Used SYSTEM CONTROL TECHNOLOGY / SCT VS-18C #9120860 for sale

URL successfully copied!

Tap to zoom

ID: 9120860

Wafer Size: 2"

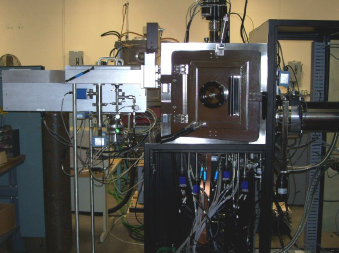

Sputtering system, 2"

Process gases: Ar

Inlet pressure: 10 psig

Flow rate: 100sccm

Compressed air:

Inlet pressure: 70-120 psig,

Flow rate: minimal amounts, intermittent

Gaseous nitrogen

Inlet pressure: 10 psig

Flow rate: 10cfm

Cooling water:

Inlet pressure: 40 psi (minimum differential)

Fitting: 3/4”NPT Female

Flow rate: 6 GPM

Temp: 25°C (Max 40°C)

Resistively: 2500 ohms/cm or higher at 25 deg C

Solid content: <250ppm

pH value: between 7 and 9

Total chlorine: <20ppm

Total nitrate: <10ppm

Total sulfate: <100ppm

Total hardness expressed as calcium Carbonate equivalent: <250ppm

Total dissolved solids: ≤ 640,000 / Specific resistivity (ohms/cm)

Exhaust:

Roughing pump

Pressure: <ATM pressure

Fitting: ISO-63 for Leybold dry pump

Flow rate: 150cfm for Leybold dry pump

380 V, 3 phase, 50 Hz, > 30 amp, 5 wires including neutral and low “Z” ground.

Equipment CONTROL TECHNOLOGY / SCT VS-18C is a high power cathode sputtering system designed for use in a variety of vacuum and physical vapor deposition applications. This sputtering unit uses a direct current (DC) magnetron source to produce vaporized coating materials which adhere to the substrate material. The machine comprises of a compact and sealed deposition chamber that consists of the cathode, anode and polarity switch. It further includes a controller unit, high-pressure chamber port and a 25 mm heated substrate holder capable of reaching temperatures up to 1000 degrees Celsius. SCT VS-18C comes with an optional Controller Unit that provides full tool control, monitoring and storage of up to 16 individual recipes. This asset is rated for a vacuum range of 100 mTorr to about 10 Torr, with ultimate vacuum pressure of 0.5 Torr. As a function of DC power, the deposition rate can be adjusted between 0.01 and 10 nm/s, ideal for creating thin films with uniform surface and microstructures. Other adjustable parameters range from source to substrate distance, target material, substrate holder heat and rotational speed, to name a few. Model CONTROL TECHNOLOGY VS-18C provides a choice of five different shaped targets with sizes ranging from 2" to 10" allowing users to select the optimum target for their applications. Additionally, this sputtering equipment comes with an optional high-pressure chamber port which enables the deposition of materials at levels up to 2bar. The substrate holder and lift come with full range of sensors and automated controls to ensure safe operation of the system. VS-18C unit is designed for use in a variety of research and development applications including metal alloys depositions, thin film resistors, X-ray imaging, and other nano-scale device fabrication. It also has wide application in aerospace and industrial sectors that require intricate layer deposition or high-integrity seals. Machine CONTROL TECHNOLOGY / SCT VS-18C is robust, versatile and capable of continuous open-ended operation to support a wide range of high-performance thin film materials. With its advanced capabilities, SCT VS-18C is a great solution for those looking for precision and high rate of deposition.

There are no reviews yet