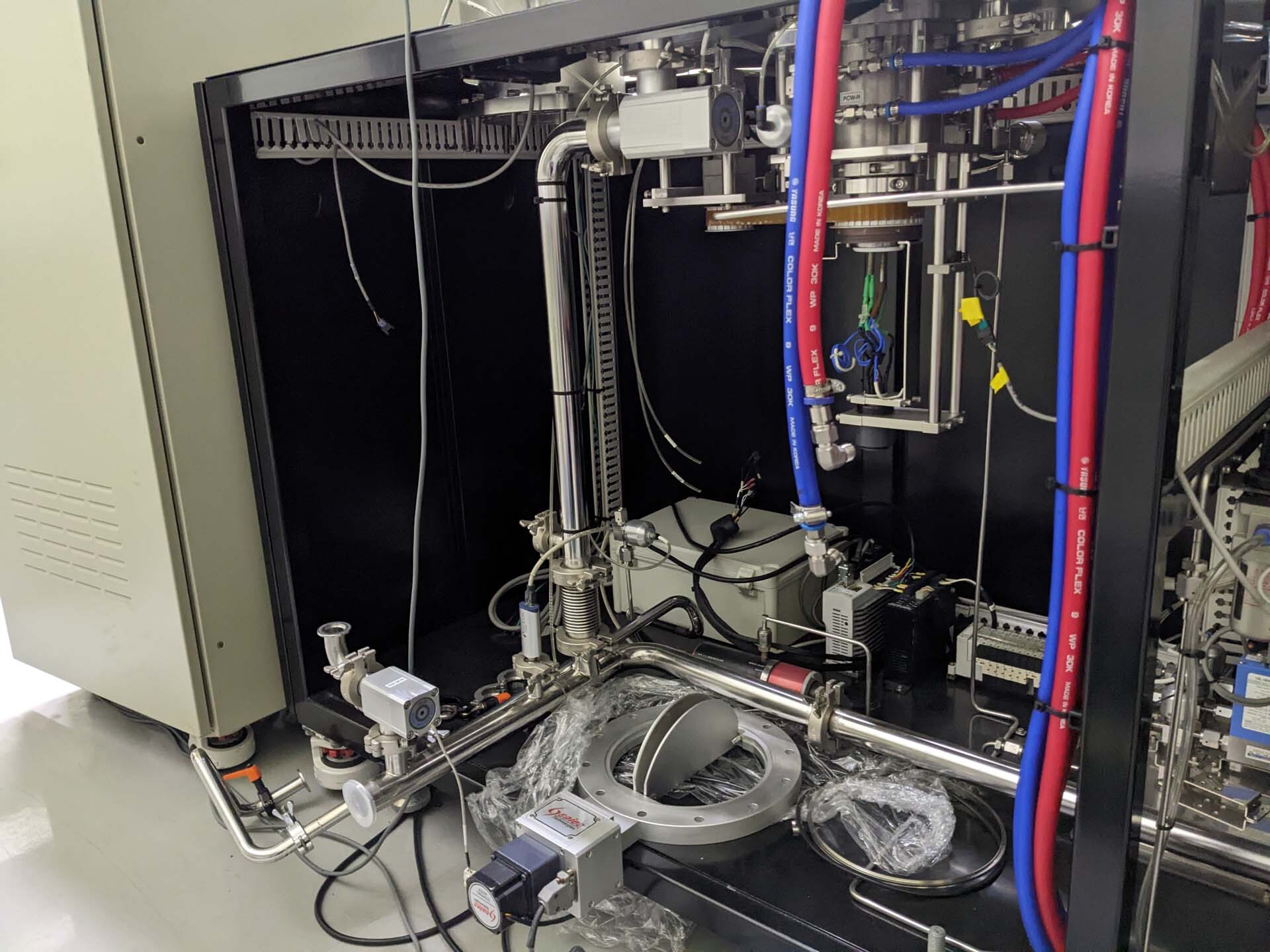

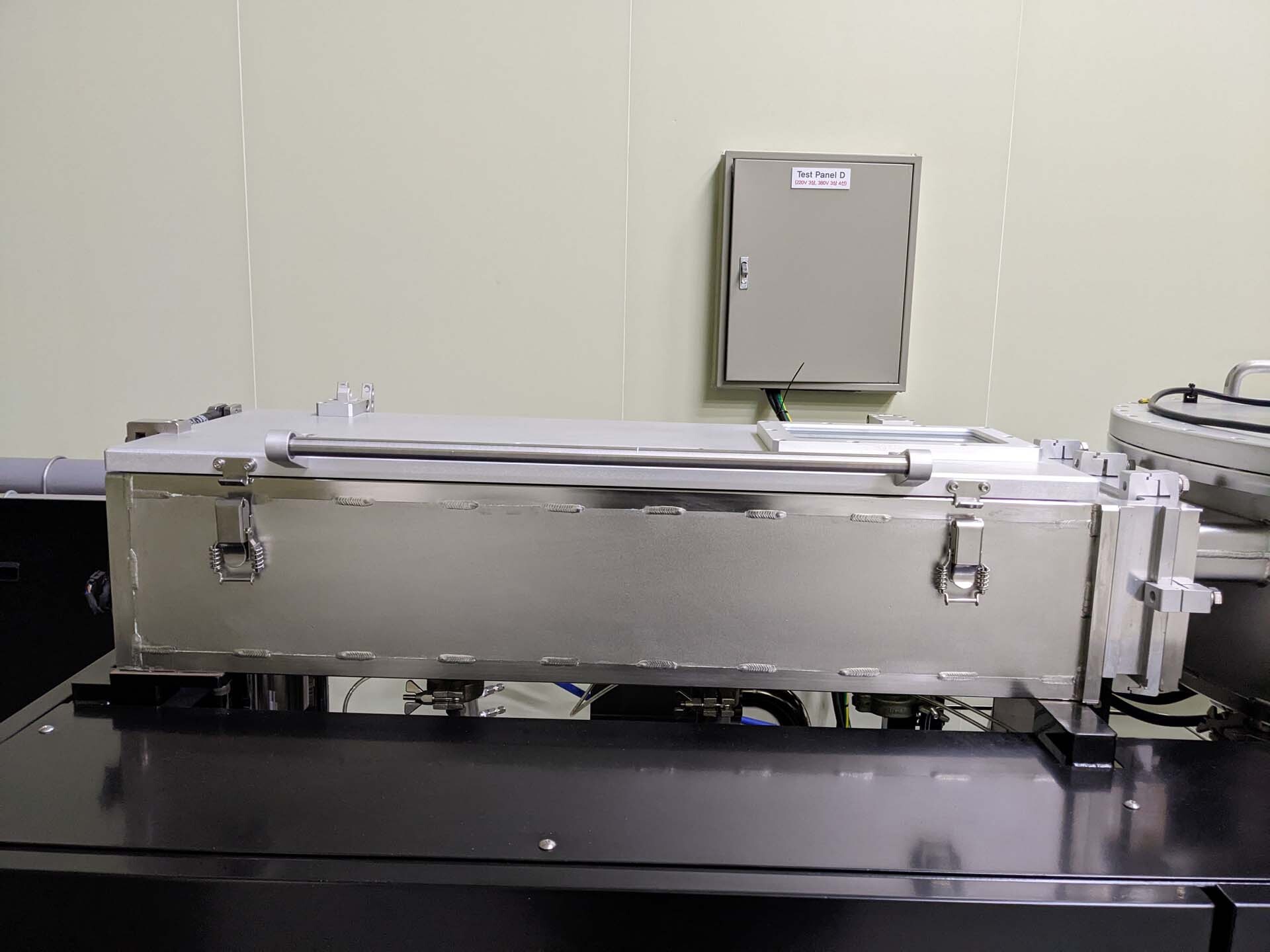

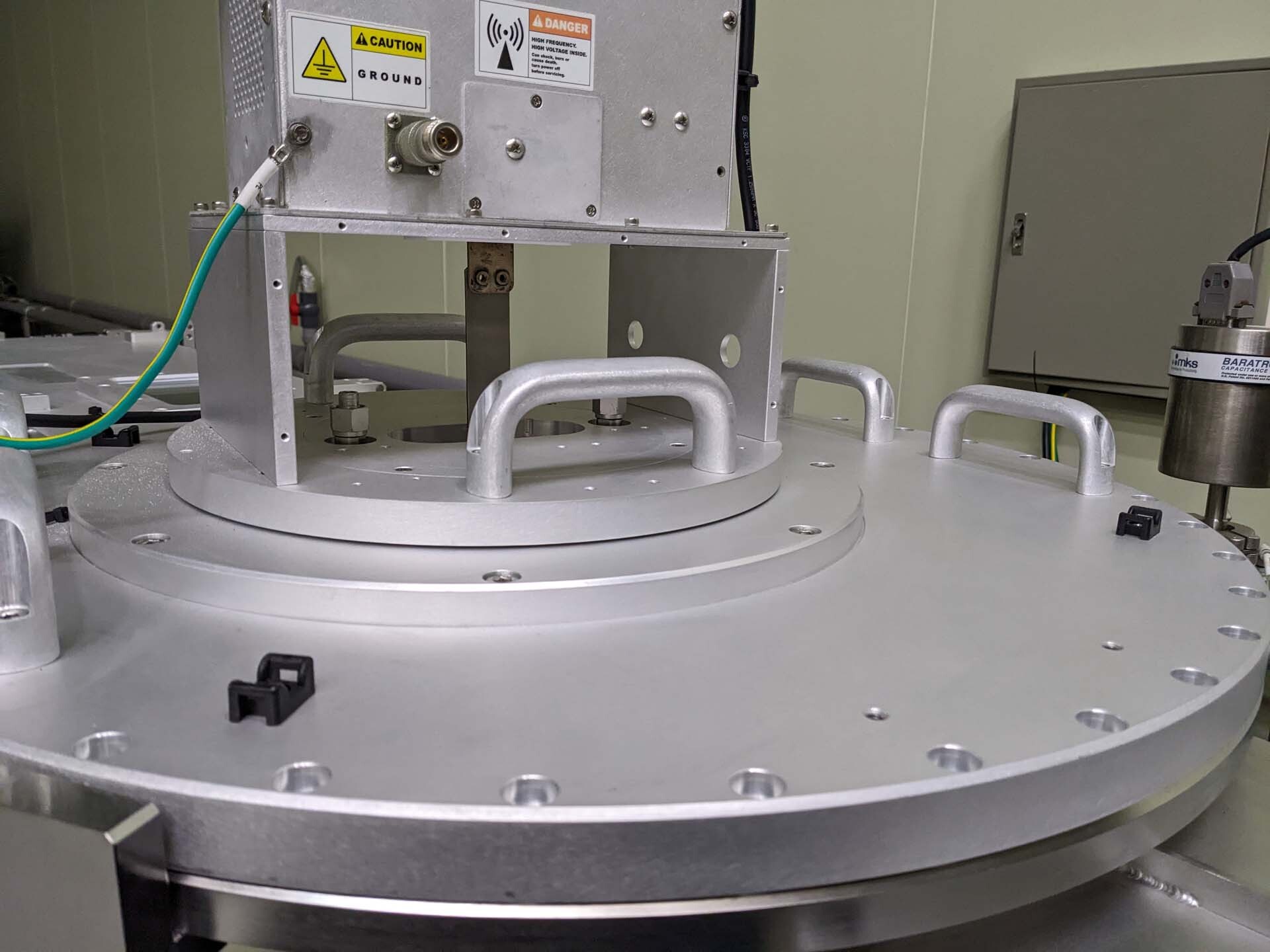

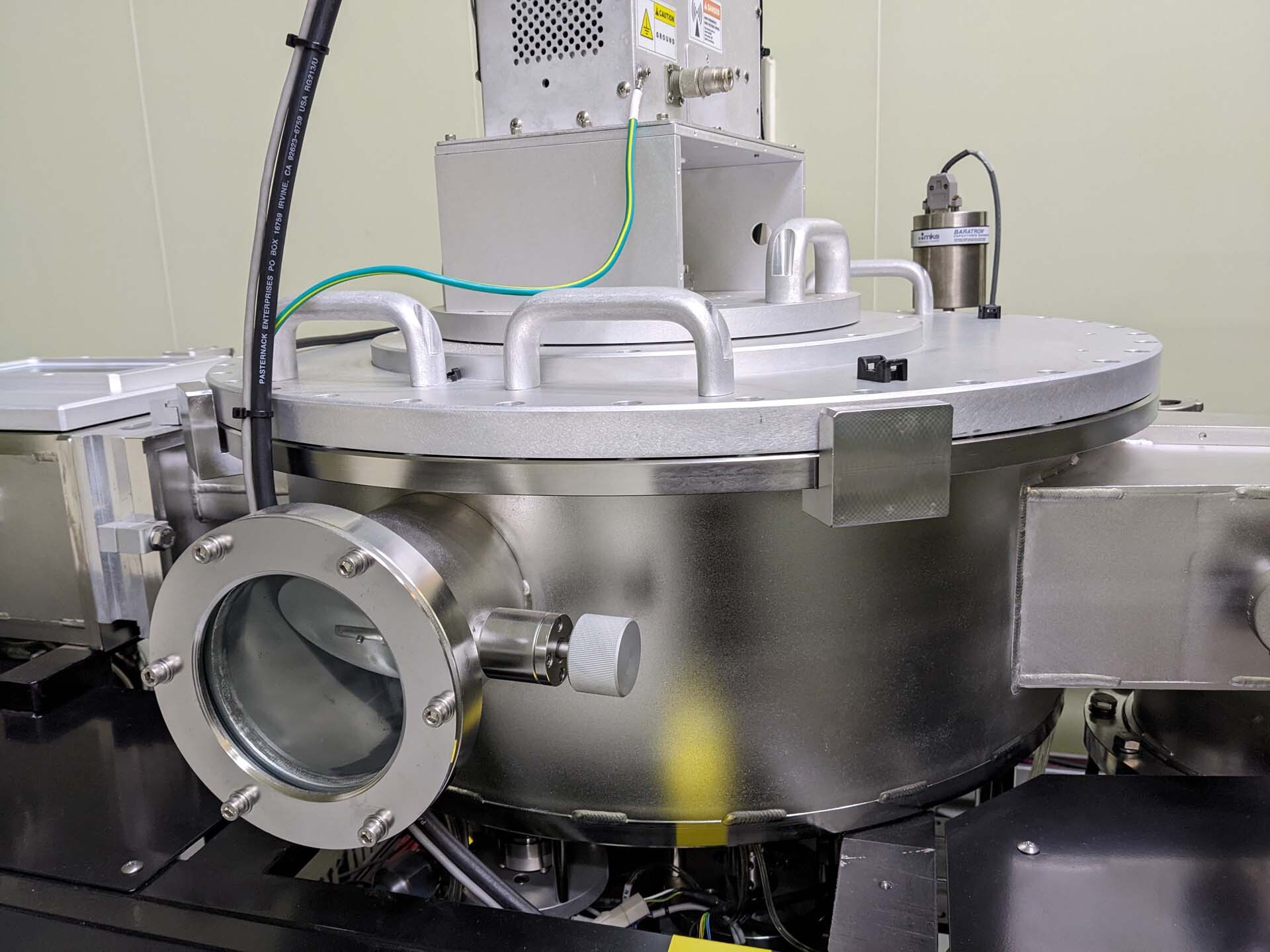

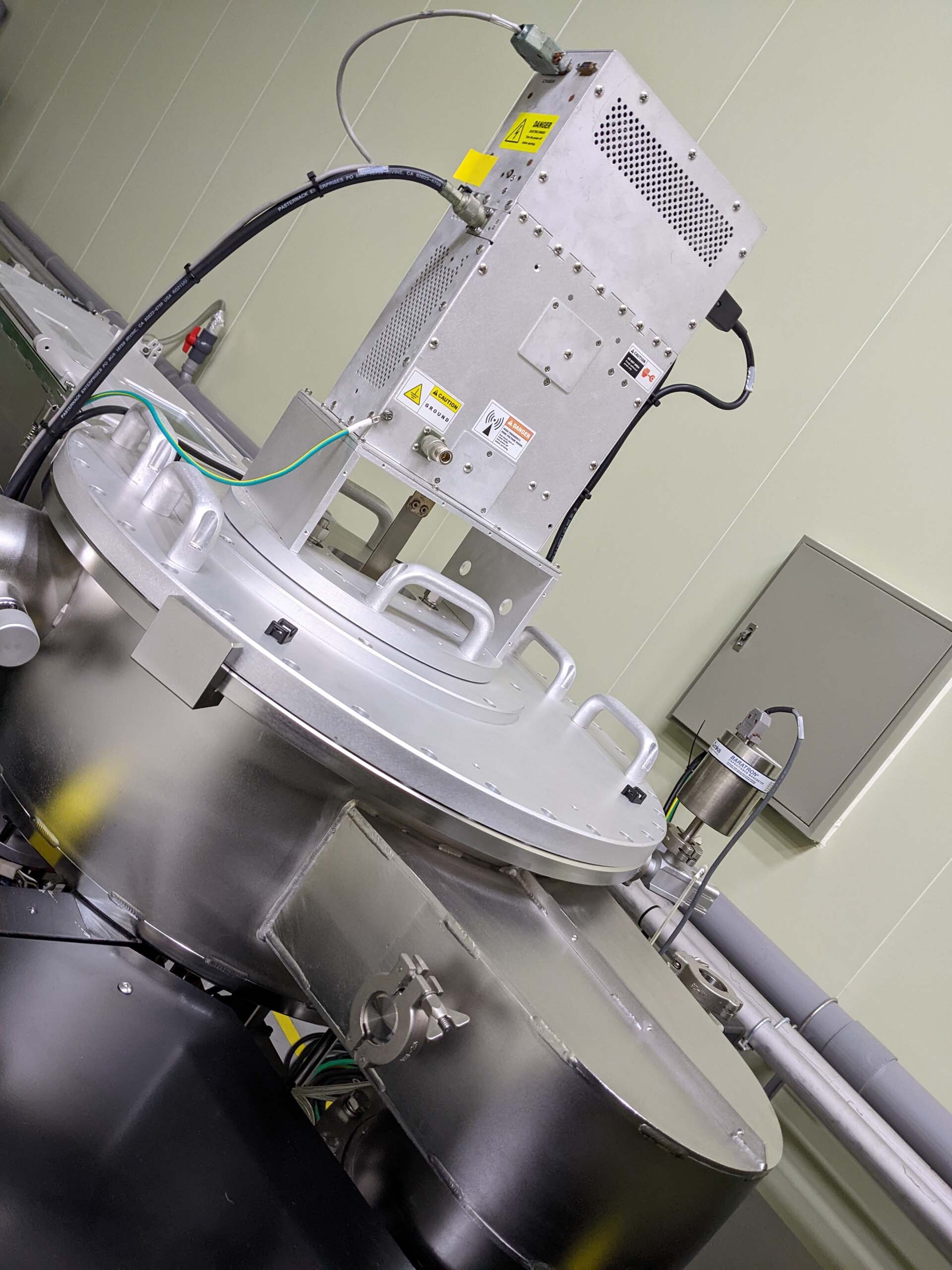

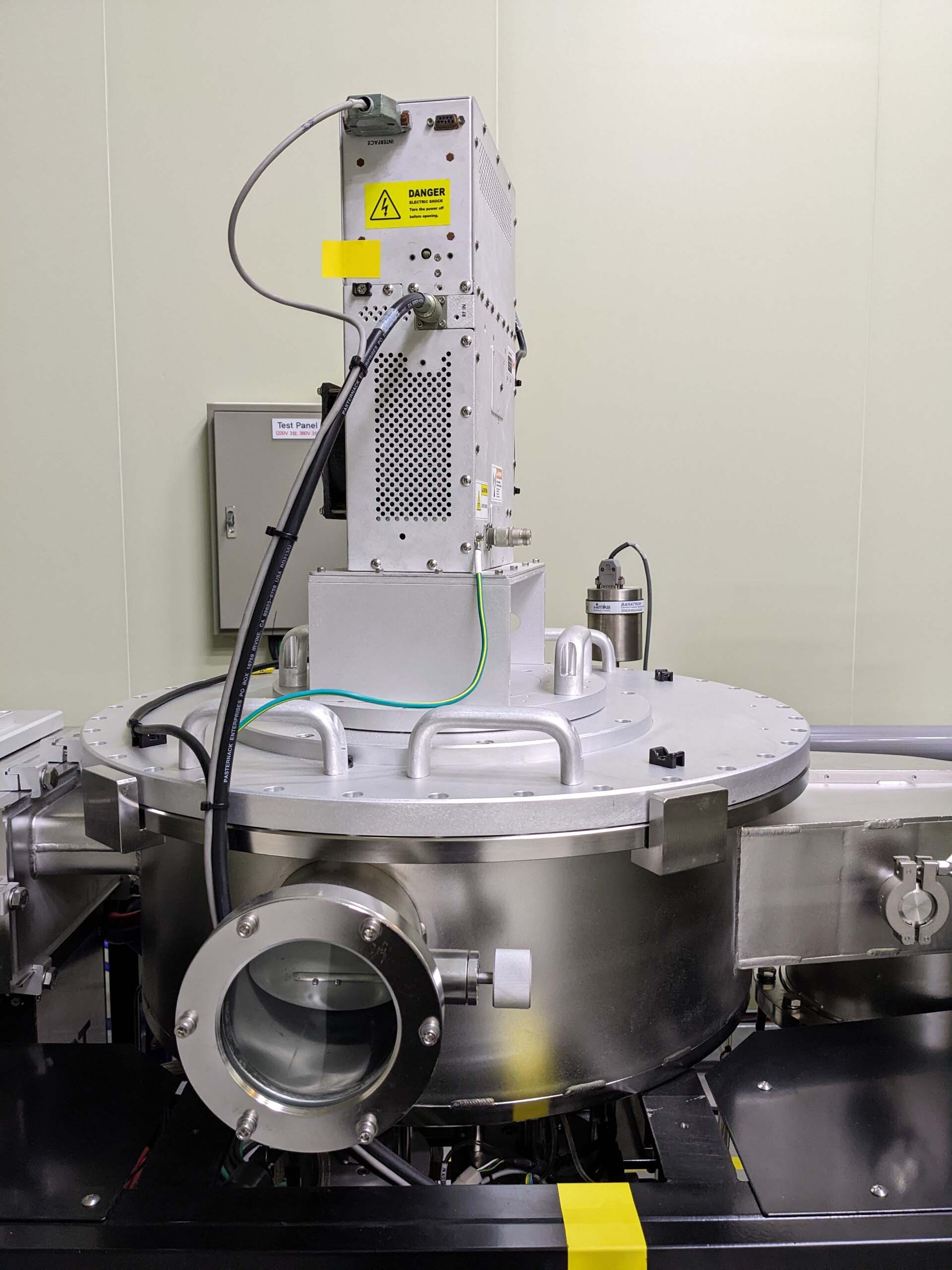

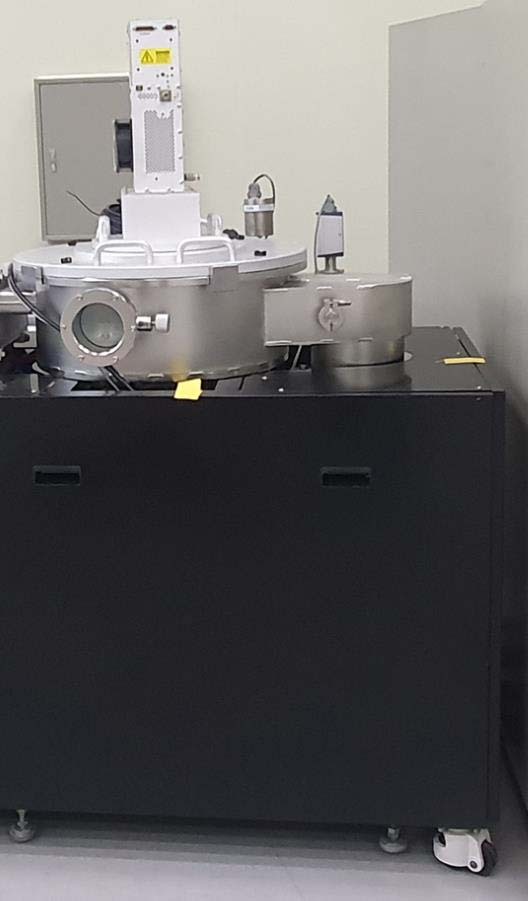

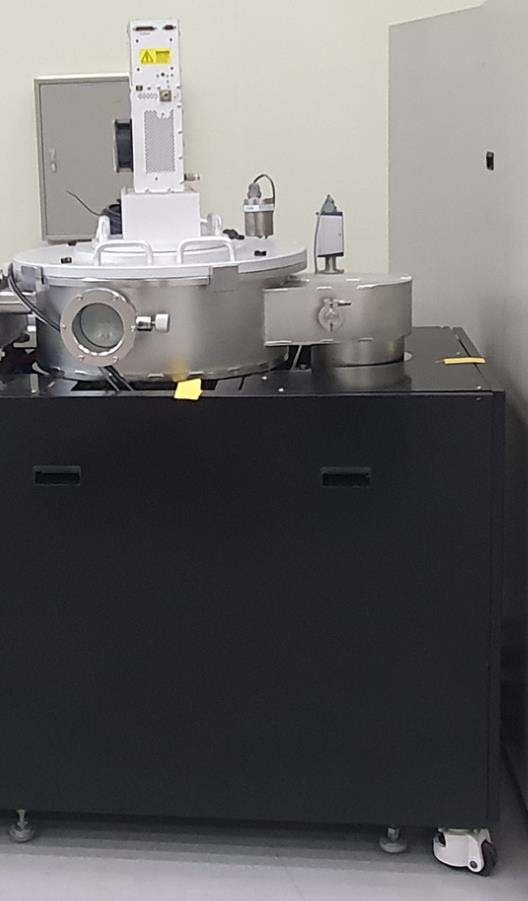

Used SUNIC NPM-1250PCA #293639063 for sale

URL successfully copied!

