Used PERKIN ELMER 4450 #9199550 for sale

URL successfully copied!

Tap to zoom

ID: 9199550

Wafer Size: 8"

Sputtering system, 8"

Wafer loading: Manual with load lock

Cathode:

(3) Delta shapes

(4) Circle shapes

Sputter method:

RF/DC

Diode / MAGNETRON

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Gas line with MFC

N2

O2

SCCM

Customized

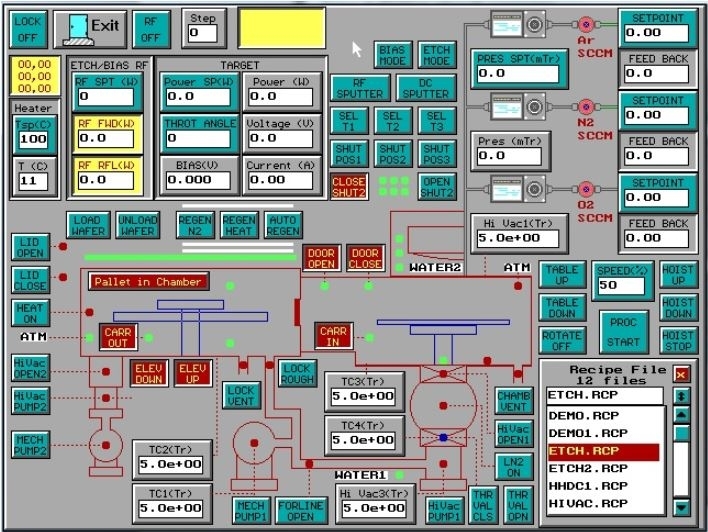

System PC control

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Materials:

AI+W

InSnO

AI2O3

Ag_

Au

C

Cr

Cr/Co

Cr/Au

Cr+Cu

Cr/Si

Cr/SiO

Cr/Si02

Si02

Mo

MoSi2

Mo2Si5

Mc>5Si3

Ni

Ni/Cr

Ni+Ni/Cr

Ni/Fe

Pt

Ti02

SiC

Ti/W

Si02+02

Si+N2(Si3N4)

Si+N2+B4C

Ta

TaC

Ta+Au

TaSi2

Ta+Si02

Zr

Ti02+Cr

Ti+Au

Ti+Au+Ni

Ni/Fe+Cu+Si02

Ti/W+Au

Ti/W+Au+Ta

Ti/W+AI/Si

Ti/W+Ni/Cr+Au

Ti/W+Pt

Al+Ti/W+Ag

W+AI2O3

Zn

Zri02

Basic configuration

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration 4400 4410 / 4450

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

4400 4410 / 4450

DC Power 5 kW 5 kW / 10 kW

RF Power 1kW / 2kW 2 KW / 3 kW

Pulse DC Power 5 kW 5 KW / 10 kW

Power distribution box: AC380 V / 208 V / 3 Phase.

PERKIN ELMER 4450 is a high-performance sputtering equipment designed to deposit thin layers of materials onto various substrates. It utilizes magnetron or ion bombardment deposition techniques to create ultra-smooth layers of metal films, oxides, and various other materials. The system includes two 3-inch DC sputtering electrodes and a large vacuum chamber ideal for low-temperature sputtering operations. The high-performance magnetron sputtering process in 4450 employs an efficient and highly reliable cooling unit to ensure maximum performance and operational longevity. By using argon or nitrogen gas at high pressures, the machine is able to create superior film properties with optimum deposition rates. The tool is also equipped with advanced bead-cleaning technology for improved lifetime of the asset components. The model requires minimal maintenance and offers superior vacuum pumping. Its low operating temperature helps to minimize substrate heating and improve the quality of the cover layer. The equipment also includes a high-precision capacitance thickness monitor with a pulse-regulating monitor to ensure excellent layer deposition. This monitor also allows for different sputtering currents, providing users with an ideal level of control over the coating process. The easy to use interface of the systems allows the user to quickly and easily change between different sputtering parameters and target materials. Its low-noise operation makes it safe and reliable to use for prolonged periods of time. It has a compact and lightweight design that making it easy to store and transport to different workstations. PERKIN ELMER 4450 is the ideal choice for laboratory and industrial sputtering processes. Its advanced features and easy-to-use interface make it an ideal choice for those looking for superior layer deposition and superior performance. Its advanced cooling system and low-current instruments makes it highly reliable and efficient for low-temperature sputtering operations.

There are no reviews yet