Used PROVAC PAS200T #9116850 for sale

URL successfully copied!

Tap to zoom

ID: 9116850

Wafer Size: 12"

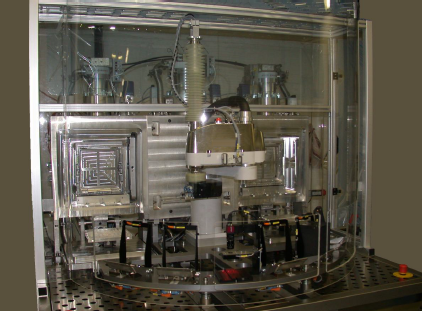

High vacuum sputtering system, 12"

Square wafers up to 8" x 8" can be coated with a distribution of < + -5%

Automatic loading and unloading

Substrates to be processed are picked up from the respective cassettes by robot handling and placed on the coating tables

Substrates subsequently evacuated and moved into the process chamber

Throughput: ≤ 48 wafers per hour

Maximum temperature of panels: 130°C

Si-sputtering:

Film thickness distribution: < + - 10%

Reproducibility: < + - 5%

Automatic process control

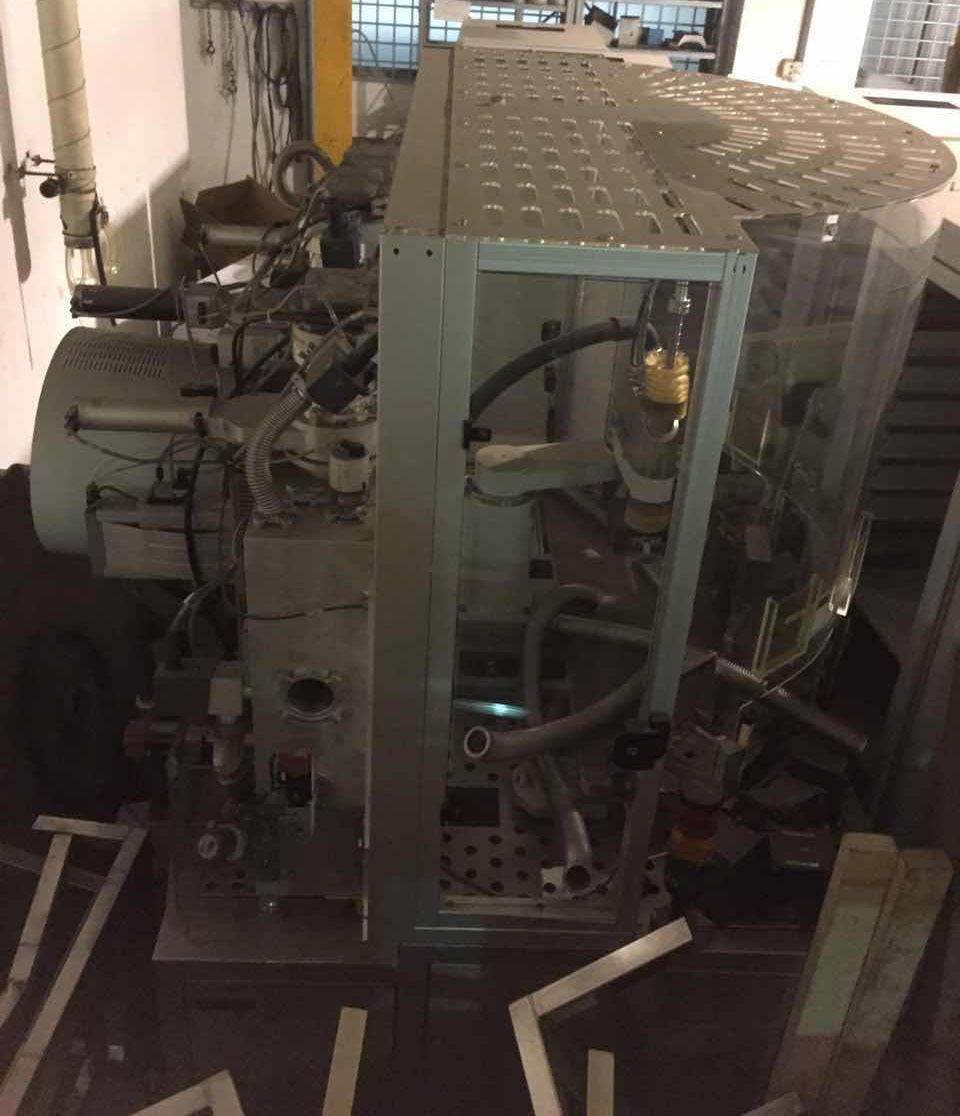

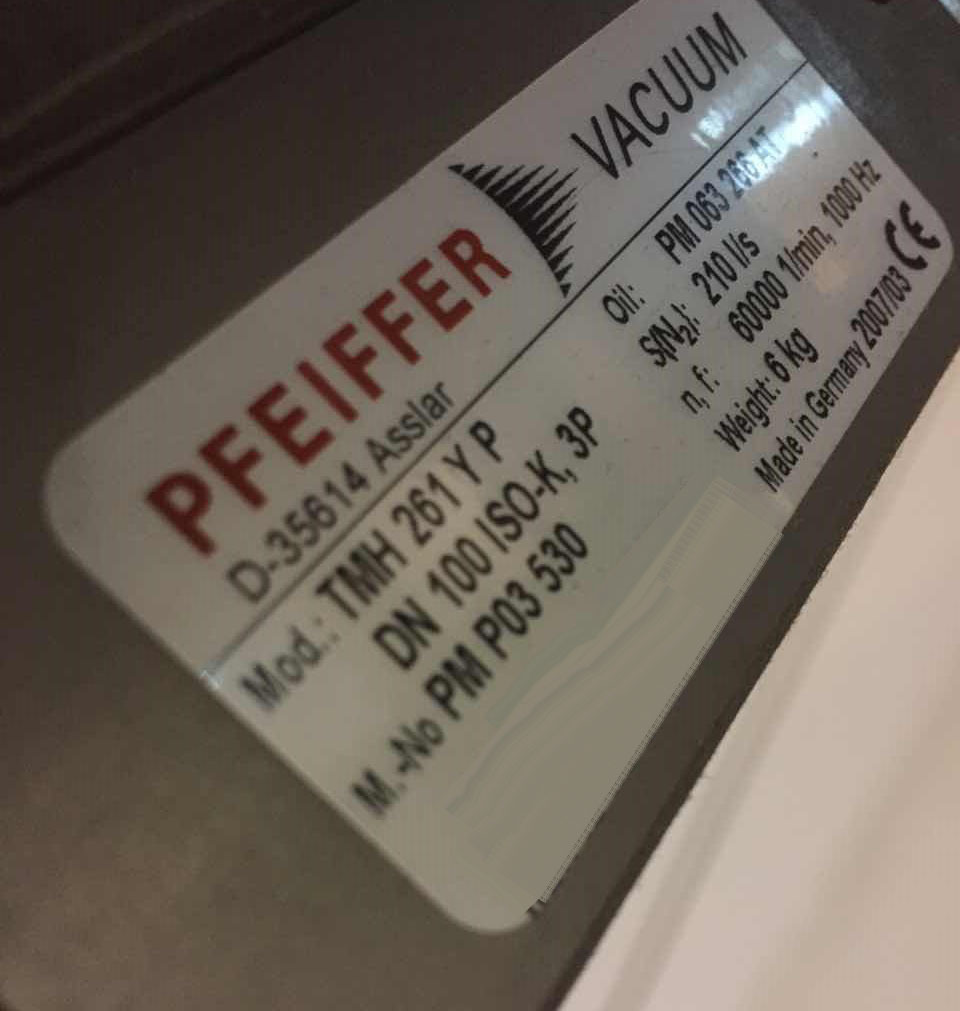

Pump set: High vacuum valves in front of the turbo pumps, one turbo pump each for the process chamber and each load lock

Magnetron: 1 x 16" ONYX-cathode with rotary magnet Pulsed DC magnetron power supply Silicon target 16"

High vacuum inline

Process chamber

(2) Load locks

Robot handling

Basic frame

Size of PC rack: integrated within the frame

Electric supply: (3) phases, full load capacity N, PE

Electrical connection data:

Voltage: 3 x 400V / 230V AC / ± 10%

Frequency: 50 or 60Hz ± 1%

Voltage: 35A

Currently warehoused.

PROVAC PAS200T is a sputtering equipment designed for thin film deposition and is the inerpreter of the PVD coater series. This system has the capability to provide the highest quality sputter deposition onto various substrates, making it ideal for electronics, optics, silicon, semiconductor, and many other industries and applications. PAS200T is capable of sputtering up to 20 materials and can be used for metal alloys, oxides, nitrides, tellurides, and carbides on a range of small, medium or large-scale substrates. The unit also features a wide range of process controls