sputtering tool with excellent control and power components, allowing it to be used in a variety of industrial and research related applications. It is designed for exceptional safety and with the modular sputter gun and integrated controls, users have the peace of mind for customizing their asset for the precise needs of the current project.

There are no reviews yet