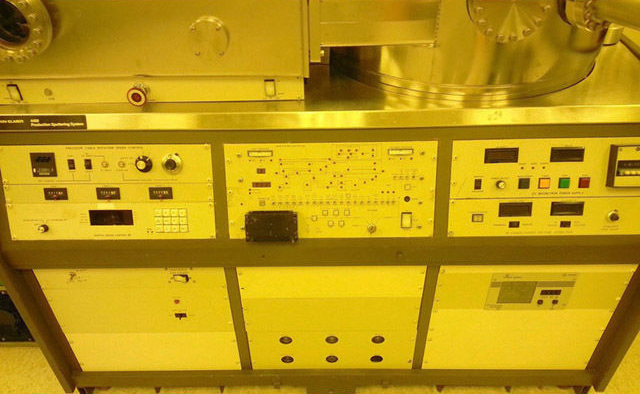

Used PERKIN ELMER 4450 #9089262 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9089262

Sputtering system, up to 6"

(3) Targets

Delta configuration

RF power supply

DC power supply

Turbo pumped load lock

CTI cryopump and compressor

LH D65B Dual stage vacuum pump.

PERKIN ELMER 4450 is a sputtering equipment, a type of tool used in vacuum systems for depositing thin films on substrates. It uses an argon sputter gun with an adjustable pressure range of 5-1000 mtorr, a base pressure of 2×10-8 torr, and a maximum pressure of 1×10-2 torr. The system can sputter a variety of materials including metals, semiconductors, and oxides. The power supply for the sputter gun on 4450 unit can be either a high-frequency alternating-current (HFAC) or direct-current (DC) source with the ability to adjust the power and frequency from 0-200 Watts and 10-500 kHz. It also features a rotating platform to ensure uniformity of coverage of the material onto the substrate. PERKIN ELMER 4450 is designed with a High Tolerance Closed Loop Feedback Technology (HTCLFT) that monitors the sputter rate to ensure consistent results and provides excellent control of the sputter process. It is also compatible with existing a gas control machine and can be used in a standard ultra-high-vacuum environment. The sputter deposition rate is adjustable from 1-1000 Angstroms/second. The tool has a semi-auto mode that allows the user to control the sputter rate, substrate bias, and substrate rotation speeds. It also has a large top-loading furnace which can accommodate substrates up to 8" in diameter. 4450 has an optional secondary electron detector that can detect surface-sputtering particles for detailed analysis of the material being sputtered. It is also capable of performing stop-motion and step-and-repeat sputtering. For processes requiring high precision, PERKIN ELMER 4450 is the perfect choice. Its durable design and intuitive controls make it easy to use and maintain over the long term. Its adjustable sputter rate and substrate bias along with its closed loop feedback technology allow for tight control over the sputter process, making the asset ideal for use in research and development, prototyping, and production applications.

There are no reviews yet