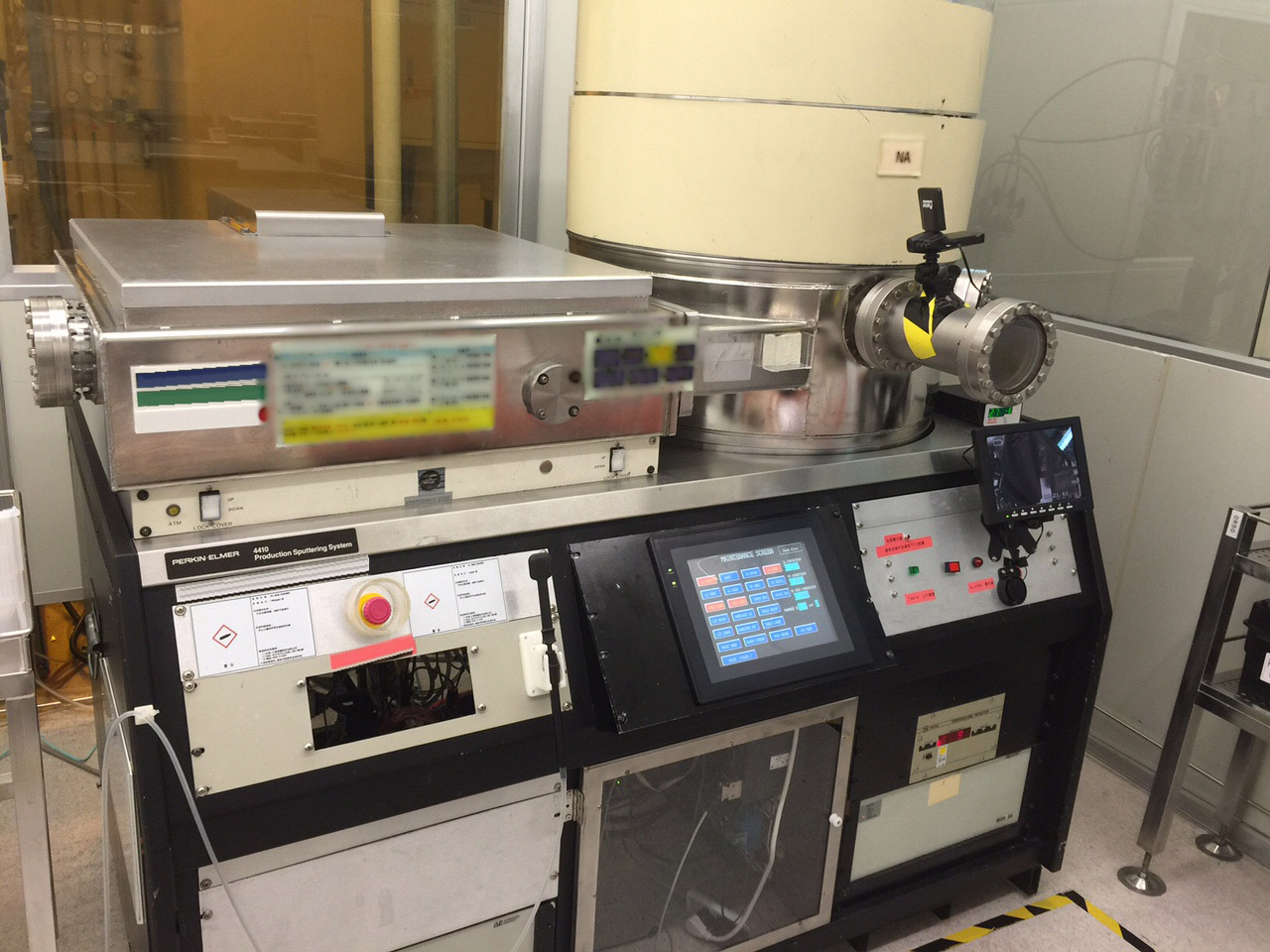

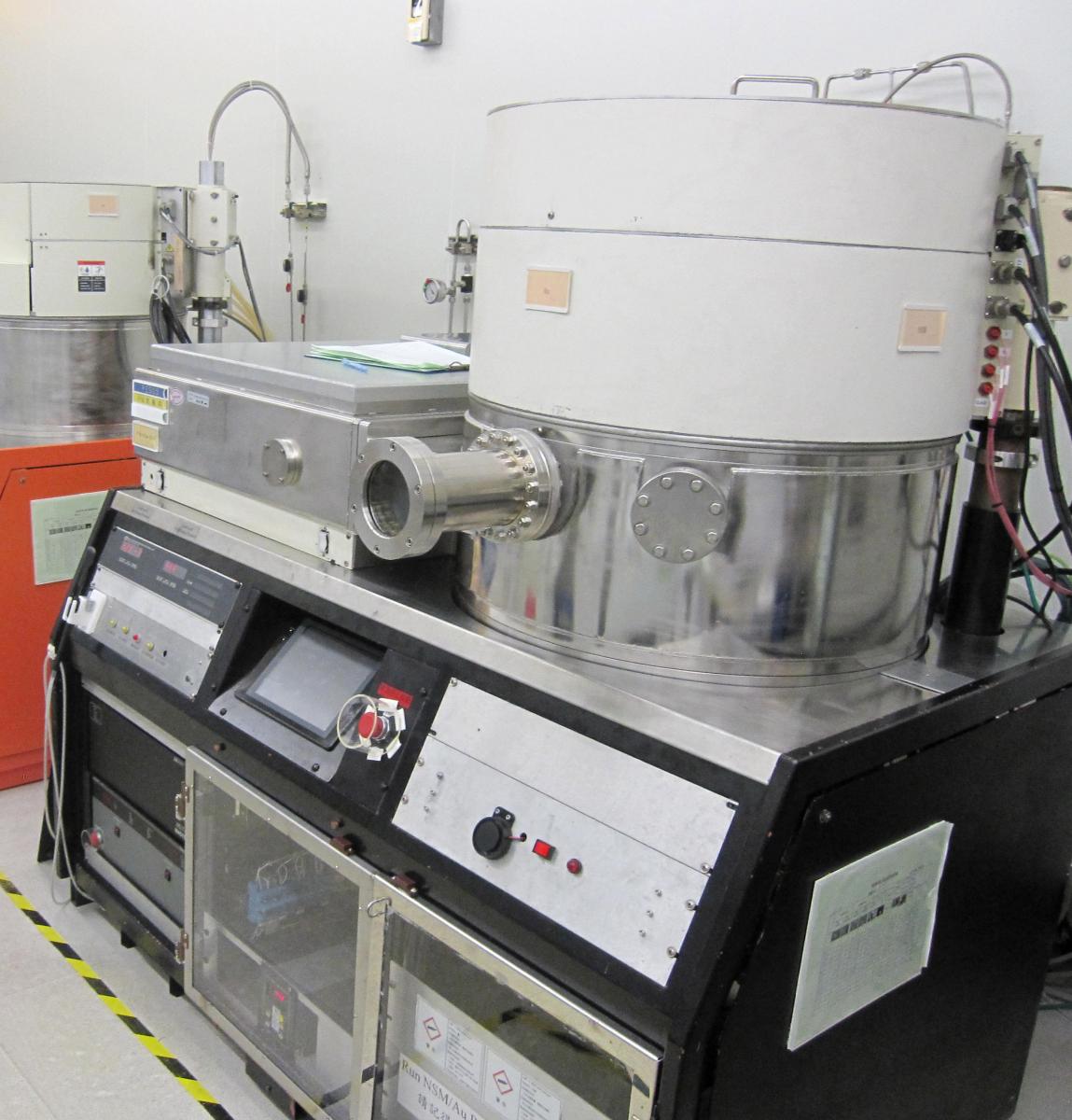

Used PERKIN ELMER 4450 #9114027 for sale

URL successfully copied!

Tap to zoom

ID: 9114027

Sputtering system

TaN process

Omron PLC Control

(2) Gas

(2) Delta target

(2) AE MDX-5 PS

CT-8 Cryo pump

Pallet, 6"

No etch, LL heat

Currently installed

2000-2005 vintage.

PERKIN ELMER 4450 is a sputtering system primarily used in the thin-film deposition and analysis of materials. It is ideally suited for a variety of research and development tasks, such as the deposition of nanostructured materials and the formation of conducting layers. The equipment consists of a sputter chamber with a target holder, a process gas inlet, and a flat-plate substrate holder situated below the target. Inside the chamber, high-purity argon or other inert gas is ionized by a hot cathode or electron gun to sputter material from the target onto the substrate. This plasma sputtered deposition is a slow, highly controlled process that enables the deposition of thin, uniform layers at precise thicknesses of materials such as gold, copper, and chromium onto substrates such as silicon, glass, and ceramics. The system's computer-controlled software enables a wide range of process parameters to be set and adjusted to meet specific deposition requirements, such as the substrate temperature or the sputter rate. These include the gas pressure, substrate bias, target power, substrate curvature, and the angle of incidence. 4450 enables full, in-situ analysis of the surface composition, chemical composition, and composition-profile of the layer which is being deposited. This is done by installing the appropriate external analytical equipment directly inside the deposition chamber. Such analysis enables researchers to optimize the properties of the deposited layers and to verify the desired layer thickness, composition, and profile. In addition, PERKIN ELMER 4450 allows users to implement a variety of techniques to improve the quality of the deposited film, such as ion-beam mixing or reactive sputtering. These techniques extend the range of possible deposited materials, improve the electrical, optical, and thermal properties of the layer, and enable the formation of compounds such as nitrides and carbides. 4450 is a highly sophisticated sputtering system which has been designed to provide precise and repeatable thin-film deposition with full in-situ analysis. With its wide range of available parameters and settings, it provides researchers with the ability to deposit a range of materials onto a variety of substrates as well as to control and optimize the layers' properties.

There are no reviews yet