Used RSI / VANGUARD Sencera #9300991 for sale

URL successfully copied!

Tap to zoom

ID: 9300991

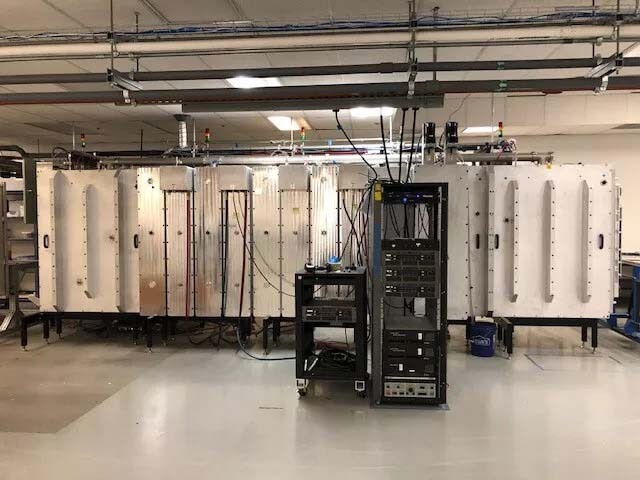

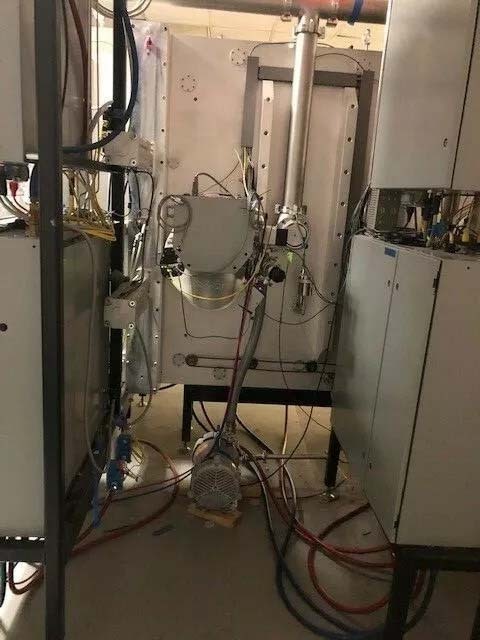

In-line sputtering system

(6) Target large panels

Vacuum pump

Turbo pump

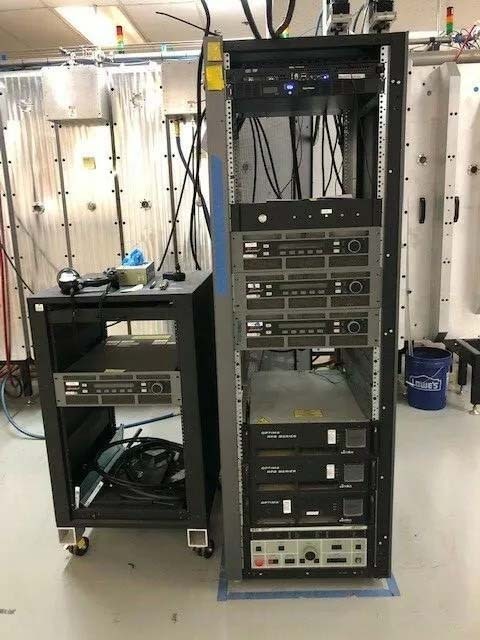

RF and DC Power supply

Qty / Make / Model / Description / Part Number

(4) / ADVANCED ENERGY / Pinnacle 3152442-102D / Generators / -

(2) / MKS / optima RPG-50Z / DC power supply / RPDG-50Z-10237

(1) / MKS / optima DCG-200Z / DC power supply / RPDG200Z-08055

(1) / ADVANCED ENERGY / MDX / 2011-000-AA / Magnetron Drive / -

(1) / ADIXEN / AD30KL / Dry pump / -

(1) / BOC EDWARDS / STP-iXA2206C / Turbomolecular turbo pumps / - / YT81-0Z-010 controller

(2) / BOC EDWARDS / STP-iXA2205CP / Turbomolecular turbo pumps / - / iPS-1200 YT63-W1-Z10 & Z00 controller

(1) / VAT / 65048-PAAP-BAS2/0001 A-1799517 / Vacuum Pendulum Control Valve / -

(1) / VAT / 65048-PAAP-BAS1/0002 A-973785 / Vacuum Pendulum Control Valve / -

(1) / VAT / 12148-PA24-AKW1/0005 A-977764 / Vacuum Pendulum Control Valve / -

(1) / VAT / 12148-PA24-AKW1/0006 A-97776 / Vacuum Pendulum Control Valve / -

(1) / ALLEN BRADLEY / 1734 / Processors and I/O / -

(1) BROOKS AUTOMATION / MFC / Delta Series / -.