Tap to zoom

ID: 293639063

Vintage: 2016

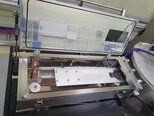

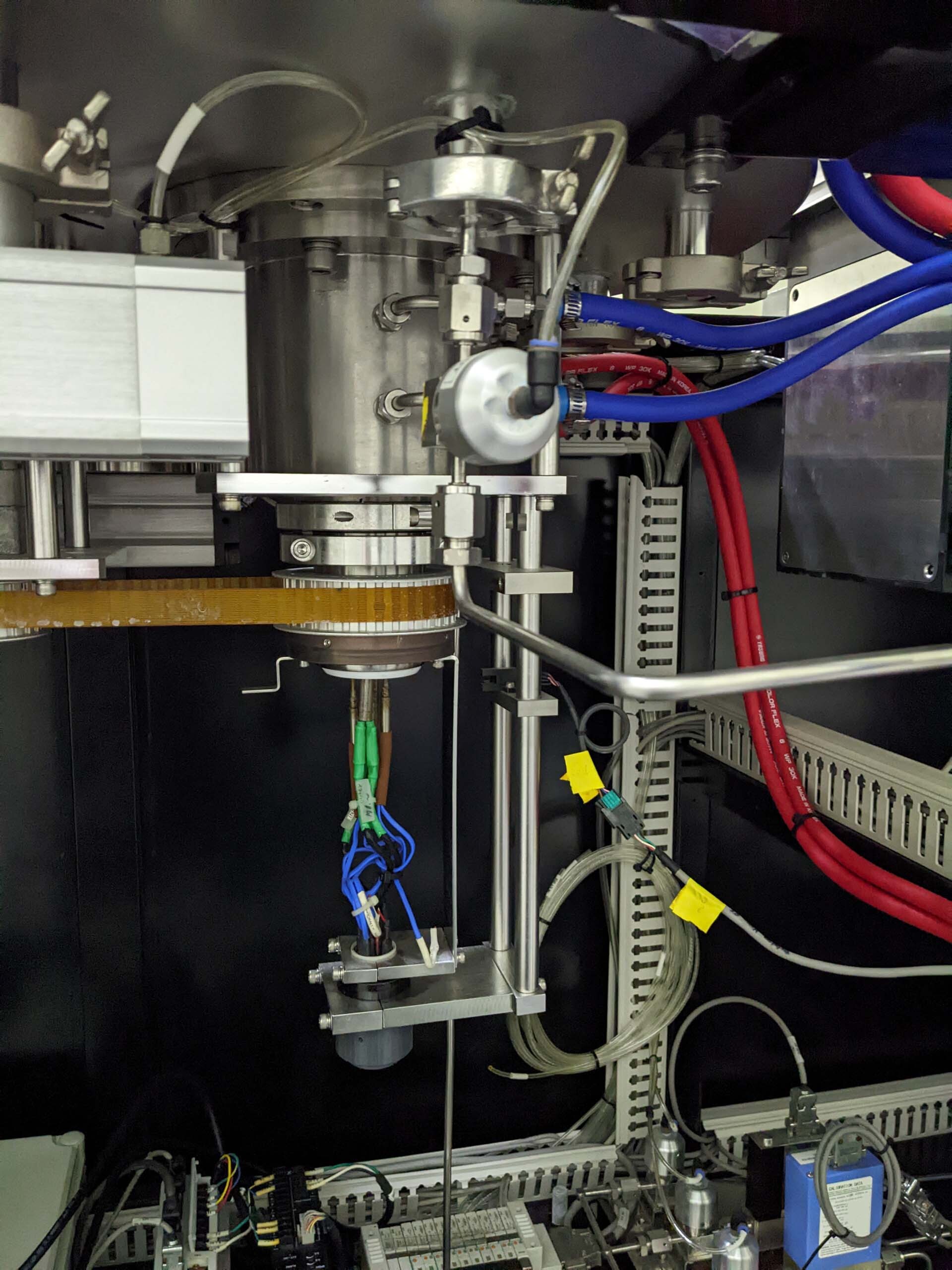

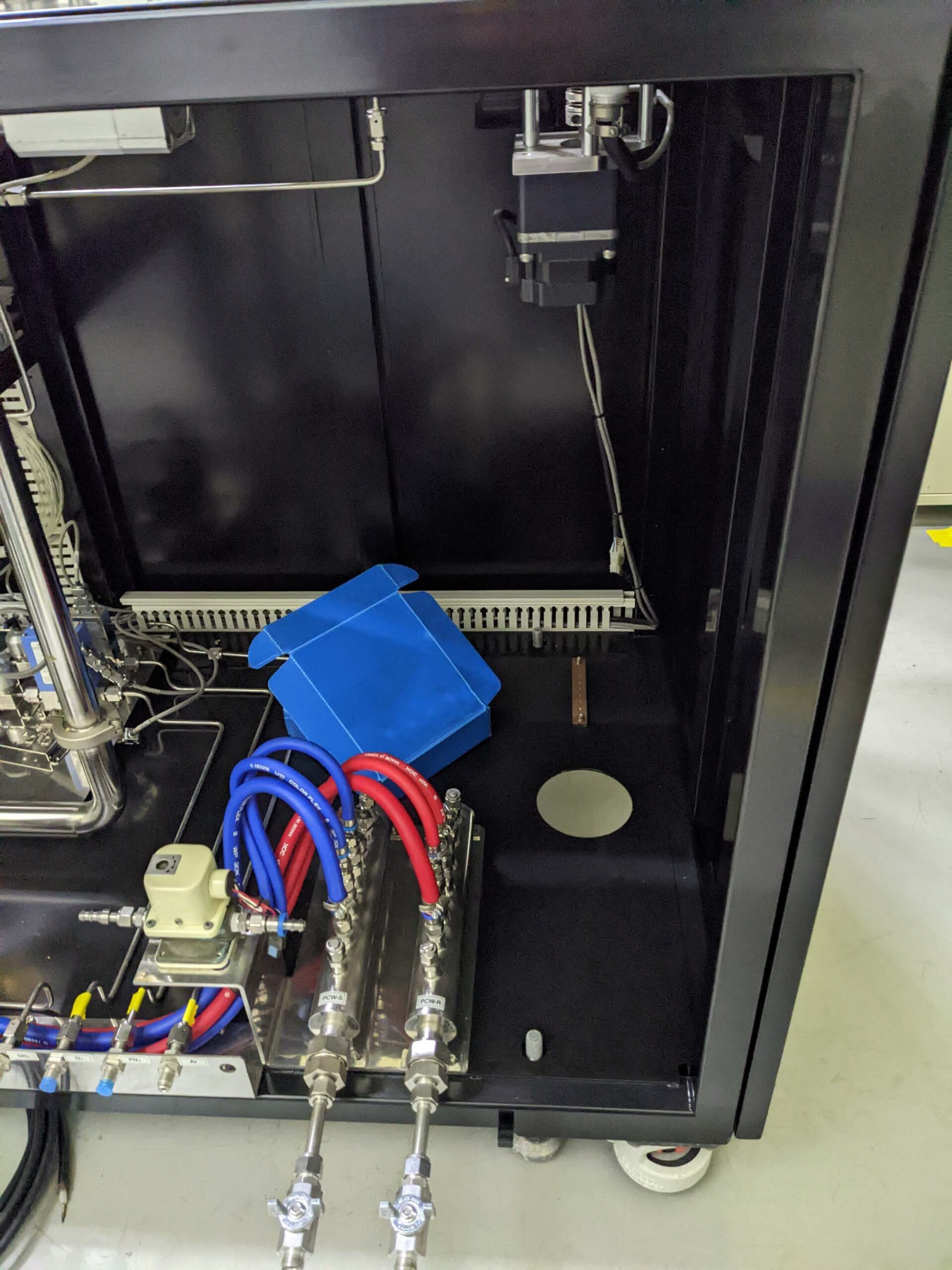

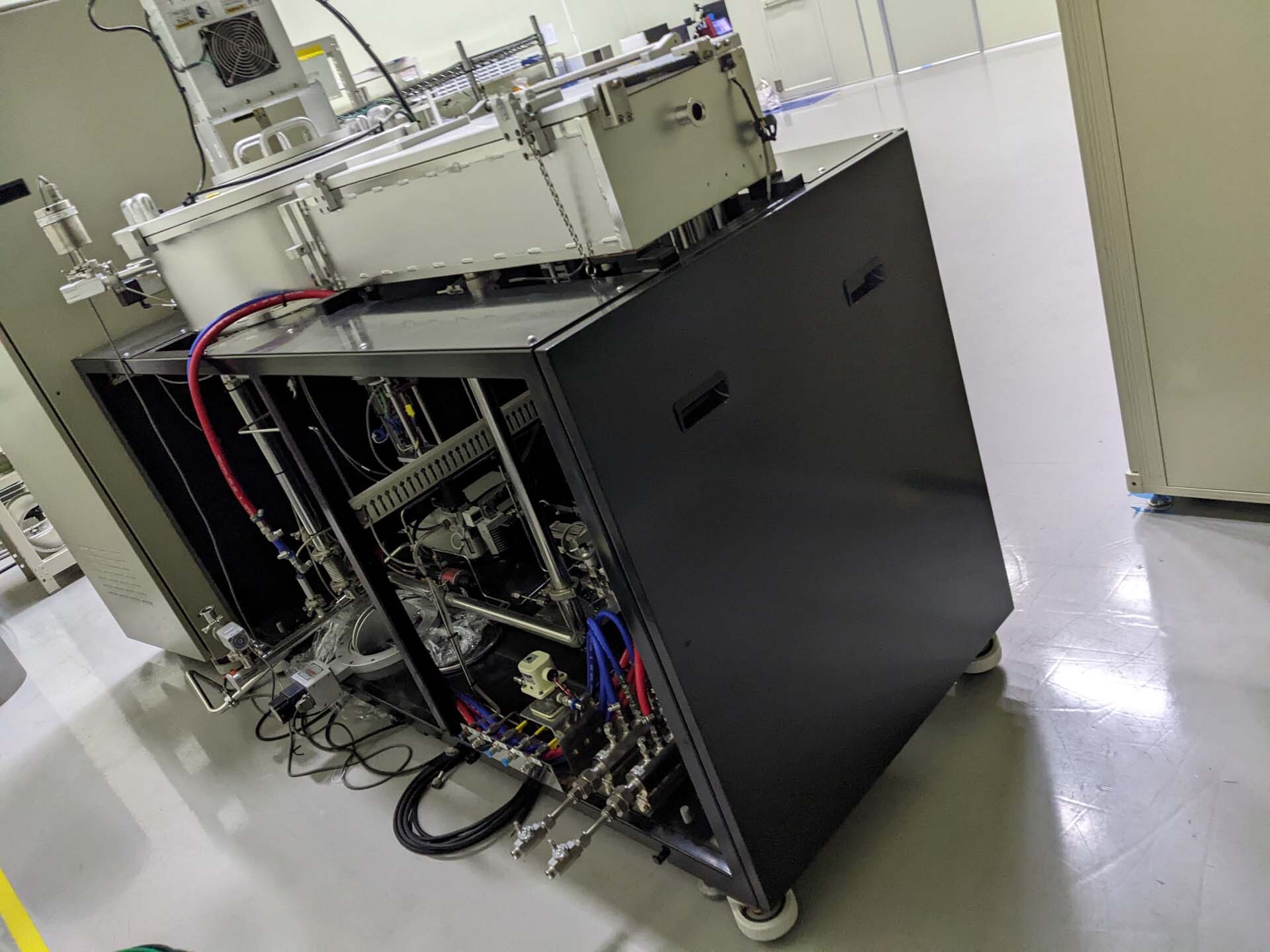

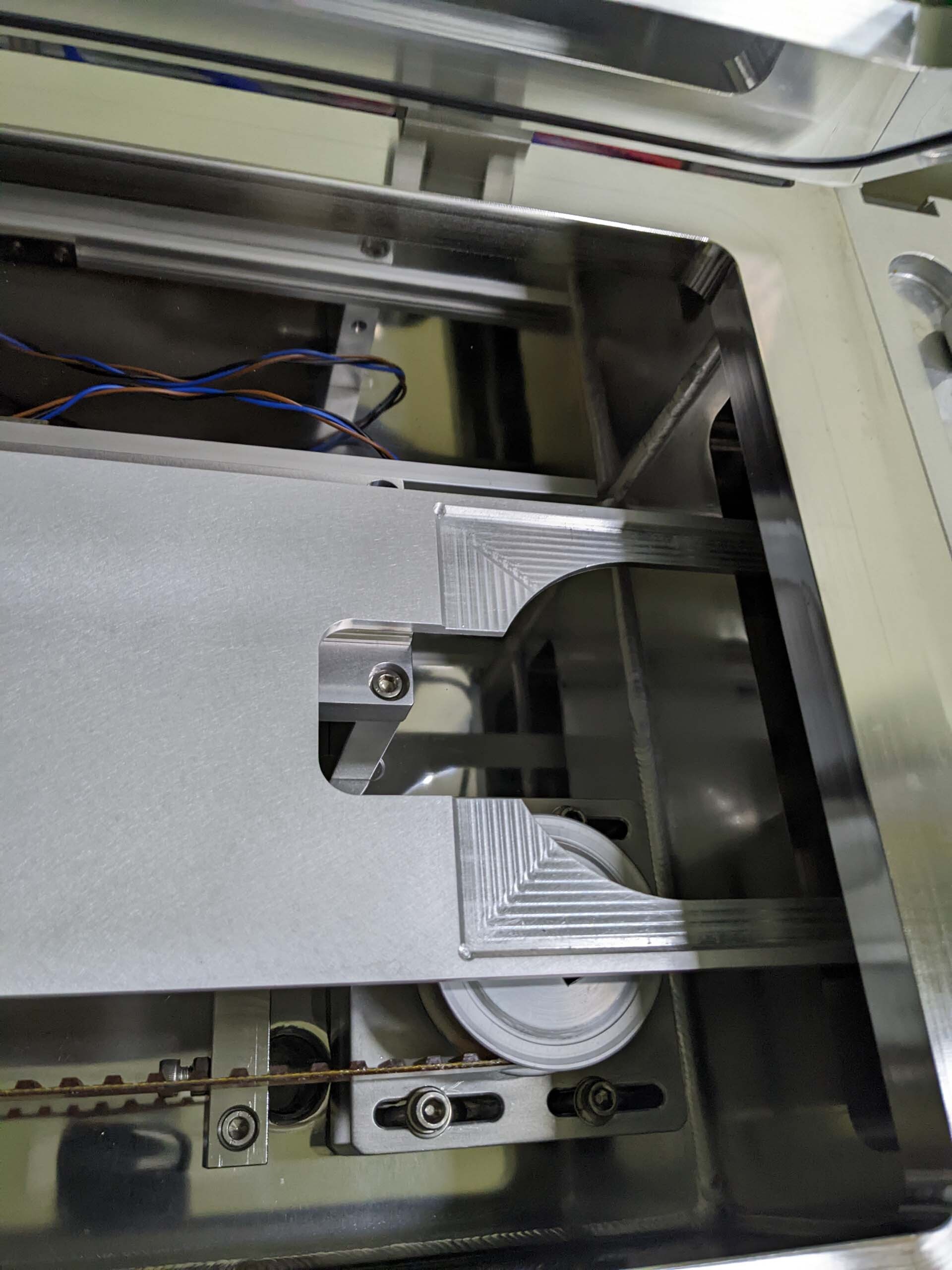

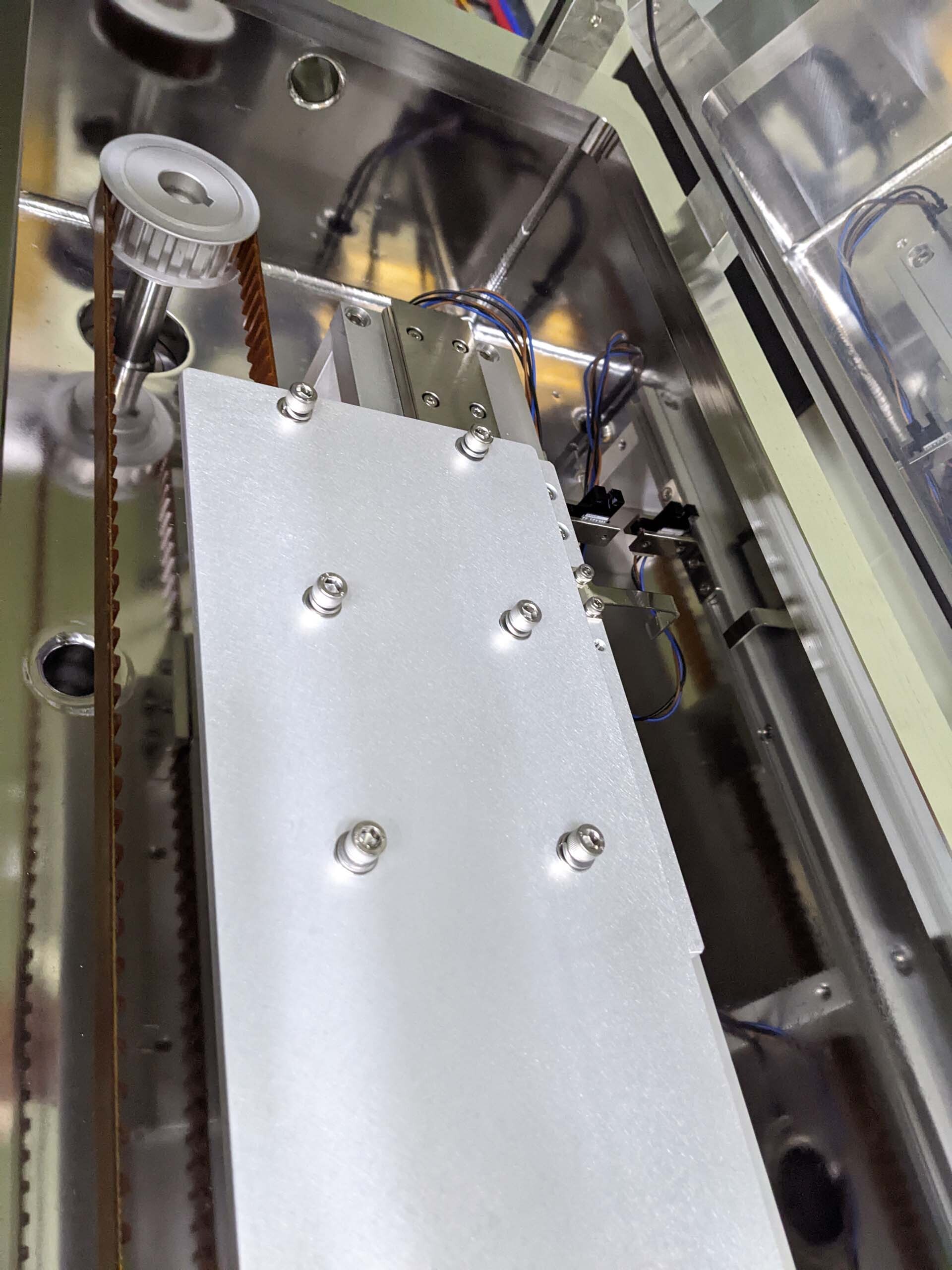

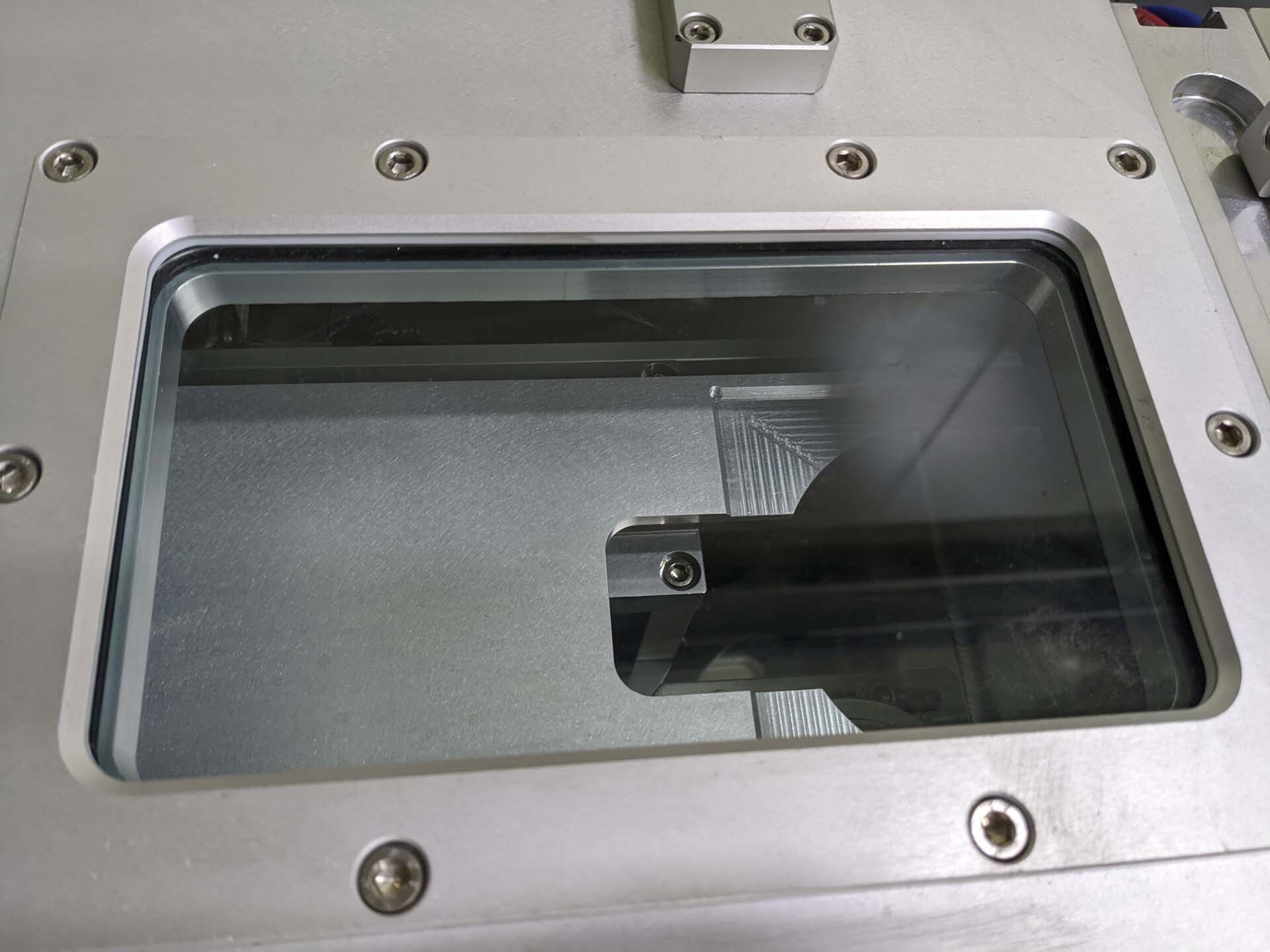

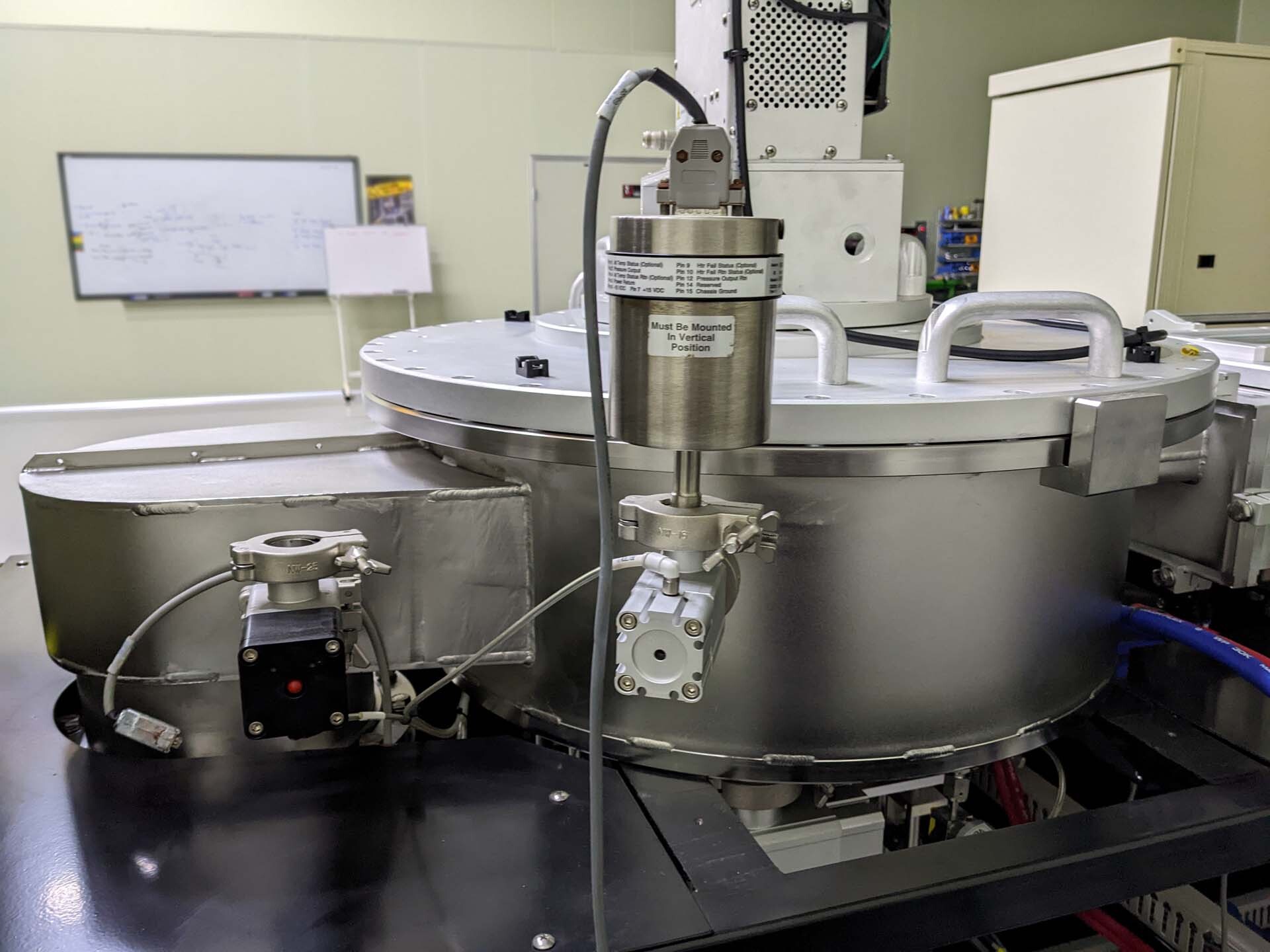

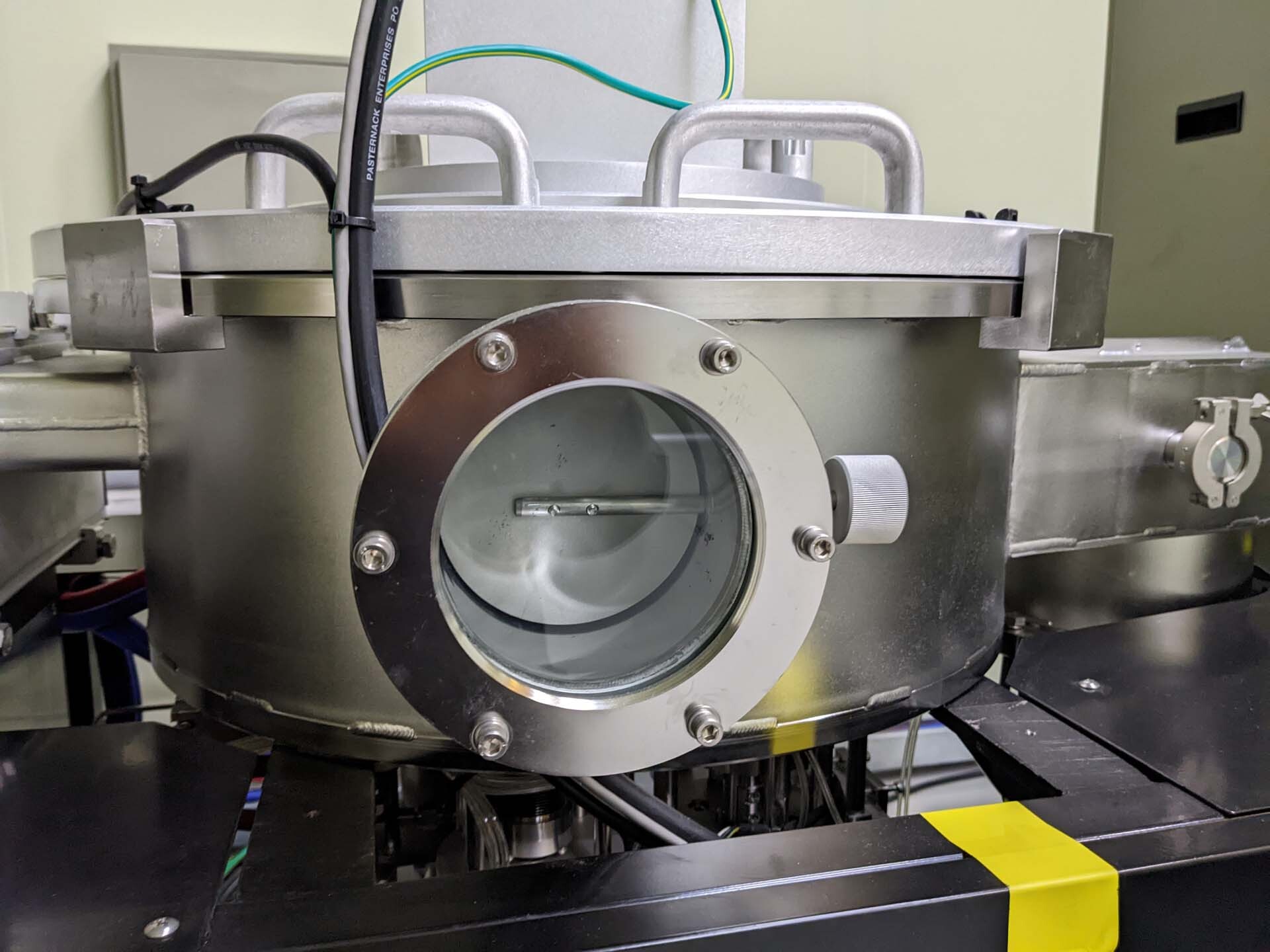

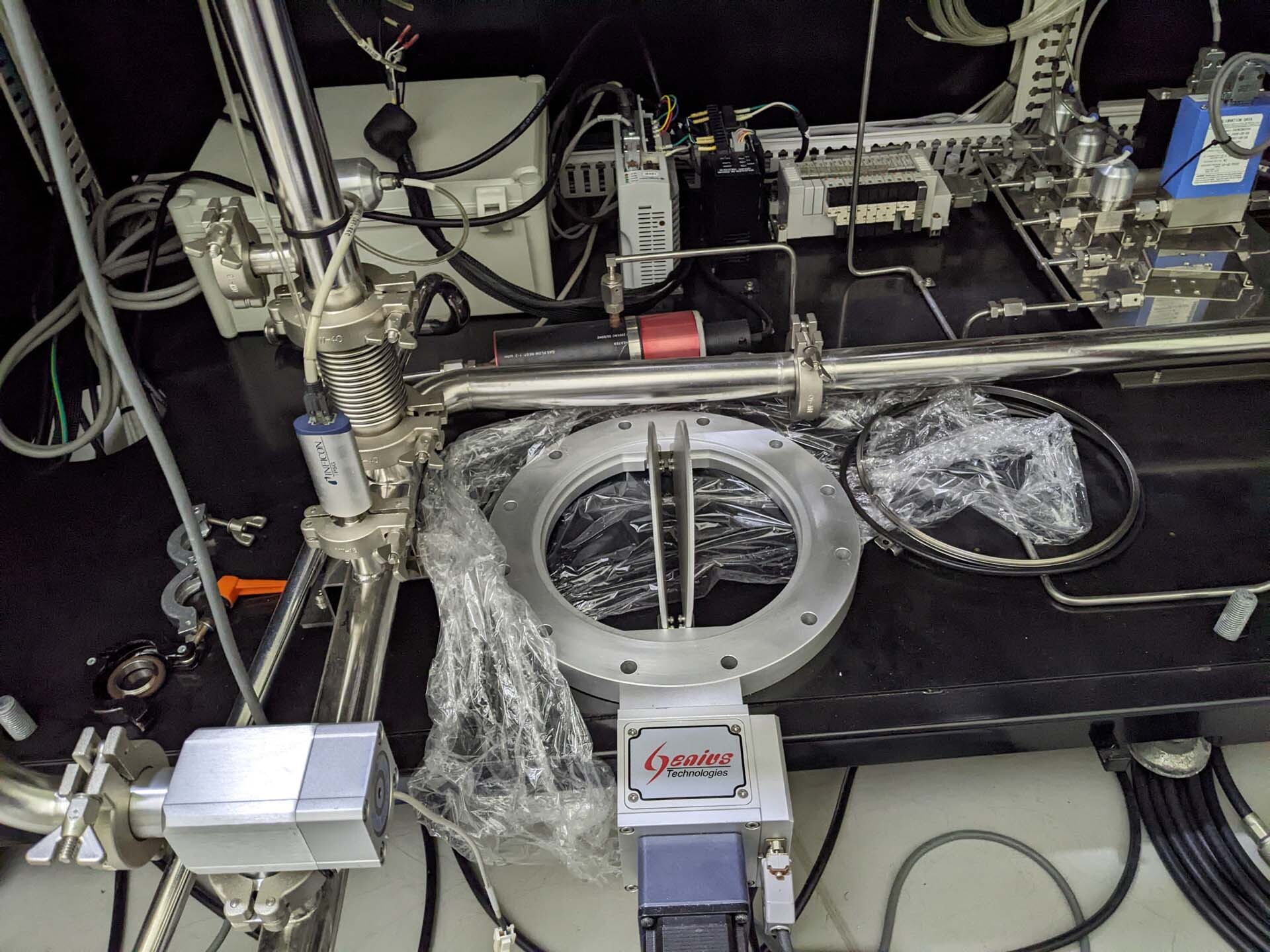

Sputtering system

100 x 100 mm

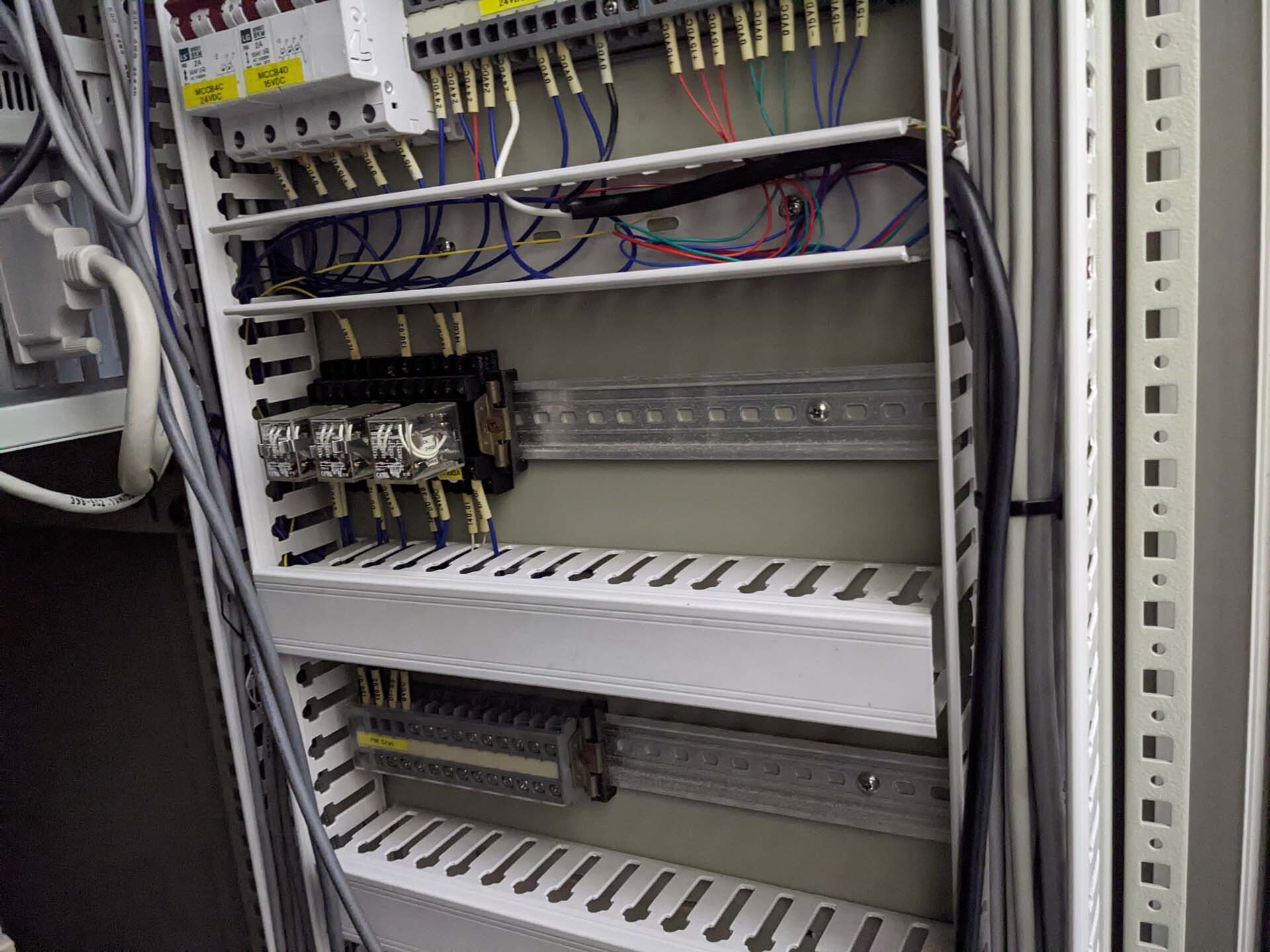