to make sure that the desired material characteristics and properties are achieved in the end result. It offers the ability to manage different process parameters such as plasma power, pressure, gas flow rate, deposition rate, and film thickness control. The machine is enclosed with an ultrahigh vacuum chamber. The chamber enables isolation from the outside interior environment, which ensures optimal process conditions for the thin-film deposition. The tool also features a top-positioned target holder, which ensures uniform rotation and consistent sputtering material exposure. It has two linear translation stages that give the engineers the ability to move the substrate up and down during the placement process to obtain optimum deposition rates and uniform coating. It also comes equipped with an in-built collimator, which is used for masking and focusing of the sputtered material onto the chosen area of the substrate. Additionally, the asset can be used with a variety of cathodes depending on the kind of material to be deposited on the substrate. PROVAC PAS200T also features several safety and convenience features such as vacuum, air, and water pressure alarms, temperature sensors and a vacuum monitor to ensure operability and safety. It also includes a high temperature protection model to protect equipment components, as well as a mechanical drive screen to prevent access to dangerous parts. Lastly, the equipment also includes a convenient set of digital inputs and outputs which allow user to easily operate the system from any computer. In conclusion, PAS200T is a dependable sputtering unit for thin film deposition, ideal for a host of industries and applications. Its array of process control features allows for variability and accuracy, while its various safety and convenience features guarantee user-friendliness.

There are no reviews yet