Used PERKIN ELMER 4450 #9190161 for sale

URL successfully copied!

Tap to zoom

ID: 9190161

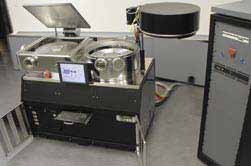

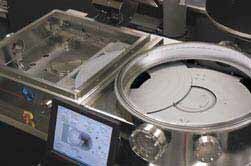

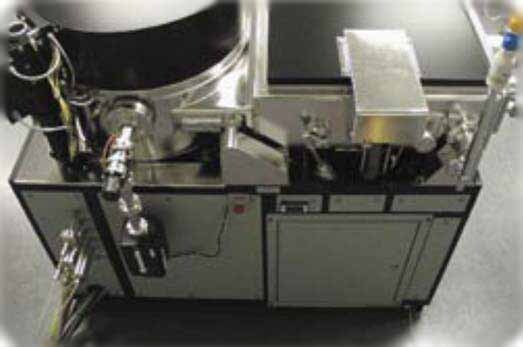

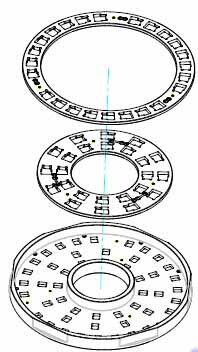

Sputtering system

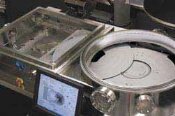

(4) Target systems

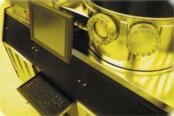

Round target, 8"

RF Target

(3) DC Targets

Load lock pallet, 24"

Data logging

Recipe control

Remote operation

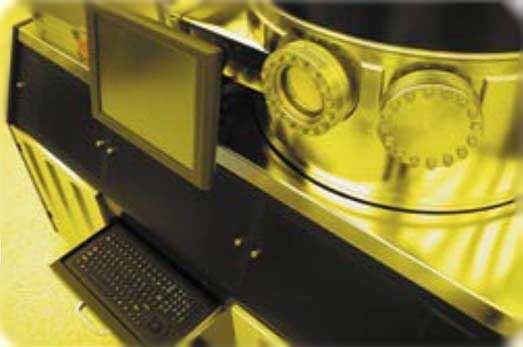

Color touch screen

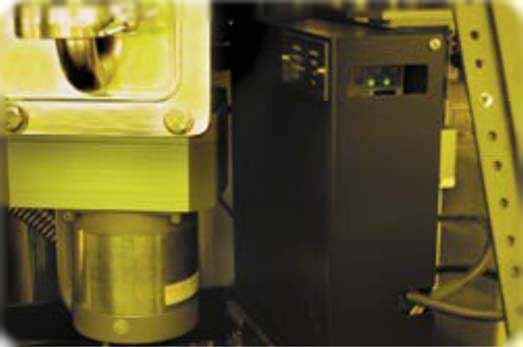

Jennings vacuum: 5kW

Optical shutter position sensors

Simplified sputter head design

Industrial PC

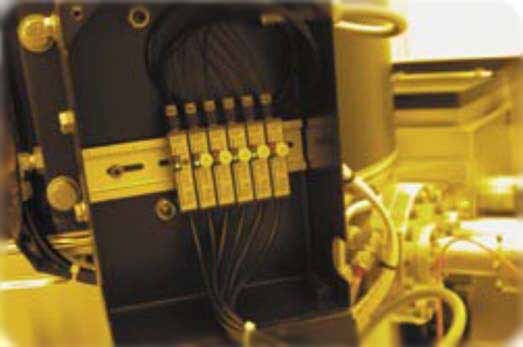

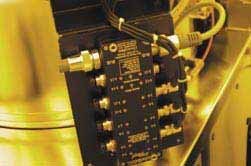

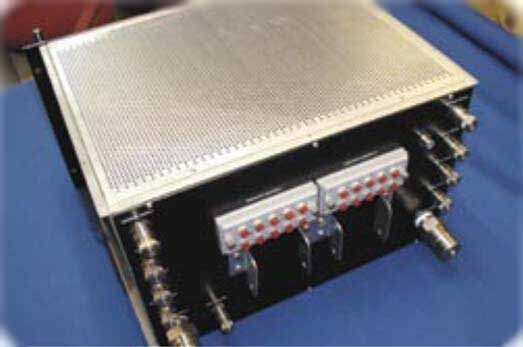

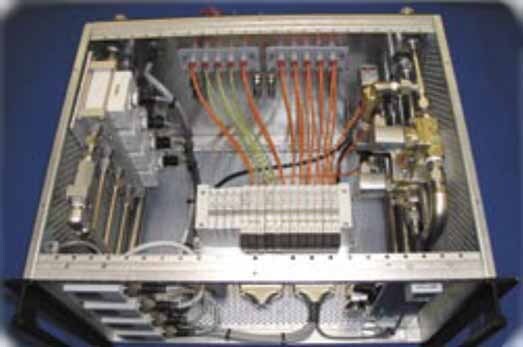

Water / Pneumatic distribution box

Electro polished chambers

VAT Throttling gate valve

Keyboard

Vexta precision table motor

Controllers

Oil free scroll type mechanical pump

Color coded air

N2

Water lines

Mass flow controller

Residual gas analyzer

Quick disconnects

Mounted rails for easy access

Touchscreen display

Process logic controller.

PERKIN ELMER 4450 is a high-end hydride sputtering system designed to deposit thin films of metal or alloys onto substrates in a controlled and uniform manner. It is commonly used in the manufacturing of semiconductors, magnetic devices, optics, and other electronic components. The system is made up of several components: a chamber, a substrate holder, a power supply, an evaporator, a shutter mechanism, and a radio frequency (RF) generator. The chamber is made up of two stainless steel walls and is sealed to retain a vacuum. The substrate holder is mounted on the chamber and is used to secure the substrate being treated. The power supply is used to provide a constant voltage and current to the chamber and support it during operation. The evaporator is used to vaporize the material to be sputtered onto the substrate. The shutter mechanism is used to control when material is vaporized. Lastly, the RF generator is used to provide a stream of electrons that deflects the vaporized material onto the substrate. Once the material is vaporized, the substrate holder is placed inside the chamber, and then a vacuum is created. The RF generator is used to create an electric field inside the chamber and generate an electron beam which causes the material to sputter off the surface of the substrate. This process is repeated hundreds of times until the desired thickness of the film has been reached. The advantage of using the sputtering technique is that it allows for the deposition of uniform layers of material onto the substrate, which can then be patterned or coated. Additionally, the process can be used to create high-performance, durable materials with excellent electrical, optical, and mechanical properties. 4450 can be used for many different applications, including the creation of high-quality semiconductor components, magnetic materials, optical mirrors, mirror coatings, memory devices, and more. Additionally, it can also be used for research and development purposes, as the system can generate more exact and uniformized layers with mixtures of different elements and compounds.

There are no reviews yet