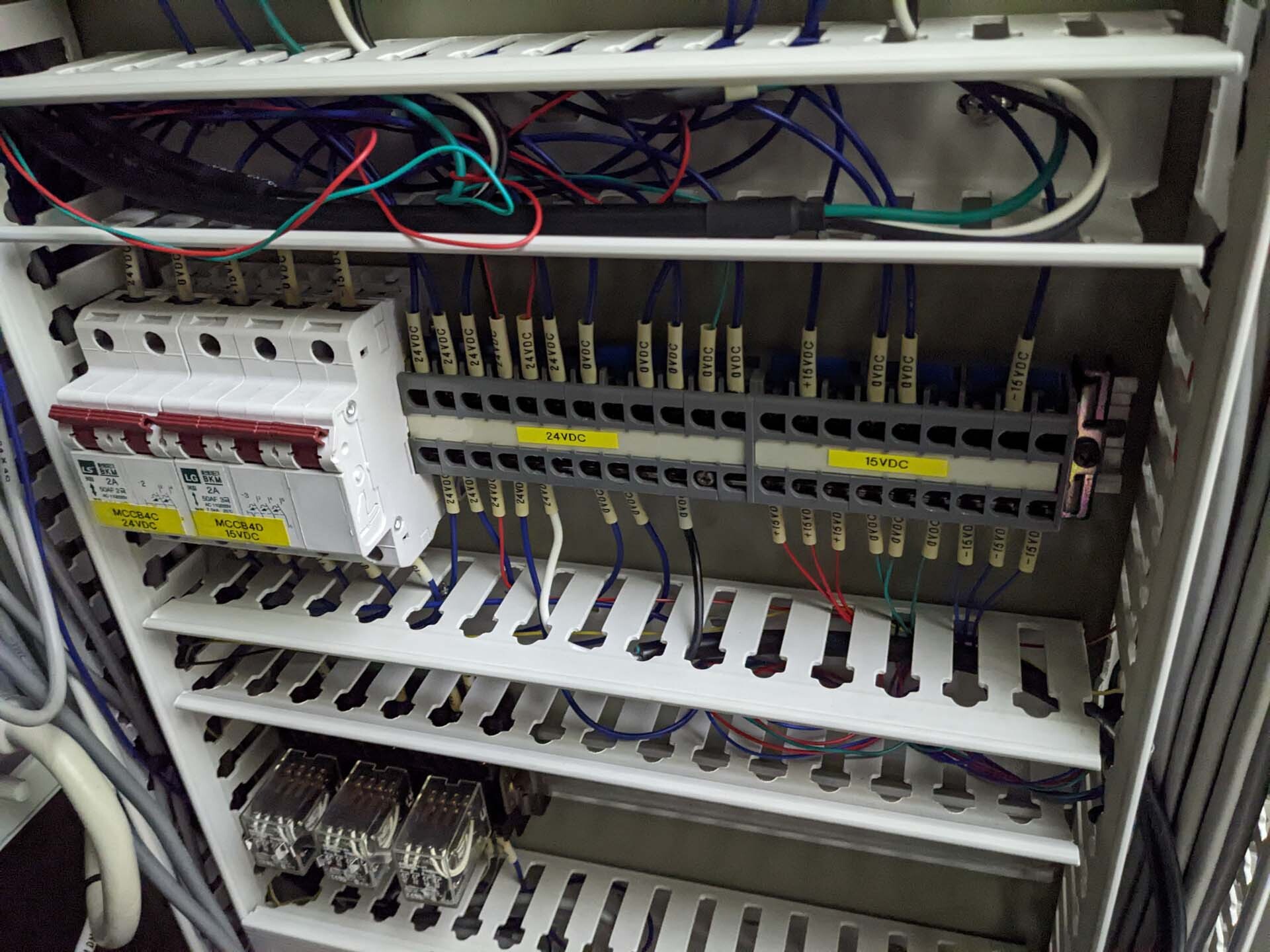

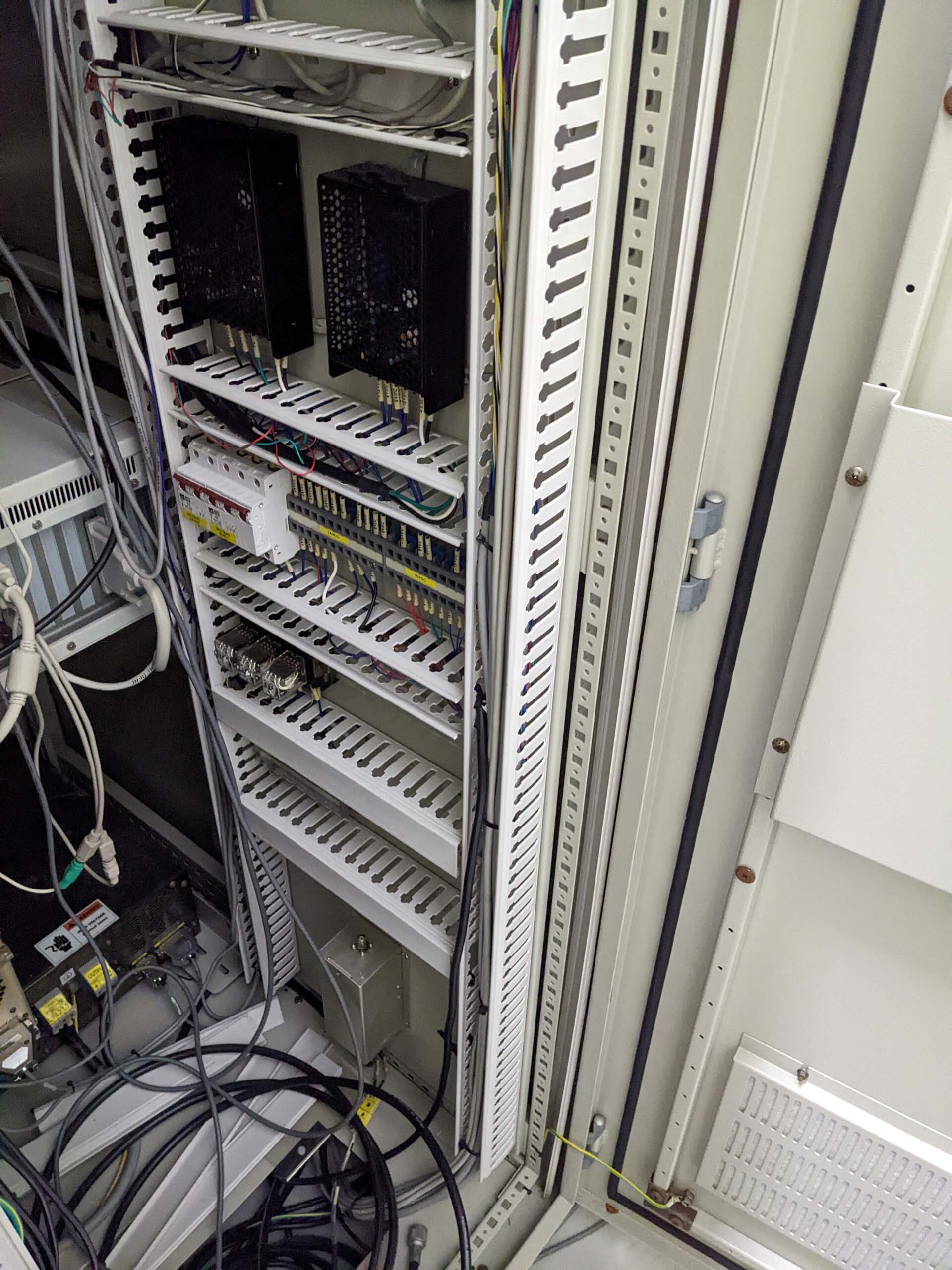

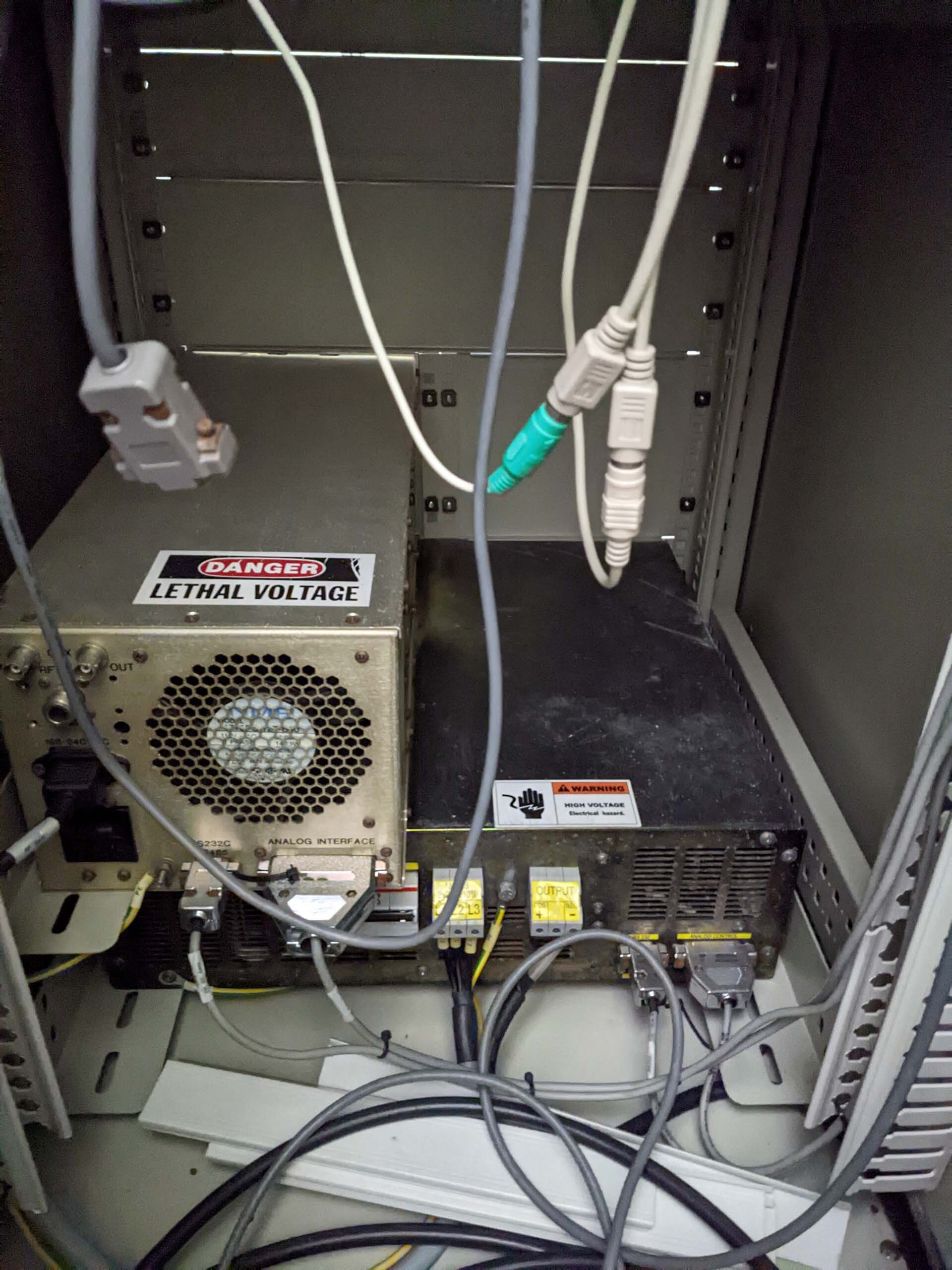

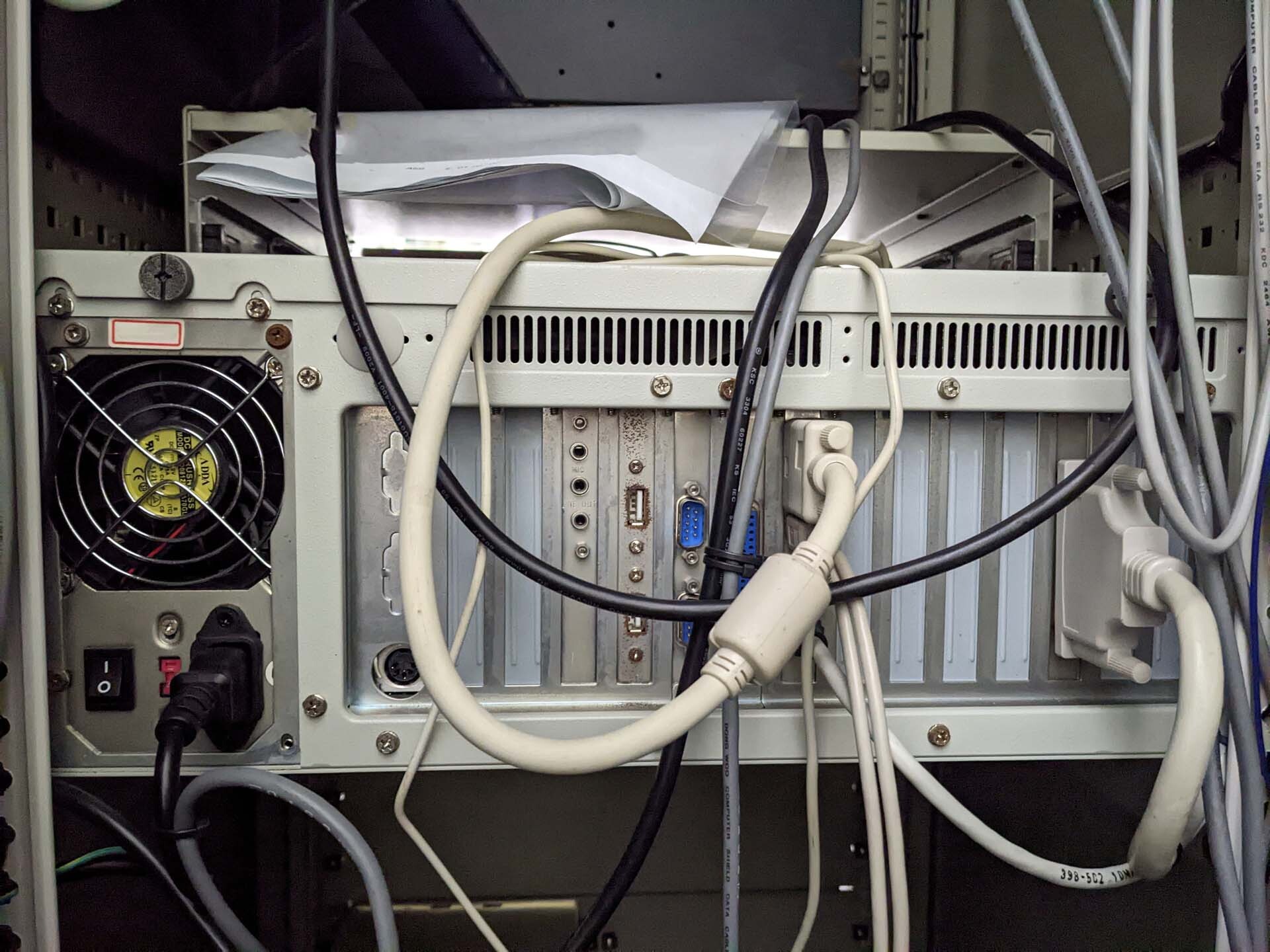

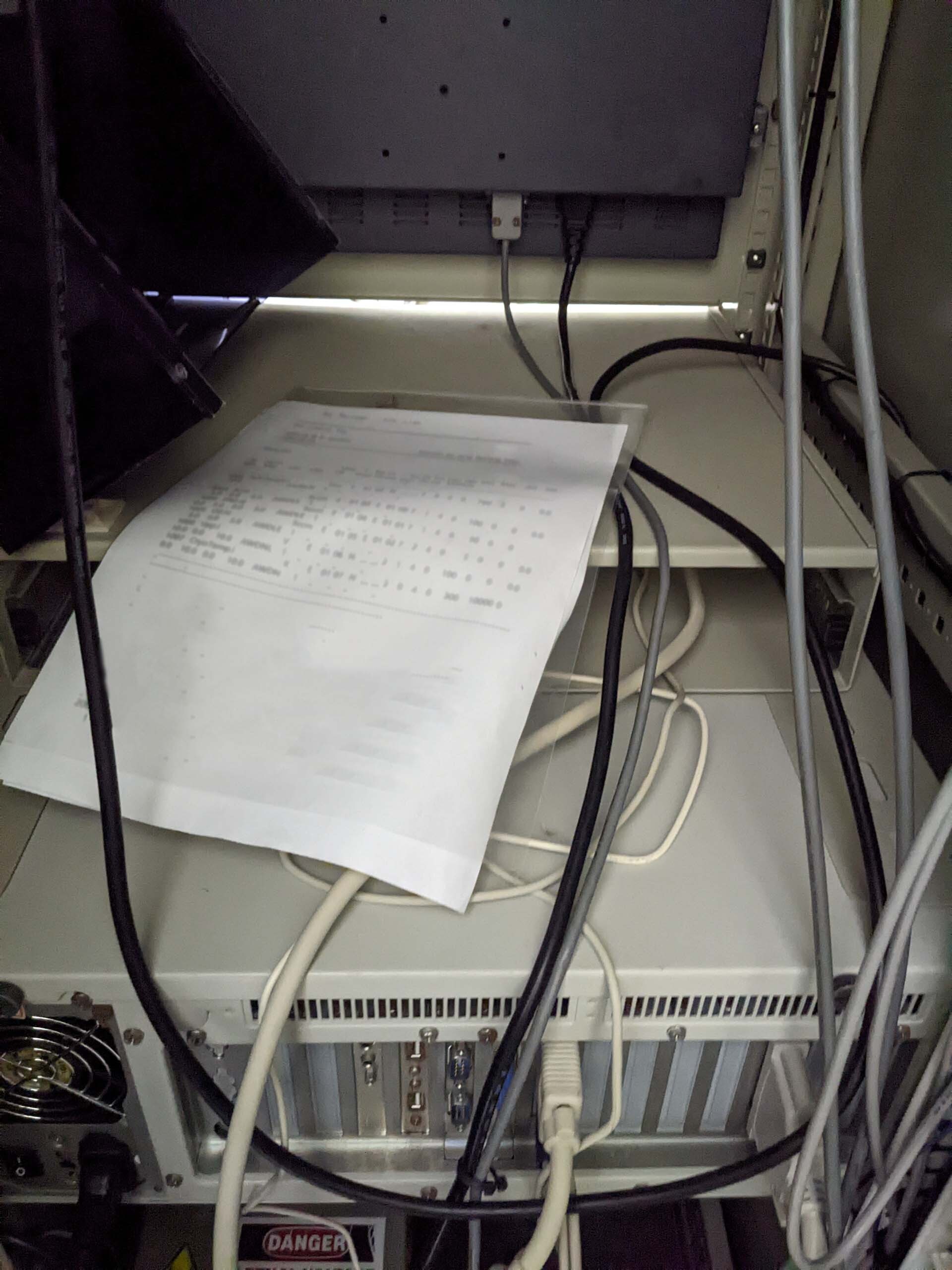

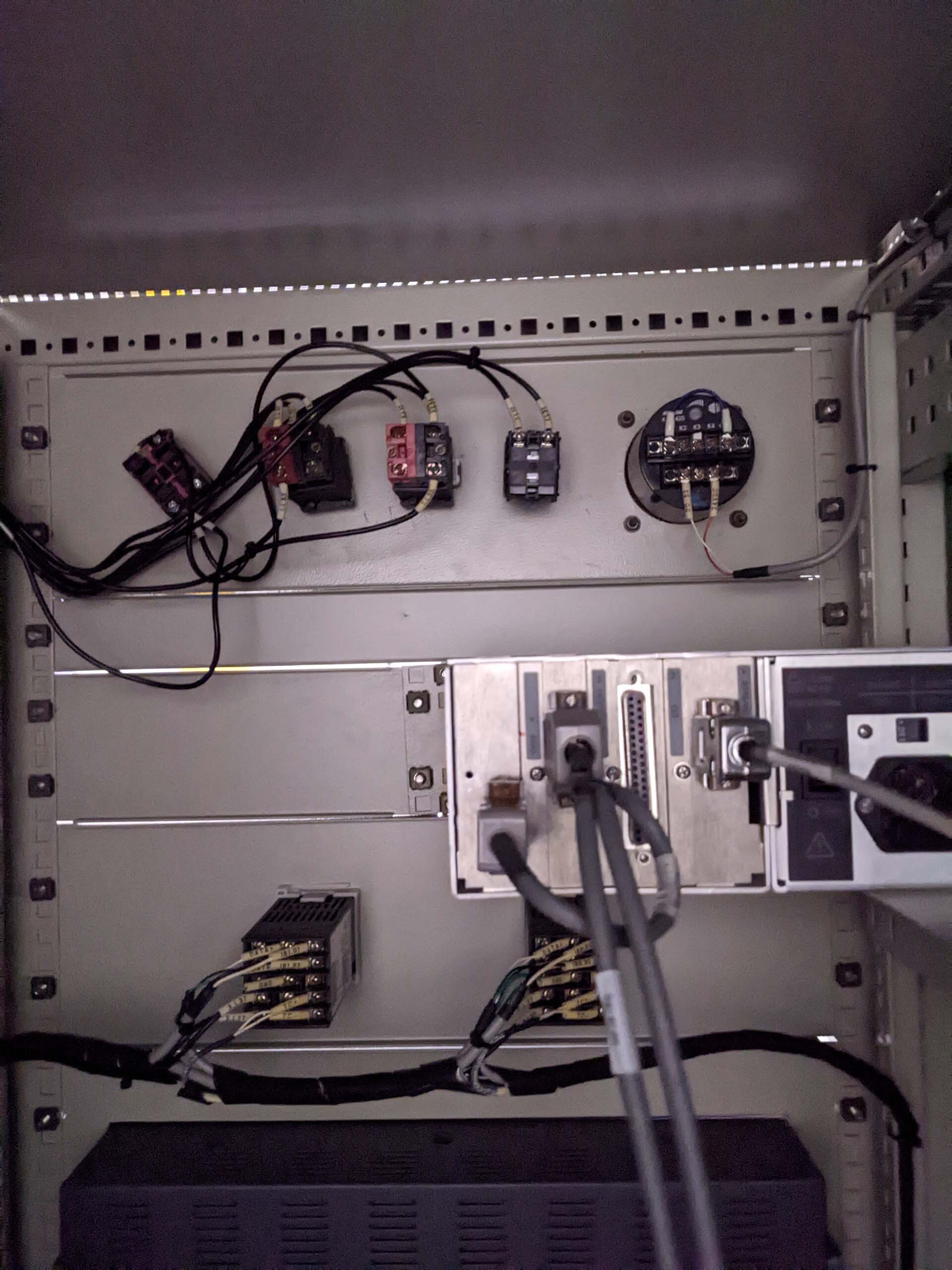

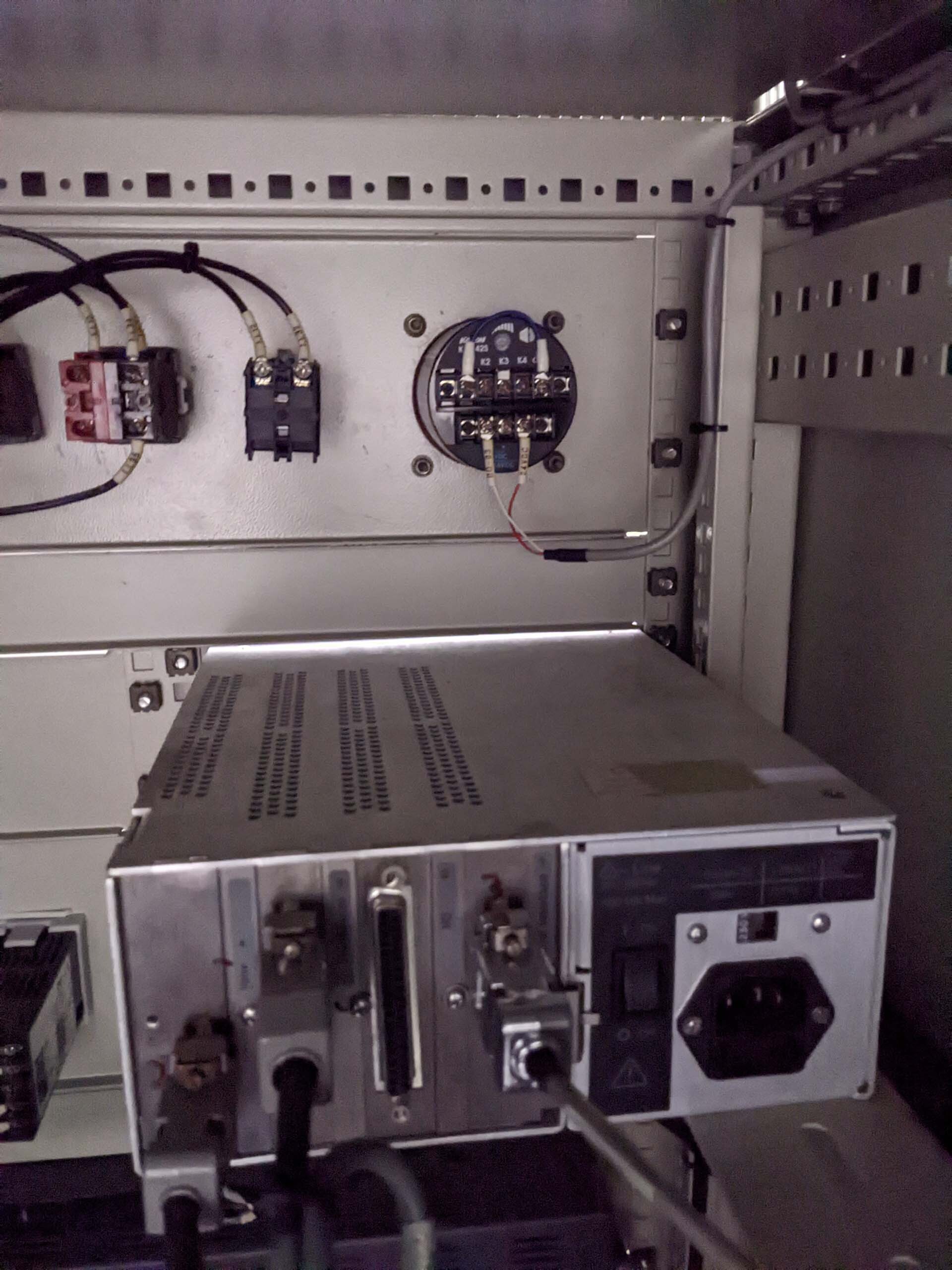

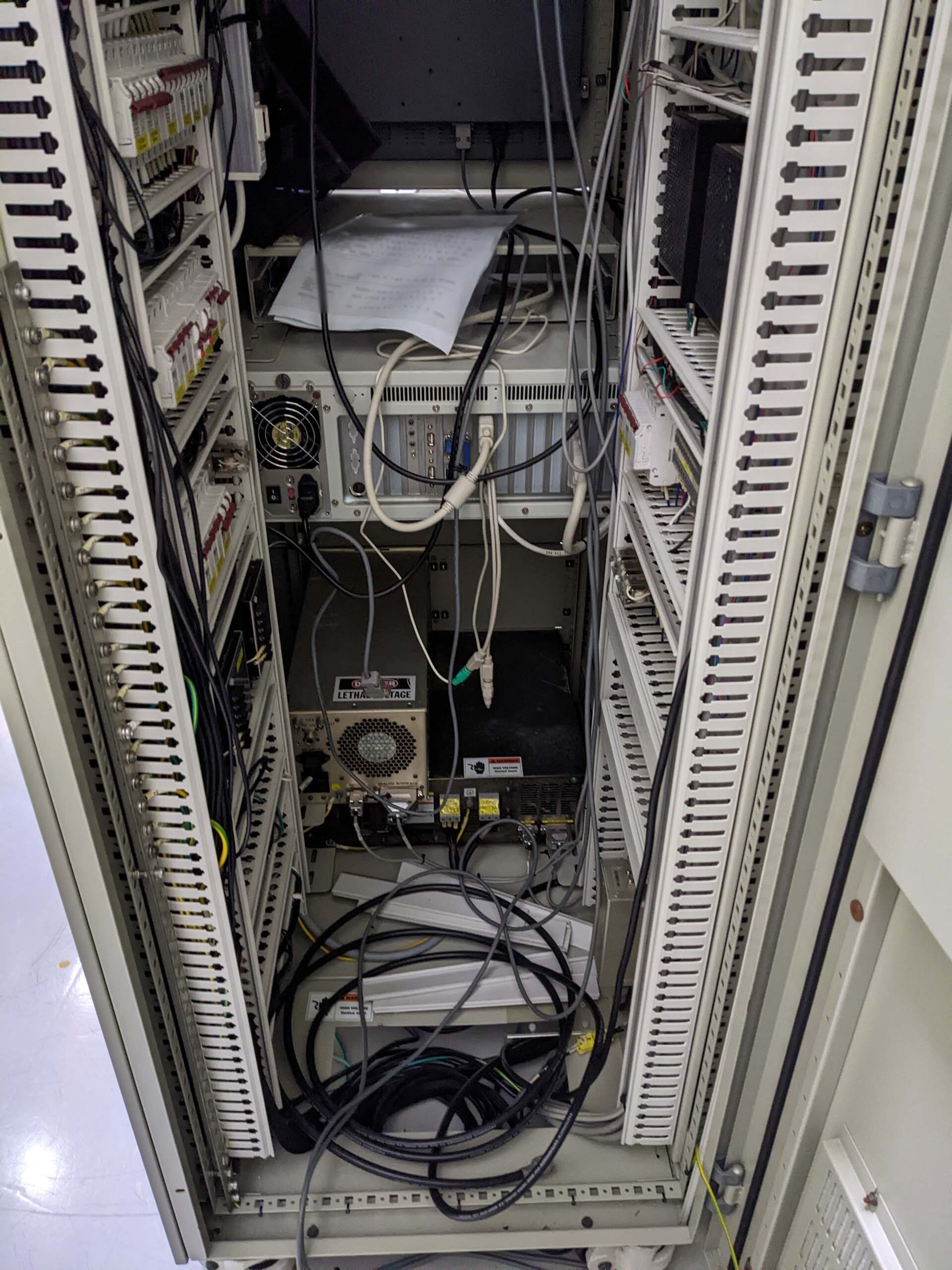

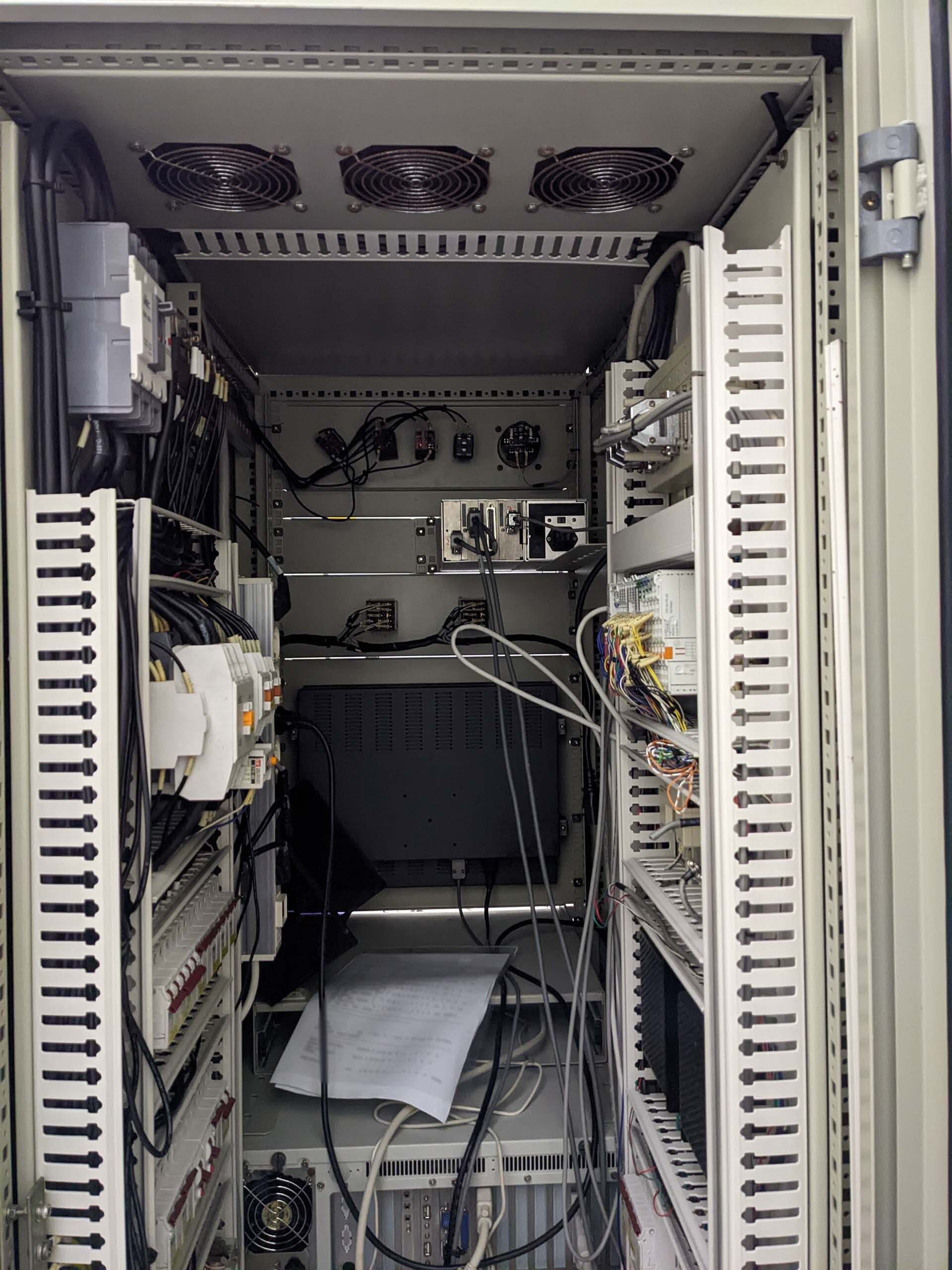

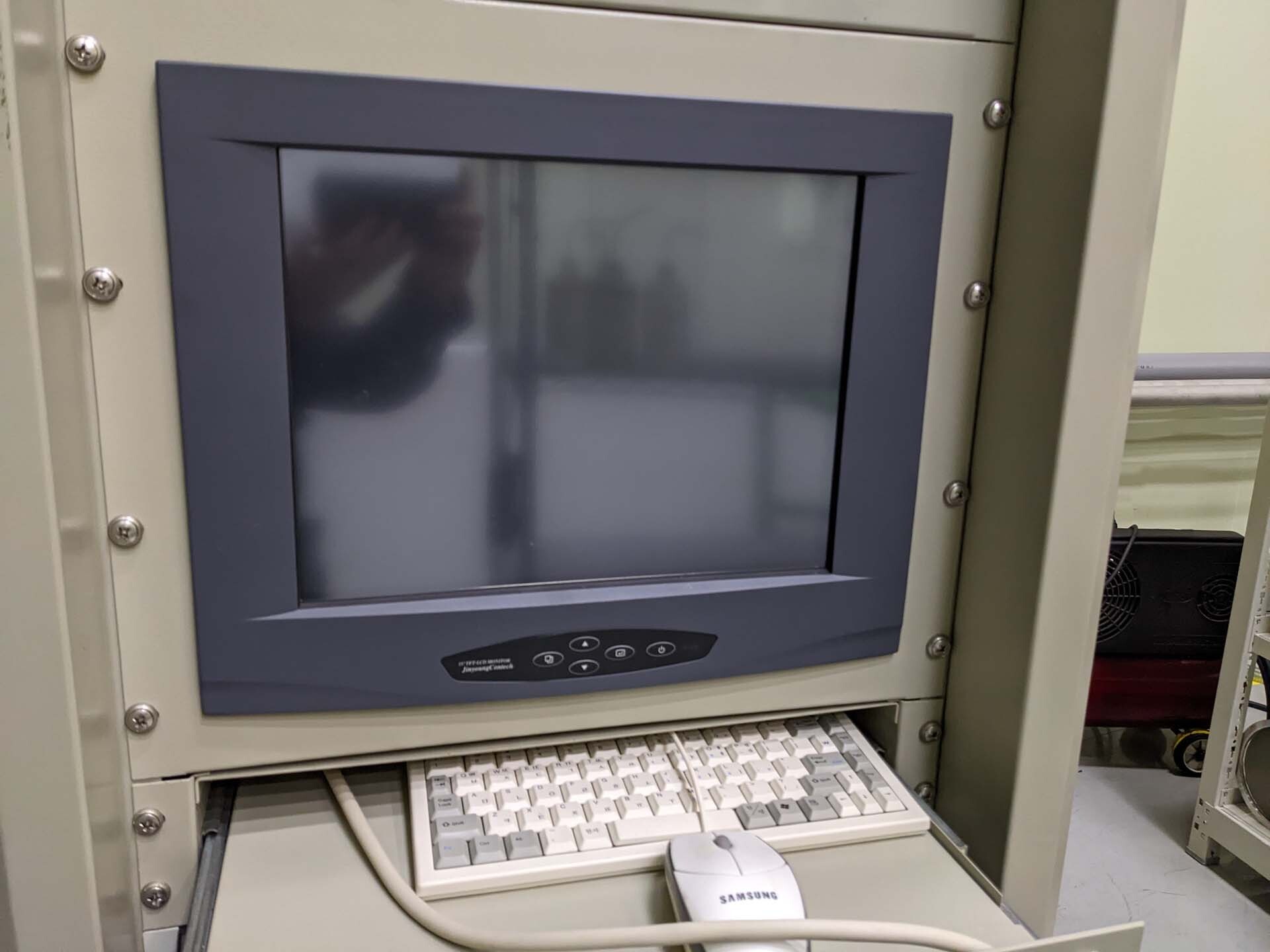

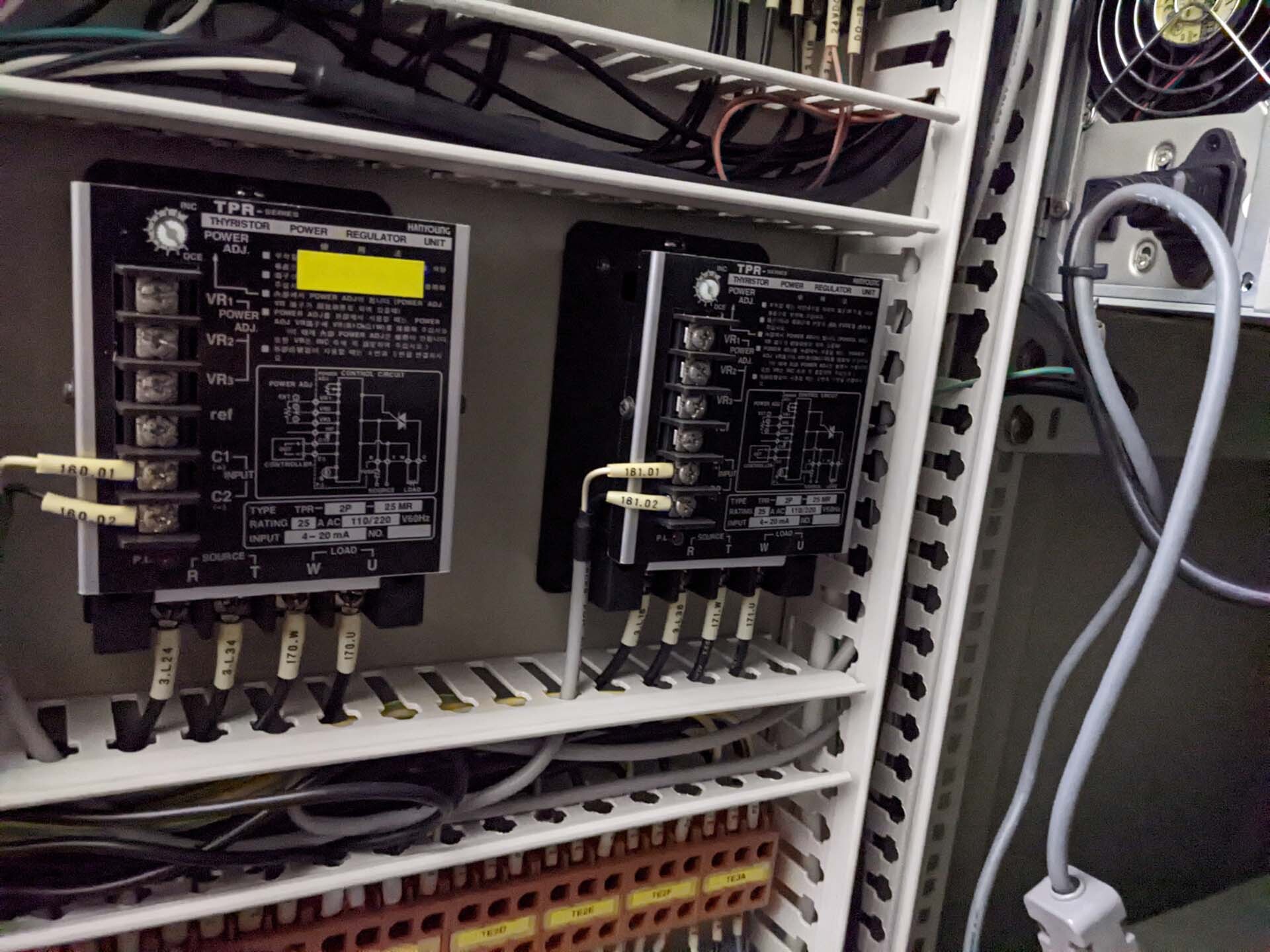

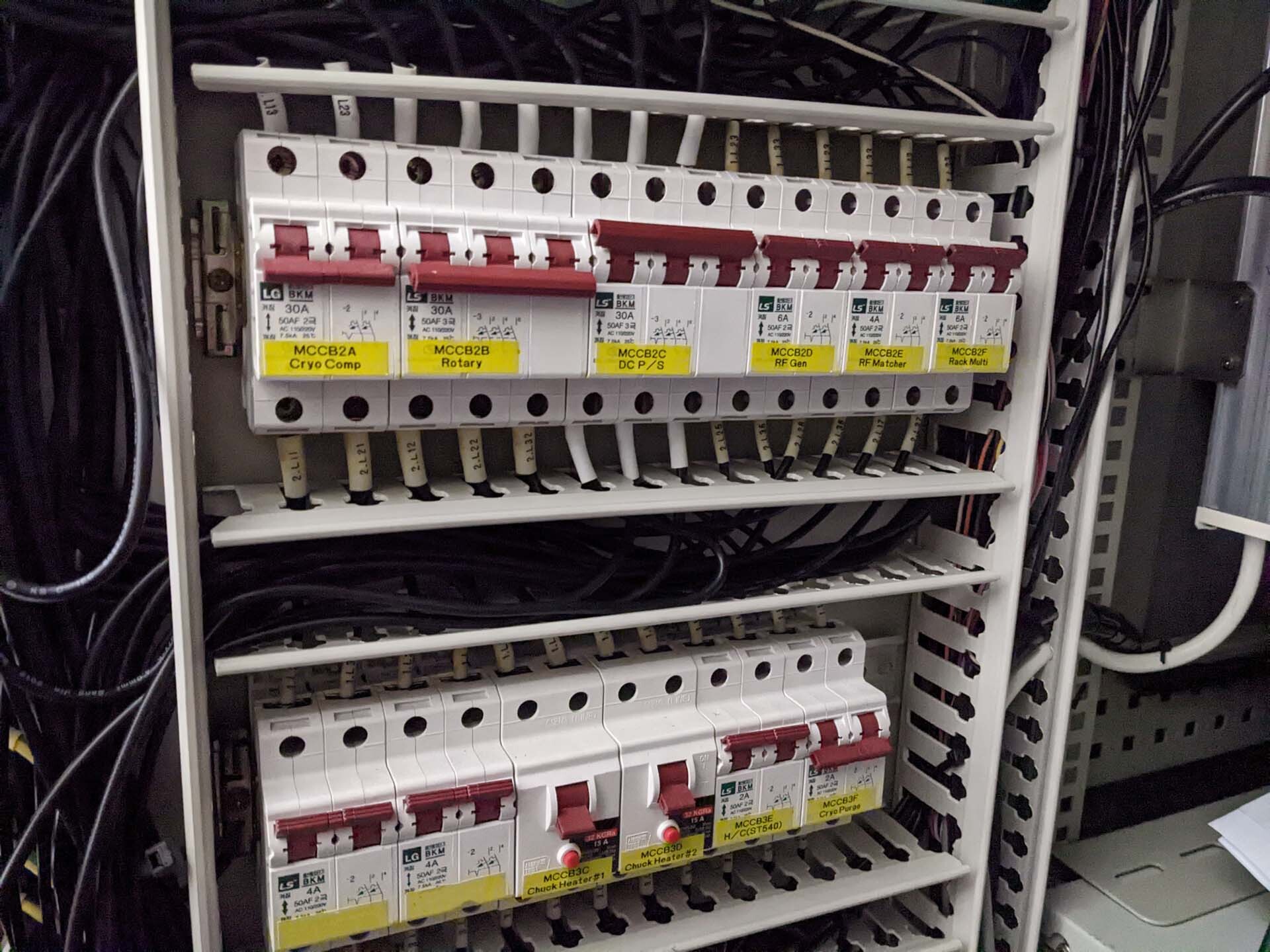

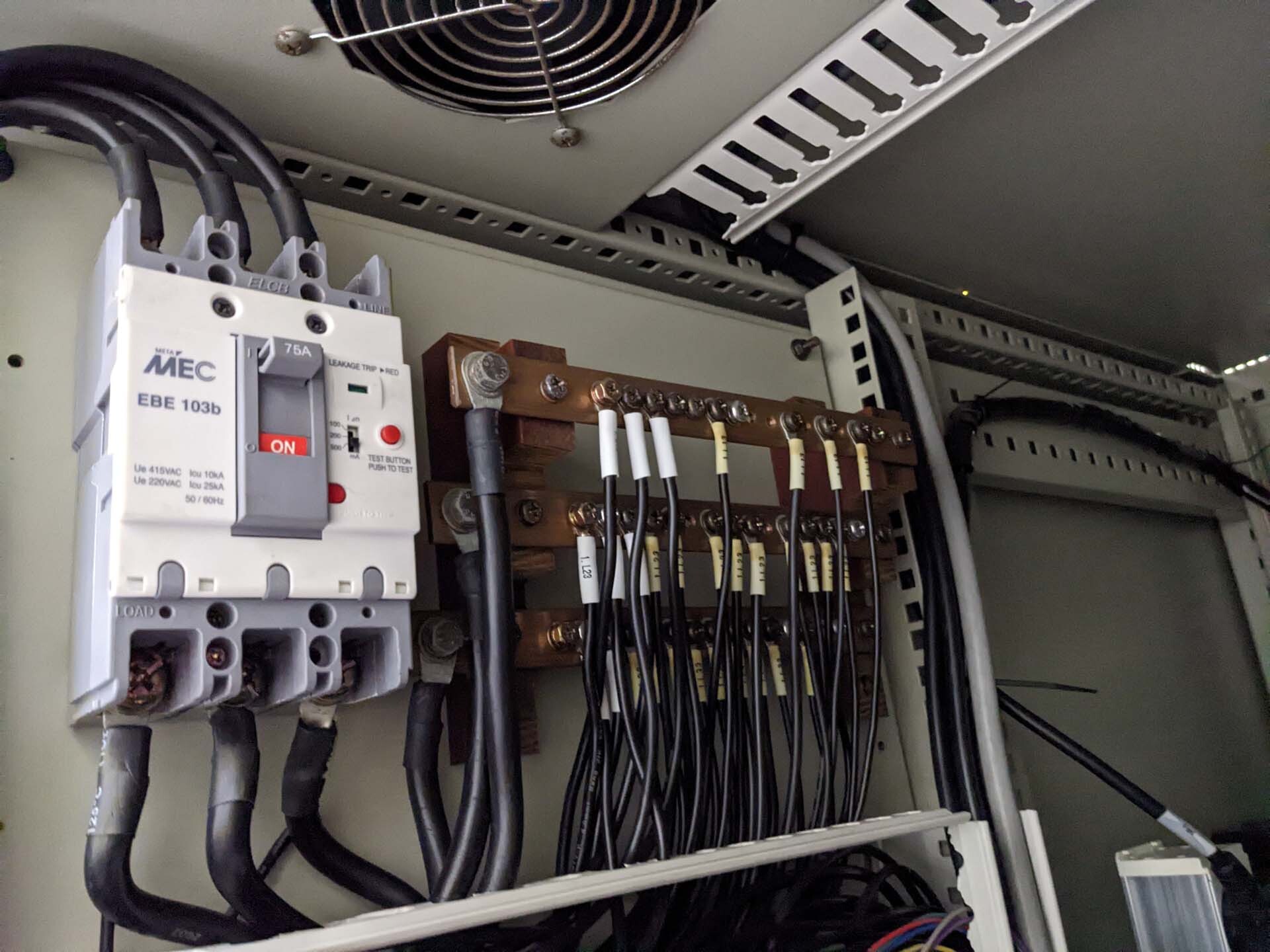

