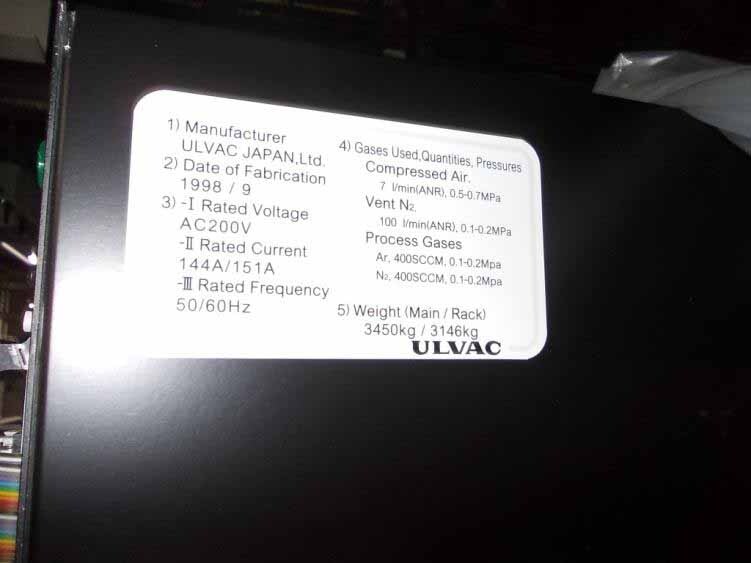

Used ULVAC CERAUS ZI 1000 #9378914 for sale

URL successfully copied!

Tap to zoom

ID: 9378914

Wafer Size: 8"

Vintage: 1998

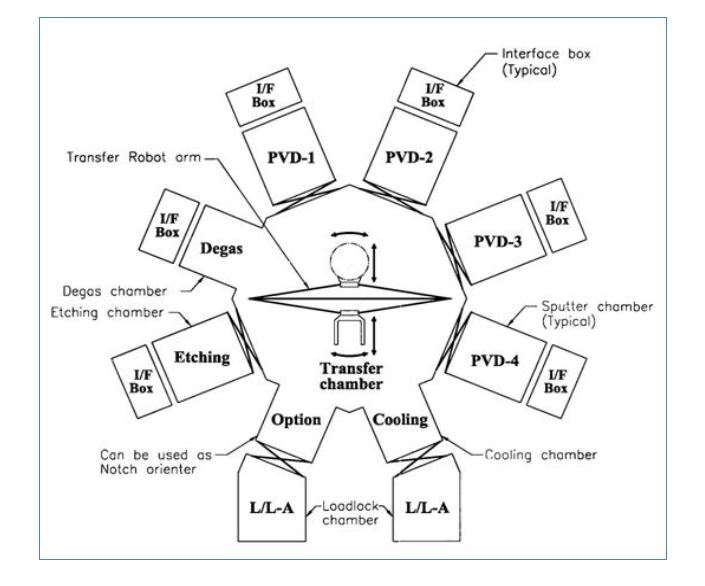

Sputtering system, 8"

CIM: SEMI Auto to CTC

Sputter Zi (LTS with sputter etcher)

PF

(6) Chambers

Transfer, LLA And LLB Chamber

P1 - ICP Etcher

P2 - Degas

P3 - ICP Etcher

P4 - LTS (Ti/TiN)

P5 - LTS (Ti/TiN)

P6 - LTS (Ti/TiN)

Loadlocks:

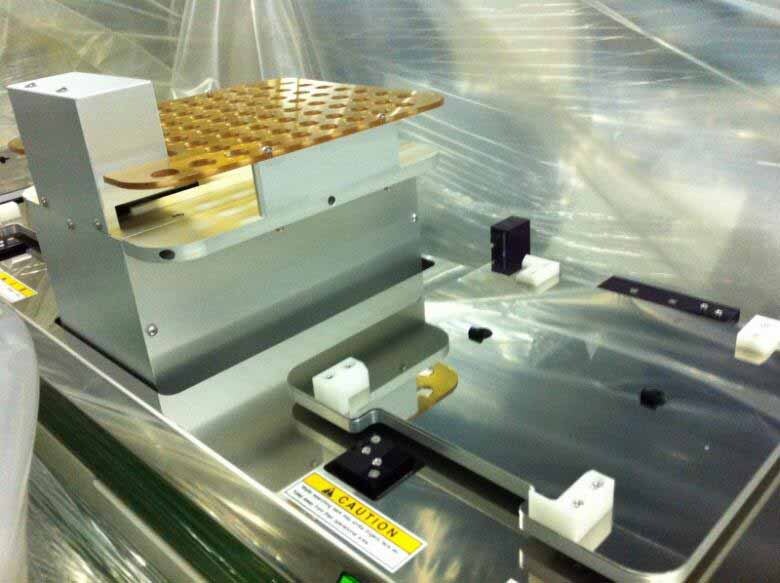

LLA VCE4, (30) Metal stocker slots

LLB VCE4, (30) Metal stocker slots

Hardware configuration:

Chamber 1: ICP

Chamber 2: Degas

Chamber 3: ICP

Chamber 4: LTS

Chamber 5: LTS

Chamber 6: LTS

In-aligner

In-cooler

Mainframe: BROOKS M800

Wafer mapping: Standard

Transfer MAG 7.1 Robot

Transfer armset MAG 6

3-Axis Bi-symmetric dual frogleg

ULVAC C30ZR Helium compressor

RISSHI CS-1700H Chiller

Handler System

Cables

Metal cover

Power supply rack

Computer with rack

Pump

Front panel

Raise platform & accessories

Process:

Chamber 1: Etch

Chamber 2: Degas

Chamber 3: Etch

Chamber 4: Ti/TiN dep

Chamber 5: Ti/TiN dep

Chamber 6: Ti/TiN dep

Wafer notch alignment

Cooler

Generators:

Chamber 1: DC 1, DC 2, ULVAC RFS05C, RF, AC Bias

Chamber 2: DC 1, DC 2, RF, AC Bias

Chamber 3: DC 1, DC 2, RF ULVAC RFS05C, AC Bias

Chamber 4: DC 1 KYOSAN, DC 2, RF, AC Bias, HPK15Zi

Chamber 5: DC 1 KYOSAN, DC 2, RF, AC Bias, HPK15Zi

Chamber 6: DC 1 KYOSAN, DC 2, RF, AC Bias, HPK15Zi

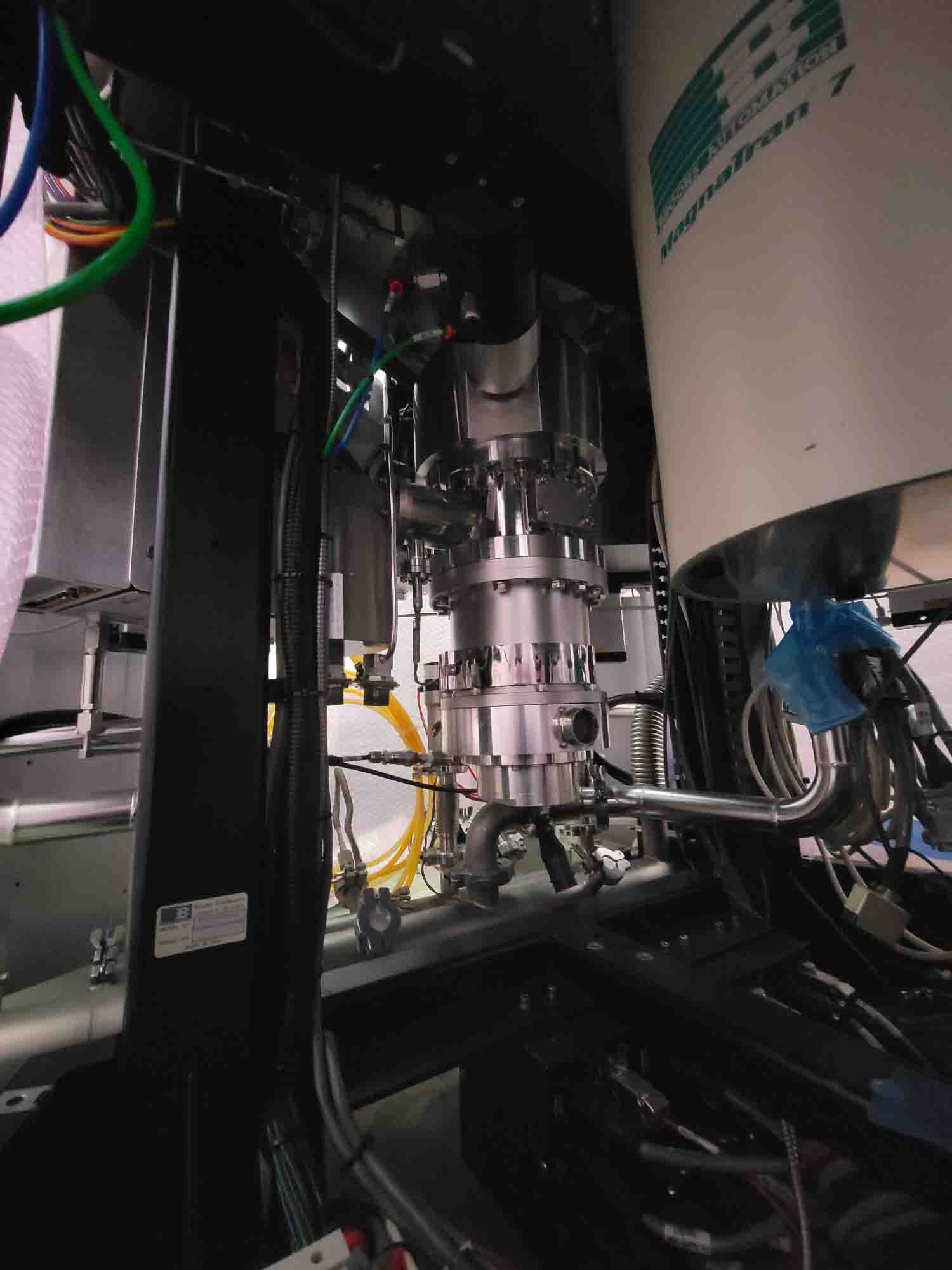

Turbo pumps:

SHIMADZU 303LM

SHIMADZU 303LM

SHIMADZU 403LM

SHIMADZU 1003LM

SHIMADZU 1003LM

SHIMADZU 1003LM

SHIMADZU 1003LM

SHIMADZU 1003LM

1998 vintage.

ULVAC CERAUS ZI 1000 is a sputtering equipment made by ULVAC (Ultra-Low Vacuum Apparatus Corporation), a leading high-tech manufacturer of vacuum coating equipment. This system uses a ceramic target and an ionized inert gas such as Ar or He to coat a wide variety of materials with a layer of desired material. The target is placed in a vacuum chamber, and ions are accelerated toward the target by a powerful modulated voltage source. The collision of the accelerated ions with the target creates an atmosphere of nano-sized particles, allowing the coating material to adhere to the observed substrate in a precise manner. ULVAC CERAUS ZI-1000 offers unique performance features that make it stand out from other sputtering systems. Its advanced temperature control unit allows for precise temperature control and stable operations, even during prolonged operations. This helps to ensure that the coating is consistent throughout the process. It also features a pre-ignition machine, which reduces start-up times and improves efficiency. The tool is designed to provide uniform deposition of the coating material, with high uniformity and excellent particle density across the entire substrate. CERAUS ZI 1000 has an integrated vacuum asset, which allows for low pressure deposition. This model has a maximum vacuum of 1 x 10-3 Torr, which enables the coating material to travel in a more efficient straight line towards the substrate, allowing greater control over the coating thickness. It also features water and safety interlocks and a laser obstructs to ensure safety. CERAUS ZI-1000 is capable of providing excellent results in all types of reactive sputtering and thermal evaporation applications. It is ideal for achieving precise coatings on a wide variety of substrates, from polymers to highly sensitive semiconductors. It is renowned for its reliable manufacture and superior performance, making it perfect for a wide range of industrial applications.

There are no reviews yet