Used PERKIN ELMER 4450 #9173056 for sale

URL successfully copied!

Tap to zoom

ID: 9173056

Wafer Size: 6"

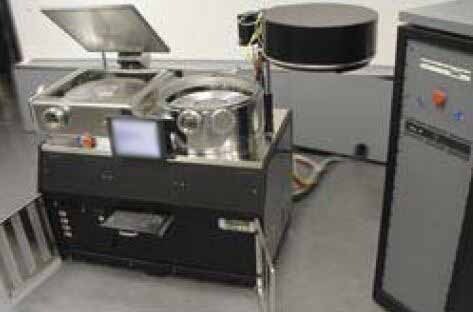

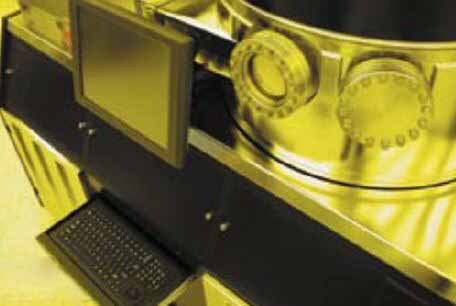

Sputtering system, 6"

Load lock system

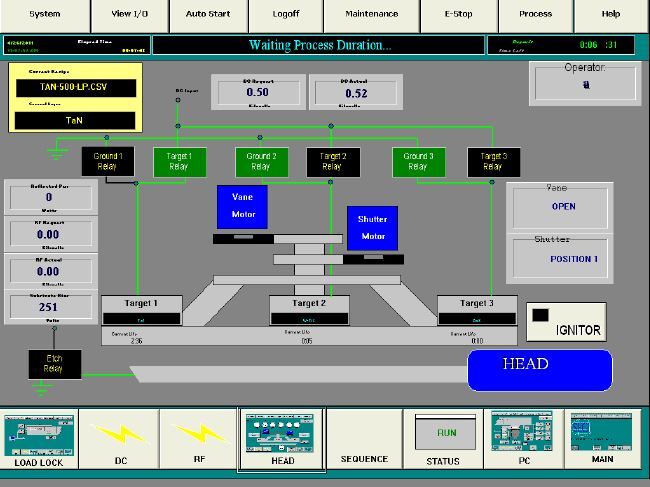

(4) 8” Target head assemblies, bonded

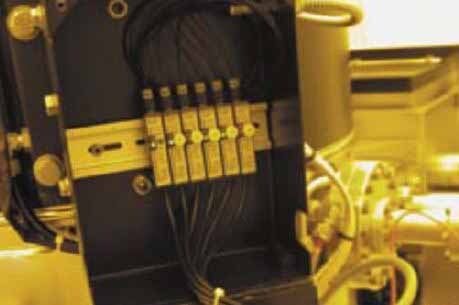

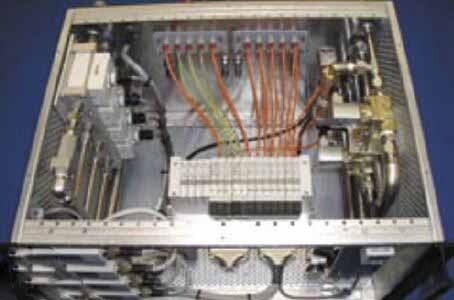

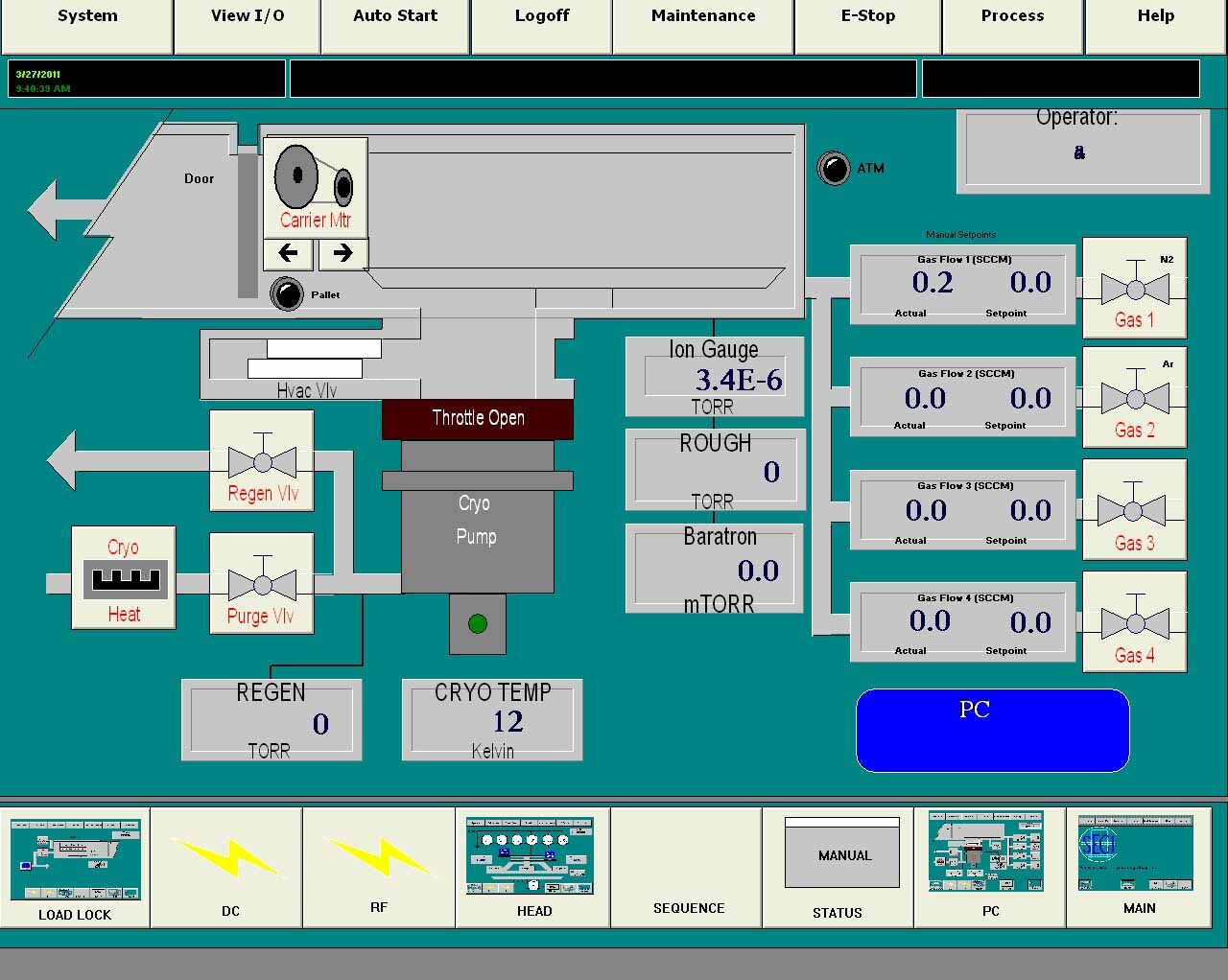

MKS Gas control with MKS MFC and CMT

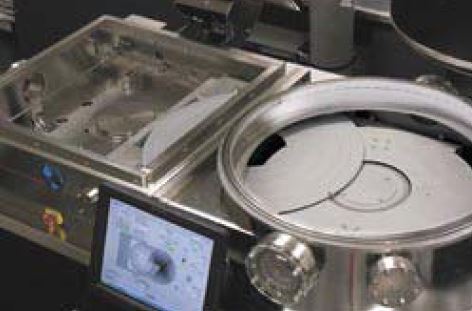

Pallet

(7) Positions

GP 303 Ion gauge controller

With dual convectron & IG tubes

VAT throttling gate valve

Vexta precision table motor and controller

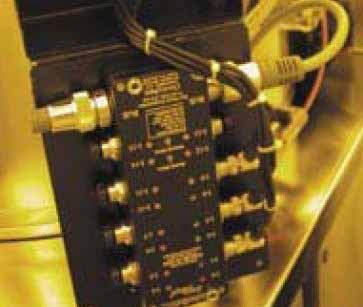

AE Pinnacle 6 kw RF power supply

AE MDX-10 DC power supply, 10 kW

ENI RF Generator with matching unit for etch

RGA (Residual Gas Analyzer)

21 CFM Mechanical pump

CT-8 Cryo and SC compressor.

PERKIN ELMER 4450 is a high quality sputtering equipment suitable for depositing thick films of various materials on a wide variety of substrates. The system is engineered to provide ultra-smooth and uniform coats of material on any given substrate, as well as offer a wide variety of sputtering material choices. 4450 is designed to maximize productivity and minimize downtime, by offering easy access to sputtering targets, a high-performance cooling dielectric, and precise control over pressure, power, and process time. The unit features a dual-target, non-evacuating chamber that provides the user with a high degree of flexibility for complex sputtering processes. It has a vacuum range of 10-6 mbar with a maximum sputtering speed of 500 Å/sec and a base pressure of 6 × 10-8 mbar. The sputtering targets are mounted in electron guns that are easily removed and replaced for quick access to different sputtering materials. The machine is equipped with a high-precision motion stage controller which, when coupled with the dual-target setup, allows for sample thickness uniformity over wide areas. PERKIN ELMER 4450 incorporates advanced controller logic into its design, which provides a high degree of flexibility and control over the sputtering procedure. It includes a ramp-up/ramp-down feature which is particularly useful when sputtering thicker films over larger substrates. The user is able to program their desired process parameters including power, pressure, and time duration, all through an easy to use graphical user interface. This allows for very accurate control over the process, thus ensuring precision coating results. The tool is equipped with a fully integrated cooling dielectric to maintain target and source temperatures during sputtering operations. The dielectric is designed to maintain low temperature during sputtering operations, which is essential for minimizing evaporation of target materials and degradation of the plasma. It also helps to maintain a uniform sputtering process and uniform substrate coverage. 4450 is a great choice for a wide range of applications including deposition of materials for MEMS, semiconductor, and photovoltaic devices. With its advanced control logic and integrated cooling dielectric, the asset ensures highly uniform, thick films with minimal effort from the user.

There are no reviews yet