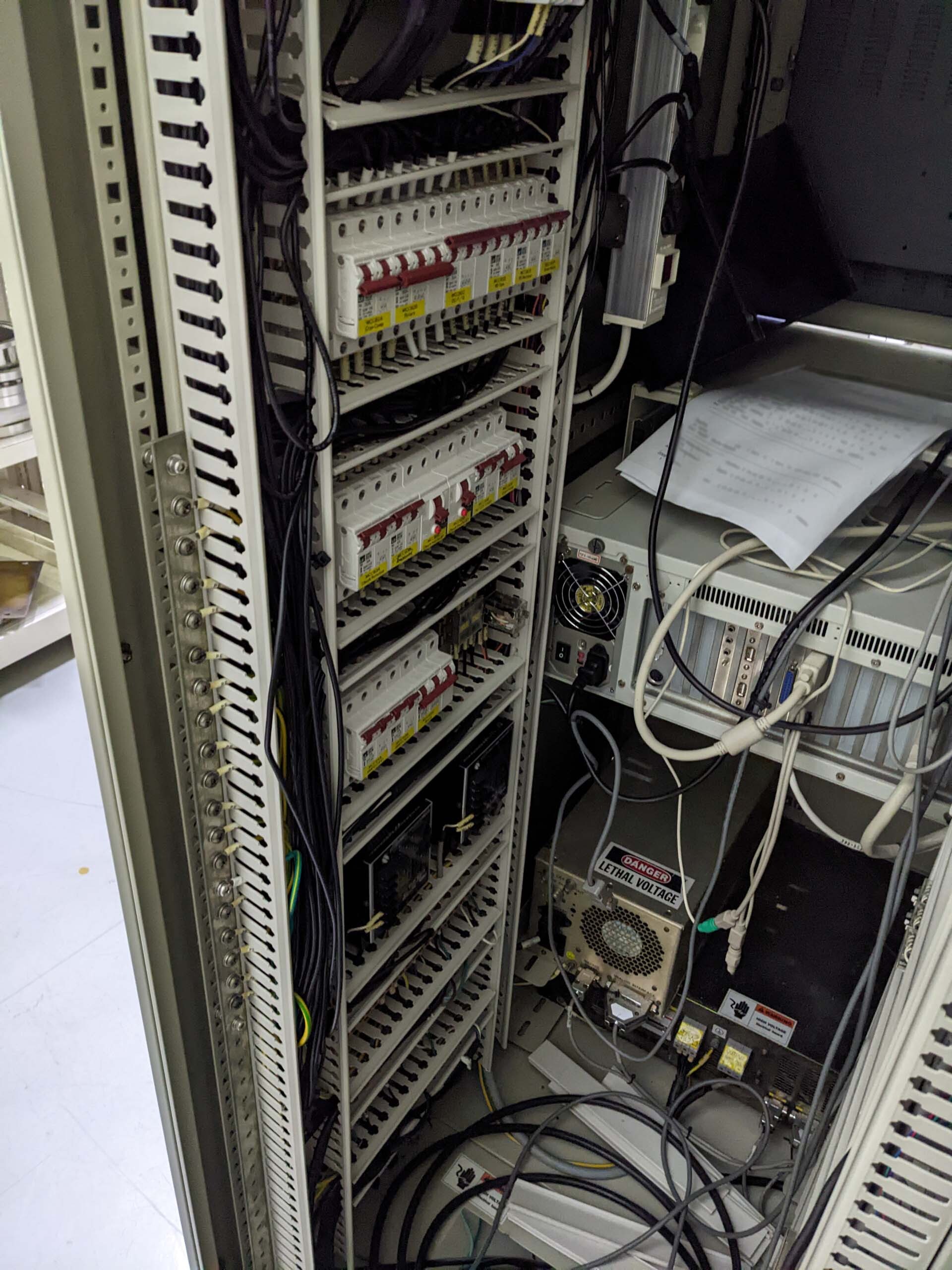

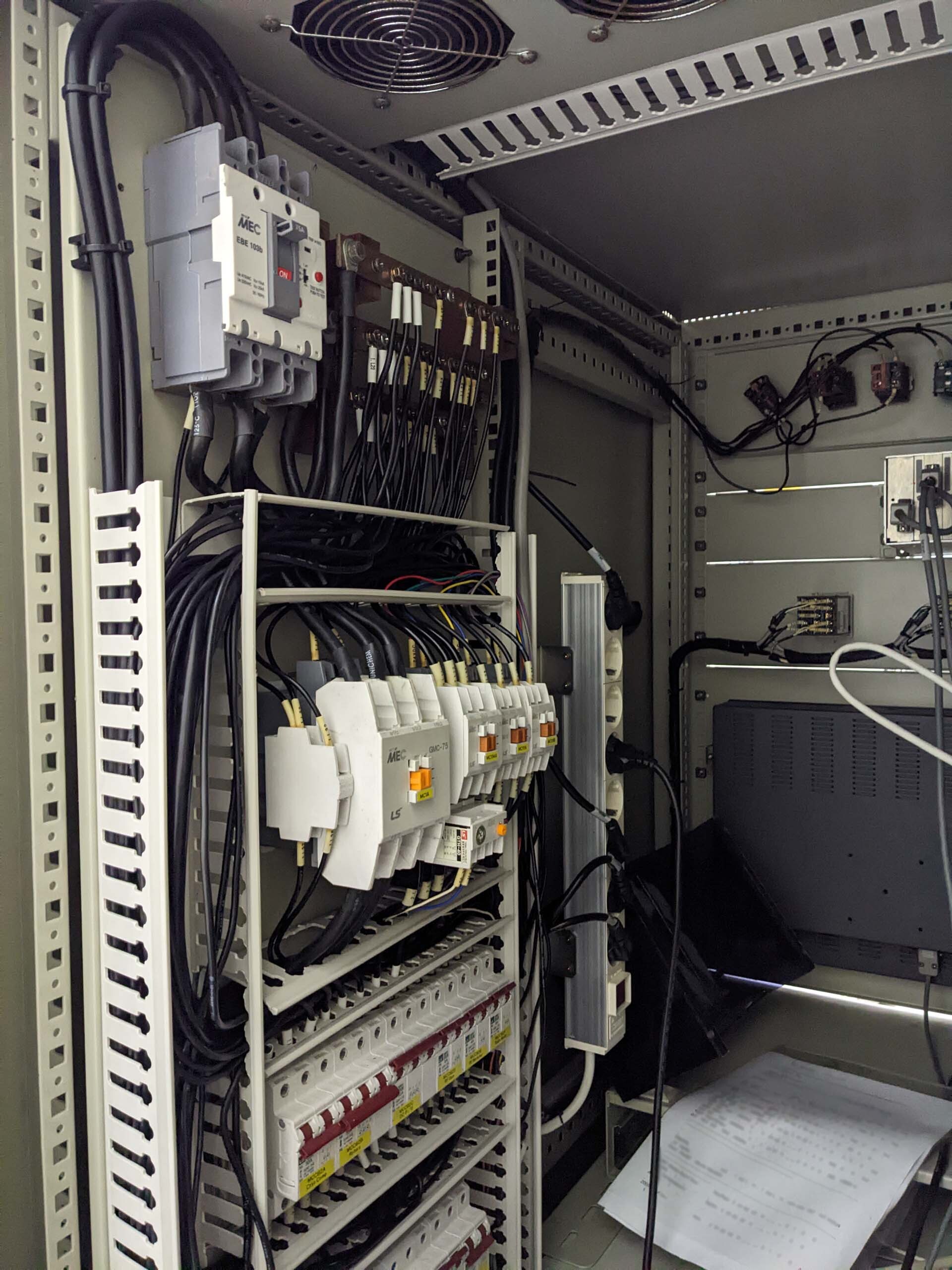

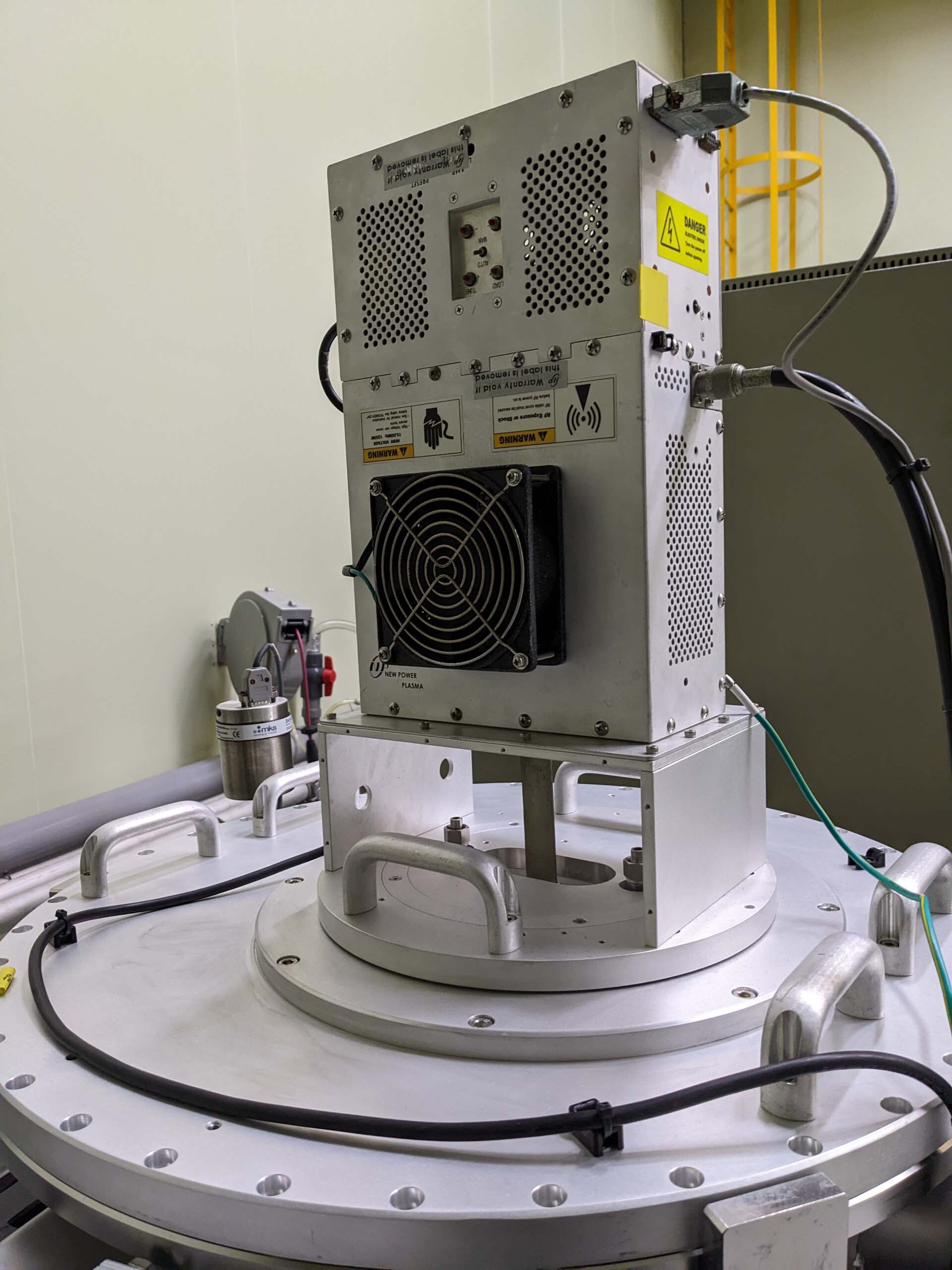

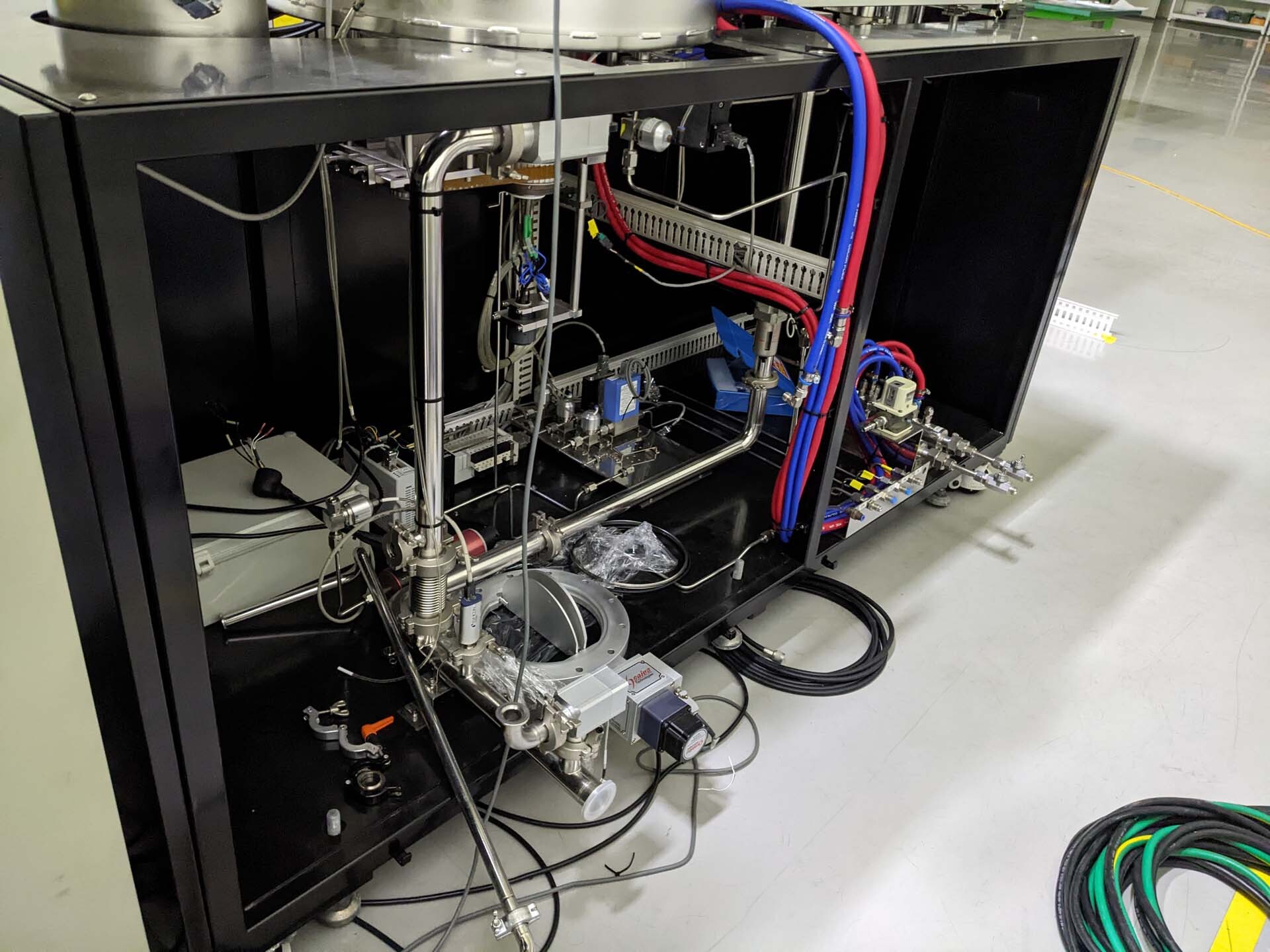

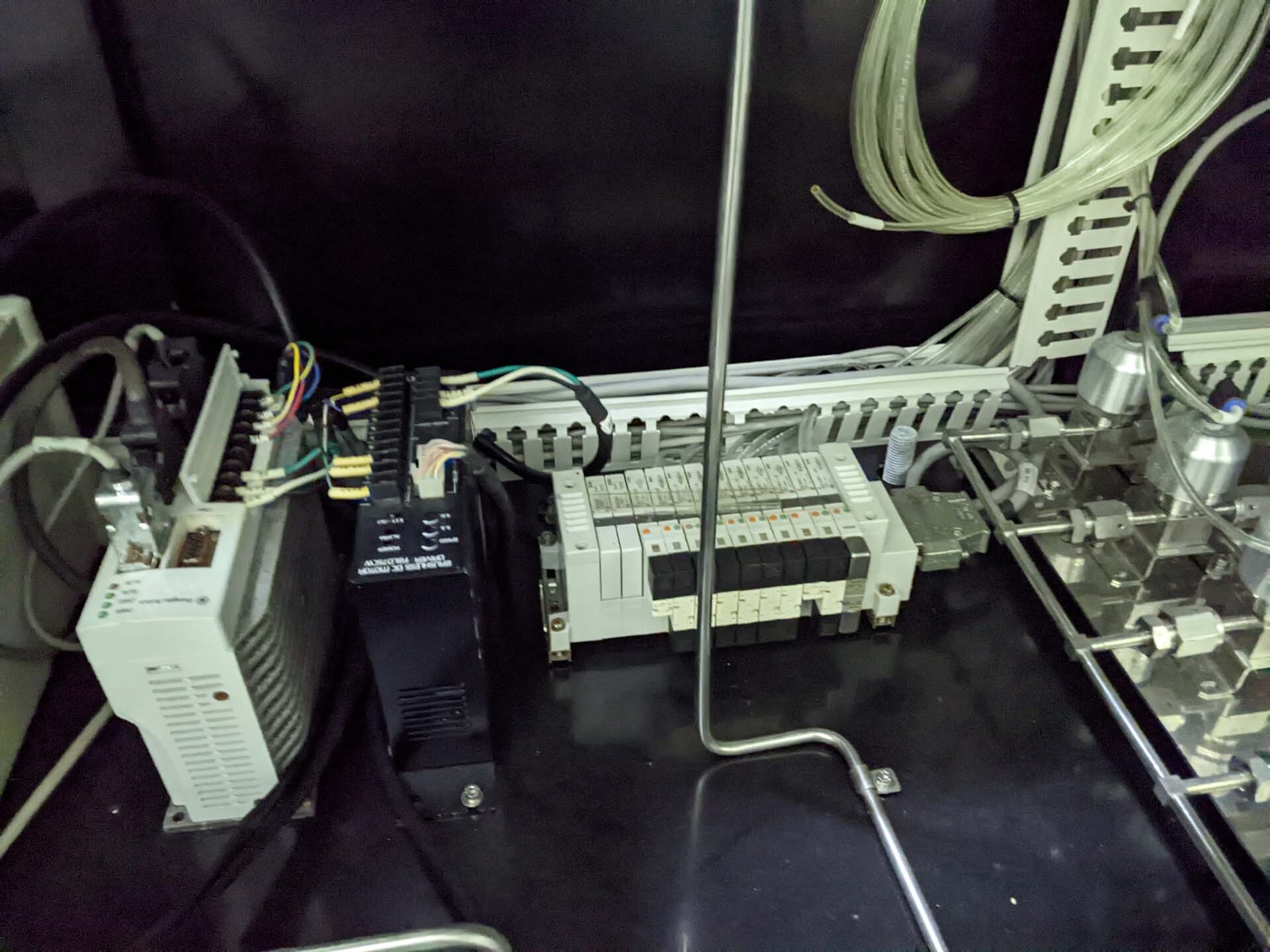

Power rack

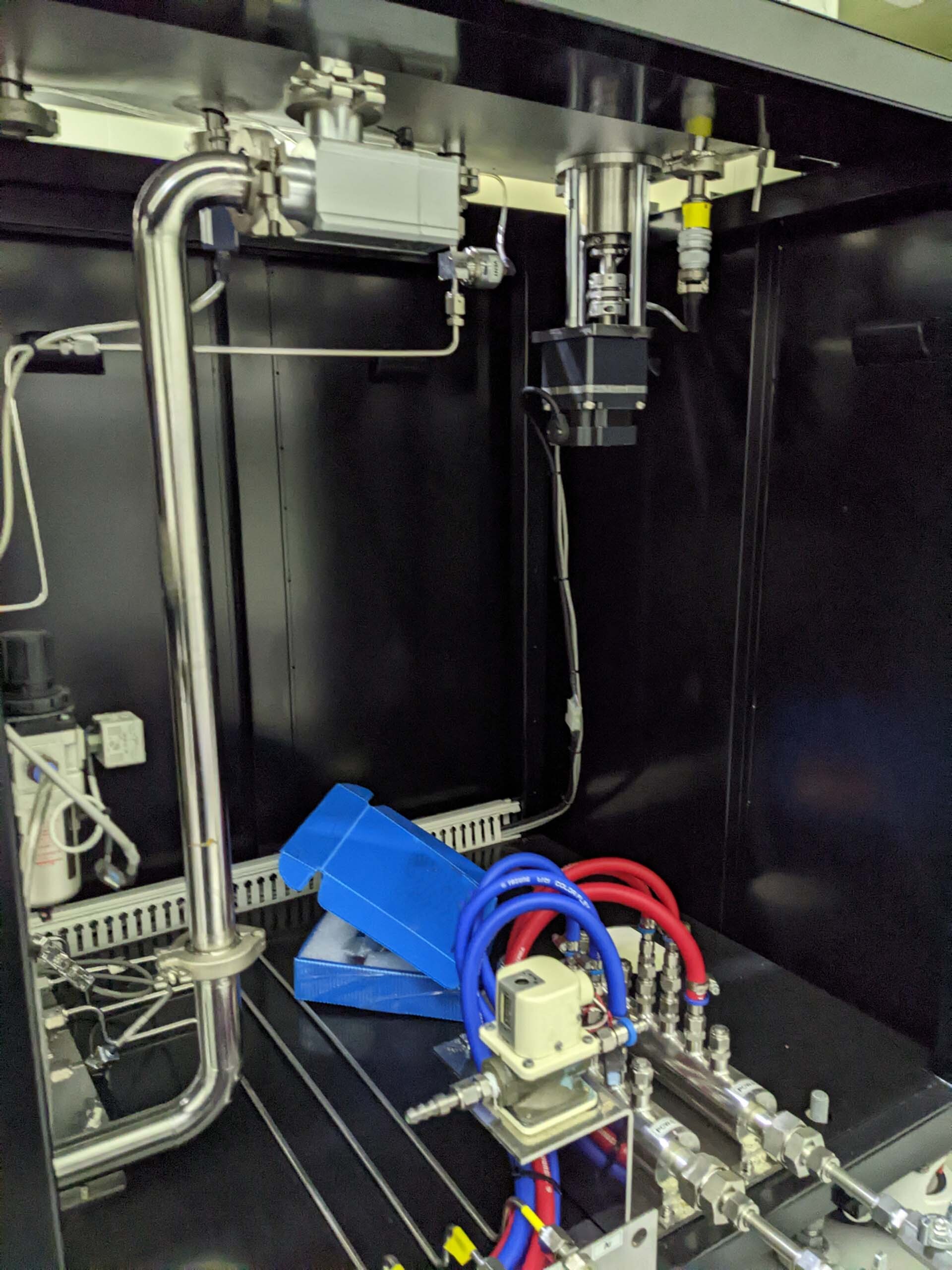

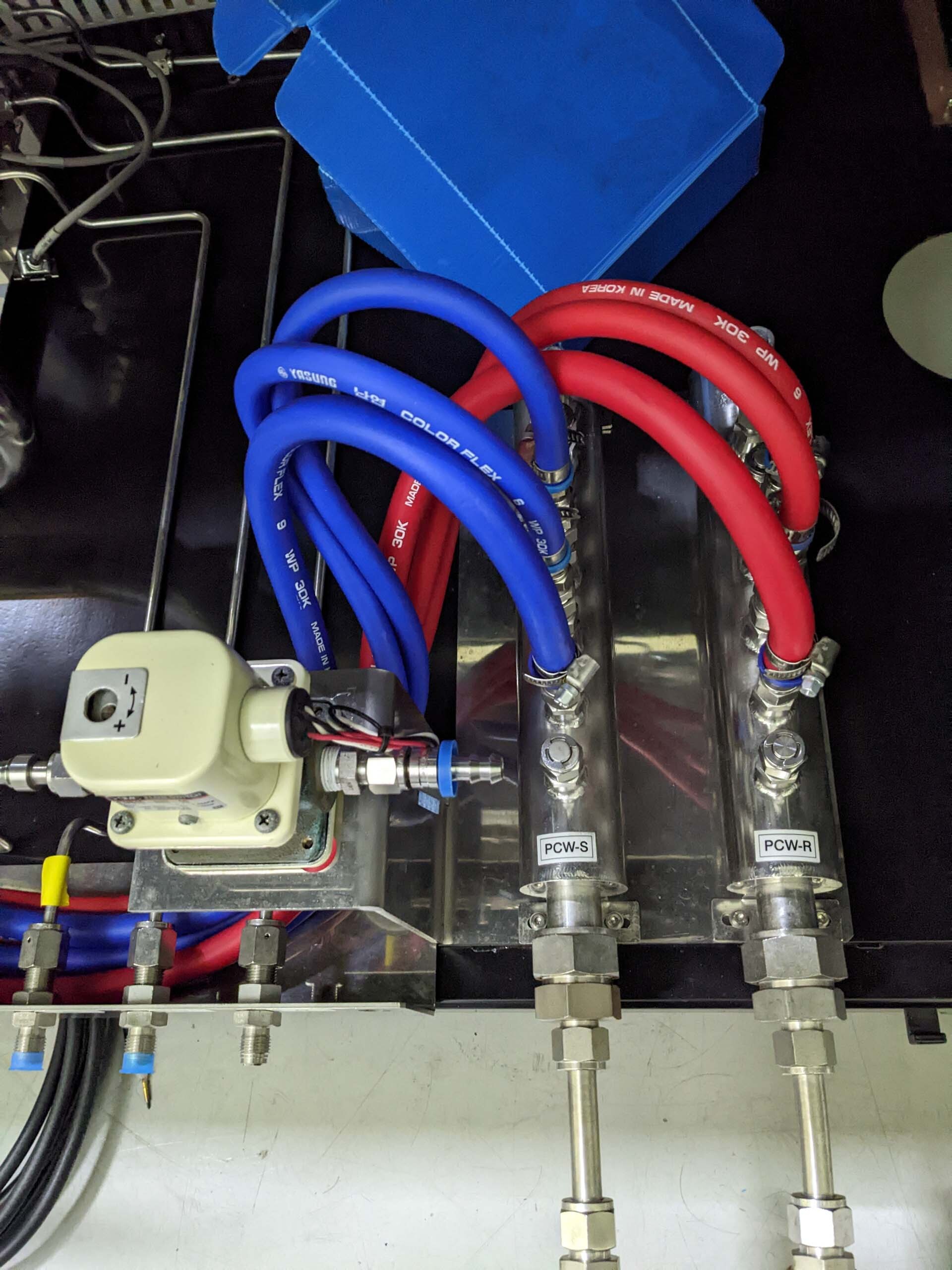

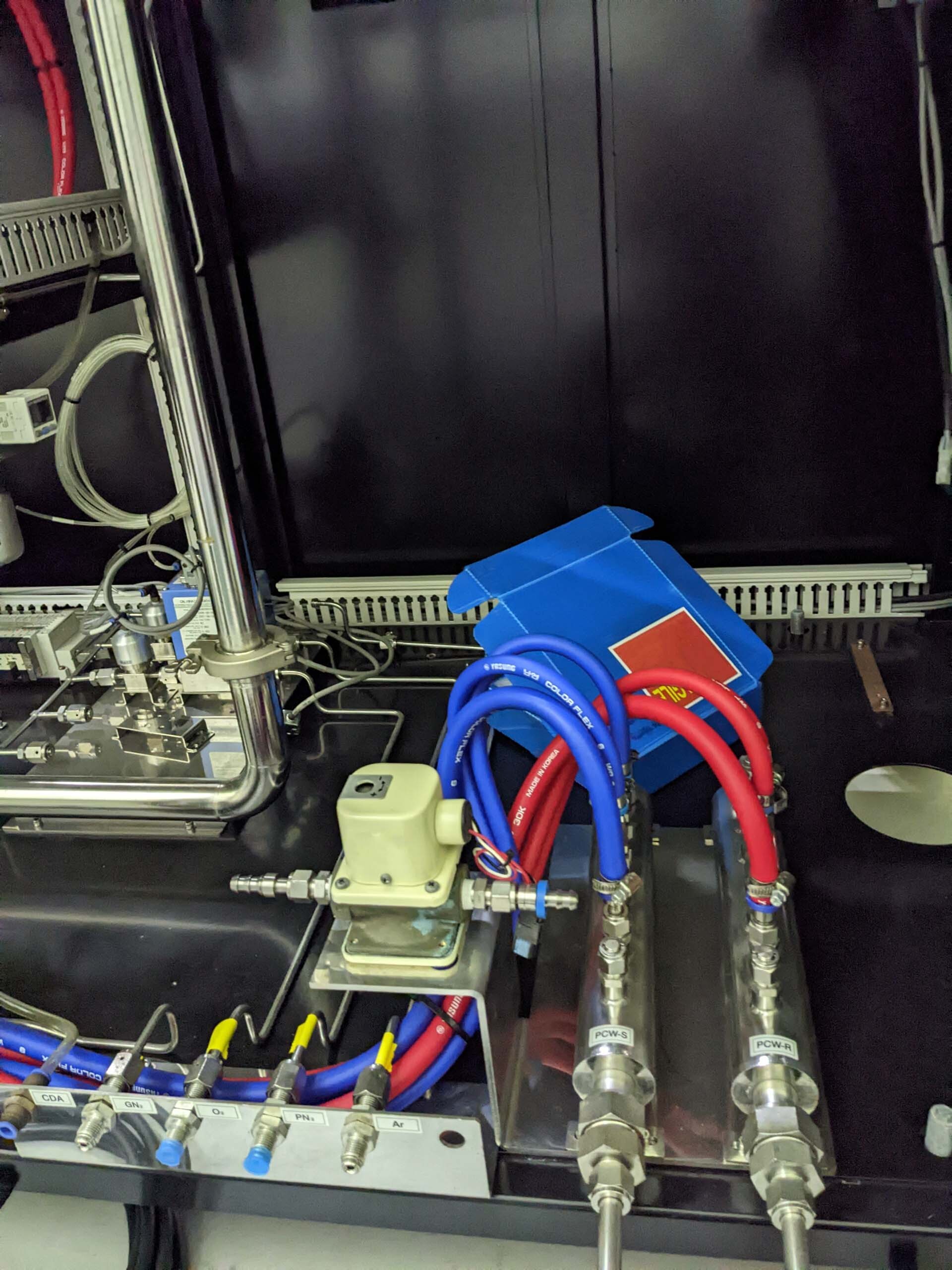

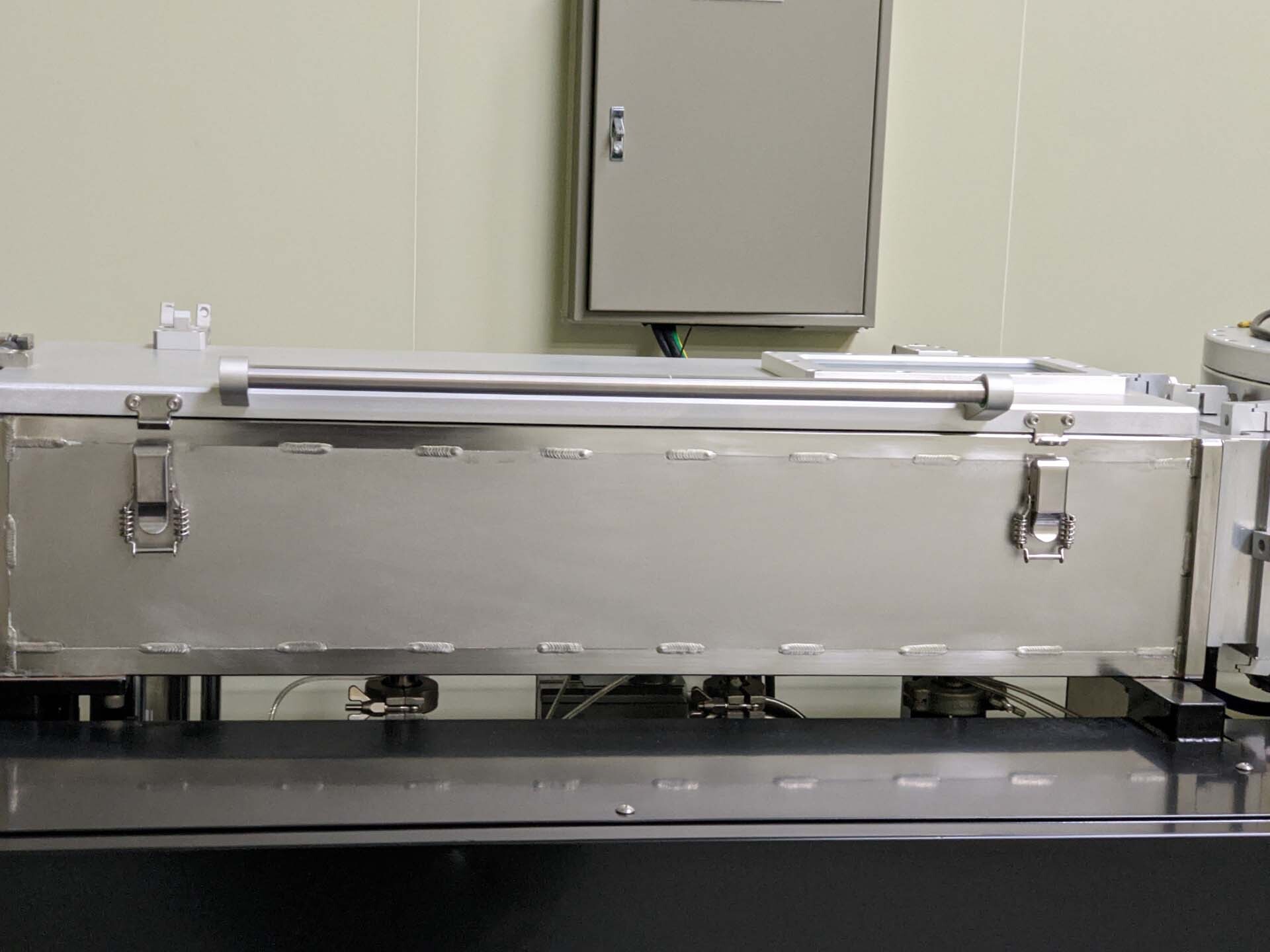

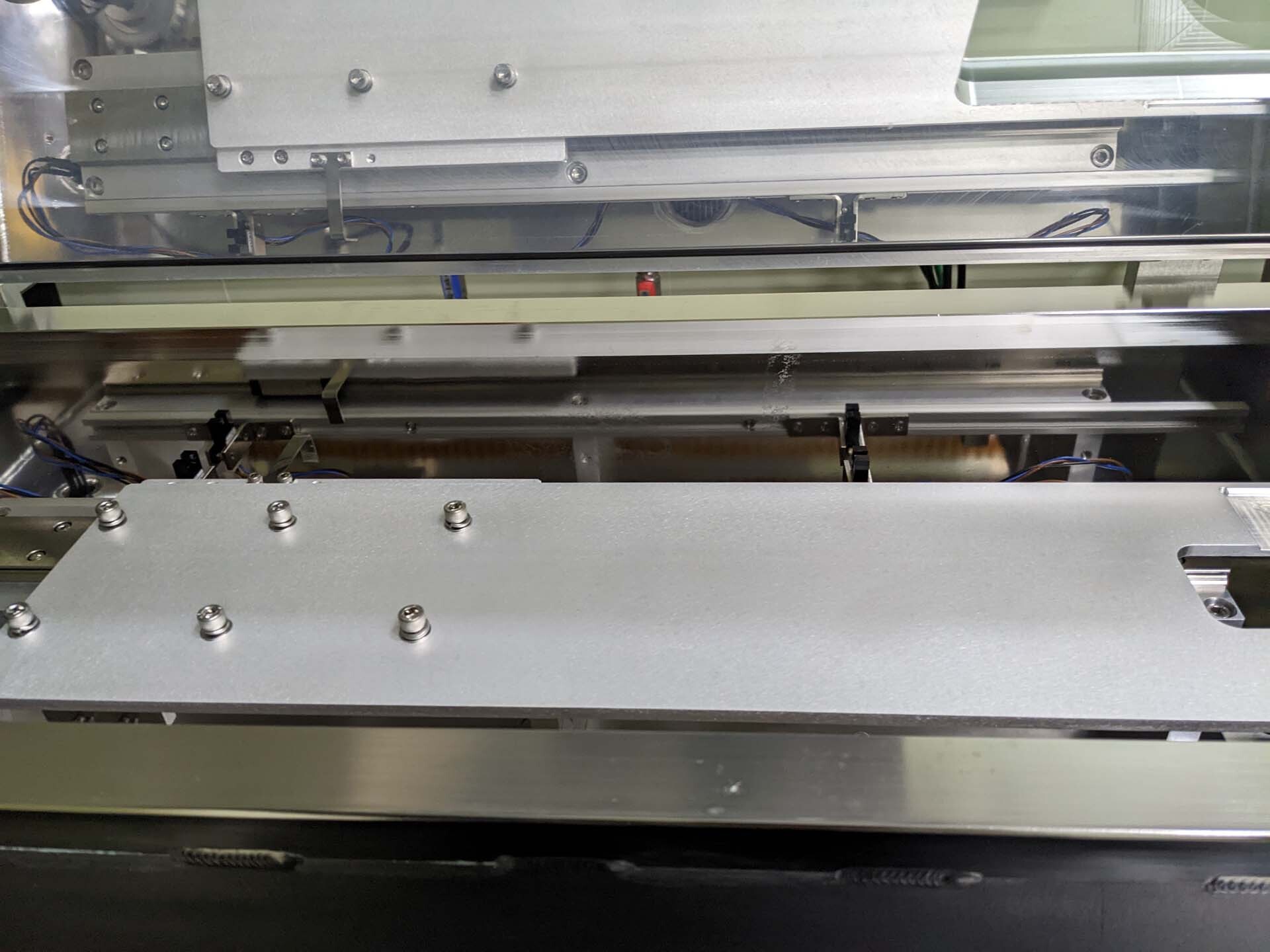

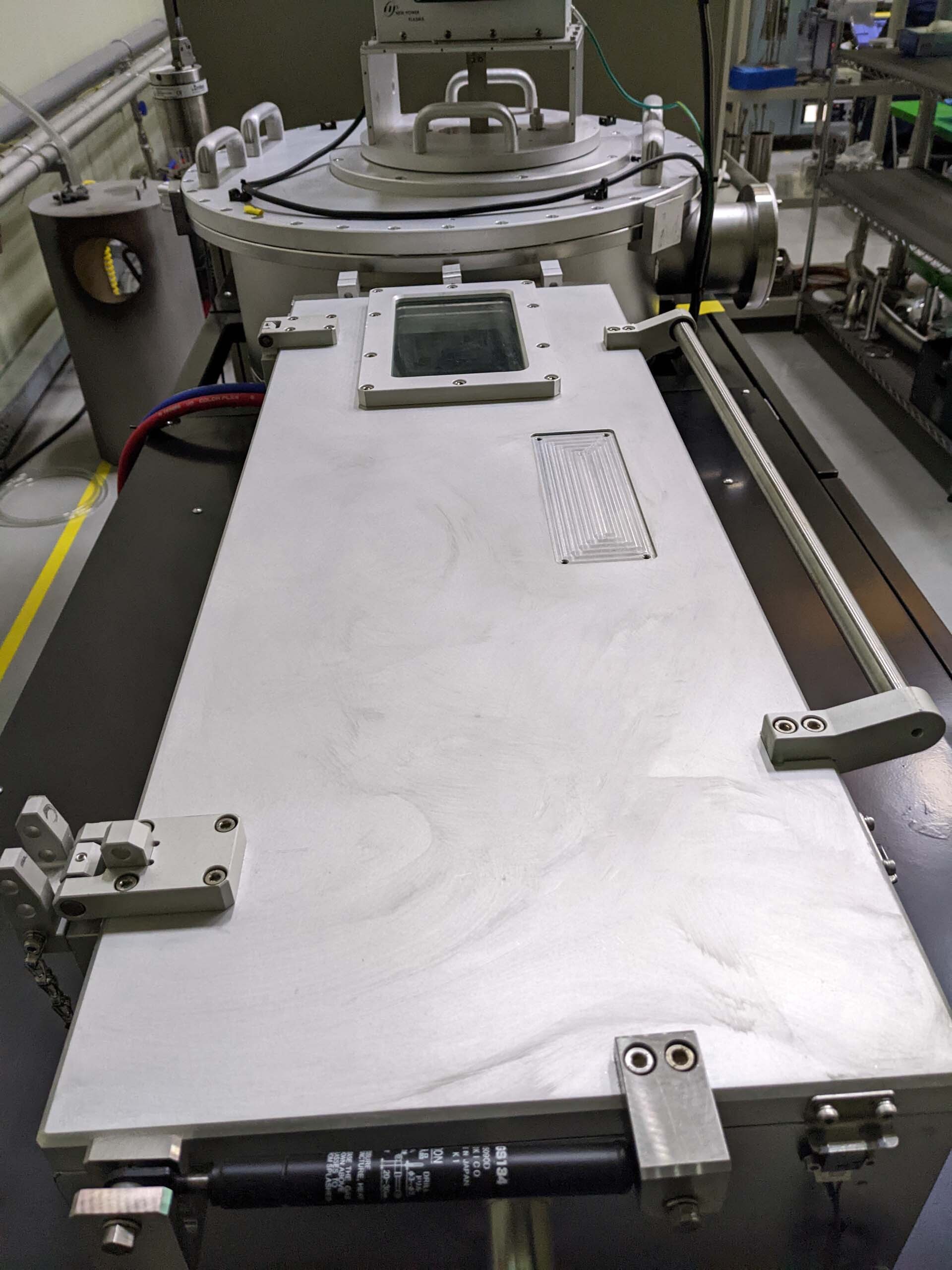

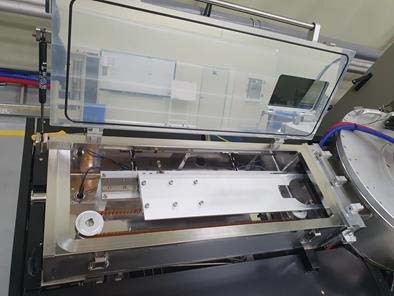

Loading and unloading chamber:

Substrate size: 120 x 120 mm

SUS-304 Chamber type: Square, vertical

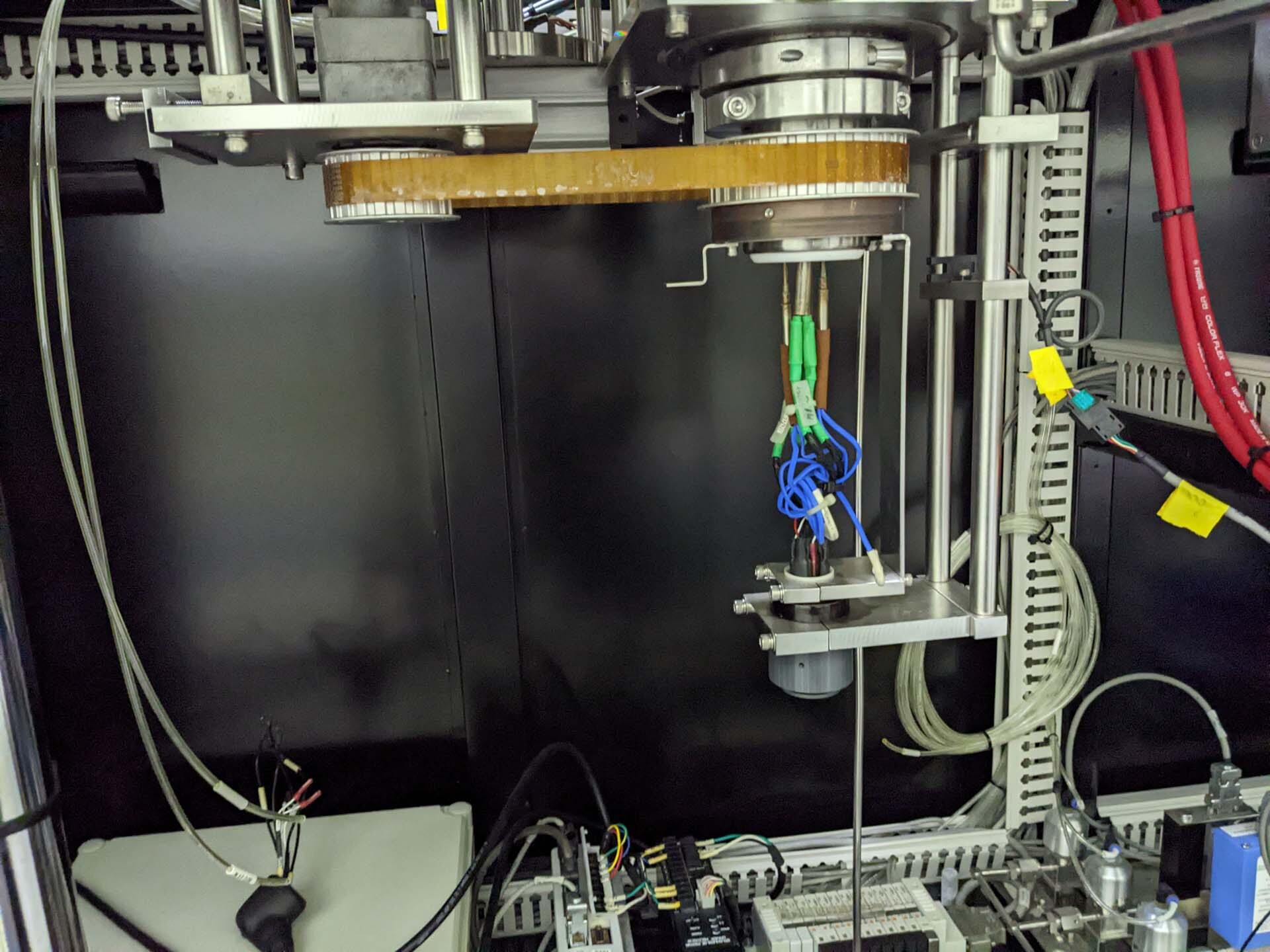

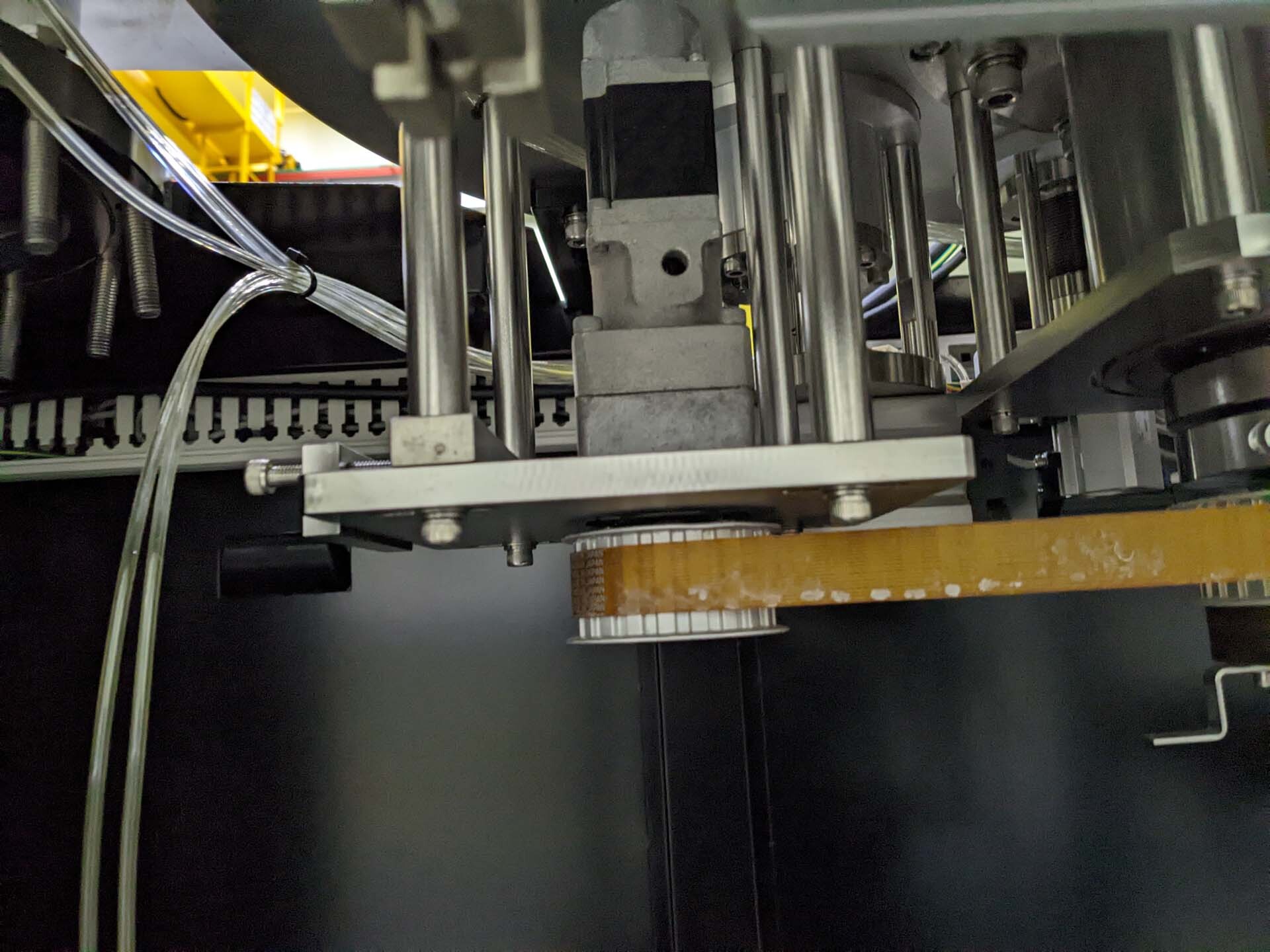

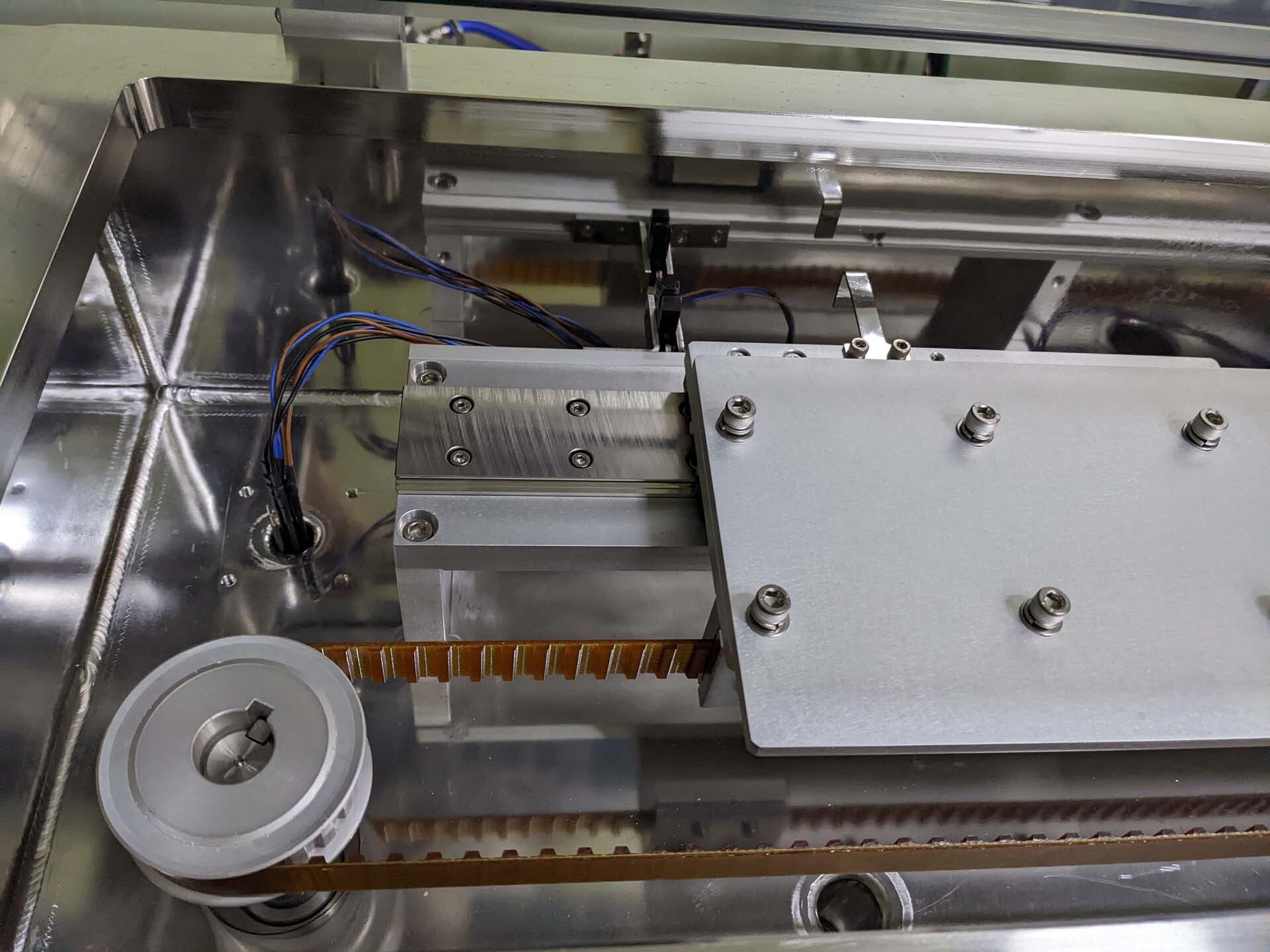

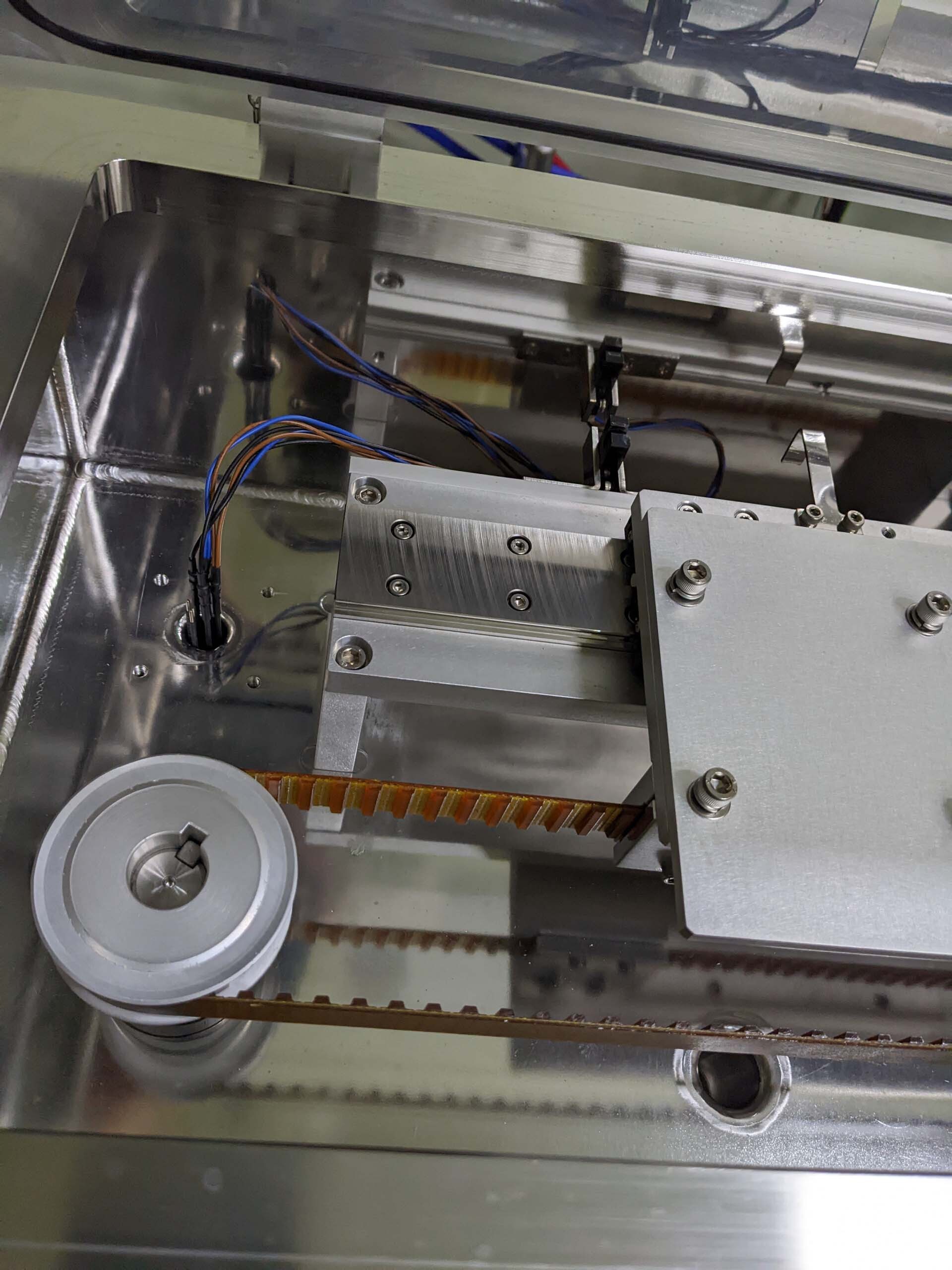

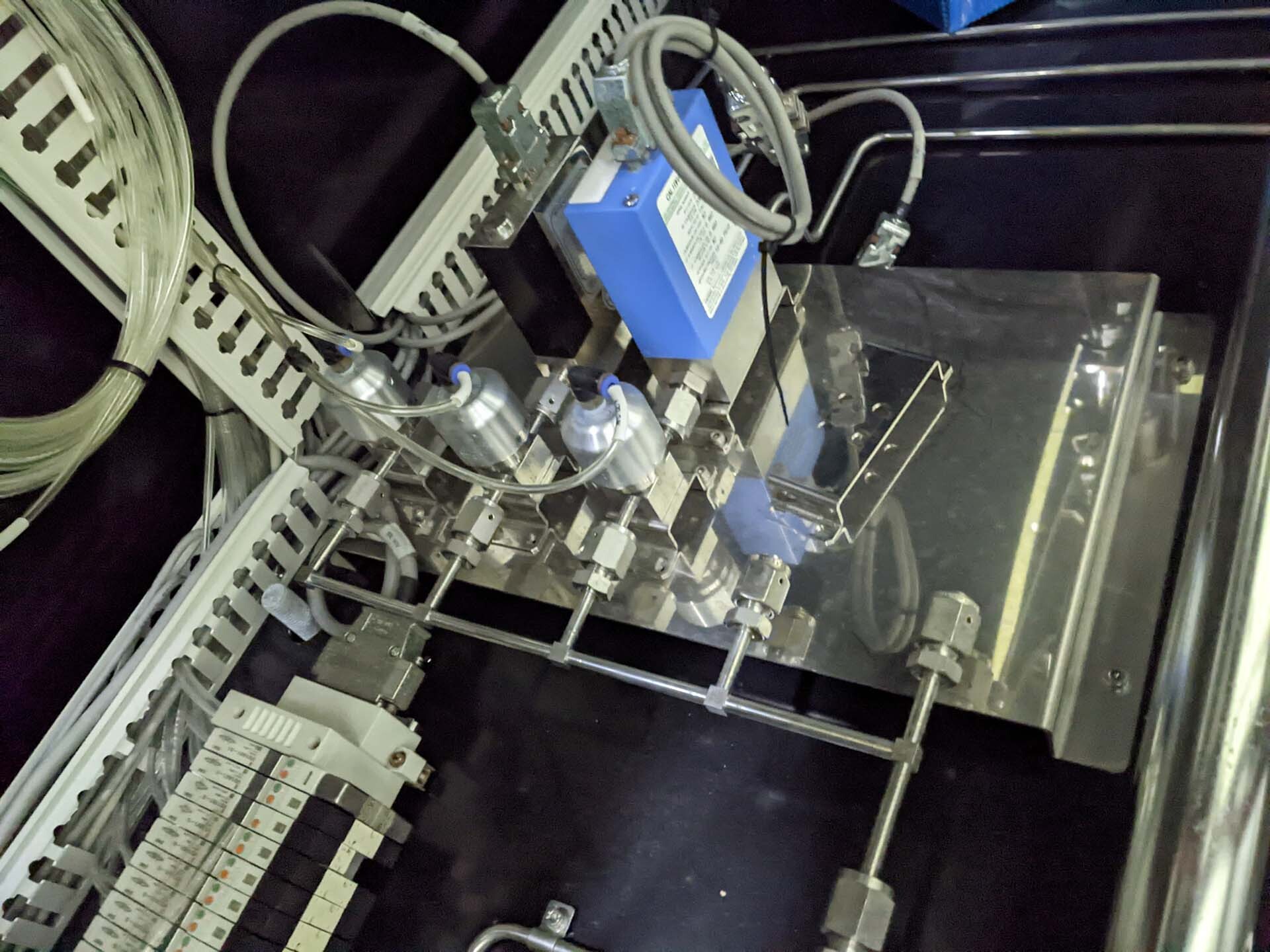

IMS Linear transfer kit

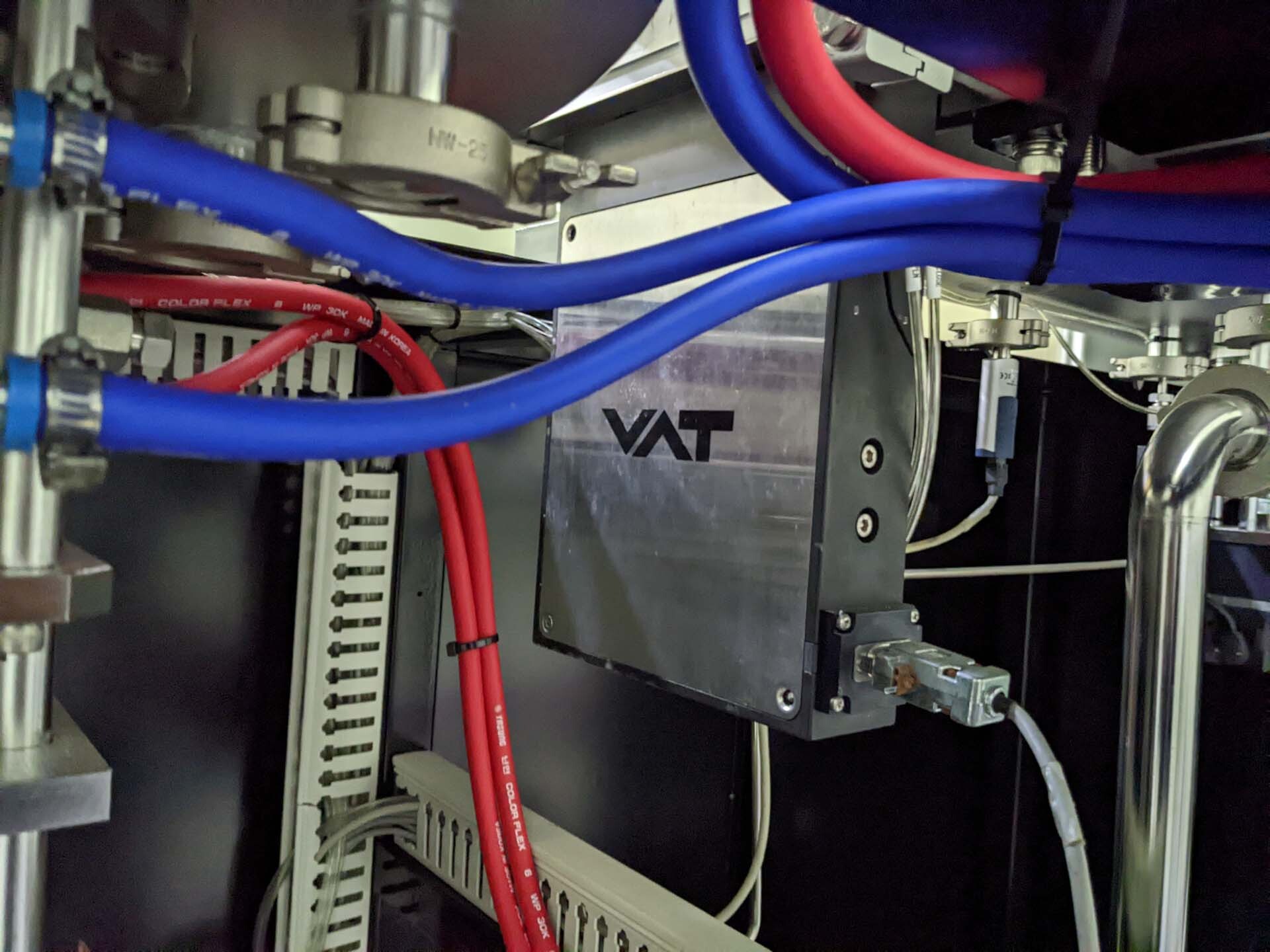

VAT Gate valve: Rectangular type

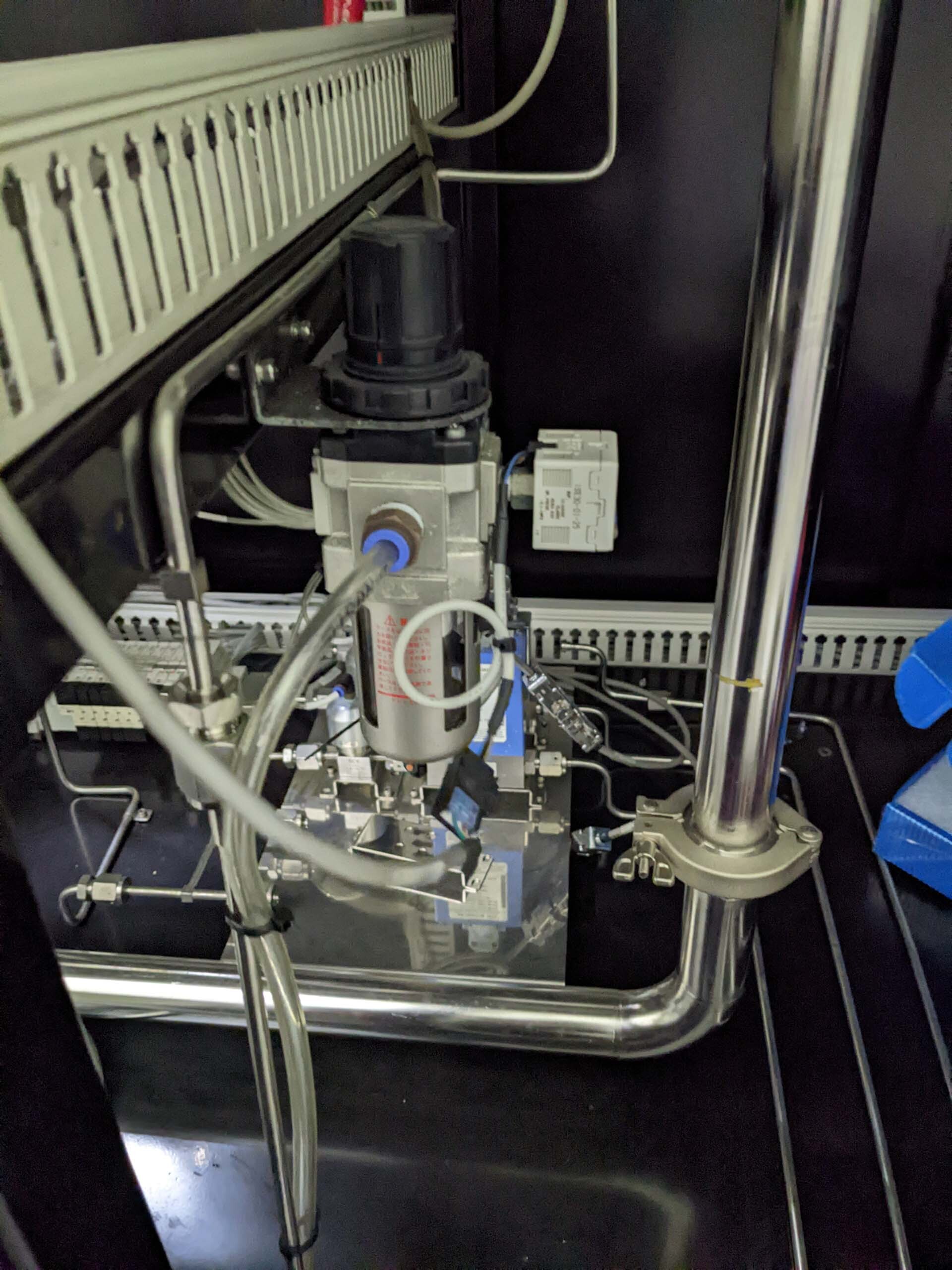

Low vacuum pump: Rotary pump

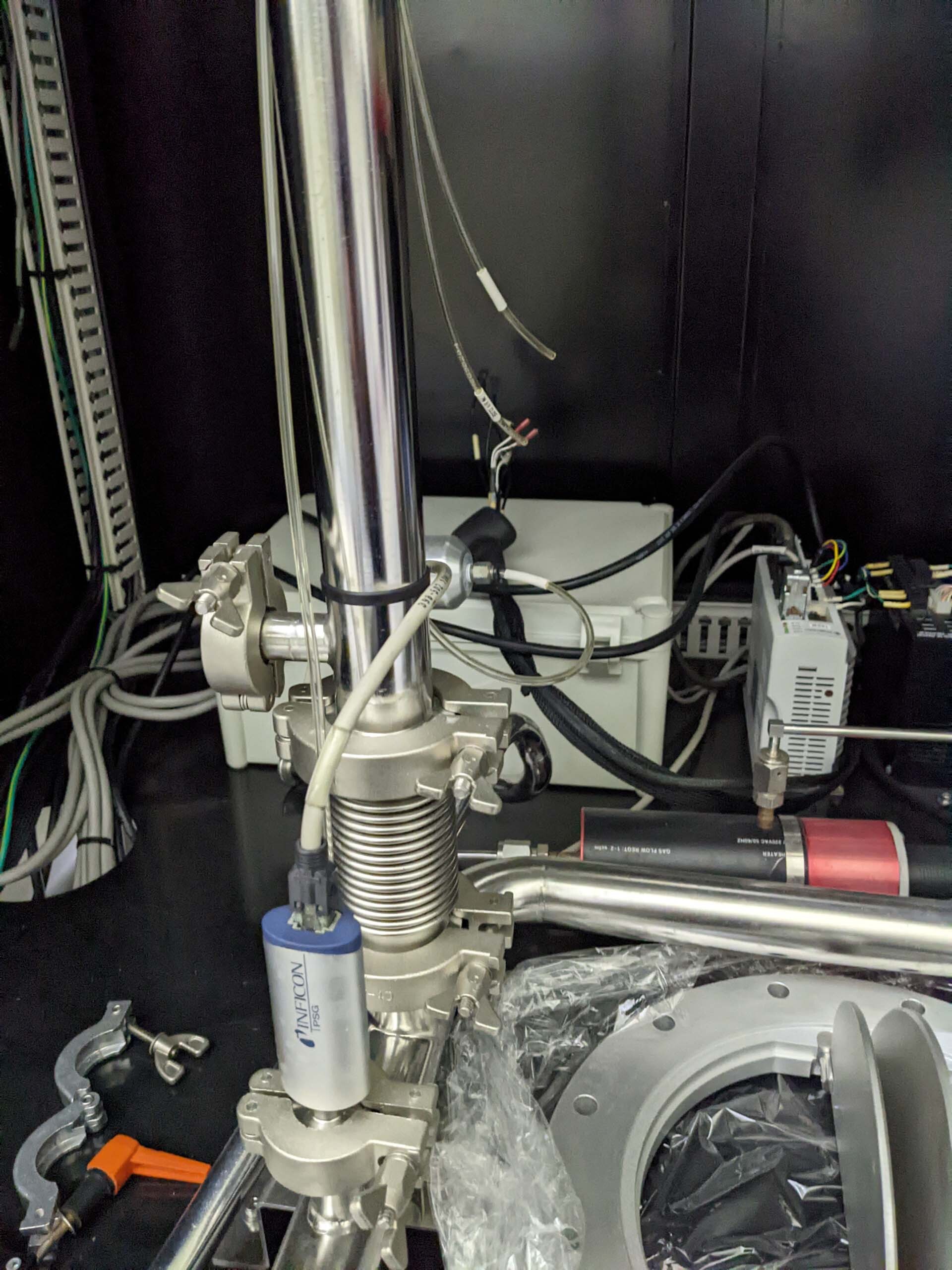