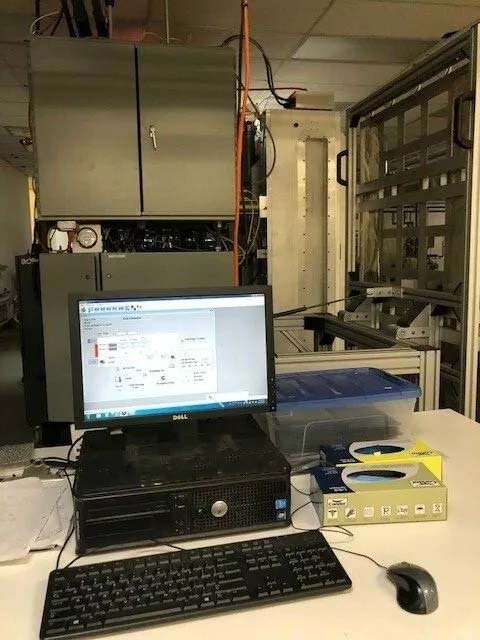

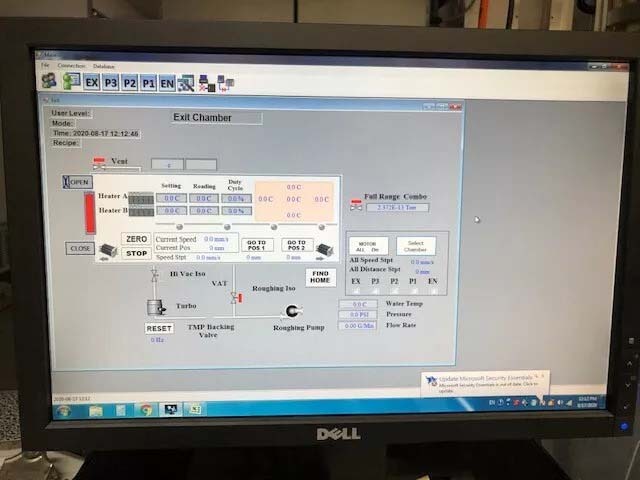

RSI / VANGUARD Sencera is a sputtering equipment designed for thin-film deposition and coating applications. It utilizes two cryogenically cooled cathodes to evaporate material from the cathode targets in a high vacuum environment, which is then deposited onto a substrate. The material evaporated is typically titanium, aluminum, chrome, or iron, and RSI Sencera system is capable of deposition rates of up to 2 angstroms per second.VANGUARD Sencera has a bi-polar sputtering mode for controlling the direction and energy of the material ionization. This mode helps with uniform deposition and coatings, low spattering, and low parasitic redeposition. The unit also contains internal magnets for controlling the ionization of charged particles and a frequency sweep generator to ensure uniform coverage. Sencera machine includes a compact deposition chamber and an industrial grade vacuum pump for creating a high vacuum environment. The chamber is equipped with an electrode surrounding the substrate to target and trap the evaporated material and measure the temperature. The temperature of the chamber can be monitored and controlled to between 5 and 40 degrees celsius. RSI / VANGUARD Sencera has a user-friendly interface with multiple modes of operation, including a preset mode that allows for easy recall of an experiment that yielded desired results. A programmable rate feeder allows sputtering process parameters such as deposition rate to be determined with greater accuracy. The tool also includes built-in safety features such as over-voltage protection and power shutdowns. Overall, RSI Sencera asset is a superior sputtering model for thin-film deposition and coating applications. Its magnet and frequency sweep technology enables a high deposition rate and uniform ionization, while its friendly interface and adjustable temperature control make it easy to use. Additionally, its built-in safety features make it safe and reliable for repeatable experiments with reproducible results.

There are no reviews yet