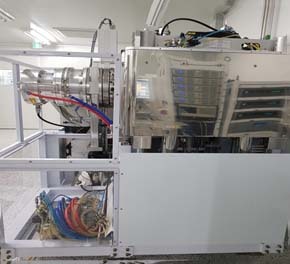

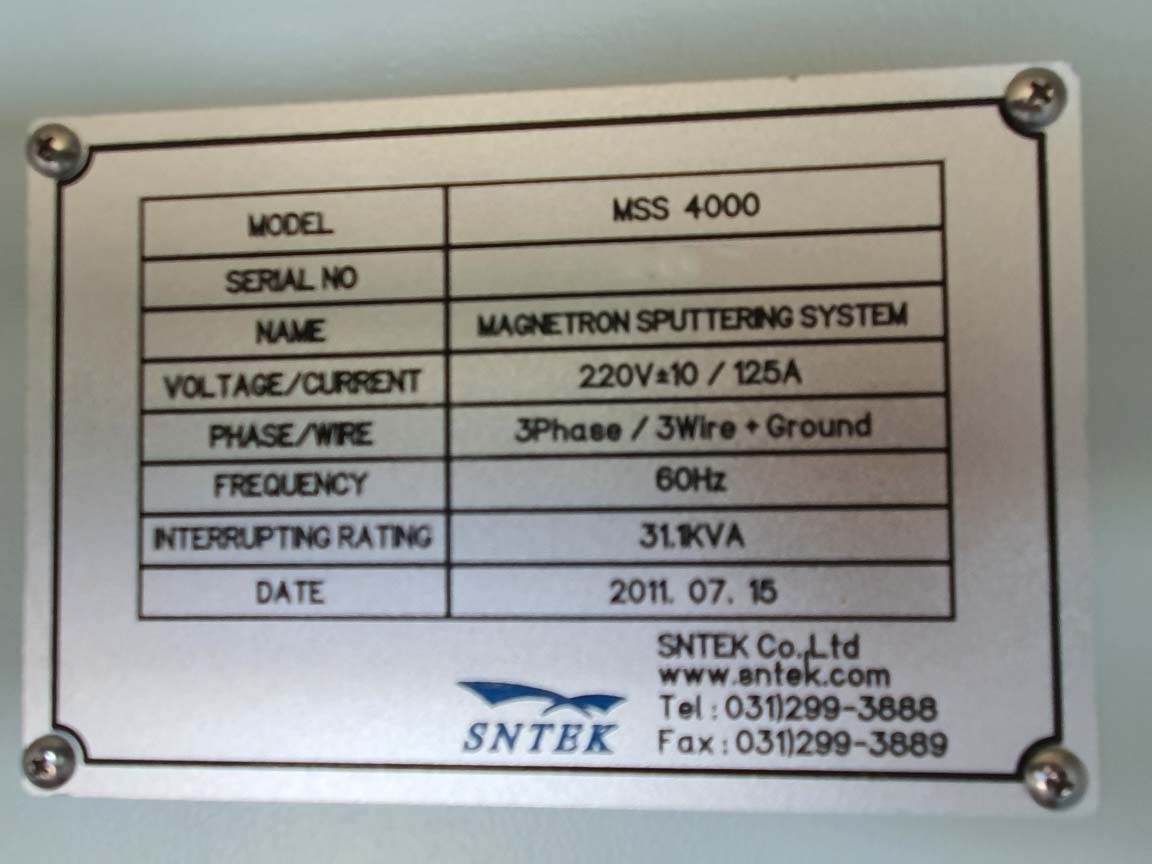

Used SNTEK MSS 4000 #293638179 for sale

URL successfully copied!

Tap to zoom

ID: 293638179

Vintage: 2011

Sputtering system

Loadlock chamber and TM Arm concept

Metal sputtering process: Ti, Cu and Au

Maximum substrate: 320 mm (6) Loadings / Cassette

Magnetron sputtering source: (3) Tilt guns, 8"

Substrate rotation speed : 5~20 RPM

Maximum temperature sheath heater: 300°C on substrate

PLC Based PC Control: HMI, Semi-automation control

Compressed air drive: 6~7 kg/cm², ¼"

Chamber vent: 3~4 kg/cm², ¼"

Process gas: Ar, 1~2 kg/cm², ¼"

Chamber pump exhaust: Normal exhaust line, 25 pi

Vacuum pumping unit:

Rough pump: SUS304 E.P tube and bellows, 40 pi

Sputter chamber: TMP and Dry

Transfer chamber: TMP and Dry

Loadlock chamber: TM's share

Pressure control type: Downstream ( Auto TH/V)

Gas supply unit: MFC Control (Ar)

Cooling water:

Heater and chamber: 3~4 kg/cm², L/Min, ½"

Sputter gun: 3~4 kg/cm², L/Min, ½"

Electricity:

Power: 220 V, 3 Phase, 60 Hz, 120 A (3 wire)

Ground: Class A (10 Ω or below) (1 wire)

Power supply:

Main chamber: (3) DC Power, 5kW

Loadlock chamber: RF Power, 1kW

Plasma cleaning source with RF Power at loadlock system

2011 vintage.

SNTEK MSS 4000 sputtering equipment is a high-vacuum deposition system designed to deposit thin films and coatings onto substrates. Using a triode-style magnetron sputter configuration, MSS 4000 can deposit metals, alloys, and a variety of other materials with extremely high uniformity and repeatability. The unit can be used to create thin-films, bulk coatings, and layered structures. SNTEK MSS 4000 is equipped with two independent sputter chambers capable of operating at pressures down to 10-7 torr and temperatures up to 400°C. Each chamber can be individually configured with an innovative, configurable target assembly that allows the user to select from a wide variety of target shapes and sizes. The target assemblies are even capable of spinning targets on an axis in order to uniformly distribute the wear of the target surface. MSS 4000 is driven by a comprehensive process controller equipped with a wide range of options and tools to accurately control and monitor the deposition process. The process controller allows for precise power and gas flow regulation for optimal deposition performance. Additionally, the process controller is capable of registering and storing various process parameters allowing for accurate analysis of the deposited films. SNTEK MSS 4000 can be interfaced with a wide range of other instruments for analyses and testing of films. This machine also comes with a remote control and power saving functions to save energy and improve overall efficiency. Overall, MSS 4000 sputtering tool is an excellent choice for depositing thin films and coatings with precise control and repeatability. SNTEK MSS 4000 allows users to produce films with high uniformity and excellent repeatability with minimal downtime and resources spent. Furthermore, the asset can integrate easily with other process instruments and provides users with a full suite of process control options.

There are no reviews yet