INFICON Chamber gauge: Pirani gauge

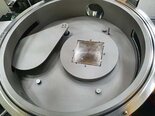

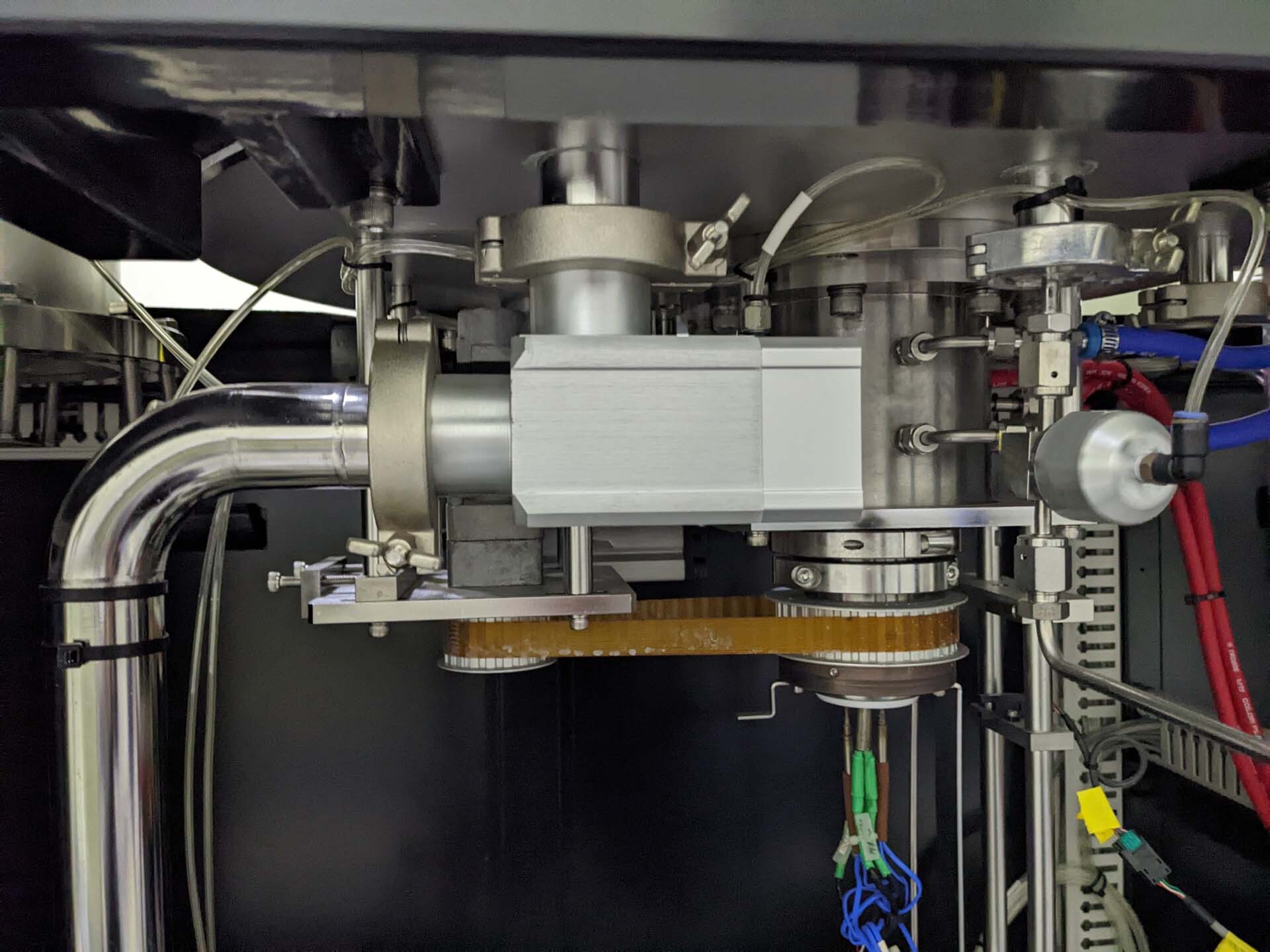

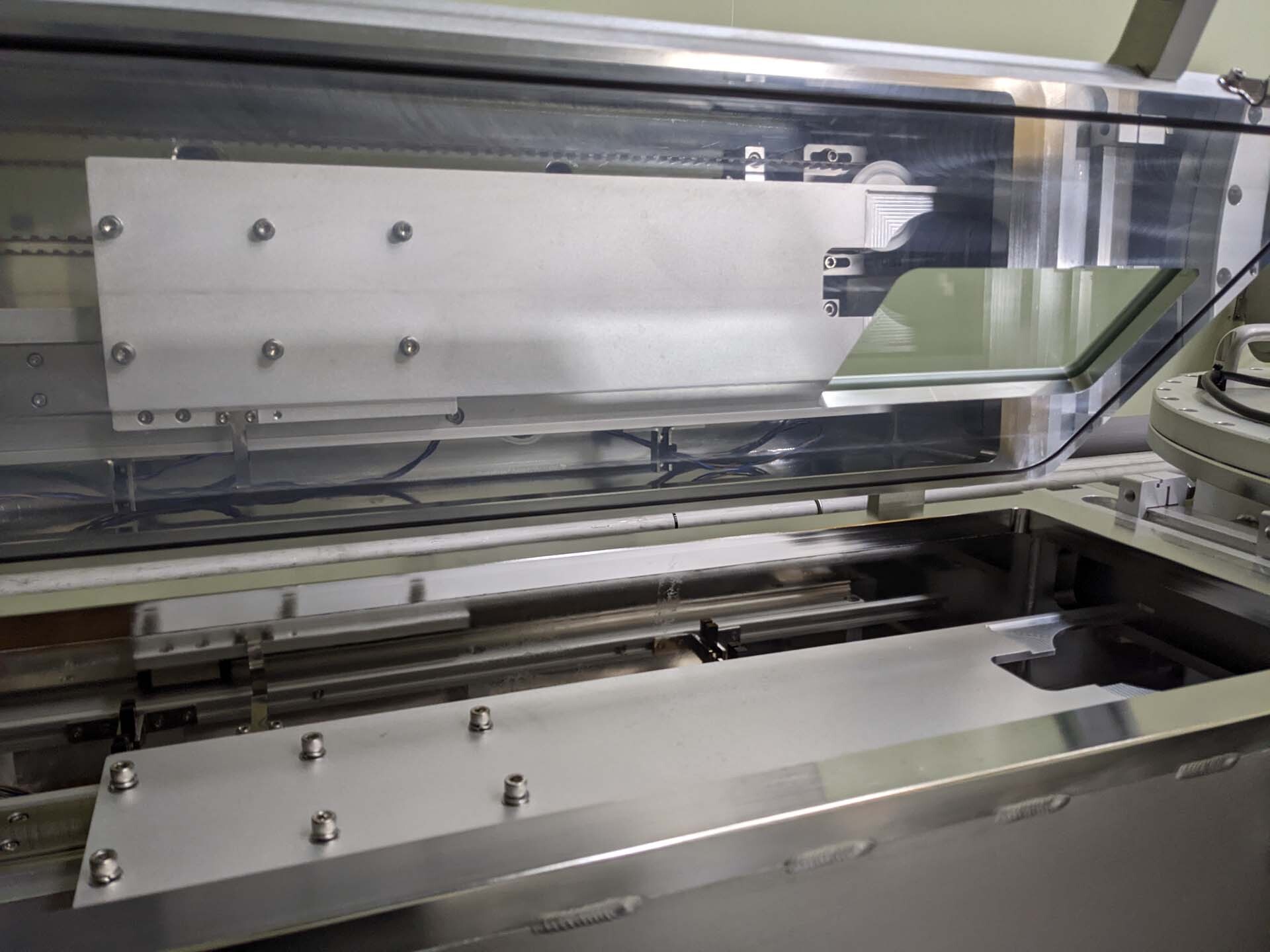

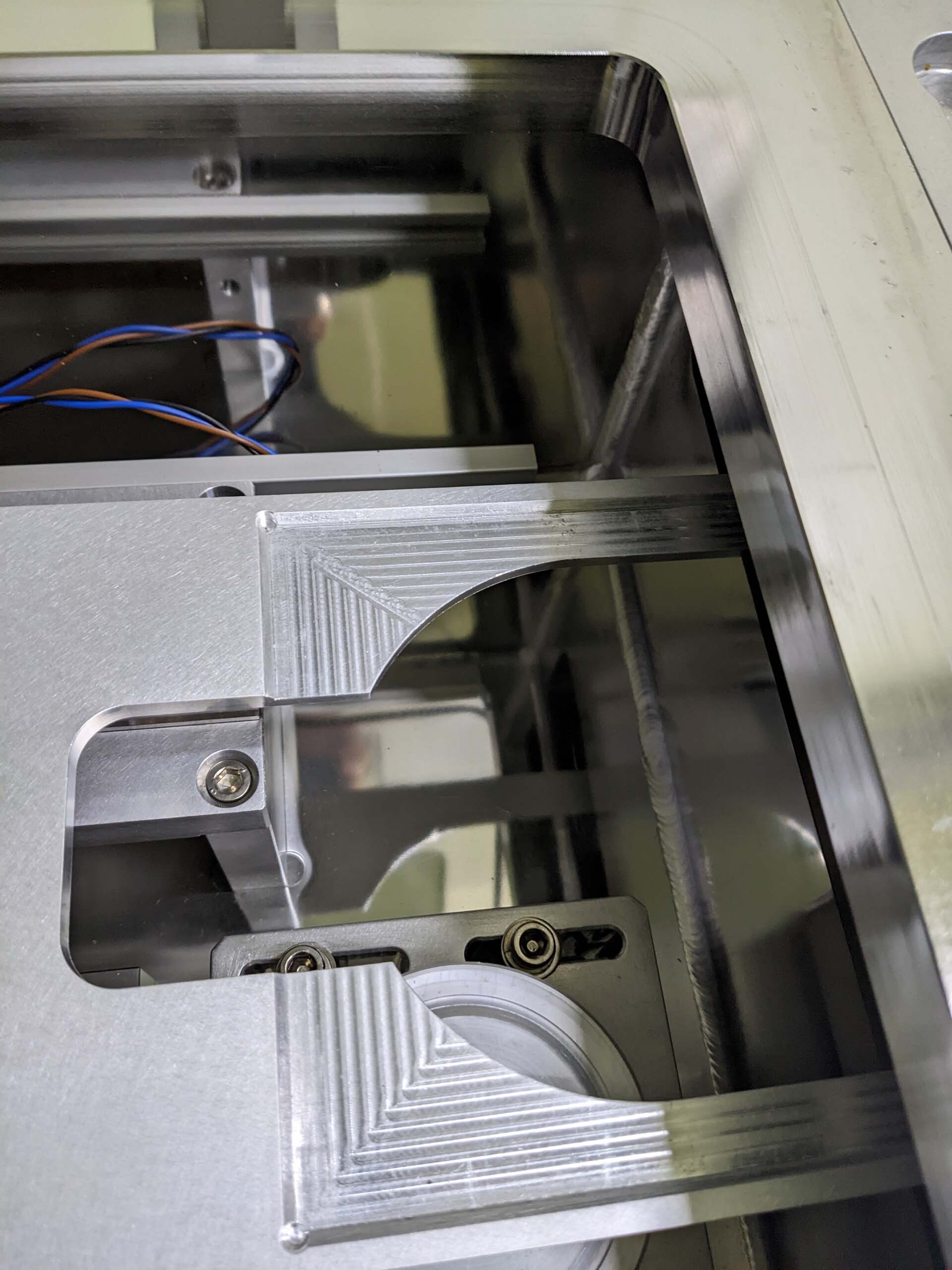

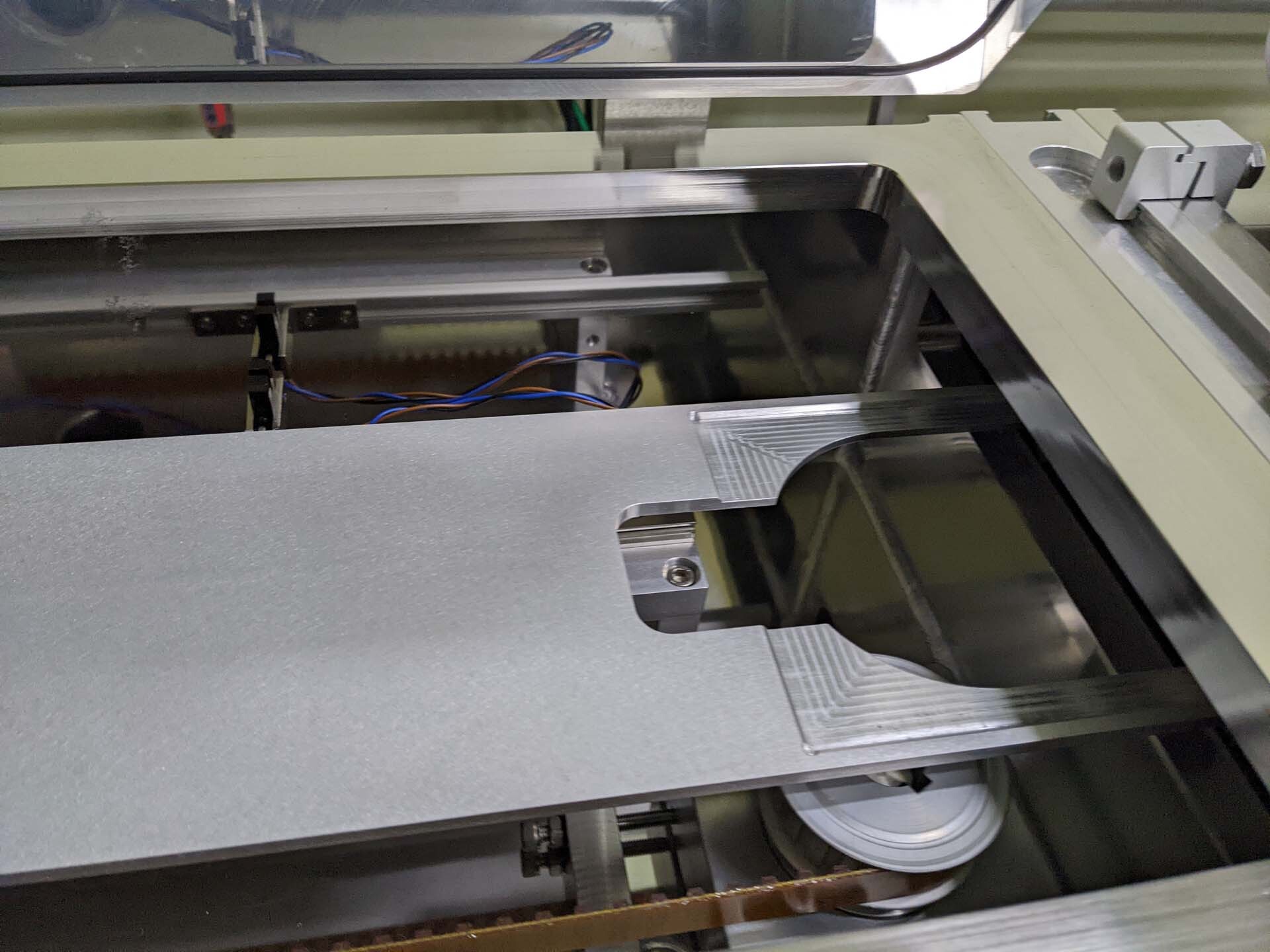

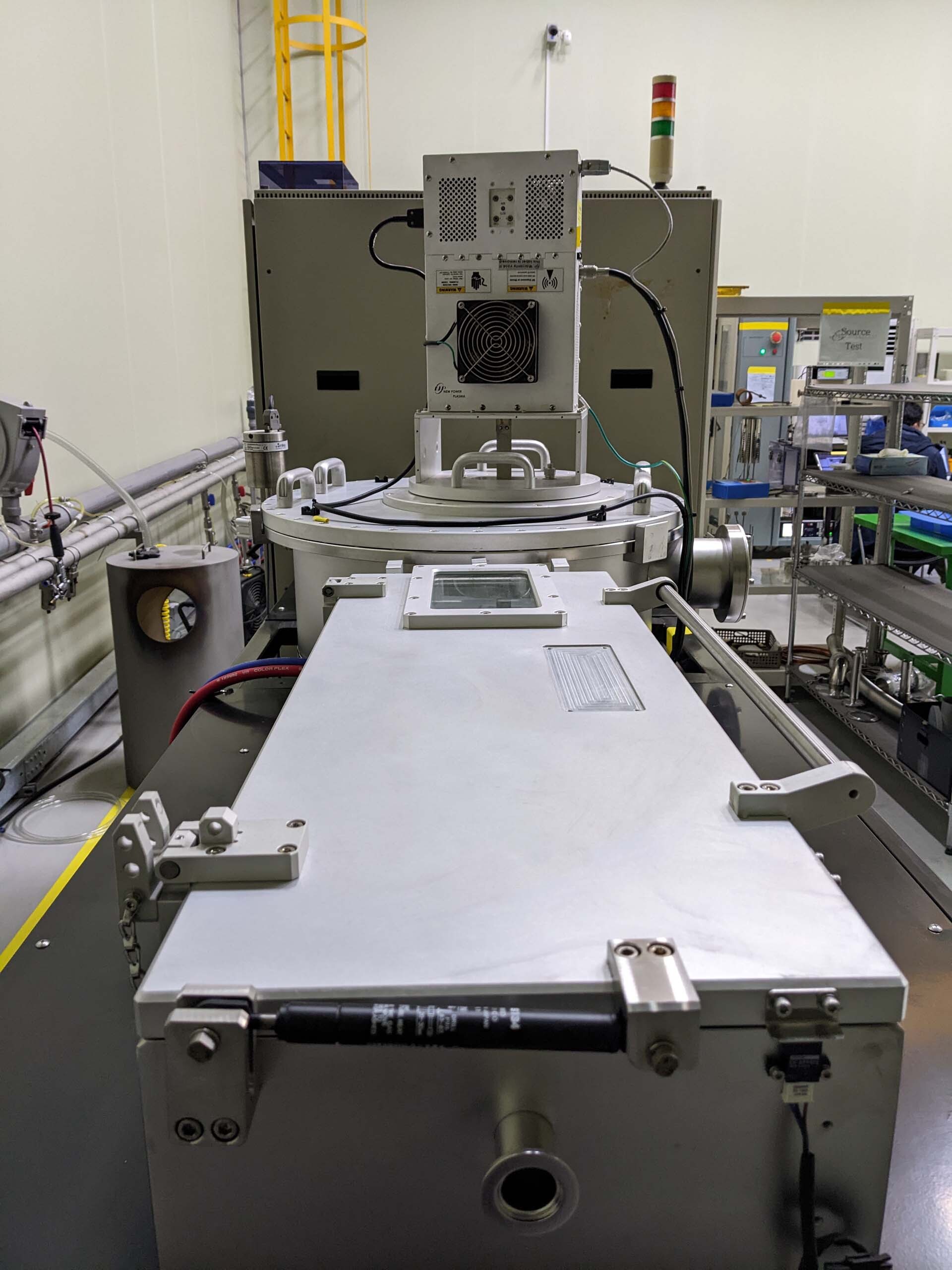

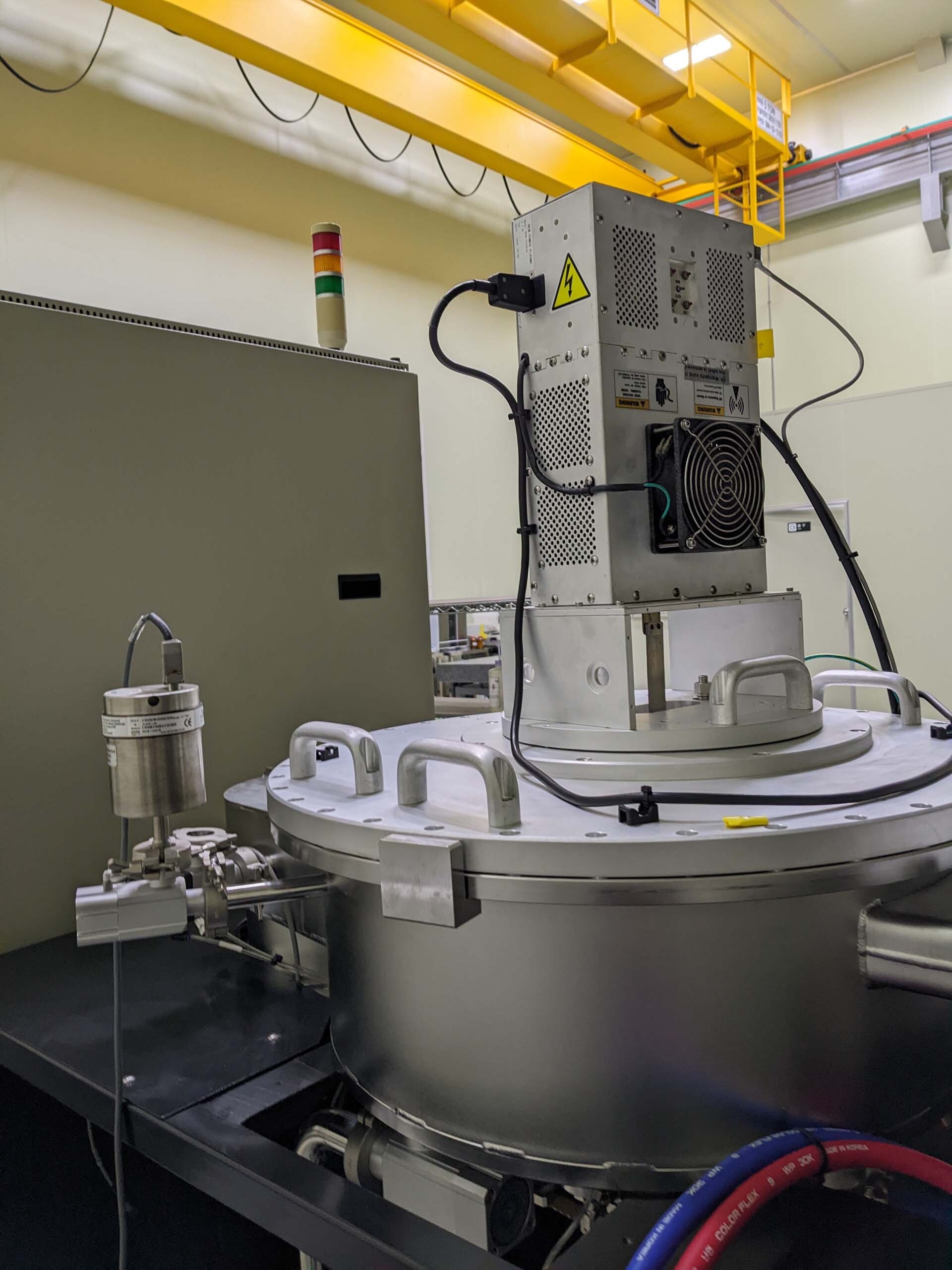

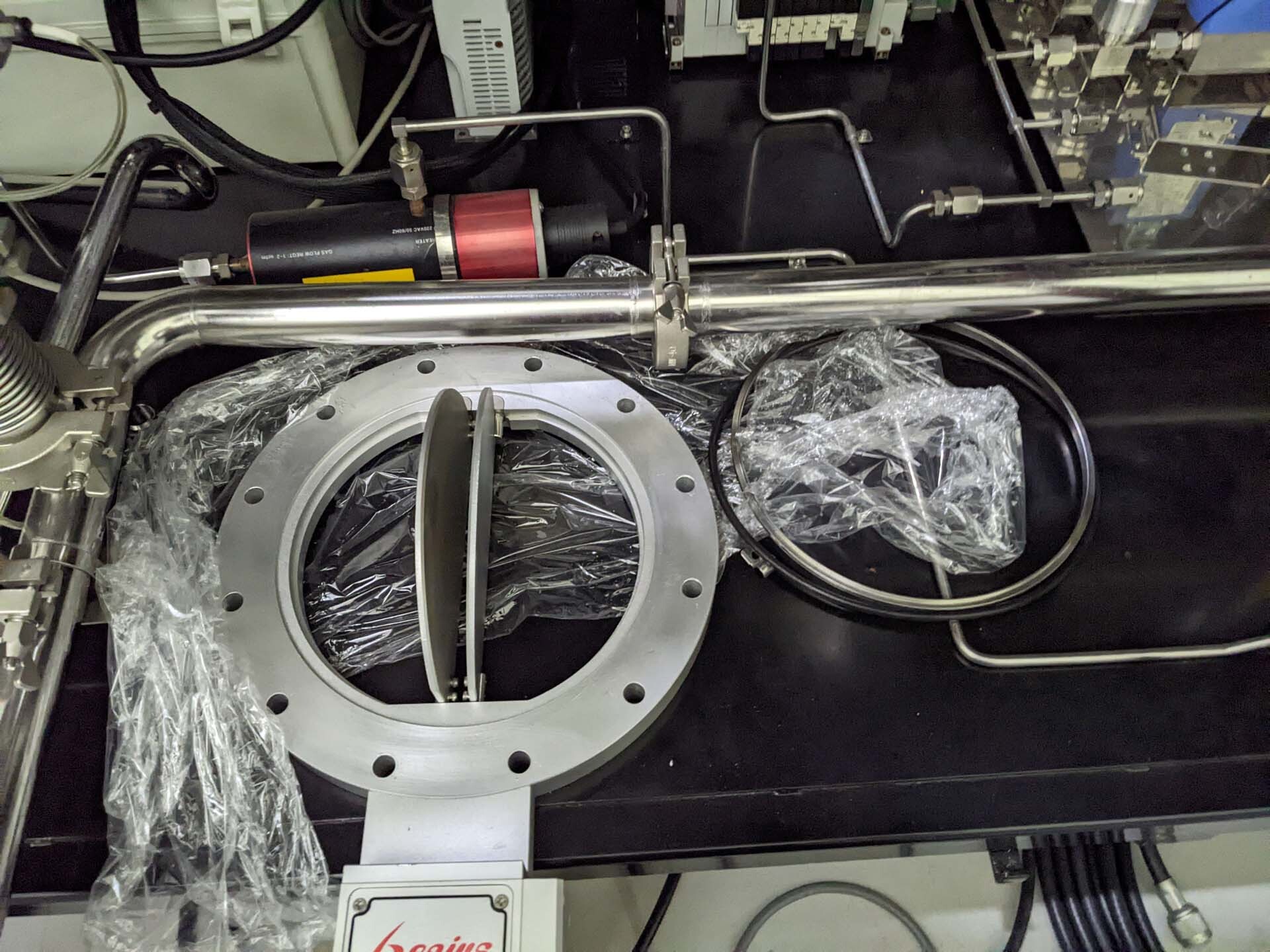

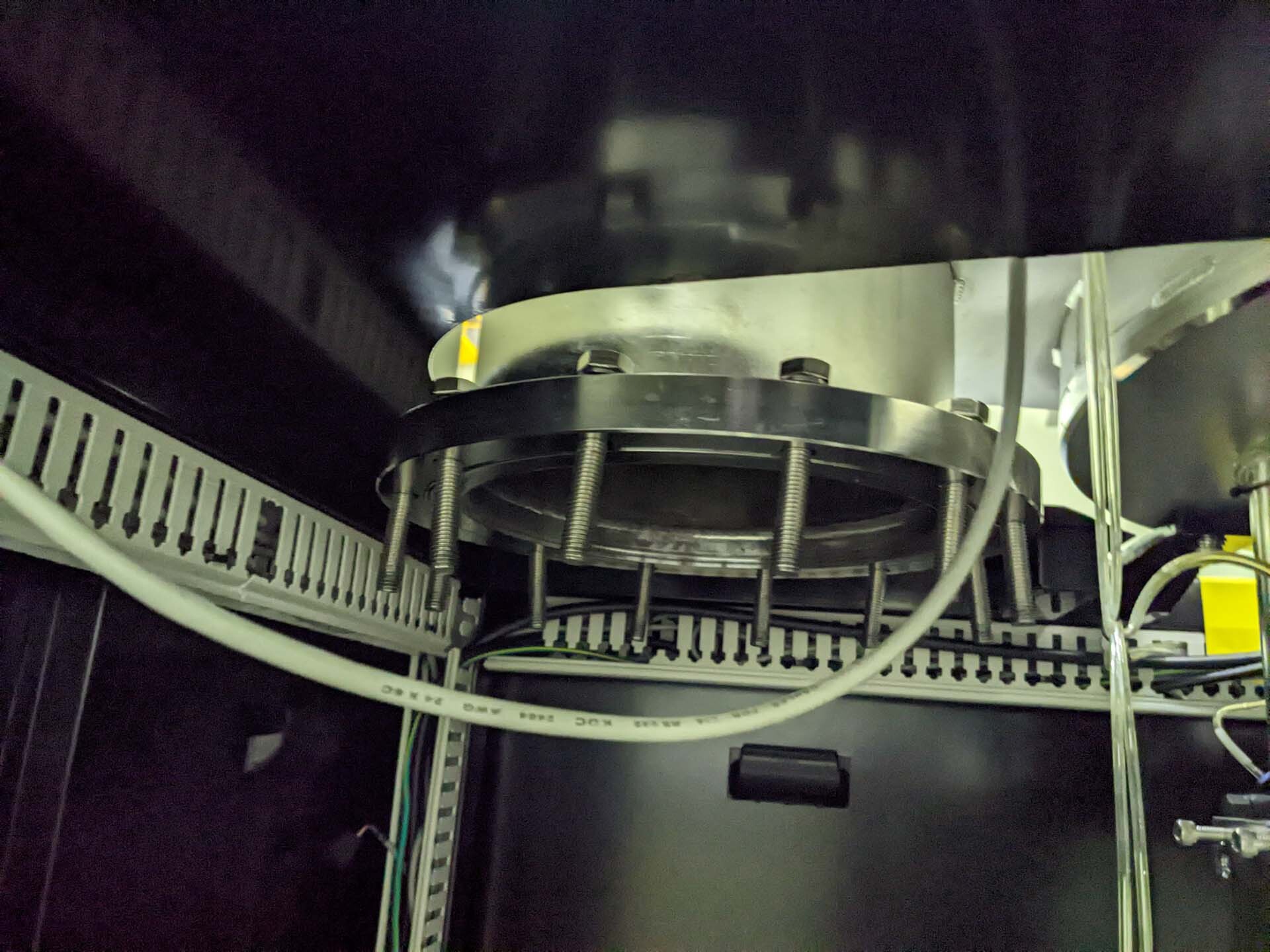

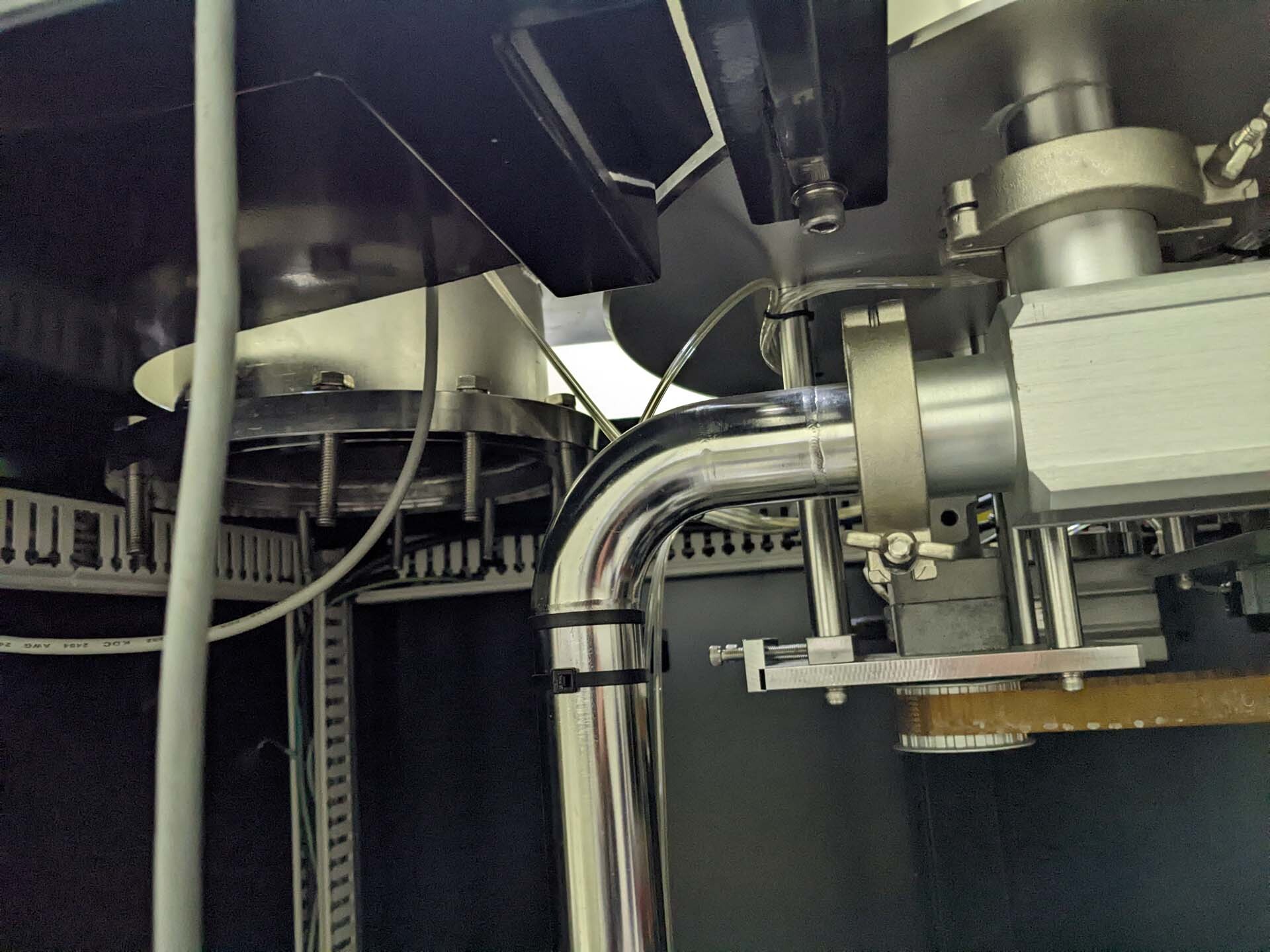

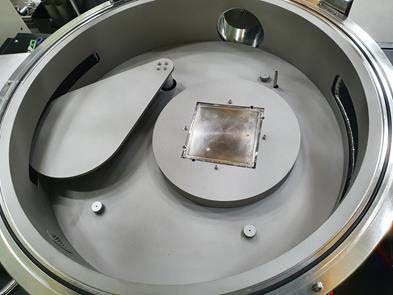

Sputter chamber:

Substrate size: 120 x 120 mm

SUS-304 Chamber type: Square, vertical

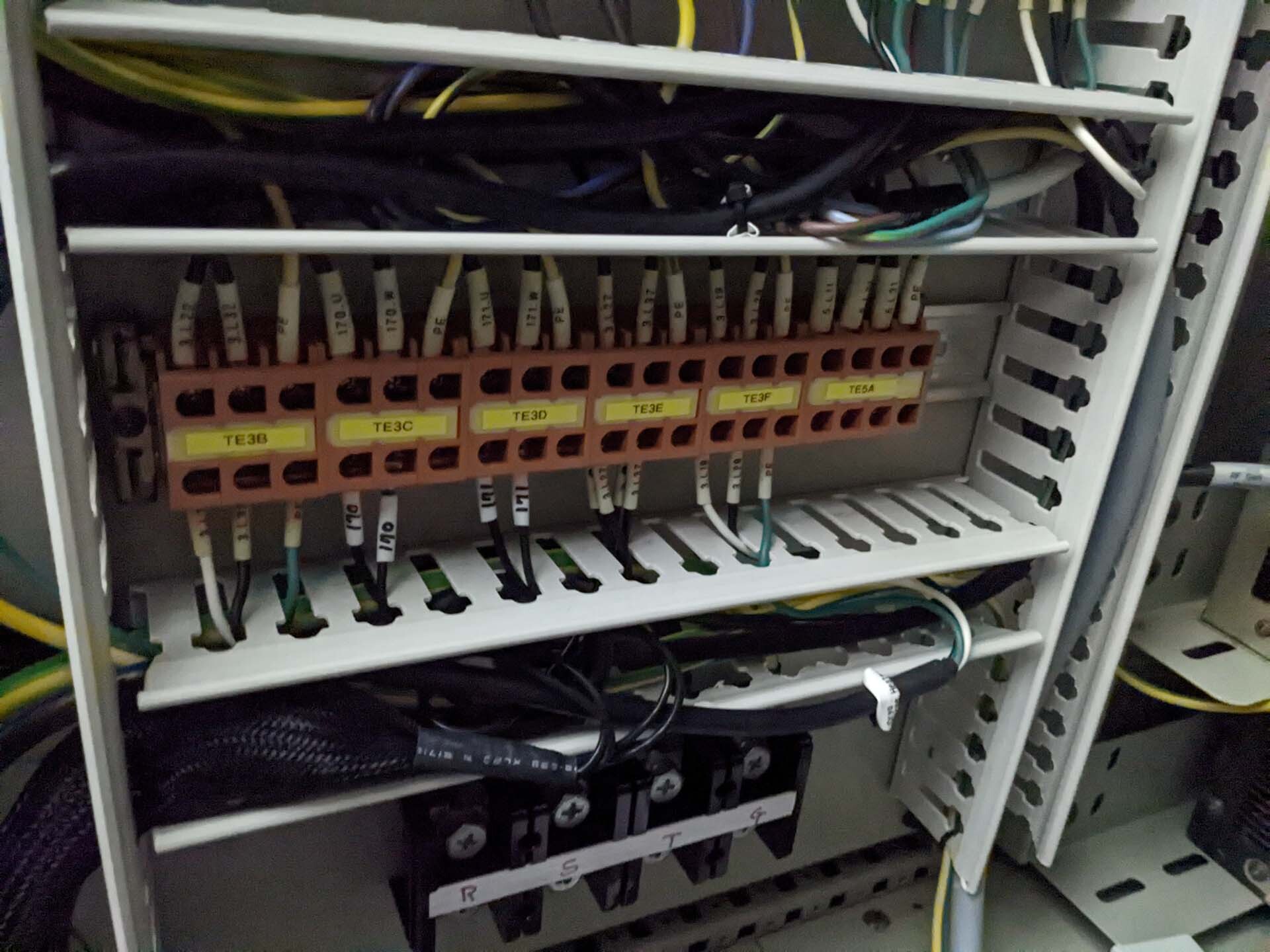

Substrate heater: Inner and outer heater

Substrate rotation speed : 5~10 RPM

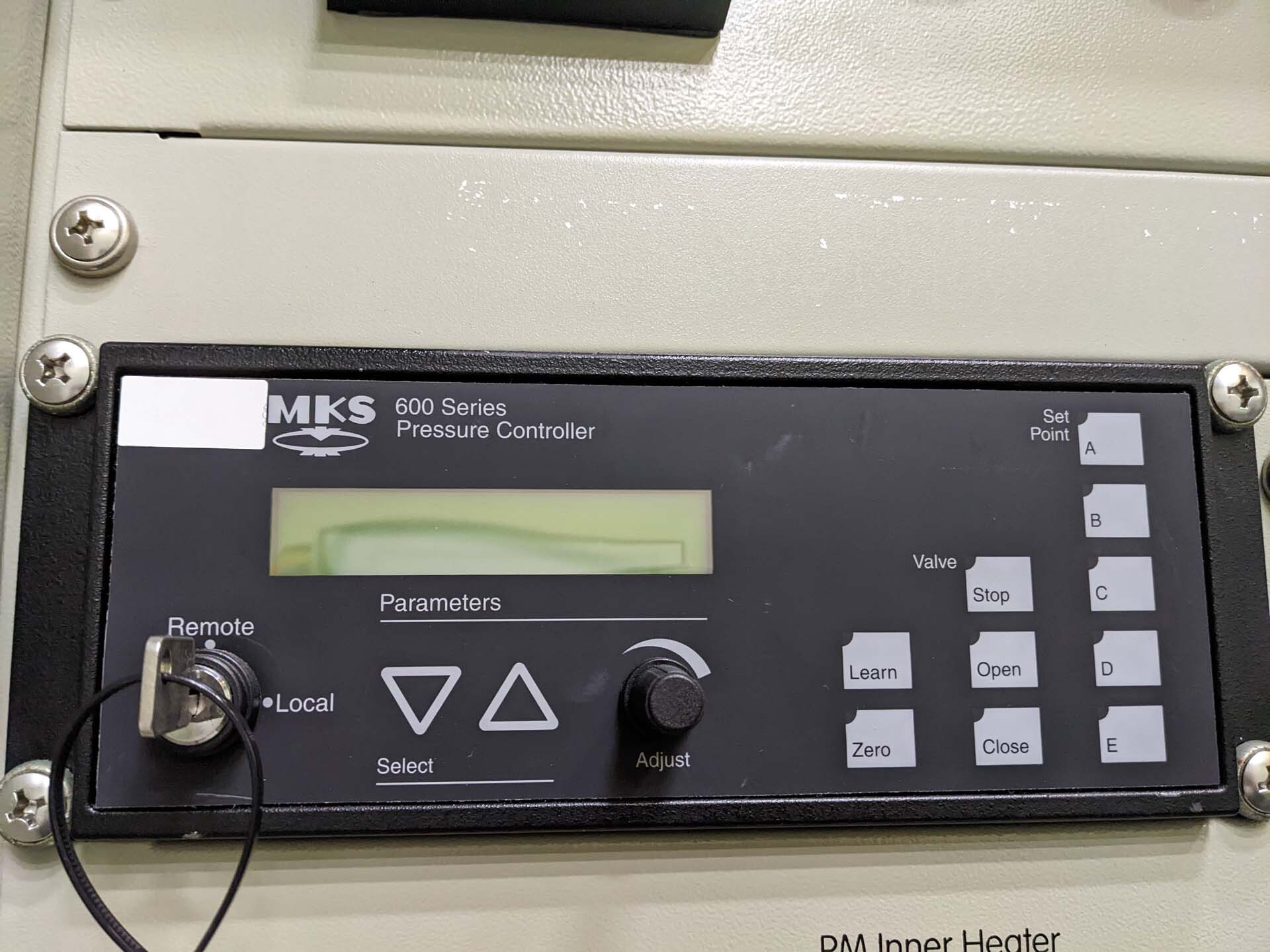

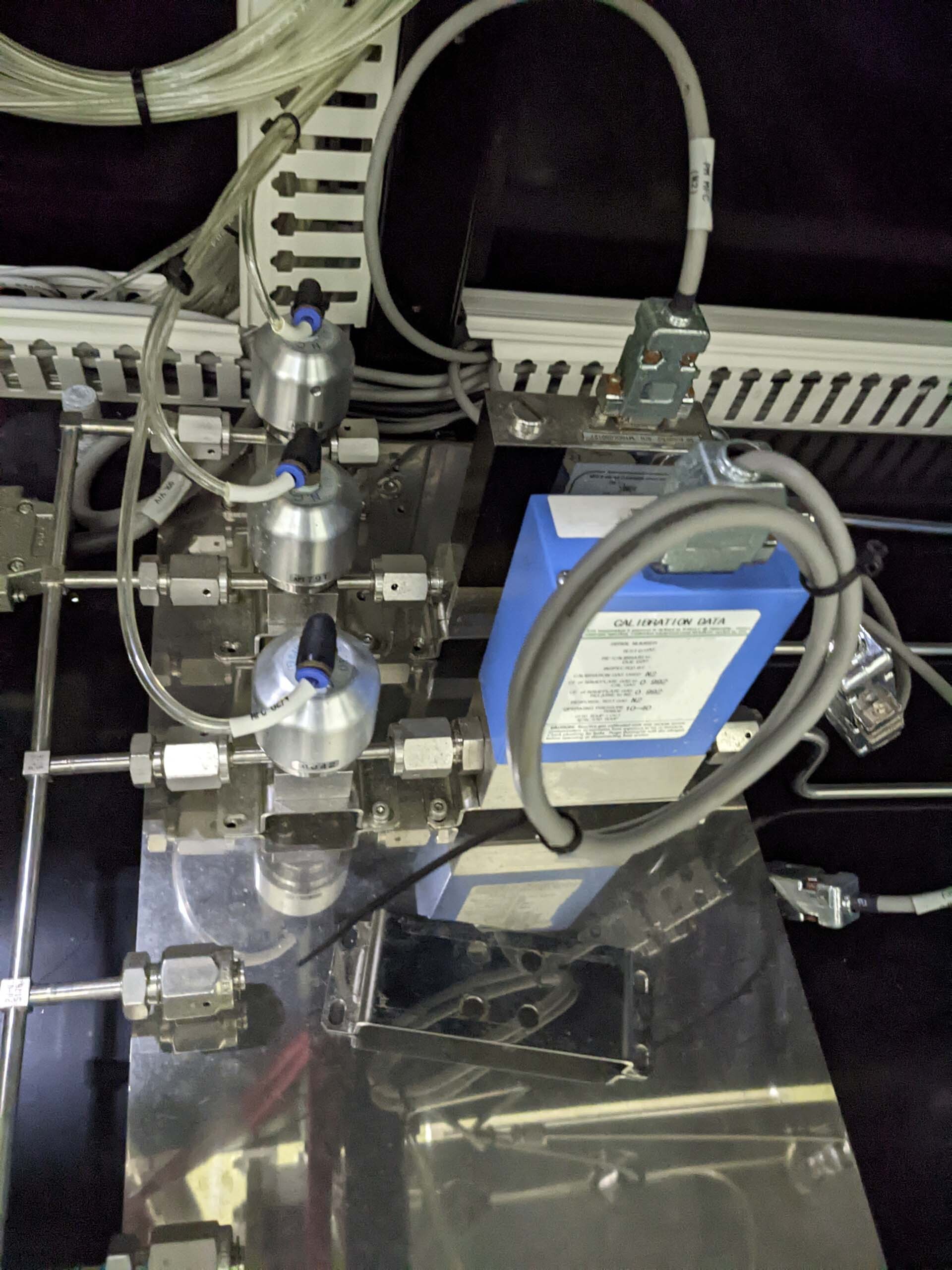

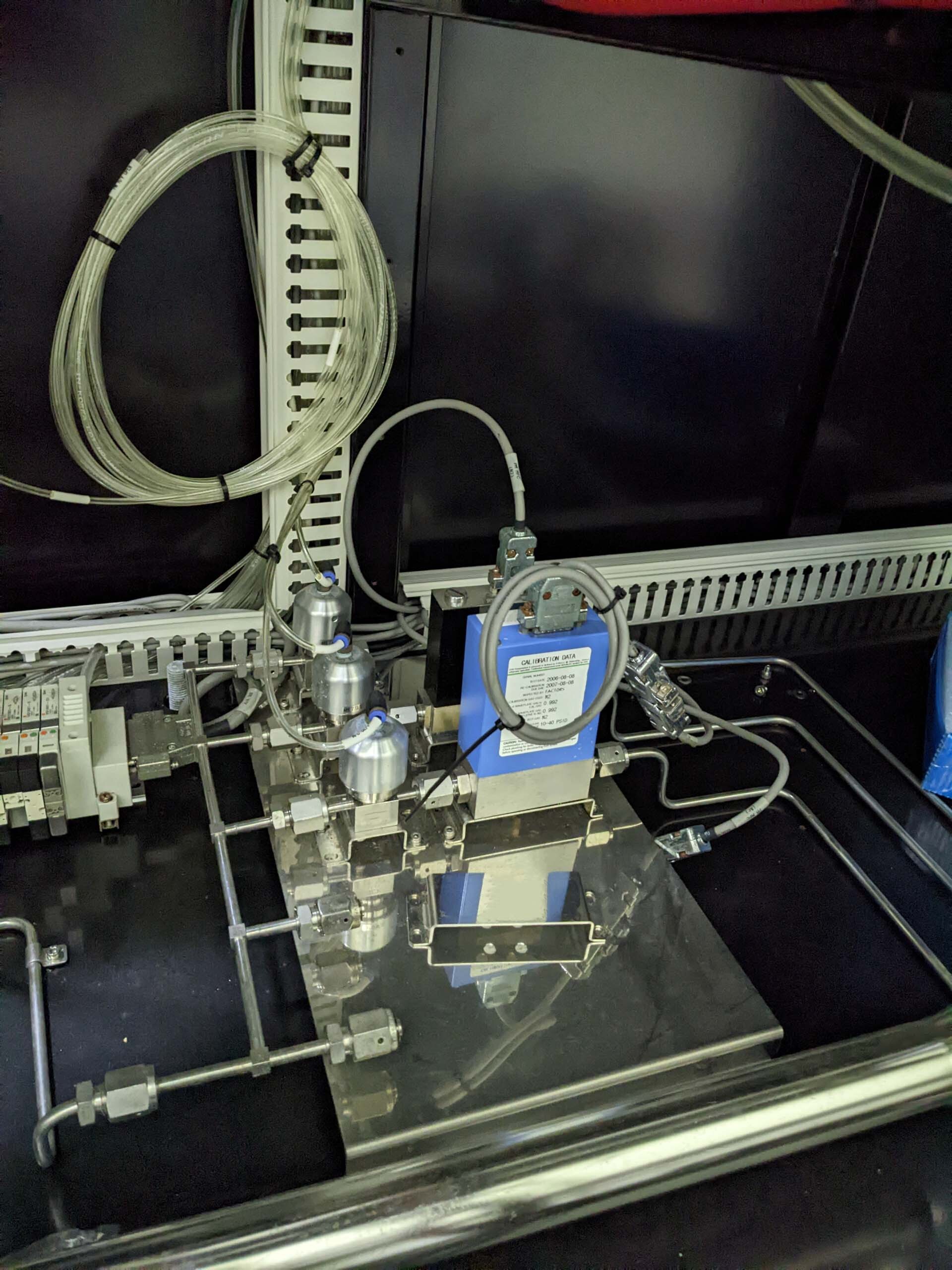

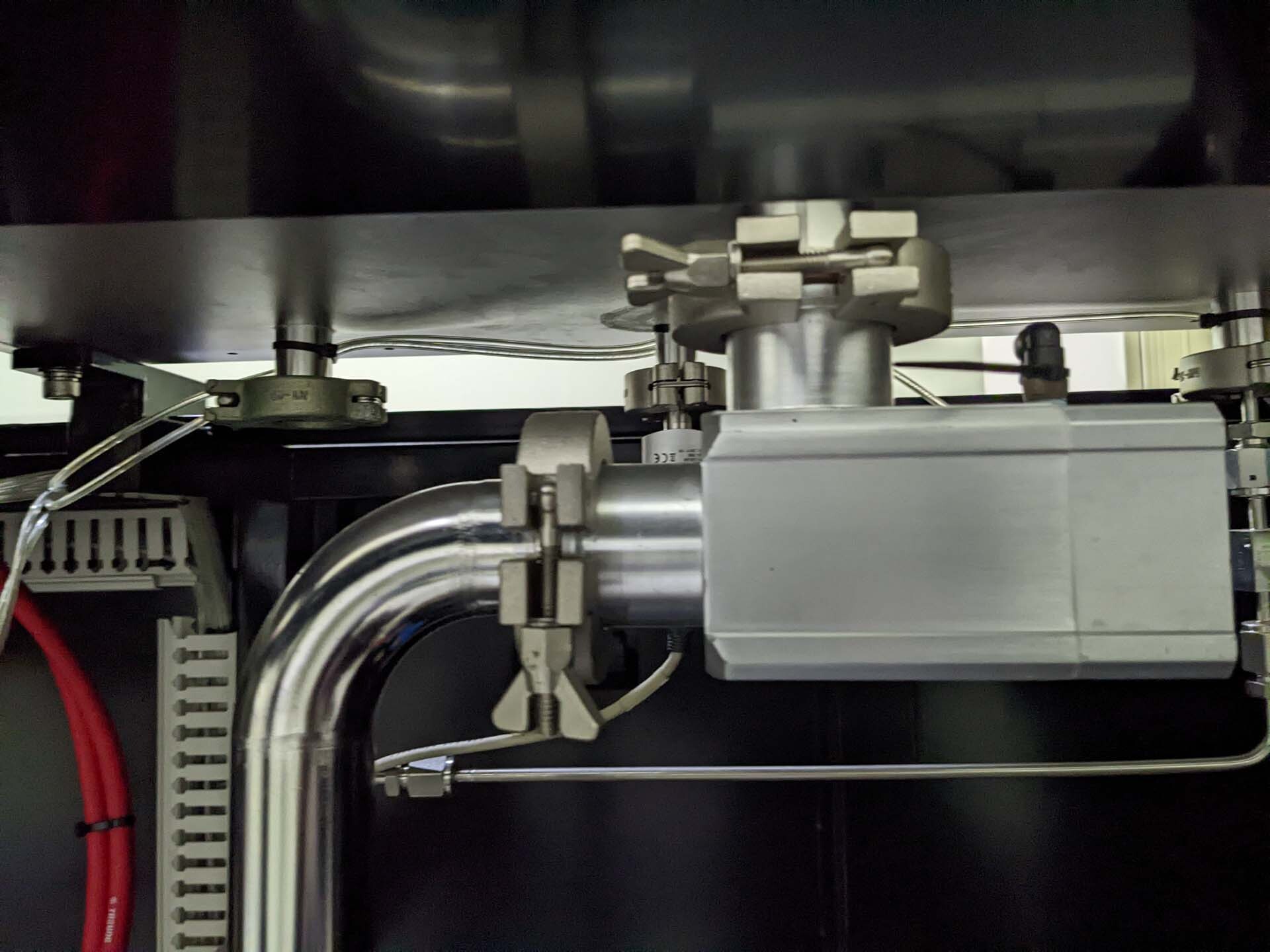

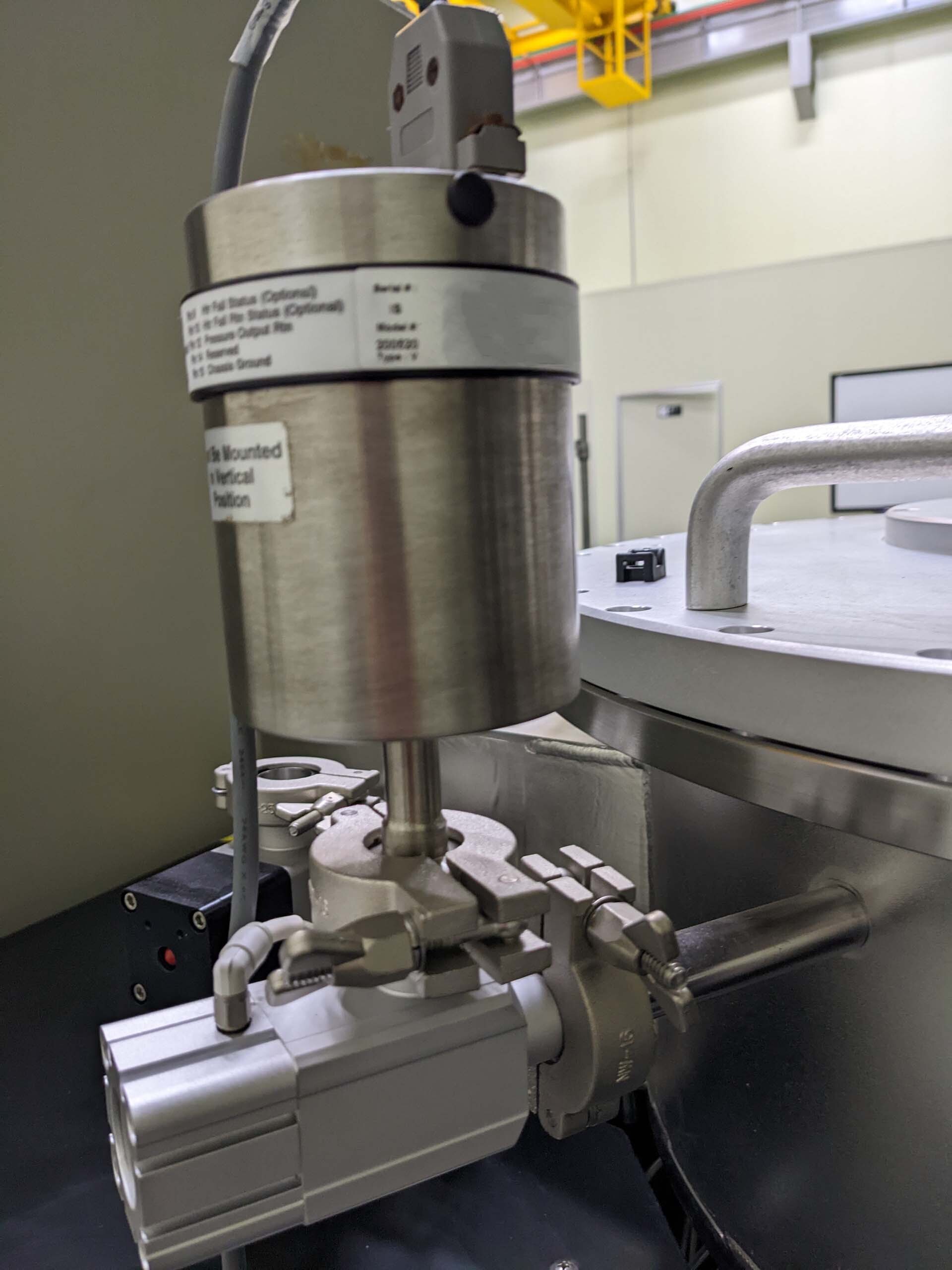

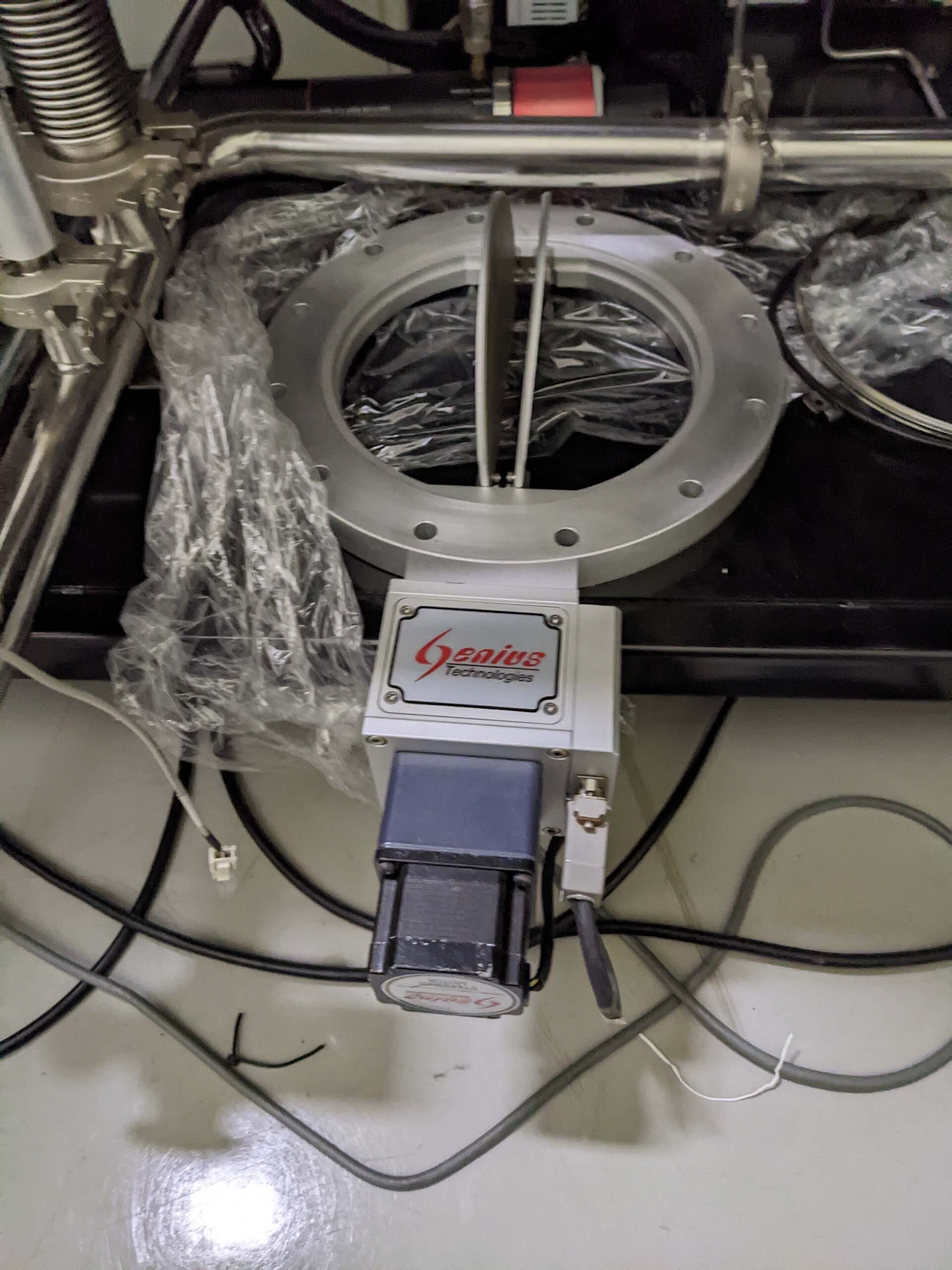

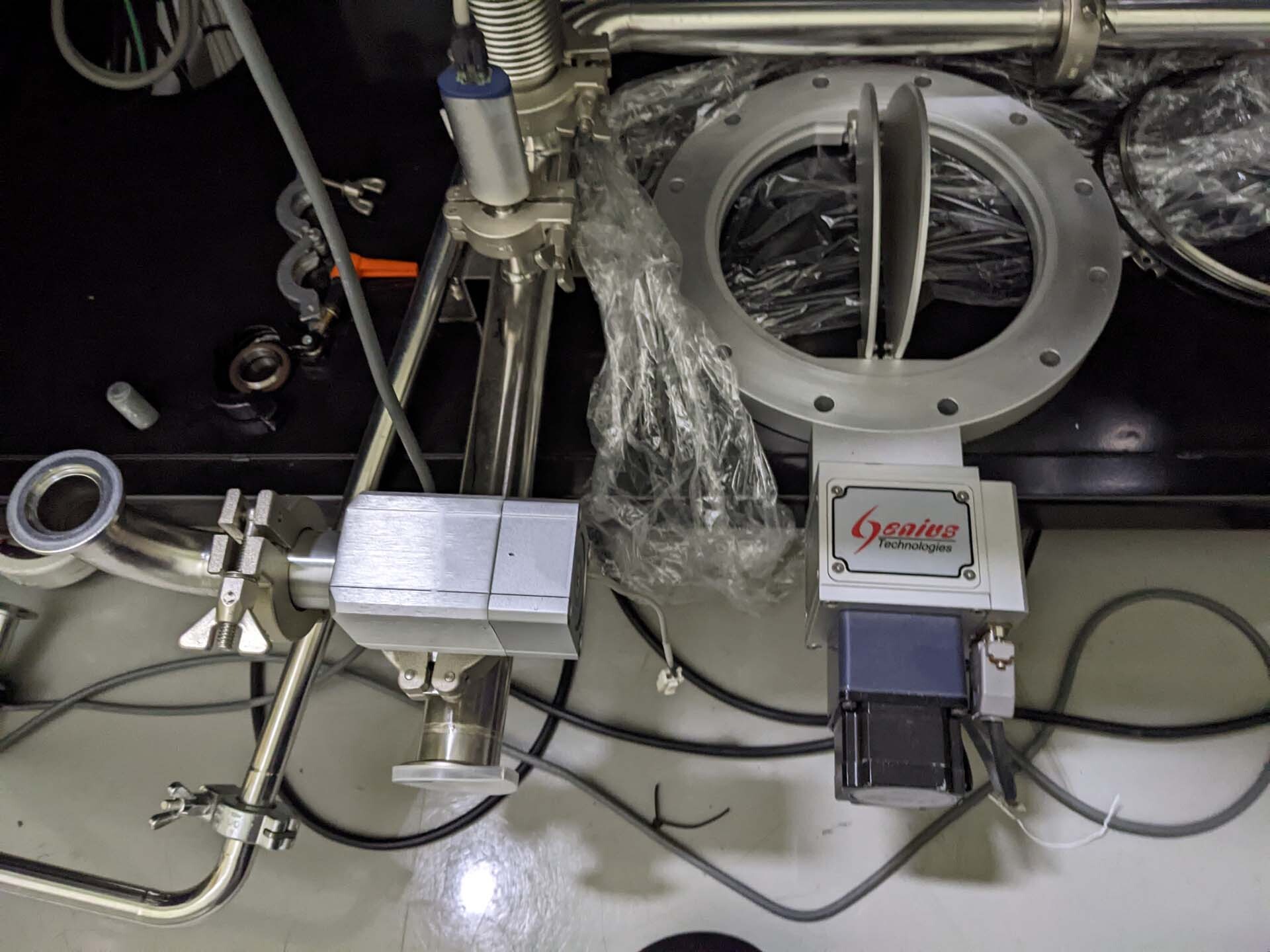

GENUIS Pressure control valve: Throttle valve, ISO 200

MKS Pressure control gauge: CDG gauge, 0.1 Torr

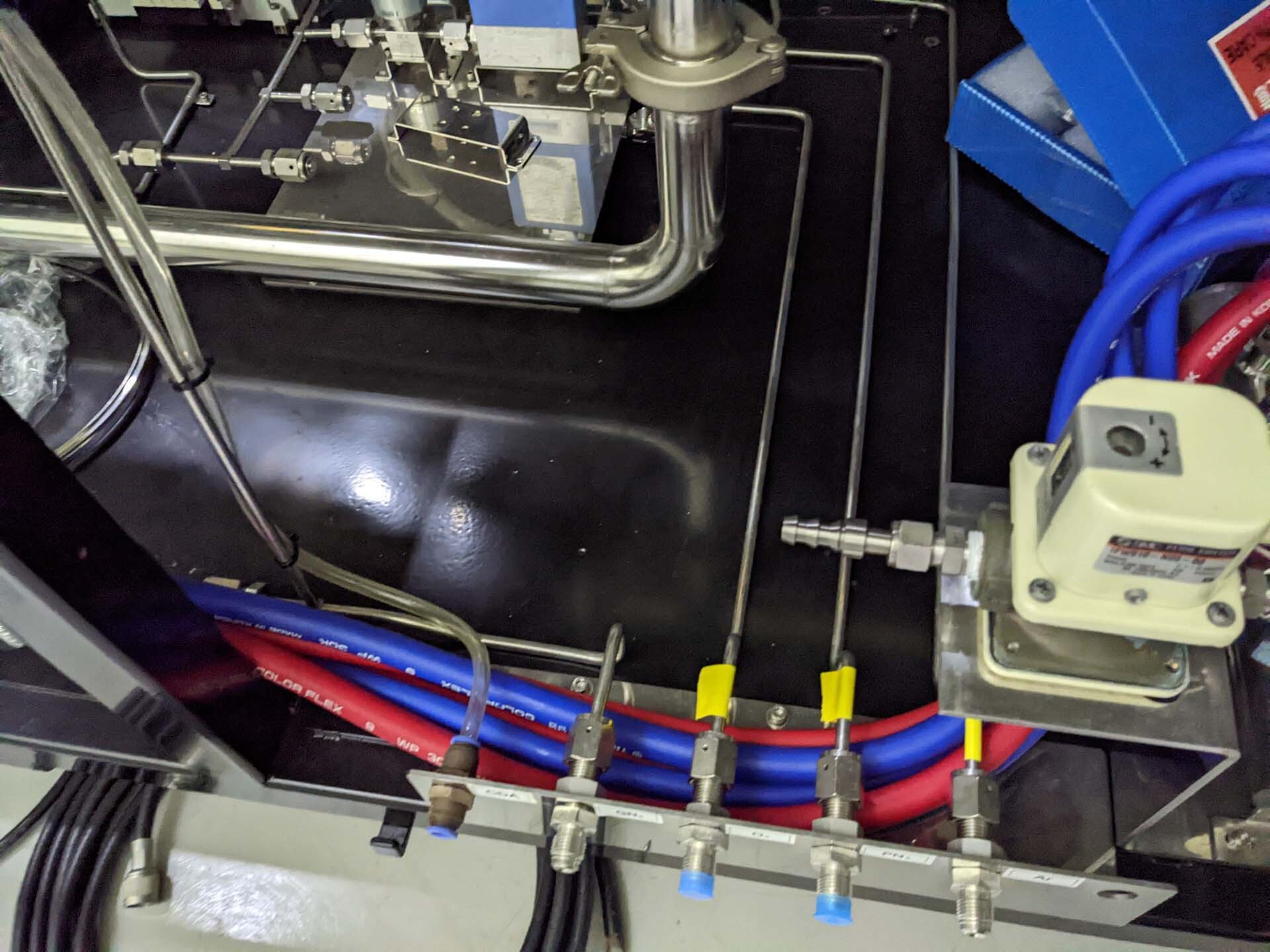

Process gases control, MFC: O2: 5 sccum, N2: 50 sccum

Low vacuum pump: Rotary pump

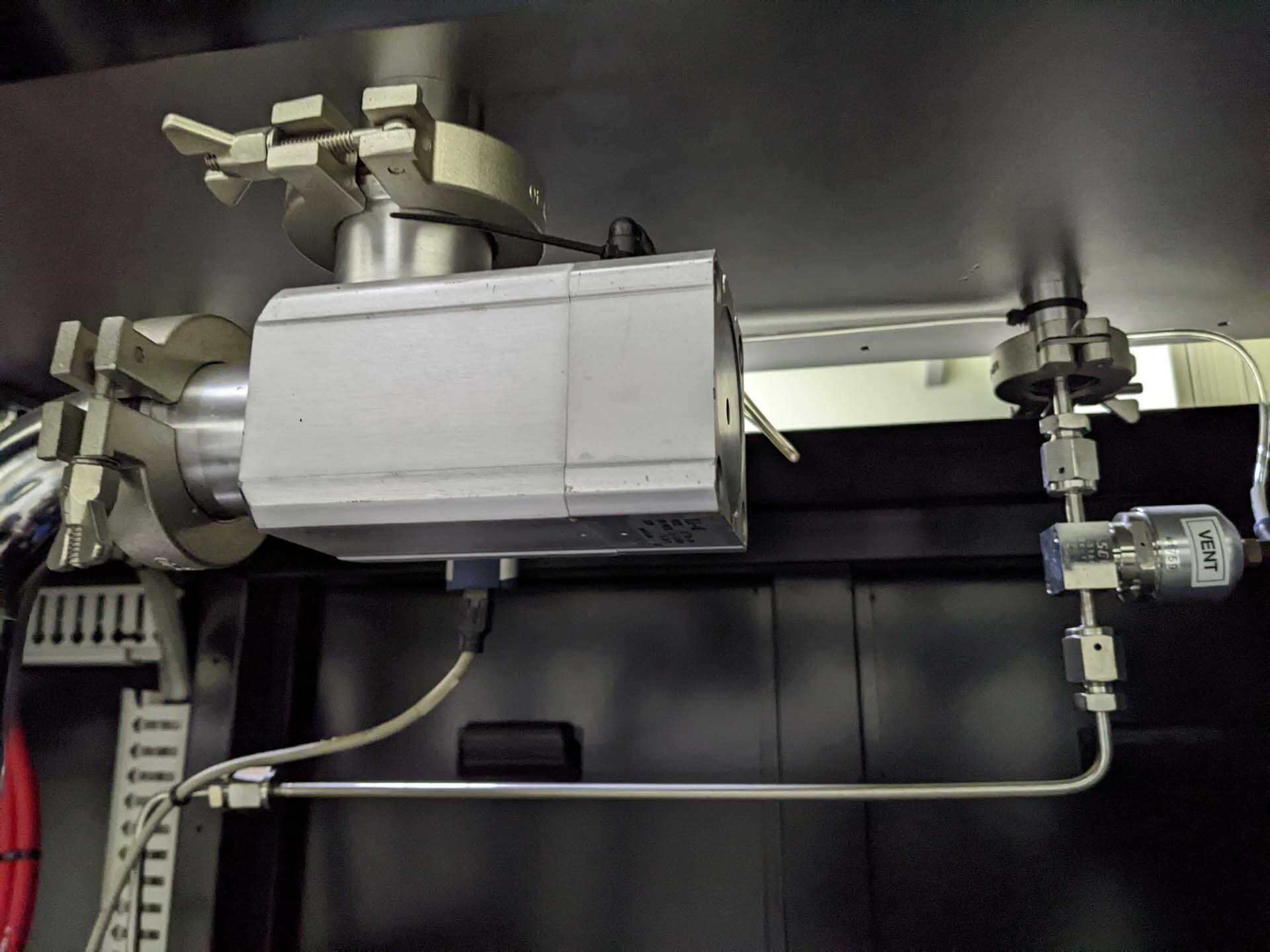

GENESIS Cryo / ISO 200 High vacuum

MGI ISO 200 High vacuum valve

INFICON Pumping line gauge: Pirani gauge

INFICON Chamber gauge: Full range gauge

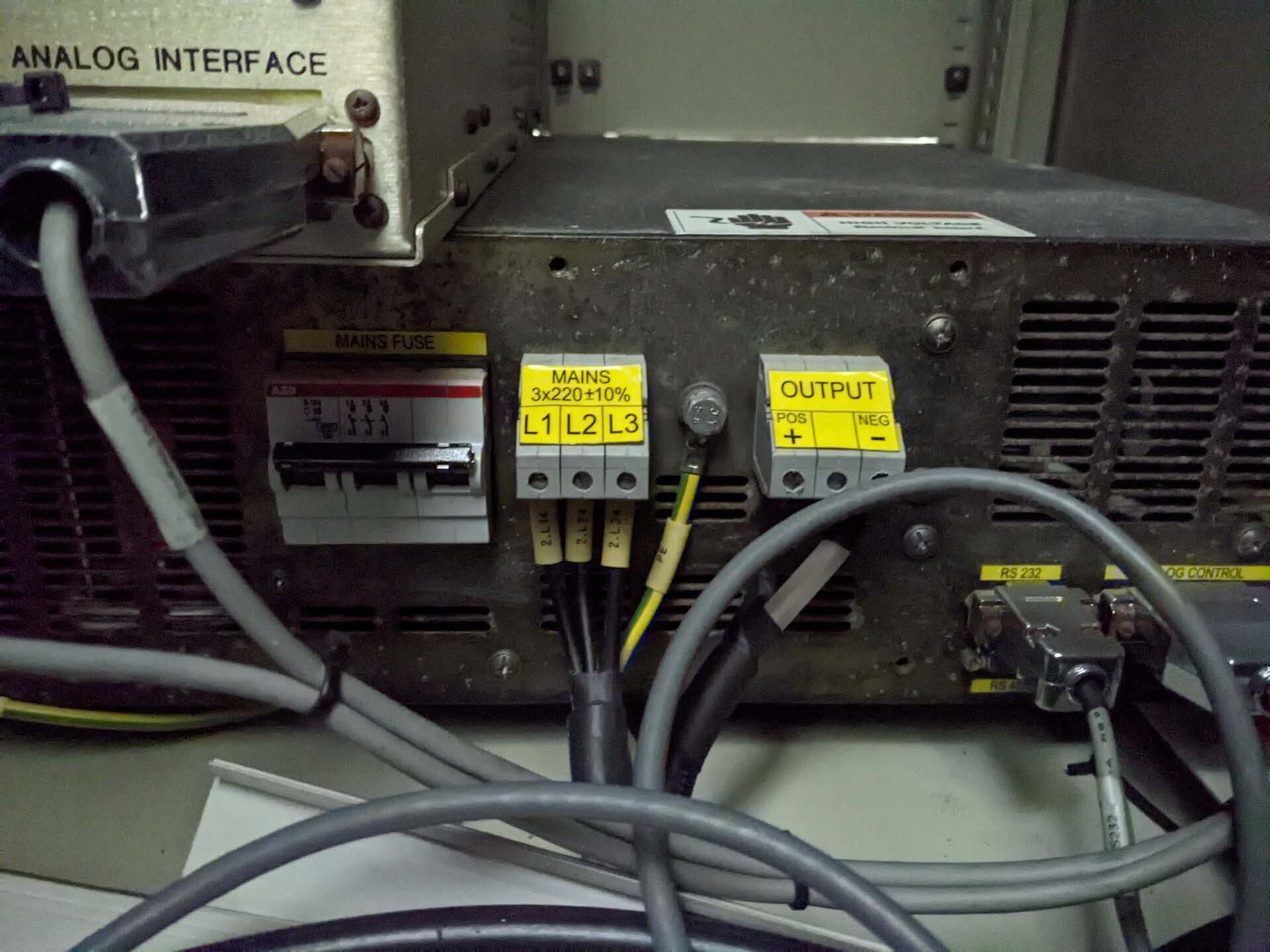

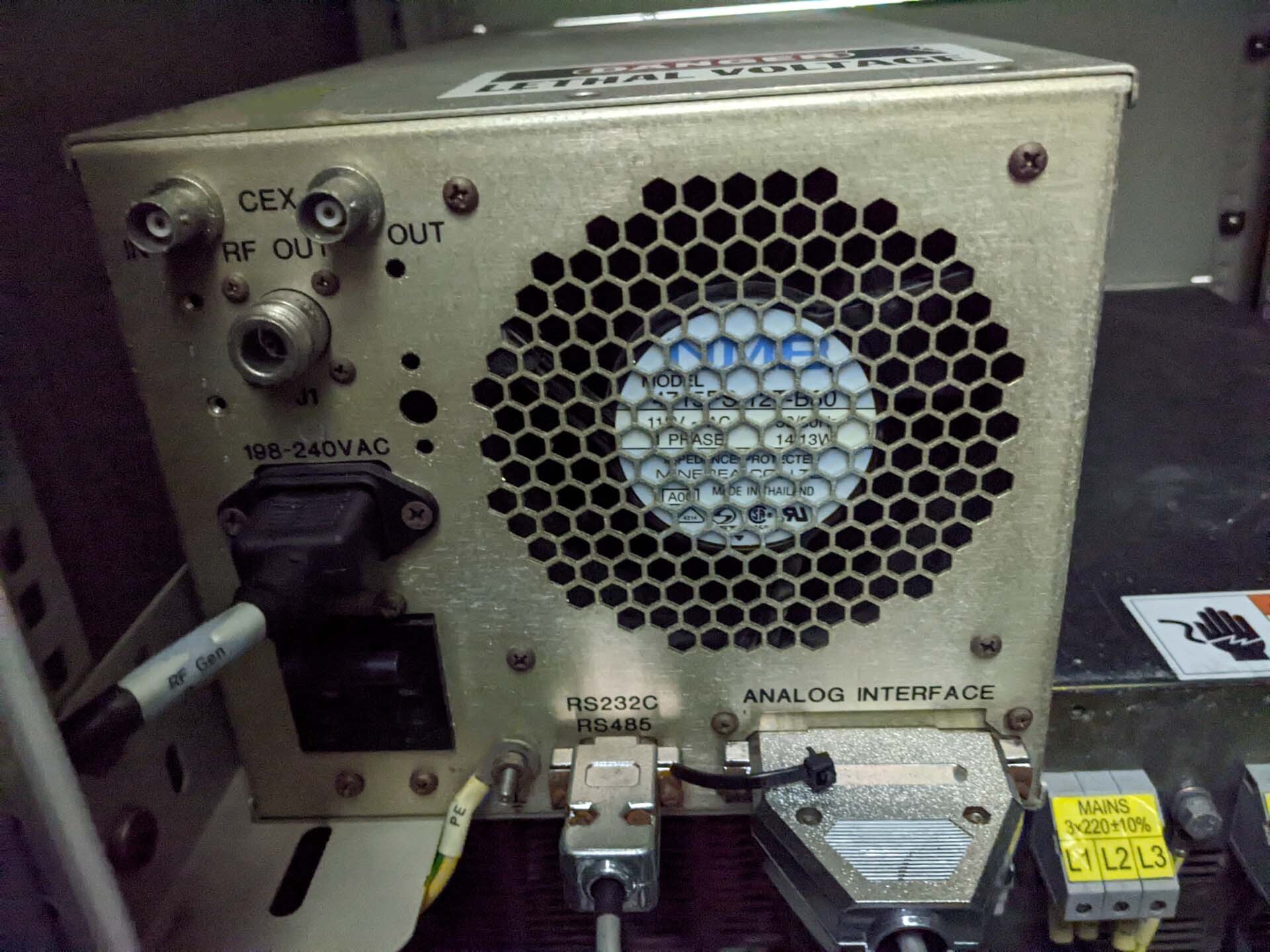

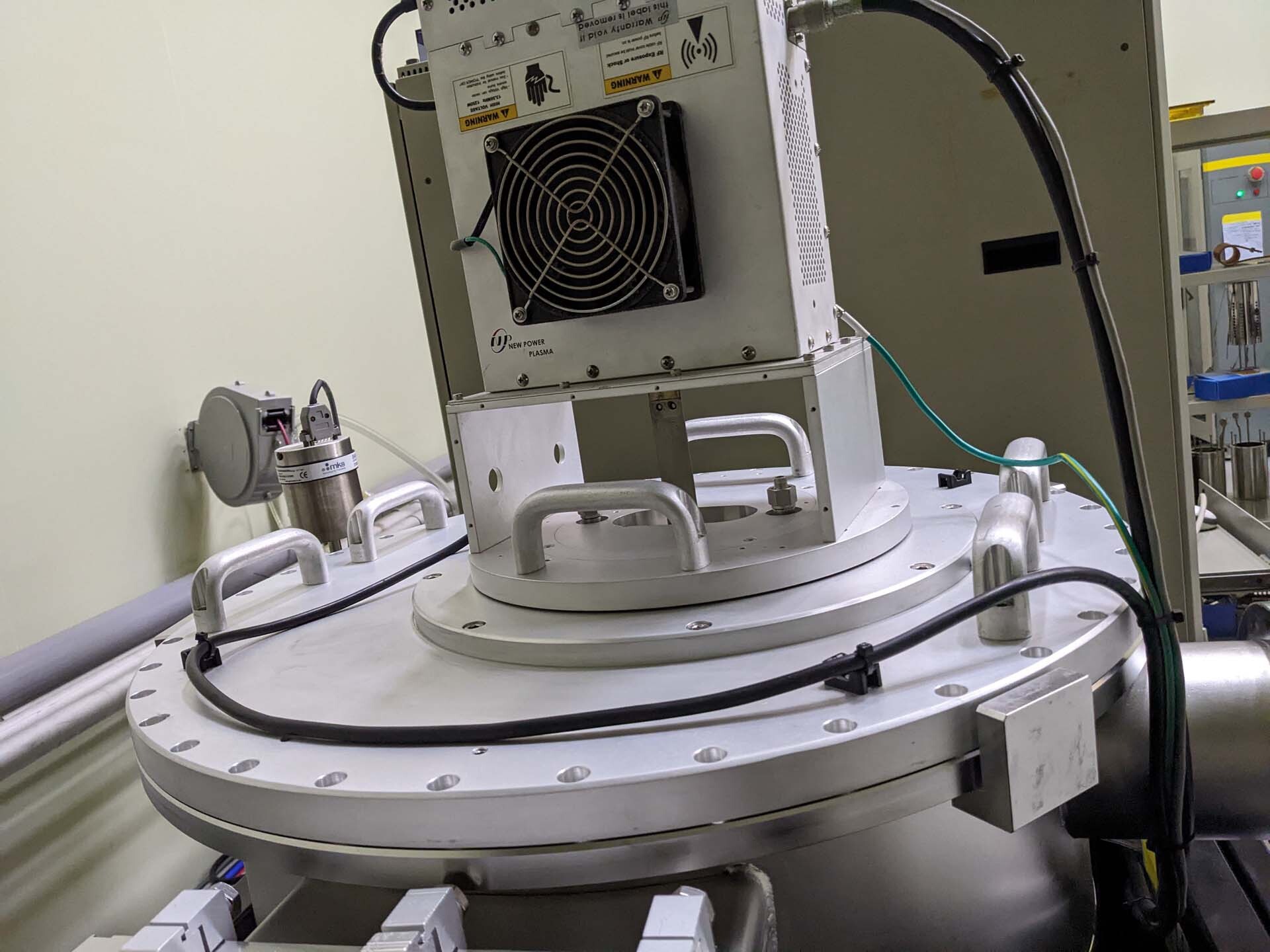

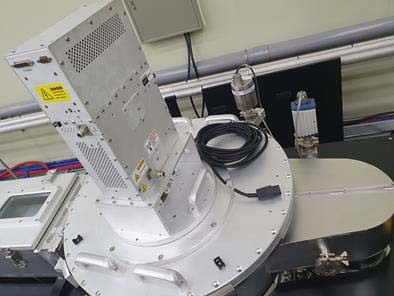

Plasma source unit:

IMS gun, 4"~6"

RFPP RF Power: 13.56 MHz, 500W

NP Power supply: 13.56 MHz, matching box

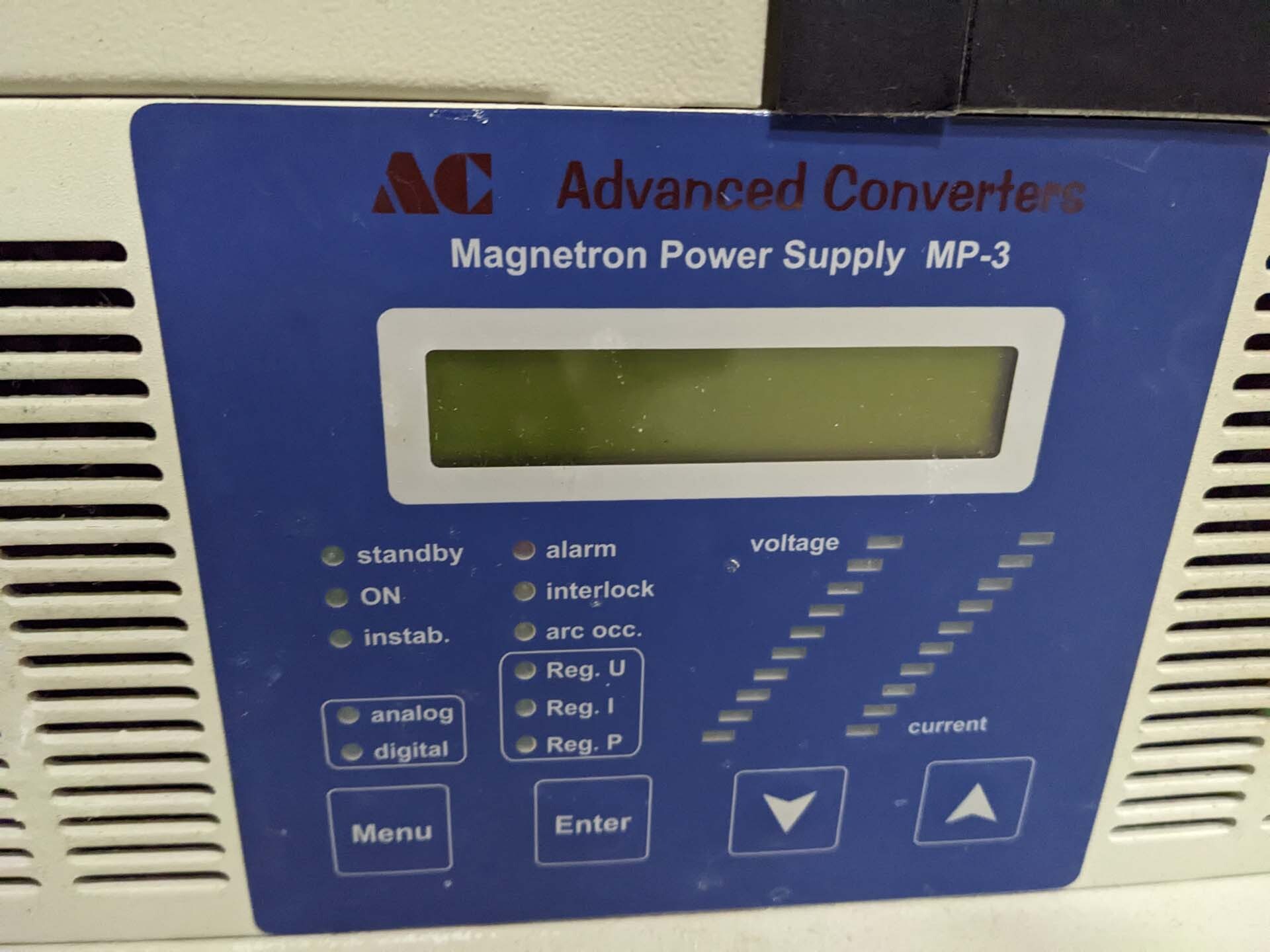

AC Magnetron DC supply: 3kQ

TS: 70 mm (Non variable)

Offset: 100 mm (Non variable)

Heating block: Φ220 / Substrate plate 120 x 120 mm

Substrate loading and unloading: Pin up / down

2006 vintage.

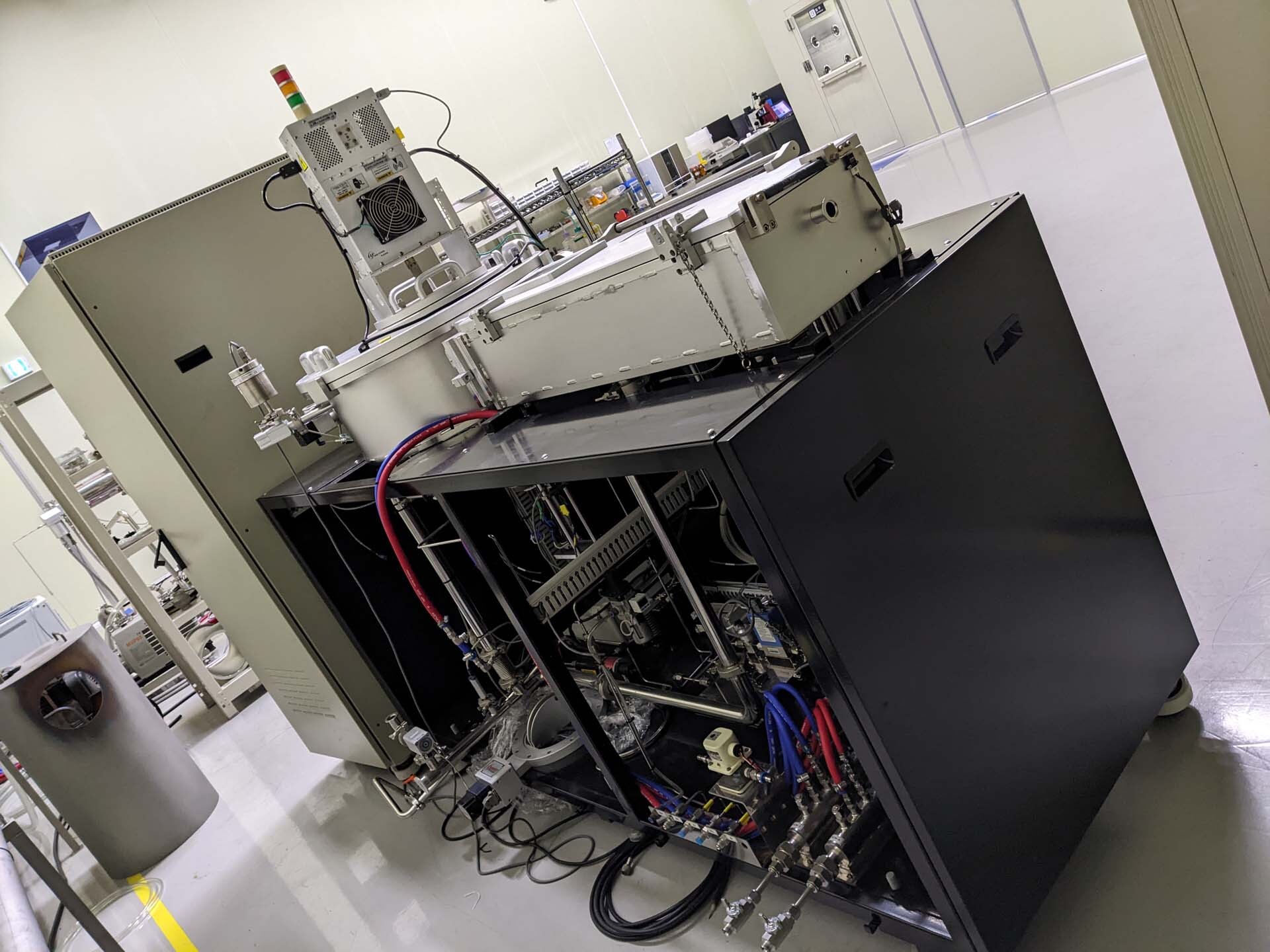

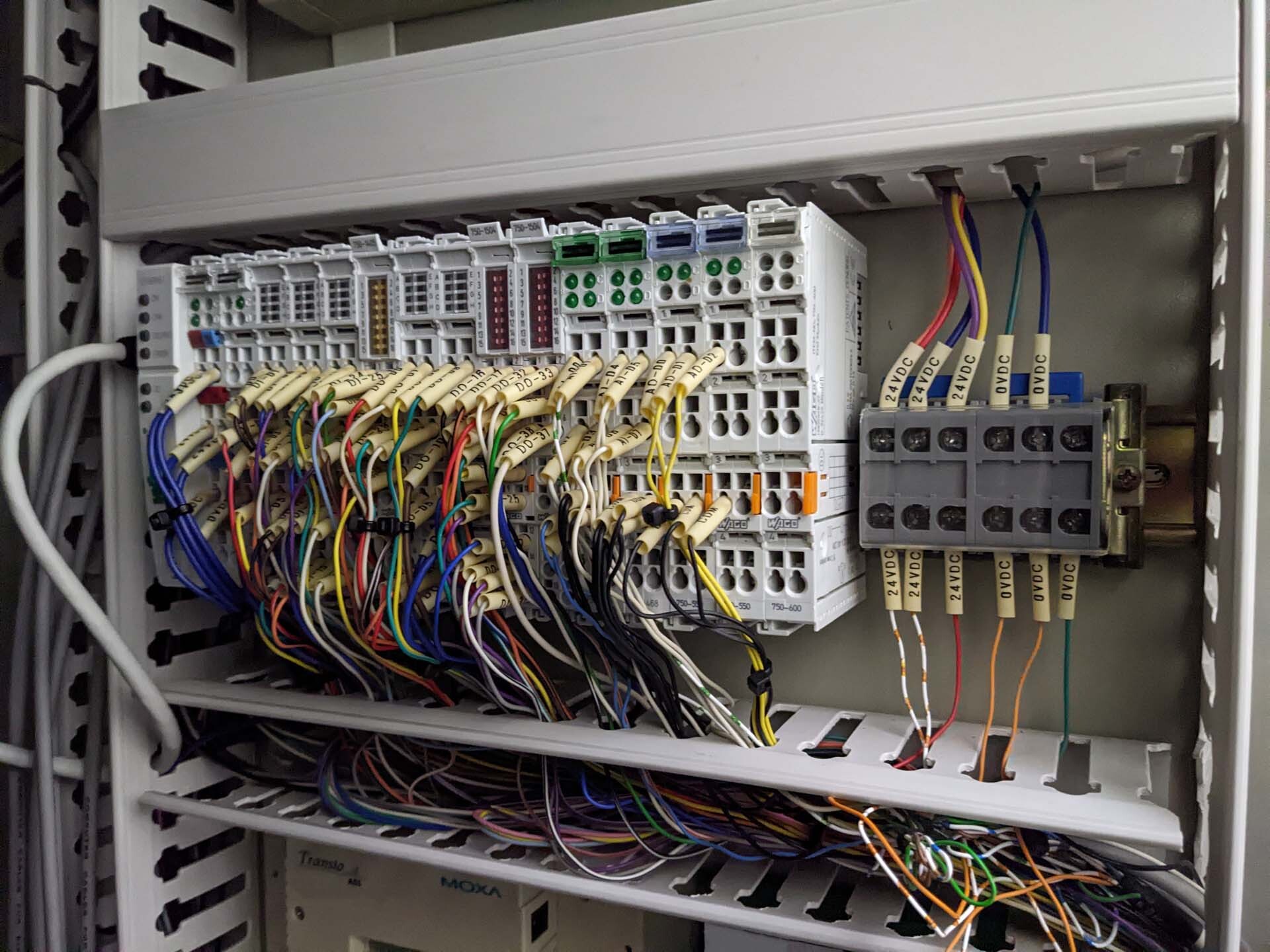

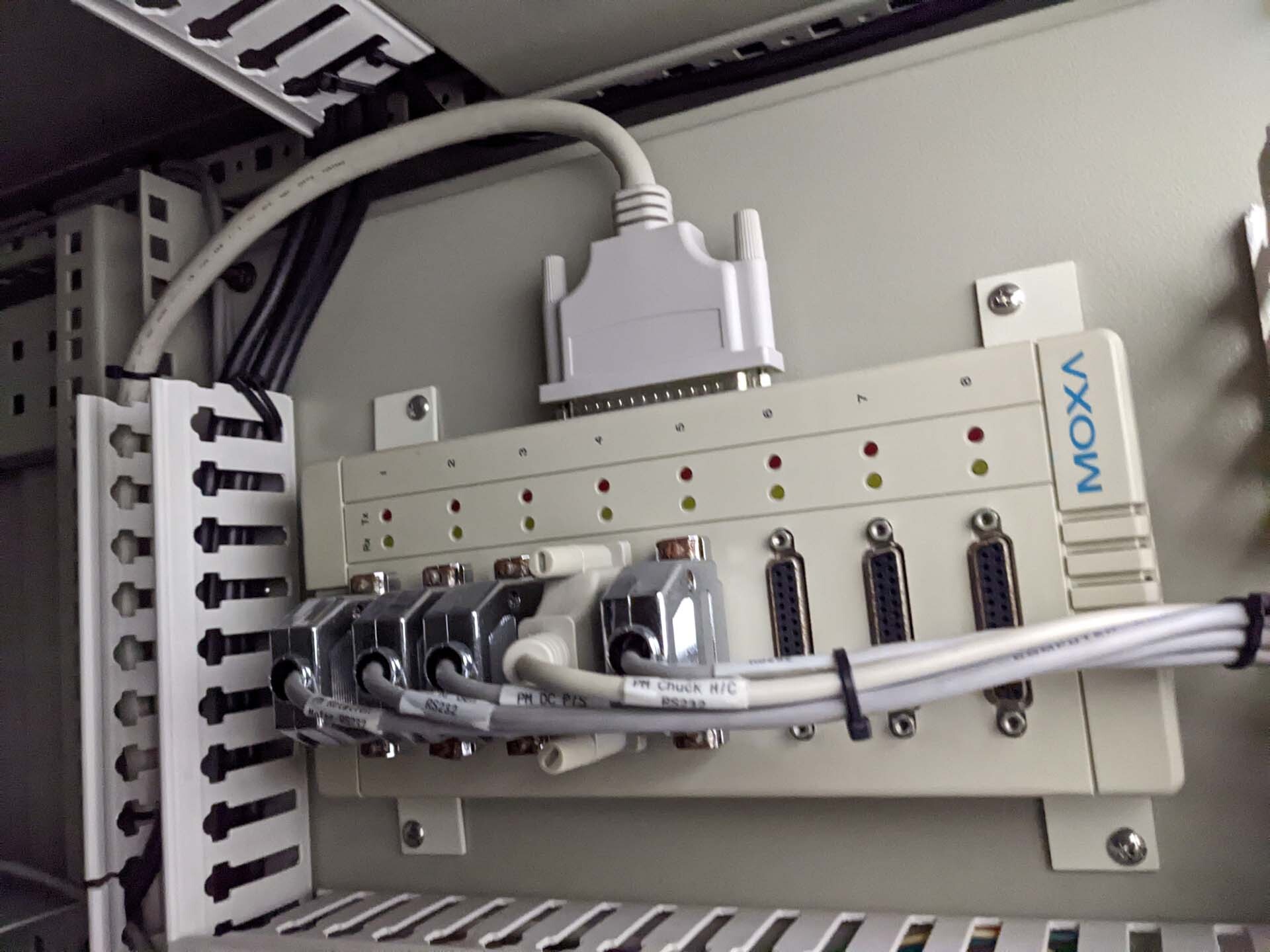

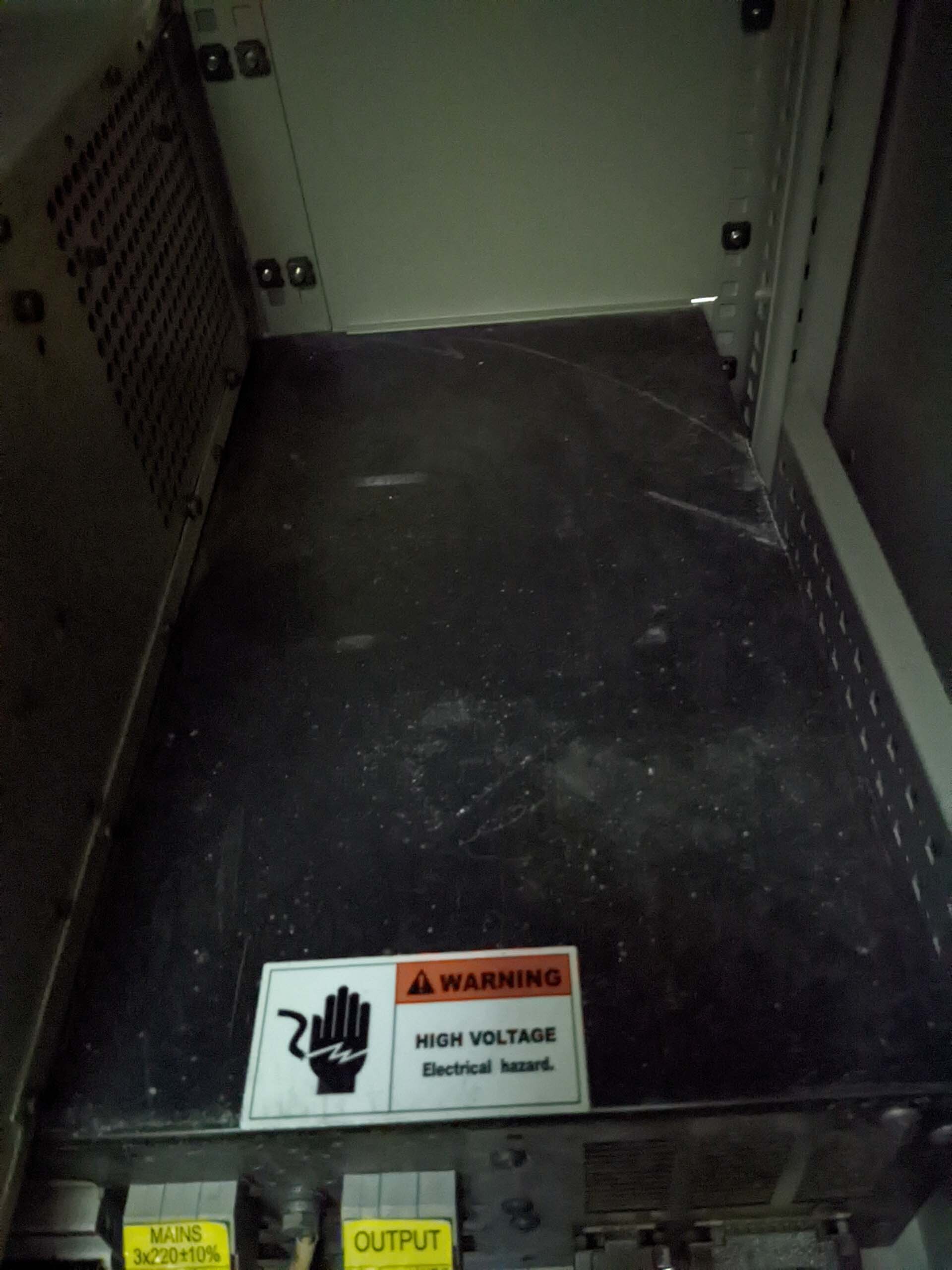

SUNIC NPM-1250PCA is a sputtering equipment designed for high performance thin film deposition of a variety of materials. This system utilizes high power pulsed DC magnetron sputtering technology in a single chamber, enabling two-sided coating of a wide range of substrates by two independent magnetic sources (cathodes). The sputter control unit, which allows for up to twelve different process steps and up to twelve programmable power settings, makes the machine versatile and reliable. The sputter rate can be adjusted over a wide dynamic range while the robot arm provides precise deposition rates and uniform coverage of surfaces. NPM-1250PCA tool is equipped with a PLC touchscreen controller that allows the operator to set and modify parameters such as sputtering power, sputtering rate and pressure, as well as to store up to ten user-defined profiles for accurate operation. The asset is designed to allow for simultaneous processing of up to eight substrates in a number of practical sizes, including rectangular, circular and square shapes. The model has a base pressure of 10-6 mbar and can be pumped up to a maximum of 10-2 mbar with a fast-acting diaphragm vacuum pump. The working chamber volume is 142 liters and the dimensions are 800 x 800 x 500 mm. The available process gases are Argon, Nitrogen and Oxygen and can be controlled through an automated gas flow-meter for precision deposition. The equipment is capable of depositing a wide range of materials, including metals, ceramics, semiconductors and oxides, with excellent optical and electrical properties. It is compatible with a variety of deposition techniques such as thermal evaporation, electron beam and oblique angle evaporation, sputter deposition and chemical vapor deposition (CVD). The system can also be used for PECVD and reactive ion etching to allow for a complete solution for advanced thin-film processing. SUNIC advanced cooling unit ensures stable and repeatable temperature control for the deposition materials, resulting in consistent and reliable film characteristics for performance-critical applications. Overall, SUNIC NPM-1250PCA sputtering machine provides an ideal platform for a wide range of thin film deposition and etching applications. Its unique features and reliability make it a suitable choice for creating high quality, precision products.

There are no reviews yet